The Dual CS522 family of turntables can be upgraded to a very high performance level. Spare parts are available in Europe and provides endless upgrade/modification path.

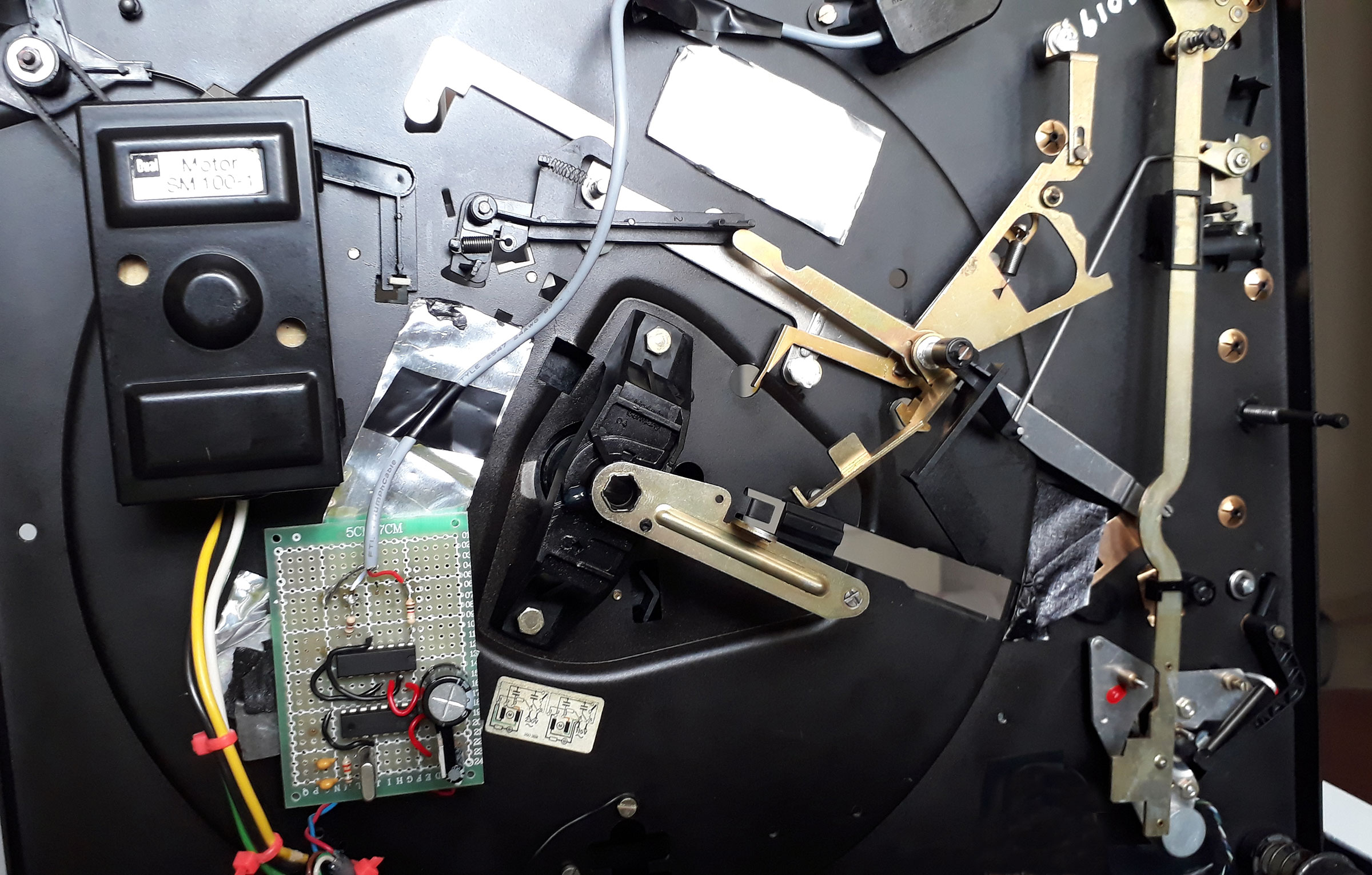

This project restored a severely damaged CS522. Instead of using the original ULM arm, a new CS505-4 arm, new 4 point pivot bearings were installed. The automatic start and stop are not really needed and were disabled. The Segment plate which the arm sits on, drives an light aluminium arm that activates the stop cam wheel to bring the arm back to rest. The activation arm degrades the performance of the tonearm and is worthwhile removing it.

