Separation - Yes Dd, that's the key point, as I said in # 81: if there was a bidirectional feedback between the two parts, this arm would not be too different from the other passive ones. I was thinking that the headshell could also rotate (it could, if the back side was curved, but it does not need it), but then your accurate description has dissolved my doubts, and I wanted to verify graphically.

Separation is a very brilliant logic leap, difficult to understand. For the mini parallel tracker the rail is purely static: so those who want to investigate the tracking forces (SD - SF - skating) must consider only this sub-system, which is very close to the ideal of the cartridge gliding on a rail nearly coincident with a radius.

That's why a Bravo! to Ralf, a compliment that here we reserve only for those who allow us to listen exceptional music

carlo

Separation is a very brilliant logic leap, difficult to understand. For the mini parallel tracker the rail is purely static: so those who want to investigate the tracking forces (SD - SF - skating) must consider only this sub-system, which is very close to the ideal of the cartridge gliding on a rail nearly coincident with a radius.

That's why a Bravo! to Ralf, a compliment that here we reserve only for those who allow us to listen exceptional music

carlo

Last edited:

Yes thank you. I realized that the lines were not converging in that way but that anyway there is a force counteracted by the inertia of the servo/arm/plinth interface as LD mentions. So while the forces are there they are counteracted and skating is not present. I think I got this, I hope.

Hello ThomasA,

One thing I forgot to mention is that, the center line of the tone arm tube passes precisely through the tone arm pivot and the stylus center when the stylus is in the center of the cradle.

Sincerely,

Ralf

Hello ThomasA,

One thing I forgot to mention is that, the center line of the tone arm tube passes precisely through the tone arm pivot and the stylus center when the stylus is in the center of the cradle.

Sincerely,

Ralf

Hm you make me confused again. My question is more if the tangent of the reocrd movement at the stylus point aka friction vector is 180 degrees compared to the line/vector describing the stylus point to the tonearm fixing point (aka the pivot in a traditional arm). In a tradtional linear tracking arm it is 180 degrees, always, but never so in pivoted arms.

Thanks Ralf. Yes, for the stylus to see no skate force relies on the headshell effectively being rigidly connected to the plinth. Achieved via servo. There's still skate torgue in the support arm, but it's resolved at the connection with the plinth, not at the stylus end.Hello luckythedog,

That's exactly right. Good show!

Sincerely,

Ralf

However, it's still not clear to me how the arm copes with eccentricity of the record/centering etc?

If that's by servo allowing free movement of the support arm at very low frequencies, such as 0.55Hz eccentricity, then I think skate torque mechanics will be like a normal offset pivoted arm and the stylus will see more or less normal skate force at least the DC and lf part of it which is the most part.

If that's by servo tracking eccentricity forces and moving the arm accordingly, then how does it tell the difference between skate force and eccentricity force? They both apply a force which tries to move the arm at low frequency/DC, which on the face of it can't be told apart?

Or does the servo apply a fixed anti-skate torque, as per normal mechanisms?

Could you explain please, Ralf ? Thx

LD

In a traditional linear tracking arm it is 180 degrees, always, but never so in pivoted arms.

It is NOT a pivot arm!

It is NOT a pivot arm!

I know and I did not claim it was.

Thanks Ralf. Yes, for the stylus to see no skate force relies on the headshell effectively being rigidly connected to the plinth. Achieved via servo. There's still skate torgue in the support arm, but it's resolved at the connection with the plinth, not at the stylus end.

However, it's still not clear to me how the arm copes with eccentricity of the record/centering etc?

If that's by servo allowing free movement of the support arm at very low frequencies, such as 0.55Hz eccentricity, then I think skate torque mechanics will be like a normal offset pivoted arm and the stylus will see more or less normal skate force at least the DC and lf part of it which is the most part.

If that's by servo tracking eccentricity forces and moving the arm accordingly, then how does it tell the difference between skate force and eccentricity force? They both apply a force which tries to move the arm at low frequency/DC, which on the face of it can't be told apart?

Or does the servo apply a fixed anti-skate torque, as per normal mechanisms?

Could you explain please, Ralf ? Thx

LD

Hello luckythedog,

That gets a little tricky to answer, but I'll do my best.

When I first designed my tone arm, I allowed ±.090 inches of motion of the head-shell upon the cradle. I correctly assumed that, that would be enough to allow the cradle to keep up with the head-shell without the head-shell bumping into the cradle. The servo amplifier can be designed in one of two ways: Its gain may be set to provide a large degree of gain, or it can be set to operate on the sluggish side. When gain is set high, the tone arm will follow the head-shell in and out when tracking an eccentric LP., and when gain is on the sluggish side, the inertia of the tone arm prevents the tone arm/cradle from following the outward excursion of the head-shell when tracking an eccentric LP. Someone with the proper test instruments will have to figure out, which of the two conditions above produces the best sound.

