I have an old Sony TC-645 tape recoder that I took out of the basement where it has been until now, and I started paying with it. The kickoff was given by kevinkr's thread

So you think you want to play with tape: An Otari Story

This machine is not in the same league, but it is still capable of good sound. It has 3 motors and 3 "glass" heads, but mediocre tape handling.

I purchased an IEC calibration tape with reference level 250 nWb/m and various test tones for setting the head azimuth etc. After I adjusted everything what the cal tape offered, I was still unsatisfied. Especially the S/N was still poor: some 53 dB (A-weighted, rec to playback).

Then I vaguely remembered that the head should be demagnetized, so I created a quick tool from a soldering gun and a couple of turns of copper wire. It has done the trick, now I could reach the factory specs (56 dBA).

The next step was the playback EQ. I could set it roughly with the help of the calibration tape (700Hz/10kHz -10dB played back at equal level).

Now came the tricky part: the recording bias. I fed a low distortion 1kHz sine to the line input, and monitored the output with a distortion analyzer. I fed the residual (distortion+noise, i.e. the 1kHz filtered out with a notch filter) o the oscilloscope. Then I adjusted the bias until the distortion (mainly 3rd harmonics) and noise were the lowest. The VU meter showed increasing level when I increased the bias, and then dropped by about -0.5dB. This setting gave the lowest distortion.

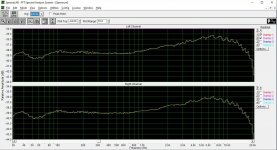

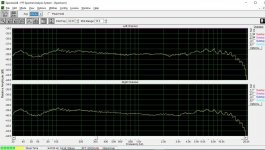

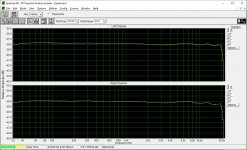

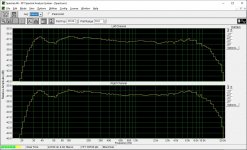

I checked the frequency response with a pink noise generator that I originally built for loudspeaker testing. It is basically a PRBS (pseudo random binary sequence) generator in a MM5837N chip, and a subsequent -3dB/slope R-C filter. The first picture shows the frequency response after having done the above adjustments. I did not like the 3dB rise in the high frequency region, so I adjusted the playback EQ a little bit back. The second picture shows the result. The recording level was around -20dB.

So you think you want to play with tape: An Otari Story

This machine is not in the same league, but it is still capable of good sound. It has 3 motors and 3 "glass" heads, but mediocre tape handling.

I purchased an IEC calibration tape with reference level 250 nWb/m and various test tones for setting the head azimuth etc. After I adjusted everything what the cal tape offered, I was still unsatisfied. Especially the S/N was still poor: some 53 dB (A-weighted, rec to playback).

Then I vaguely remembered that the head should be demagnetized, so I created a quick tool from a soldering gun and a couple of turns of copper wire. It has done the trick, now I could reach the factory specs (56 dBA).

The next step was the playback EQ. I could set it roughly with the help of the calibration tape (700Hz/10kHz -10dB played back at equal level).

Now came the tricky part: the recording bias. I fed a low distortion 1kHz sine to the line input, and monitored the output with a distortion analyzer. I fed the residual (distortion+noise, i.e. the 1kHz filtered out with a notch filter) o the oscilloscope. Then I adjusted the bias until the distortion (mainly 3rd harmonics) and noise were the lowest. The VU meter showed increasing level when I increased the bias, and then dropped by about -0.5dB. This setting gave the lowest distortion.

I checked the frequency response with a pink noise generator that I originally built for loudspeaker testing. It is basically a PRBS (pseudo random binary sequence) generator in a MM5837N chip, and a subsequent -3dB/slope R-C filter. The first picture shows the frequency response after having done the above adjustments. I did not like the 3dB rise in the high frequency region, so I adjusted the playback EQ a little bit back. The second picture shows the result. The recording level was around -20dB.

Attachments

> I adjusted the playback EQ a little bit back.

If the Play EQ is per IEC Calibration tape, recording using maker-specified tape, level is not-high (-20dB may be good, though I would prefer sine-sweep to pink-noise), and bias is good, any residual error should be fixed in Record EQ. (Yes, you can't buy Sony 150 or SLH tape anymore, and modern tape may be a hair hotter than what we had in 1974.)

