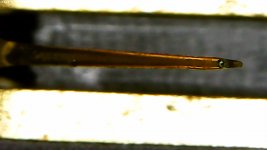

Thanks, Bill. Yes, that's the shot and resolution you need. Not easy, is it?

One potential serious health warning though: the small bundle of strands accumulating on the upper rear of the stylus body is prob vinyl shavings IME. I examined such debris under very high mag and looks very like ribbons of dark material that I take to be vinyl.

To an extent, that seems to happen anyway, but far more so on fine radius styli IME. I suppose that makes sense when one thinks about it. But I also reckon that when SRA is right and the stylus/groove surface approach angle is optimal, any shredding should also be minimal.

HTH! Keep calm and carry on

LD

One potential serious health warning though: the small bundle of strands accumulating on the upper rear of the stylus body is prob vinyl shavings IME. I examined such debris under very high mag and looks very like ribbons of dark material that I take to be vinyl.

To an extent, that seems to happen anyway, but far more so on fine radius styli IME. I suppose that makes sense when one thinks about it. But I also reckon that when SRA is right and the stylus/groove surface approach angle is optimal, any shredding should also be minimal.

HTH! Keep calm and carry on

LD

Possibly, but there were a number of other potential contamination sources around, including a 1958 mono recording that I haven't cleaned I was playing before I took that picture.

I will keep an eye on it though.

I need to find a table mount tripod I can bolt to the turntable shelf. I move the wooden floor too much. Either that or move the whole TT to the kitchen for photo sessions. I didn't thing that bit through when building the shelving.

I will keep an eye on it though.

I need to find a table mount tripod I can bolt to the turntable shelf. I move the wooden floor too much. Either that or move the whole TT to the kitchen for photo sessions. I didn't thing that bit through when building the shelving.

Ah yes that explains it - I can confirm that. I found shredding and clogging to be a general problem with 50s/60s mono pressings when played back with fine radius styli - so I absolutely stopped doing that. I set up a separate mono rig. Which tracks heavily, uses a correctly sized spherical stylus, is wired for mono, sounds correct and doesn't shred.Possibly, but there were a number of other potential contamination sources around, including a 1958 mono recording that I haven't cleaned I was playing before I took that picture.

Horses for courses.

I suspect composition of vinyl changed continually over the history of vinyl pressing? Or maybe its the base clearance. Perhaps the mid-late 70s or so is the watershed I use for fine radius stylus playback. And yer modern stuff is not a problem, IME.

My 2p worth of opinion is that fine radius styli generally present a different load to the vinyl surface, probably more stressful in the broadest sense. No pain no gain and all that.

LD

Yes - reading between the lines of history, perhaps 0.5mil spherical was Shure's intention prior to the elliptical variants which solved some of the loading issues? I think this is perhaps what drove toward the ultra-light tracking force push from Shure which achieved some excellent results, of course?

My 2p worth is that 0.5mil spherical it has a lot of merit in theory, especially for stereo playback. And sphericals are, by definition, SRA tolerant! And azimuth tolerant too, at least for effects beyond coil geometry crosstalk.

I think the 0.5mil spherical might load groove walls with about the same stress as fine radius styli, and have about the same base clearance? So might as well go fine radius, I figure. 0.7mil is a good compromise though. Strictly 1mil is the intended mono spec, but it isn't guaranteed to fit stereo groove depth and could ride on the top of the groove V sometimes for stereo records in principle.

But it's worth noting that a 0.5mil spherical escapes the issues with SRA, in theory.

LD

My 2p worth is that 0.5mil spherical it has a lot of merit in theory, especially for stereo playback. And sphericals are, by definition, SRA tolerant! And azimuth tolerant too, at least for effects beyond coil geometry crosstalk.

I think the 0.5mil spherical might load groove walls with about the same stress as fine radius styli, and have about the same base clearance? So might as well go fine radius, I figure. 0.7mil is a good compromise though. Strictly 1mil is the intended mono spec, but it isn't guaranteed to fit stereo groove depth and could ride on the top of the groove V sometimes for stereo records in principle.

But it's worth noting that a 0.5mil spherical escapes the issues with SRA, in theory.

LD

Stationary. Not sure I could do moving with my current setup.

For myself the 0.5mil might be suboptimal, but nothing ventured etc. The cost to me is quite low and if it fails I have a rather nice nude 0.65mil Denon DL-107 to try out.

Attached is a (bad) pic of an AT-150 carrier fitted with a cactus cantilever and 0.5mil 'microcone'.

Interesting conjecture and worthy I think of discussing in a separate thread. So much good discussion on stylii was purged I think work collecting various bits here would be good. I'll knock up a starter post tonight.I think the 0.5mil spherical might load groove walls with about the same stress as fine radius styli, and have about the same base clearance? So might as well go fine radius, I figure. 0.7mil is a good compromise though. Strictly 1mil is the intended mono spec, but it isn't guaranteed to fit stereo groove depth and could ride on the top of the groove V sometimes for stereo records in principle.

But it's worth noting that a 0.5mil spherical escapes the issues with SRA, in theory.

LD

For myself the 0.5mil might be suboptimal, but nothing ventured etc. The cost to me is quite low and if it fails I have a rather nice nude 0.65mil Denon DL-107 to try out.