Tuning the arm pivot bearing need not follow the torque values stated in the service manual. It is difficult for individual to obtain the torque wrench that handles such a low torque. Afterall, there are part to part variations; the values stated may be an average value for mass production.

Suggested adjustment method:

1. Attach only the tonearm gimble to the tonearm. Set spring force to 0.

2. Use only fingers to screw in the grub screw lightly, until it touches the bearing balls. The back off the screw slightly.

3. Secure the grub screw with the lock nut using specialized nut locking tool. Do not use force.

4. Use both hands to feel there are no gaps between the gimble and tonearm bearings. Adjust grub screw lightly to allow a very faint gap.

5. Check gimble can freely swing. If the gimble does not swing freely, the assembly is too tight.

6. The gimble should be able to oscillate freely , with virtually no free play between the gimble and tonearm.

7. Repeat if needed until there are no free play, and the gimble can swing back and forth with a very slight shake.

The horizontal can be adjusted when the top screw is installed:

1. Set anti skate to 0.

2. Set spring force to 0.

3. Balance the tonearm. The arm should by itself stay at mid point over the record.

4. Slowly screw in top grub screw with fingers, lightly, and then back off slightly..

5. Tighten lock nut. Check there are no free play, or gaps.

6. Turn the grub screw until there are no gaps and arm can swing freely.

7. At standstill, applying just 0.1g of anti skate the arm will swing back to rest position immediately. The lower the value of anti skate the better.

With the correct tracking force of 2g, and antiskate adjusted, the tonearm cartridge assembly can maintain stationary on a CD at 33.33 rpm.

The turntable has a dedicated 100Hz LED pulse to check for speed. The tonearm wires are tapped directly and bypassed the muting switch. Use high quality RCA cable with low capacitance (30cm) and attach directly to the RIAA amplifier. This greatly reduce hum and ensures signal integrity.