Sony TC-645 - Manual - Stereo Tapecorder - HiFi Engine

Ah, the Record EQ, all that stuff in Q101 emitter leg, is switchable/fixed. And the network and switching is complicated enough to foil intuitive tinkering. You could pick a speed/tape, then SPICE that configuration, tinker until you find your 2-3dB drop @ 6KHz.

If the Play EQ is per IEC Calibration tape, recording using maker-specified tape, level is not-high (-20dB may be good, though I would prefer sine-sweep to pink-noise), and bias is good, any residual error should be fixed in Record EQ. (Yes, you can't buy Sony 150 or SLH tape anymore, and modern tape may be a hair hotter than what we had in 1974.)

Sony TC-645 - Manual - Stereo Tapecorder - HiFi Engine

Ah, the Record EQ, all that stuff in Q101 emitter leg, is switchable/fixed. And the network and switching is complicated enough to foil intuitive tinkering. You could pick a speed/tape, then SPICE that configuration, tinker until you find your 2-3dB drop @ 6KHz.

If it's been sitting unused for years, don't you also have to consider mechanical aspects? The electronic adjustment is the next area I want to go into with my own decks - it's a little outside my experience and understanding at this point - but it seems to me that one of the first things people do with an old machine is replace the belt - some will do it whether it "needs it" or not - and make sure that the pinch roller in good condition. If not, that gets replaced too. It can be expensive, but it's crucial.

There's some variation between brands in what's likely to need attention - with TEACs, it's often the pinch roller bearing and arm, which tends to seize up, so needs to be cleaned out and relubricated. Capstan motor can be noisy too, and that can need lubrication. Technics decks can have a problem with squealing during fast winding: it's caused by the pulley for the tape counter, and again is fixed with a little lubrication of the pulley bearing. You get the picture - lot of things that involve lubricating, and a lot of other things related to rubber parts. I'm just a little surprised that you didn't mention any of this but did some pretty technical adjustment on the electronic side of things.

Also a lot of people recap the boards, especially with decks of this age - it's 1970s, isn't it? I have seen a lone voice or two saying you don't need to, but the general opinion seems to be that if you're working in the back of the deck anyway, this is something worth doing. Reading about how capacitors perform after 30 years or so, it's hard to disagree. I haven't done it on my decks - yet - but it doesn't mean I don't need to.

In my case, for peace of mind, I wouldn't attempt demagging with a homemade device either. But this site is DIY Audio, so I'd better not get into that....

There's some variation between brands in what's likely to need attention - with TEACs, it's often the pinch roller bearing and arm, which tends to seize up, so needs to be cleaned out and relubricated. Capstan motor can be noisy too, and that can need lubrication. Technics decks can have a problem with squealing during fast winding: it's caused by the pulley for the tape counter, and again is fixed with a little lubrication of the pulley bearing. You get the picture - lot of things that involve lubricating, and a lot of other things related to rubber parts. I'm just a little surprised that you didn't mention any of this but did some pretty technical adjustment on the electronic side of things.

Also a lot of people recap the boards, especially with decks of this age - it's 1970s, isn't it? I have seen a lone voice or two saying you don't need to, but the general opinion seems to be that if you're working in the back of the deck anyway, this is something worth doing. Reading about how capacitors perform after 30 years or so, it's hard to disagree. I haven't done it on my decks - yet - but it doesn't mean I don't need to.

In my case, for peace of mind, I wouldn't attempt demagging with a homemade device either. But this site is DIY Audio, so I'd better not get into that....

I did not mention it, but the first thing was to disassembe, lubricate, and check the mechanical parts. Fortunately this is an idler wheel transport machine, no belts at all (except the counter). The pinch roller and all bearings are in relatively good condition.If it's been sitting unused for years, don't you also have to consider mechanical aspects? ... I'm just a little surprised that you didn't mention any of this but did some pretty technical adjustment on the electronic side of things.

The PCB of this machine is rather difficult to service. Cables are soldered in and are too short to access the component side easily. I had one bad transistor and it was a pain to replace it (it measured good, though). I am still considering recapping, only 5 or 6 different types are needed. Just collecting the courage.Also a lot of people recap the boards, especially with decks of this age - it's 1970s, isn't it? I have seen a lone voice or two saying you don't need to, but the general opinion seems to be that if you're working in the back of the deck anyway, this is something worth doing. Reading about how capacitors perform after 30 years or so, it's hard to disagree. I haven't done it on my decks - yet - but it doesn't mean I don't need to.