The servo amplifier does one thing only, it keeps the head-shell and the cradle from colliding with each other. The controlling force of the servo amplifier is NOT constant. It varies with the vinyl composition and the frequency and level content of the particular LP being played.

One other thing I wanted to explain is that, the "inside force" that every tone arm with an off-set head-shell experiences is not synonymous with skating! Skating occurs when the "inside force" is not properly compensated. So, while my tone arm is subject to the "inside force" it cannot skate!

I have been wanting to make a video of my tone arm for weeks now, but keep getting interrupted. A few days ago my wife's computer crashed and guess who got elected to fix it. But next week I'll get to it or else.

If I haven't addressed something, let me know.

Sincerely,

Ralf

Hello luckythedog,

That gets a little tricky to answer, but I'll do my best.

When I first designed my tone arm, I allowed ±.090 inches of motion of the head-shell upon the cradle. I correctly assumed that, that would be enough to allow the cradle to keep up with the head-shell without the head-shell bumping into the cradle. The servo amplifier can be designed in one of two ways: Its gain may be set to provide a large degree of gain, or it can be set to operate on the sluggish side. When gain is set high, the tone arm will follow the head-shell in and out when tracking an eccentric LP., and when gain is on the sluggish side, the inertia of the tone arm prevents the tone arm/cradle from following the outward excursion of the head-shell when tracking an eccentric LP. Someone with the proper test instruments will have to figure out, which of the two conditions above produces the best sound.

The servo amplifier does one thing only, it keeps the head-shell and the cradle from colliding with each other. The controlling force of the servo amplifier is NOT constant. It varies with the vinyl composition and the frequency and level content of the particular LP being played.

One other thing I wanted to explain is that, the "inside force" that every tone arm with an off-set head-shell experiences is not synonymous with skating! Skating occurs when the "inside force" is not properly compensated. So, while my tone arm is subject to the "inside force" it cannot skate!

I have been wanting to make a video of my tone arm for weeks now, but keep getting interrupted. A few days ago my wife's computer crashed and guess who got elected to fix it. But next week I'll get to it or else.

If I haven't addressed something, let me know.

Sincerely,

Ralf

Thanks for this, it clarifies things. While the torque that equals the "skate force" exist you have the inertia of the servo/arm/plinth as counterforce. The traditional arm has the anti-skate mechanism (spring or weight). Both leads to that the net force is null and thus no skating occurs. (Also it is not the off-set headshell that is the cause of the torque/skate force, pivoted arms with no headshell offset also experience skating force.).

One other thing I wanted to explain is that, the "inside force" that every tone arm with an off-set head-shell experiences is not synonymous with skating! Skating occurs when the "inside force" is not properly compensated. So, while my tone arm is subject to the "inside force" it cannot skate!

Ralf,

I don’t want to start a skating war but, there is no such thing as “properly compensated” skating! Because the friction drag on the stylus is determined by a number of variables, not the least of which is dynamic change in recorded modulation level, any anti-skate method or setting is a compromise and is only “properly compensated” for one very narrow set of conditions. As far as the cartridge is concerned, stylus friction drag in your arm gets resolved in the cradle, and the stylus does not see any side forces beyond what is needed to overcome the friction in the four cradle bearings. Stylus friction drag does try to make the entire arm skate, but the torque developed about the arm pivot is held in check by the servo.

IMO this distinction is the critical advantage of your pivoting tangential arm design, and the advantage of this unique feature gets lost when you describe it as being “properly compensated”. Your arm is not “properly compensated”. From the perspective of the cartridge/stylus, it doesn’t see any skating effects in the first place. IMO this would be the most difficult concept to explain to prospective customers, and this is where your arm is different from every previous implementation of pivoted linear tracking that I’m aware of. Hopefully the collective questions from myself and other followers of this thread will help formulate a way of presenting the unique engineering aspects of your design in a way that a person walking up to it for the first time will “get it” and be able to see how it works within a few minutes of attention span. A video of the arm in action demonstrating its operating principles is a must. This is much more than “just another” high-end tonearm.

Your choice of +/- 0.09 inches of lateral motion of the headshell is ample. A record that far off center will intrinsically exhibit objectionable wow anyway, regardless of the arm's capabilities.