Attached is a (bad) pic of an AT-150 carrier fitted with a cactus cantilever and 0.5mil 'microcone'.

Attachments

perhaps 0.5mil spherical was Shure's intention prior to the elliptical variants which

solved some of the loading issues?

Shure thought that the 0.5 mil spherical rides too close to the bottom of the groove,

and went with 0.6 mil instead. See page 20.

Attachments

Last edited:

Hi Guys, One thing I have just found out by changing cartridges over is that we need to take cartridge compliance into consideration, Previously I had my XX1 cartridge mounted, and there was virtually no stylus deflection when playing. I have now got my Onkyo MC100 & it deflects quite markedly when queued onto the LP, therefore greatly altering it's SRA from a none loaded position.

Cheers Derek

Deflection is related to the suspension compliance and VTF. You may experience individual variation and this is also partly why there is a range of VTF given. Suspension age is another factor.

And one can calculate the (vertical) compliance by measuring the vertical tracking force and the stylus deflection. This will be a static value, not taking the stylus drag into consideration. Deflection can be measured by some optical method, I suppose.Deflection is related to the suspension compliance and VTF. You may experience individual variation and this is also partly why there is a range of VTF given. Suspension age is another factor.

Hi Guy's, Did a little more digging into this and found this excellent article in The Art of Sound. so now I understand that the SRA must be measures at the rear of the Stylus face.

Setting Up A Phono Cartridge | The Absolute Sound

Cheers

Yes, but note only for a certain type of stylus. The vdH/Fritz Gyger on e.g. Ortofon OM40 SRA measures more traditional.

Attachments

Hi, sorry what is "measures more traditional", do we vary from measuring the angle at the back of the stylus profile.?

Yes it varies depending on stylus. See pic below.

An externally hosted image should be here but it was not working when we last tested it.

You need to know what the stylus type is for your stylus to set SRA. Is it a Fritz Gyger S? Fritz Gyger II? Microline/Microridge? Shibata? Fine line? etc

Most types are traditional, and as you saw from the patent papers earlier in the thread, the Fritz Gyger S has its SRA at the back.

What is your stylus type?

Most types are traditional, and as you saw from the patent papers earlier in the thread, the Fritz Gyger S has its SRA at the back.

What is your stylus type?

Hi, Well after reading much information, the old general rule "the arm should be parallel" would seem not to be correct in many cases.

I do not have any conical or elliptical cartridges to check if the rule stands up for these types.

I do have several cartridges having Hyper Fine line & Shibata styli.

However I can not understand why the F/G S stylus is measured at the back & everything else is though the centre line??

In the case of the Absolute Sound article the cartridge used was a very high end Ortofon Anna which has what is called a Replicant 100 stylus and that stylus is clearly measured at the back.?

Cheers

Yes correct the replicant is measured at the back as well. The parallell thing is correct, most cartridges are made to have specified VTA/SRA when the arm is parallell and at nominal VTF.

And the reason for the different angles is that the stylii are differently cut. Simple as that.

Last edited:

Hi, Spend the morning taking photos of the Shibata cartridge in position & have managed to get a half useful shot.

Superimposed that onto a XL spread sheet to try & guesstimate the angle & have come up with 95/96 degs, slightly over adjusted. but it still sounded fantastic, with bass slam to die for.

Have slightly backed it off & this afternoon will do some more listening and report back.

It is difficult to see from that pic. However, as I mentioned before, the cartridges are designed to be parallell to the record surface for correct SRA/VTA and nominal VTF. If there are big deviations for this, the cartridge is faulty. I have not found that any of my cartridges need to be different than a parallell arm to get the desired SRA/VTA.

If you should optimise cartridge setup, look at these:

Lateral tracking angle (be as precise as possible)

Vertical tracking force

Arm parallell to record surface

Antiskate force

Azimuth.

Resonance >10 Hz.

Last edited:

Lateral tracking angle might vary +/- 2 degrees for a pivoted arm. As for the azimith, I used the following method: lay a pencil refill lead across the headshell. Lower the cartridge onto a thin mirror. Both ends of the lead should be at the same height, this can be checked visually or by a caliper.

Lateral tracking angle might vary +/- 2 degrees for a pivoted arm. As for the azimith, I used the following method: lay a pencil refill lead across the headshell. Lower the cartridge onto a thin mirror. Both ends of the lead should be at the same height, this can be checked visually or by a caliper.

The visual setting is always a good start but unfortunately you cannot see if the internal coils are aligned with the grooves. The fine-tuning can be checked with test signals. But then as mentioned which test record do you trust?

Hi Guy's I see a big problem with this theory that the arm should be parallel to the record surface, as in many cases it is not possible.

- Most arm produced do not have VAT adjustment (fortunately my one does)

- LP's themselves vary in thickness from 1mm to 2.5mm

- Cartridges vary in depth from around 14mm Rega Bias/18mm Dyna DV20

Therefore just with the LP thickness & cartridge depth variation this is 5.5mm, that is quite significant.And that is why it is recommended nowadays to check the SRA not VTA. VTA is only there to facilitate correct SRA.

Cheers

The most comprehensive summary of VTA ans SRA I know of is at Josh pages. Its worth a read.

VTA

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- SRA, why 92 degrees