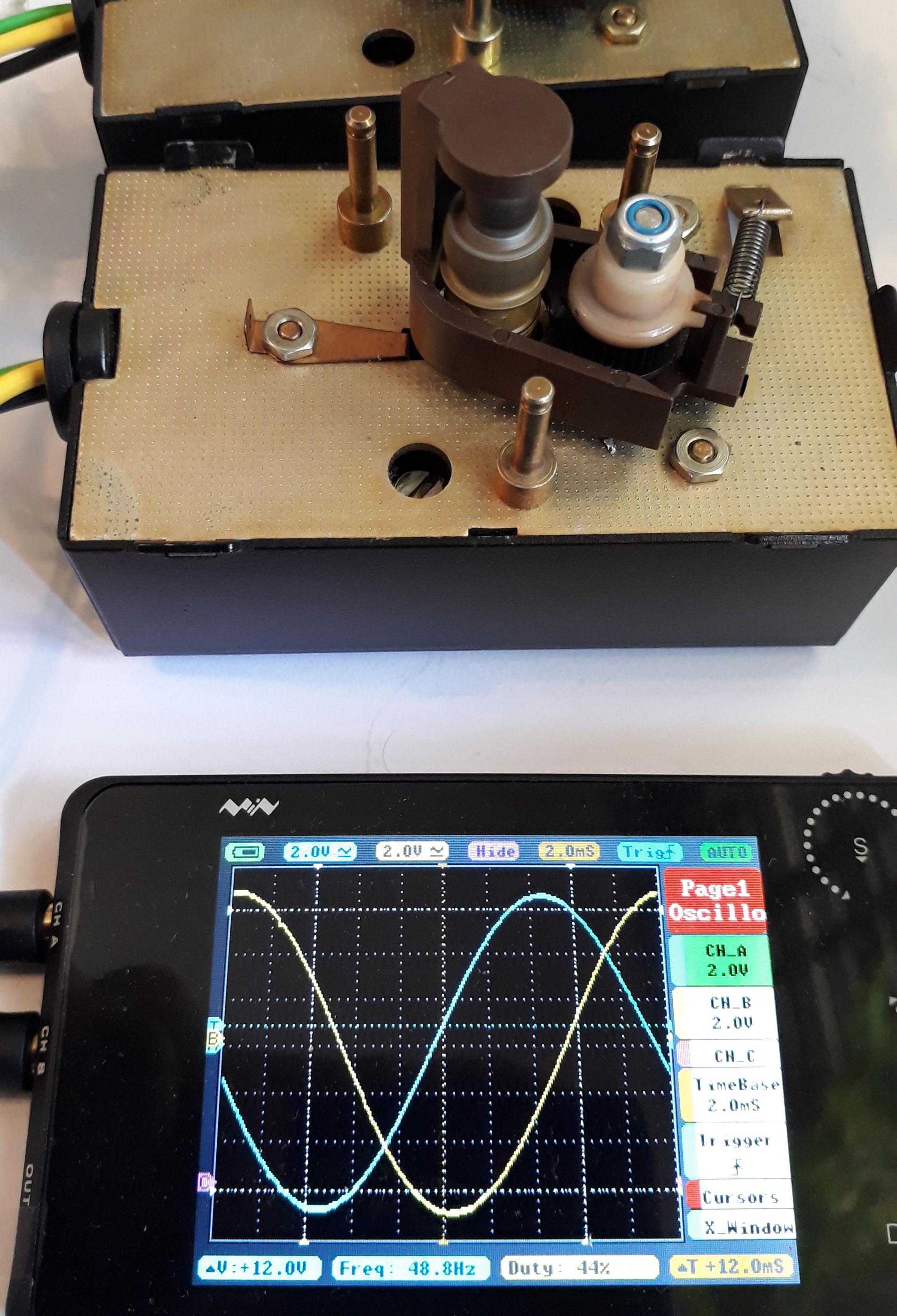

The motor is driven by a Lingo clone circuit, with 2 X 115V 50hz pure sine wave at 120 degrees difference. The motor has virtually no vibration or noise.

The support bearing can be replaced by 5X1.34mm ceramic bearing balls. Using adhesive oil (chain saw oil) to lubricate the main bearing assembly.

This is an extensive modification. The turntable performance is on par with many very expensive turntables.

Even with a cheap AT95E the sound stage is already very impressive. The 505-4 arm allows swapping of different 1/2 inch cartridges easily. Tone arm can be aligned using Baerwald alignment.

Although the tone arm is light, it is not a ULM arm. It works very well with AT95E, AT VM95E and also with Ortofon OM10 OM20.

This project restored a severely damaged CS522. Instead of using the original ULM arm, a new CS505-4 arm, new 4 point pivot bearings were installed. The automatic start and stop are not really needed and were disabled. The Segment plate which the arm sits on, drives an light aluminium arm that activates the stop cam wheel to bring the arm back to rest. The activation arm degrades the performance of the tonearm and is worthwhile removing it.

Tuning the arm pivot bearing need not follow the torque values stated in the service manual. It is difficult for individual to obtain the torque wrench that handles such a low torque. Afterall, there are part to part variations; the values stated may be an average value for mass production.

Suggested adjustment method:

1. Attach only the tonearm gimble to the tonearm. Set spring force to 0.

2. Use only fingers to screw in the grub screw lightly, until it touches the bearing balls. The back off the screw slightly.