Ray K

Last edited:

Ralf,

I don’t want to start a skating war but, there is no such thing as “properly compensated” skating! Because the friction drag on the stylus is determined by a number of variables, not the least of which is dynamic change in recorded modulation level, any anti-skate method or setting is a compromise and is only “properly compensated” for one very narrow set of conditions. As far as the cartridge is concerned, stylus friction drag in your arm gets resolved in the cradle, and the stylus does not see any side forces beyond what is needed to overcome the friction in the four cradle bearings. Stylus friction drag does try to make the entire arm skate, but the torque developed about the arm pivot is held in check by the servo.

IMO this distinction is the critical advantage of your pivoting tangential arm design, and the advantage of this unique feature gets lost when you describe it as being “properly compensated”. Your arm is not “properly compensated”. From the perspective of the cartridge/stylus, it doesn’t see any skating effects in the first place. IMO this would be the most difficult concept to explain to prospective customers, and this is where your arm is different from every previous implementation of pivoted linear tracking that I’m aware of. Hopefully the collective questions from myself and other followers of this thread will help formulate a way of presenting the unique engineering aspects of your design in a way that a person walking up to it for the first time will “get it” and be able to see how it works within a few minutes of attention span. A video of the arm in action demonstrating its operating principles is a must. This is much more than “just another” high-end tonearm.

Your choice of +/- 0.09 inches of lateral motion of the headshell is ample. A record that far off center will intrinsically exhibit objectionable wow anyway, regardless of the arm's capabilities.

Ray K

The torque exists but that the inertia of the arm/servo/plinth is taking care of that no matter the variation in force, i.e. no skating exists. (Just to be clear, my primary question was if the torque exists or not in the first place.)

This is going to be a little stream of consciousness and maybe not entirely coherent or accurate, but here goes.

First, I had to dismiss any idea that this arm is a powered version of the Birch/Thales passive PLTs. It's not one of those with a motor stuck on someplace. It does not rely on the inherent geometry of circles, the control arm moves through a shallower angle than the Birch/Thales arms do, and I'm fairly sure the pivot bearing does not follow a circle.

The servo tower is not equivalent to the inboard pivot of a passive PLT. The stylus and floating headshell tell the servo where they need the cradle to be for the stylus to maintain tangency and the arm pivot is moved to the point that makes that possible. As far as I know, pretty much by definition, there is no such feedback loop in passive PLTs. Certainly not one that fiendishly (there's another one for you Ralf) uses that ol' devil skate as a positive factor.

Ralf and several others have explained all this before. I'm just rattling on about the thought process I've used to provide myself with an explanation, to create a mental picture.

I think this arm has qualities - technical, visual, a certain "trippiness - that give it definite commercial possibilities. I hope that happens.

Ralf, one non-technical, and slightly personal, thing I'm curious about: When and where did your "aha" moments occur?

First, I had to dismiss any idea that this arm is a powered version of the Birch/Thales passive PLTs. It's not one of those with a motor stuck on someplace. It does not rely on the inherent geometry of circles, the control arm moves through a shallower angle than the Birch/Thales arms do, and I'm fairly sure the pivot bearing does not follow a circle.

The servo tower is not equivalent to the inboard pivot of a passive PLT. The stylus and floating headshell tell the servo where they need the cradle to be for the stylus to maintain tangency and the arm pivot is moved to the point that makes that possible. As far as I know, pretty much by definition, there is no such feedback loop in passive PLTs. Certainly not one that fiendishly (there's another one for you Ralf) uses that ol' devil skate as a positive factor.

Ralf and several others have explained all this before. I'm just rattling on about the thought process I've used to provide myself with an explanation, to create a mental picture.

I think this arm has qualities - technical, visual, a certain "trippiness - that give it definite commercial possibilities. I hope that happens.

Ralf, one non-technical, and slightly personal, thing I'm curious about: When and where did your "aha" moments occur?

Ralf,

I don’t want to start a skating war but, there is no such thing as “properly compensated” skating!

Hello Ray K,

I am well aware of that, but I should have been more careful and said something like "to the best of one's ability"

IMO this distinction is the critical advantage of your pivoting tangential arm design, and the advantage of this unique feature gets lost when you describe it as being “properly compensated”. Your arm is not “properly compensated”. From the perspective of the cartridge/stylus, it doesn’t see any skating effects in the first place. IMO this would be the most difficult concept to explain to prospective customers, and this is where your arm is different from every previous implementation of pivoted linear tracking that I’m aware of. Hopefully the collective questions from myself and other followers of this thread will help formulate a way of presenting the unique engineering aspects of your design in a way that a person walking up to it for the first time will “get it” and be able to see how it works within a few minutes of attention span. A video of the arm in action demonstrating its operating principles is a must. This is much more than “just another” high-end tonearm.