I have recapped 3 of the 4 Otari machines I own, and in all cases this has resulted in a rather large subjective improvement in performance. The Otaris are 3 motor, 3 - 4 head (maybe 5 in some with time code recording) machines of considerable complexity, but were designed with service in mind.

The 4th machine is a very minty MX-50N II which urgently needs a recap (things stop working when the caps start to go in this model).

In short recap is worthwhile regardless of what the "experts" will claim to the contrary.

The 4th machine is a very minty MX-50N II which urgently needs a recap (things stop working when the caps start to go in this model).

In short recap is worthwhile regardless of what the "experts" will claim to the contrary.

Sounds like you're well ahead of me. Great to hear about another machine being brought back to use.I did not mention it, but the first thing was to disassembe, lubricate, and check the mechanical parts. Fortunately this is an idler wheel transport machine, no belts at all (except the counter). The pinch roller and all bearings are in relatively good condition.

I'm looking forward to learning how to do the electronic adjustments for my machines - got 4 of them that'll have to be sorted out eventually.

An issue I noticed is that the tape is wandering up and down at the playback head. This can be observed with a magnifier glass and a torchlight. It could be 0.05 to 0.1 mm deviation from the steady run. What could be the reason and how could I eliminate this wandering? I suppose this is the reason the Lissajous pattern is showing some phase variation at high frequency.

Old tape. Warped reels. Worn tape guides. If in-sync with capstan, pinch roller, or scrape-roller rotation, dirt/wear in these parts.

0.05mm is very small and may be normal on this class of equipment. Yes, it would skew HF phase; we did not worry too much about that in those days.

0.05mm is very small and may be normal on this class of equipment. Yes, it would skew HF phase; we did not worry too much about that in those days.

It could be normal for this machine, could also be a sign of a number of things in no particular order:

This is why analog sucks says the guy who owns 4 Otari tape decks.

- Excessive tape tension

- Insufficient tape tension

- Tape head wear (contact area not uniform)

- Insufficient contact pressure capstan to pinch roller

- Incorrect tape wrap settings

- Bearing runout in the pinch roller

- Worn pinch roller

- Worn tape guides

- Misadjusted reel table height

- Warped reels

This is why analog sucks says the guy who owns 4 Otari tape decks.

Attachments

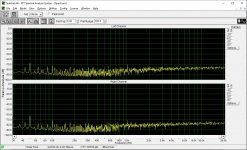

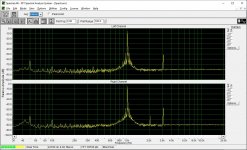

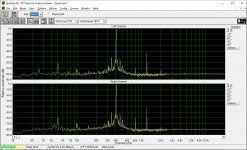

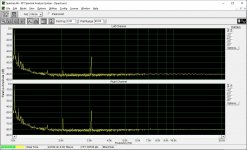

3rd harmonic @400Hz and @1kHz

What was the recording level, speed and EQ for these measurements?

Numbers look reasonable I just am not sure what the actual levels are - 10dB from standard reference level for the tape formulation and EQ you are using?

I calibrated the machine for 250nWb/m reference level, 0dB VU on the meters. Although the service manual calls for 185nWb/m.

I used BASF DP26 tape, recorded at 0dB VU @7.5 IPS. I don't have any more modern tapes. This gave about 56dB S/N (A-weighted) and about 0.8% distortion.

I really don't know what is my goal with this tape recorder, apart from having fun with its restoration. I don't have any plan to make live recodings at concerts like I did when I was younger. And there is no reason to record for FM radio, since there are no worthwile programs available. Perhaps borrowing some LPs? It does not work, obviously I wouldn't lend any of mines either. I still need to find the right source. Or just donate to them:

Magnomuzeum

I used BASF DP26 tape, recorded at 0dB VU @7.5 IPS. I don't have any more modern tapes. This gave about 56dB S/N (A-weighted) and about 0.8% distortion.