3. Secure the grub screw with the lock nut using specialized nut locking tool. Do not use force.

4. Use both hands to feel there are no gaps between the gimble and tonearm bearings. Adjust grub screw lightly to allow a very faint gap.

5. Check gimble can freely swing. If the gimble does not swing freely, the assembly is too tight.

6. The gimble should be able to oscillate freely , with virtually no free play between the gimble and tonearm.

7. Repeat if needed until there are no free play, and the gimble can swing back and forth with a very slight shake.

The horizontal can be adjusted when the top screw is installed:

1. Set anti skate to 0.

2. Set spring force to 0.

3. Balance the tonearm. The arm should by itself stay at mid point over the record.

4. Slowly screw in top grub screw with fingers, lightly, and then back off slightly..

5. Tighten lock nut. Check there are no free play, or gaps.

6. Turn the grub screw until there are no gaps and arm can swing freely.

7. At standstill, applying just 0.1g of anti skate the arm will swing back to rest position immediately. The lower the value of anti skate the better.

With the correct tracking force of 2g, and antiskate adjusted, the tonearm cartridge assembly can maintain stationary on a CD at 33.33 rpm.

The turntable has a dedicated 100Hz LED pulse to check for speed. The tonearm wires are tapped directly and bypassed the muting switch. Use high quality RCA cable with low capacitance (30cm) and attach directly to the RIAA amplifier. This greatly reduce hum and ensures signal integrity.

The motor is driven by a Lingo clone circuit, with 2 X 115V 50hz pure sine wave at 120 degrees difference. The motor has virtually no vibration or noise.

The support bearing can be replaced by 5X1.34mm ceramic bearing balls. Using adhesive oil (chain saw oil) to lubricate the main bearing assembly.

This is an extensive modification. The turntable performance is on par with many very expensive turntables.

Even with a cheap AT95E the sound stage is already very impressive. The 505-4 arm allows swapping of different 1/2 inch cartridges easily. Tone arm can be aligned using Baerwald alignment.

Although the tone arm is light, it is not a ULM arm. It works very well with AT95E, AT VM95E and also with Ortofon OM10 OM20.

Attachments

Last edited:

I was concerned about tonearm resonance (~10hz). The 505-4 tone arm is around 7gms effective mass (?).

The AT95E sings well and tracks well using 2.0gms. I suppose the unique precision spring loaded force somewhat ensures a better tracking than arms using gravity. (Only Dual can still operate well and play, with the platter tilted at 45 degrees from the horizontal)

The tonearm weight has some mechanical decoupling from the arm, as the interface is made of elastic rubber.

Listening comparison, the modified Dual is a lot more open and with wider soundstage than tables costing twice or more than a CS522.

The AT95E sings well and tracks well using 2.0gms. I suppose the unique precision spring loaded force somewhat ensures a better tracking than arms using gravity. (Only Dual can still operate well and play, with the platter tilted at 45 degrees from the horizontal)

The tonearm weight has some mechanical decoupling from the arm, as the interface is made of elastic rubber.

Listening comparison, the modified Dual is a lot more open and with wider soundstage than tables costing twice or more than a CS522.

Theoretically they will play also when upside down. It's just a matter of fixing the record to the platter and supporting the platter.(Only Dual can still operate well and play, with the platter tilted at 45 degrees from the horizontal)

Best regards!

Hello Mark,

1. Motor

The problem with many AC motor equipped decks is the synchronous motor feeding using a single phase mains - vibration.

Using a basic crystal clock to generate 50 or 60hz sine wave, driving dual TDA2030 and transformers, the AC motor can run at 375rpm with a whisper. The amount of reduction is very significant. A Linn Lingo drive is too expensive.

3. Main Bearing

The CS505-4 and CS505 has a shaft sitting on a holder Part 137 . Clean it up, and check if the journal surfaces are shiny and smooth. If not, apply a small amount of metal polish and polish until shiny but not taking away too much materials. Clean the polished surface, and use high quality synthetic Adhesive Oil (aka chain saw oil).