I really don't know what is my goal with this tape recorder, apart from having fun with its restoration. I don't have any plan to make live recodings at concerts like I did when I was younger. And there is no reason to record for FM radio, since there are no worthwile programs available. Perhaps borrowing some LPs? It does not work, obviously I wouldn't lend any of mines either. I still need to find the right source. Or just donate to them:

Magnomuzeum

I plan to use one or both of the MX-50 I have to play expensive 15ips commercial reissues of a few popular recordings I am interested in. Otherwise like you I am just playing around.

I actually dub digital program material from my HAP-Z1ES to whichever deck I feel like at any given moment, conveniently it has balanced outputs and my line stage has balanced inputs. (The Otaris have balanced I/O) This is useful in terms of assessing the performance of the individual decks before and after modification, plus you get the "benefit" of all of the imperfections of analog technology. Somewhat disturbingly/amusingly some of my friends have professed a strong preference for the tape copy over the original. (And I can understand why)

I am using modern SM900 series tape (RTM) on 10.5 inch reels which is very good tape relative to most of what I used in the past.

I actually dub digital program material from my HAP-Z1ES to whichever deck I feel like at any given moment, conveniently it has balanced outputs and my line stage has balanced inputs. (The Otaris have balanced I/O) This is useful in terms of assessing the performance of the individual decks before and after modification, plus you get the "benefit" of all of the imperfections of analog technology. Somewhat disturbingly/amusingly some of my friends have professed a strong preference for the tape copy over the original. (And I can understand why)

I am using modern SM900 series tape (RTM) on 10.5 inch reels which is very good tape relative to most of what I used in the past.

Your Sony is a NAB EQ recorder and for calibrating its frequency response with an IEC calibration tape, you need to apply corrections at test frequencies which are available in conversion tables below.

The 250nWb/m for 0dB may be a bit too hot for this Sony as it is effectively pushing it around 3dB above its specification. Thus, BASF DP26, which is an old, low output tape, was exhibiting 0.8% distortion on Sony at +2.6dB.

Try setting it as per service manual:

- set the playback level to -2.6dB (573mV on VTVM, don’t use VU meters for calibration) with 250nWb/m tone

- using your IEC calibration tape, frequency response section, set the frequencies using the following corrections (0dB=-10dB on your calibration tape):

Calibration Tape 6: 7.5 in/s, IEC (IEC1) Equalization

Desired Playback 8: 7.5 in/s, NAB (IEC2) Equalization

Recorded Playback Playback

Frequency/ Frequency/ Level/

[Hz] [Hz] [dB]

32 32 -5,00

63 63 -1,75

125 125 -0,28

250 250 0,17

500 500 0,23

1000 1000 0,00

2000 2000 -0,68

4000 4000 -1,64

8000 8000 -2,25

10000 10000 -2,35

12500 12500 -2,42

16000 16000 -2,47

20000 20000 -2,50

This should get you a flat frequency response.

Overall performance will depend on the condition of your machine, primarily on heads. Tape skewing might be due to bad roller, misaligned tape tension, and so on. You need to go trhough the service manual before measuring what your deck can do.

The 250nWb/m for 0dB may be a bit too hot for this Sony as it is effectively pushing it around 3dB above its specification. Thus, BASF DP26, which is an old, low output tape, was exhibiting 0.8% distortion on Sony at +2.6dB.

Try setting it as per service manual:

- set the playback level to -2.6dB (573mV on VTVM, don’t use VU meters for calibration) with 250nWb/m tone

- using your IEC calibration tape, frequency response section, set the frequencies using the following corrections (0dB=-10dB on your calibration tape):

Calibration Tape 6: 7.5 in/s, IEC (IEC1) Equalization

Desired Playback 8: 7.5 in/s, NAB (IEC2) Equalization

Recorded Playback Playback

Frequency/ Frequency/ Level/

[Hz] [Hz] [dB]

32 32 -5,00

63 63 -1,75

125 125 -0,28

250 250 0,17

500 500 0,23

1000 1000 0,00

2000 2000 -0,68

4000 4000 -1,64

8000 8000 -2,25

10000 10000 -2,35

12500 12500 -2,42

16000 16000 -2,47

20000 20000 -2,50

This should get you a flat frequency response.

Overall performance will depend on the condition of your machine, primarily on heads. Tape skewing might be due to bad roller, misaligned tape tension, and so on. You need to go trhough the service manual before measuring what your deck can do.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Reel to reel tape recorder adjustment