4. Remove the long alu arm part 166. It is the stop activation. It serve a negative contribution to the sound quality. Afterall when the record is stopped one still have to get up to keep the record. Remove it by unclip a C Clip on the segment, and draw out the arm. The ansi skate will be less, and tone arm can move better.

5. Tonearm bearings and adjustments

You can purchase the tonearm bearing adjustment tool from dualfred - dualfred . Many Dual tone arms are mass produced and not really precision calibrated - why I say this is because I found too many CS TT with very loose adjustments and with too much free play.

The arm itself is precision made and can be calibrated to very high performance.

By pass the muting and tap the wire directly using high quality, low Capacitance wire ( not more than 30 or 50 cm). Black wire to the shielding and preamp ground. The signal wire should not be used as ground.

6. Add some lead weight (fishing sinkers) to the plinth.

After this fine tuning, the CS505-4 is capable to perform much better than a few Thorens models.

Certainly, using a better cartridge than the Ortofon OM 5 will give a better sound. The Audio Technica AT95EX is cheap and good.

1. Motor

The problem with many AC motor equipped decks is the synchronous motor feeding using a single phase mains - vibration.

Using a basic crystal clock to generate 50 or 60hz sine wave, driving dual TDA2030 and transformers, the AC motor can run at 375rpm with a whisper. The amount of reduction is very significant. A Linn Lingo drive is too expensive.

3. Main Bearing

The CS505-4 and CS505 has a shaft sitting on a holder Part 137 . Clean it up, and check if the journal surfaces are shiny and smooth. If not, apply a small amount of metal polish and polish until shiny but not taking away too much materials. Clean the polished surface, and use high quality synthetic Adhesive Oil (aka chain saw oil).

4. Remove the long alu arm part 166. It is the stop activation. It serve a negative contribution to the sound quality. Afterall when the record is stopped one still have to get up to keep the record. Remove it by unclip a C Clip on the segment, and draw out the arm. The ansi skate will be less, and tone arm can move better.

5. Tonearm bearings and adjustments

You can purchase the tonearm bearing adjustment tool from dualfred - dualfred . Many Dual tone arms are mass produced and not really precision calibrated - why I say this is because I found too many CS TT with very loose adjustments and with too much free play.

The arm itself is precision made and can be calibrated to very high performance.

By pass the muting and tap the wire directly using high quality, low Capacitance wire ( not more than 30 or 50 cm). Black wire to the shielding and preamp ground. The signal wire should not be used as ground.

6. Add some lead weight (fishing sinkers) to the plinth.

After this fine tuning, the CS505-4 is capable to perform much better than a few Thorens models.

Certainly, using a better cartridge than the Ortofon OM 5 will give a better sound. The Audio Technica AT95EX is cheap and good.

Interesting - do you have any advice for improving a stock CS505-4?

Attachments

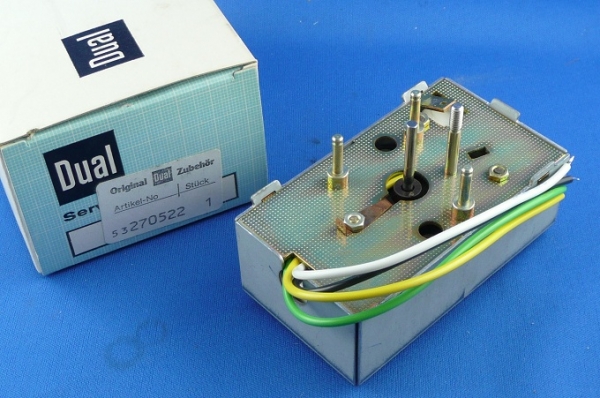

dualfred - dualfred sells a 12V version of the motor. SM112-1

It must have a much stronger magnet on the rotor to cater for the lower excitation flux from the stator.

It must have a much stronger magnet on the rotor to cater for the lower excitation flux from the stator.

You did manage to rewind a Dual SM100 motor for 12 V drive? How did you do it?

Best regards!

Attachments

> a 12V version of the motor. SM112-1 ... It must have a much stronger magnet on the rotor to cater for the lower excitation flux from the stator.

Probably the rotor is the same, and the electric Power is same/similar. The lower-voltage motor stator is wound with fewer turns of fatter wire, and draws a higher current, giving about the same flux.

Probably the rotor is the same, and the electric Power is same/similar. The lower-voltage motor stator is wound with fewer turns of fatter wire, and draws a higher current, giving about the same flux.

> a 12V version of the motor. SM112-1 ... It must have a much stronger magnet on the rotor to cater for the lower excitation flux from the stator.

Probably the rotor is the same, and the electric Power is same/similar. The lower-voltage motor stator is wound with fewer turns of fatter wire, and draws a higher current, giving about the same flux.

Yes, that is correct.

The 0.33uf phase delay capacitor in the power supply board gave problems. Maybe they changed the voltage to address the issue.

Update November 2019:

1. I am replacing the segment base which the tone arm assembly is sitting on. The CS522 segment has 2 limiting posts for 33 1/3 and 45 settings. I cannot run full manual at 33 1/3 because the arm will be stopped at the start of the record. Same for 45 it will only allow starting at the start of the 7 in LP. The CS505-4 segment will allow 100% manual operation, and it is lighter too.

2. Polishing the tip of the adjustment pivot screw of the tonearm assembly may help. Under magnification, I can see asperities on the surfaces. I am still investigating the ball bearing and pivot interface. Ideally should be as smooth as possible. The surface roughness may be opportunities for improvement. May polish using fine metal polish and check.

3. The VTA of the cartridge is slightly off using the 505-4 arm. I need to add a 1.5mm cart shim so the tone arm is perfectly horizontal, to get a correct VTA. This helped to improve the sound stage. If mounting the cart directly to the head shell, the arm dips down slightly and will not be parallel to the LP surface. So a 1.5mm 1/4 inch cart shim is needed. This thickness may vary depending on the Cart. Most Audio Technica Carts like At95EX needs 1.5mm

4. The rubber stud that lifts the tone arm need to have about 0.5mm shaved off the top. The tip may interfere with the tonearm plate after some wear and tear. This may cause track skipping. So, set the que such that there are always 1mm clearrance between the arm plate and the rubber stud.

1. I am replacing the segment base which the tone arm assembly is sitting on. The CS522 segment has 2 limiting posts for 33 1/3 and 45 settings. I cannot run full manual at 33 1/3 because the arm will be stopped at the start of the record. Same for 45 it will only allow starting at the start of the 7 in LP. The CS505-4 segment will allow 100% manual operation, and it is lighter too.

2. Polishing the tip of the adjustment pivot screw of the tonearm assembly may help. Under magnification, I can see asperities on the surfaces. I am still investigating the ball bearing and pivot interface. Ideally should be as smooth as possible. The surface roughness may be opportunities for improvement. May polish using fine metal polish and check.

3. The VTA of the cartridge is slightly off using the 505-4 arm. I need to add a 1.5mm cart shim so the tone arm is perfectly horizontal, to get a correct VTA. This helped to improve the sound stage. If mounting the cart directly to the head shell, the arm dips down slightly and will not be parallel to the LP surface. So a 1.5mm 1/4 inch cart shim is needed. This thickness may vary depending on the Cart. Most Audio Technica Carts like At95EX needs 1.5mm

4. The rubber stud that lifts the tone arm need to have about 0.5mm shaved off the top. The tip may interfere with the tonearm plate after some wear and tear. This may cause track skipping. So, set the que such that there are always 1mm clearrance between the arm plate and the rubber stud.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Dual CS522 upgrade with CS505-4 tonearm