That is very well written, and I'll take that to heart. However, that inside force/skating remark was meant to apply to pivoting tone arms with offset head-shells. I wanted to convince ThomasA to not use the term skating anywhere near my tone arm.

Sincerely,

Ralf

Ralf,

Ray K

My tone arm tracks tangentially all the way to within ~.080" of the label. It stops there and cannot move further. If the tone arm were to continue on the same path, the stylus would precisely intersect the turn table center line.

Sincerely,

Ralf

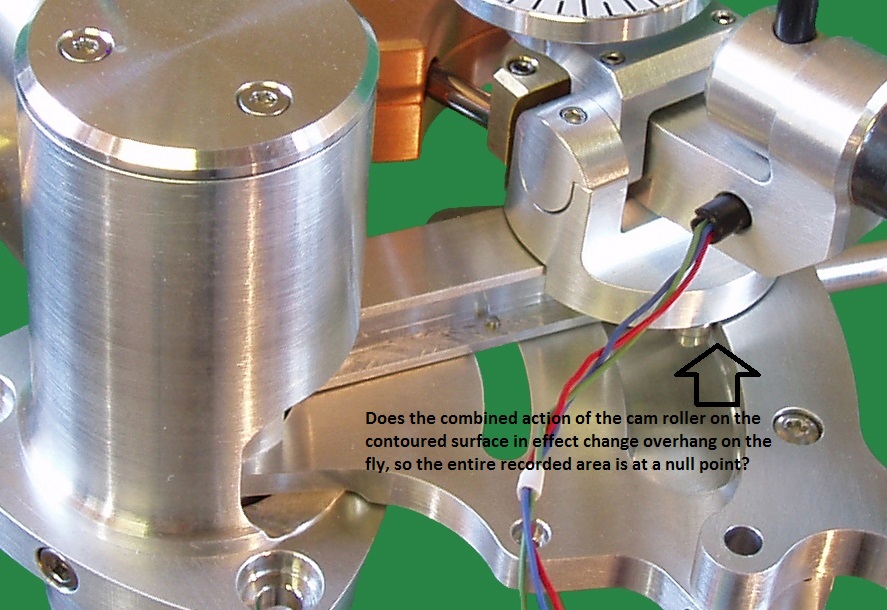

This arm is so full of small and big ideas, skills and experience that it is amusing and instructive trying to understand something. Long time ago one of my teachers said that words are no good design tools so here is a graph for the "strange offset" problem (attachment)

Imho:

- the mini parallel arm (then the stylus) has no offset = 0 tracking error, 0 skating, almost 0 stylus bending (far less than his big brothers, due the shortest possible eff. lenght)

- the servo PLT has 10°- 12 ° offset (half of a Baerwald) and an horizontal pivot angled the same, like a Rega. As the offset generates side force (skating = side force less the friction on hor. pivot) maybe here just a bit is used to facilitate the rotation. All these solicitations are dealt and held inside the servo PLT.

- H + V pivots follow a circle in FP - the guide pivot a curvilinear cam: similar to the LT, and others called "non Birch" in my simulations on Dd thread.

True? who knows, this arm is so devious...

carlo

Ralf: a claim for selling, about the "separation" plus : buy one, get two! )

)

Imho:

- the mini parallel arm (then the stylus) has no offset = 0 tracking error, 0 skating, almost 0 stylus bending (far less than his big brothers, due the shortest possible eff. lenght)

- the servo PLT has 10°- 12 ° offset (half of a Baerwald) and an horizontal pivot angled the same, like a Rega. As the offset generates side force (skating = side force less the friction on hor. pivot) maybe here just a bit is used to facilitate the rotation. All these solicitations are dealt and held inside the servo PLT.

- H + V pivots follow a circle in FP - the guide pivot a curvilinear cam: similar to the LT, and others called "non Birch" in my simulations on Dd thread.

True? who knows, this arm is so devious...

carlo

Ralf: a claim for selling, about the "separation" plus : buy one, get two!

Attachments

Last edited:

Ralf, one non-technical, and slightly personal, thing I'm curious about: When and where did your "aha" moments occur?

Hello Doug,

I don't remember a specific "aha" moment. I resumed my work on tone arms in 2010 after a thirty year pause. Sometime in 2010 after I had made a new prototype, that floating head-shell popped into my mind and I made a CAD drawing of it sitting on top of its cradle with a short piece of tone arm tubing attached to it. I think the reason there was no particular "aha" moment, was the fact that I thought it to be "off the wall" and I had no idea how it would work or why it would work. So if anything happened at all, it was a low level "aha' moment. It wasn't an instant stroke of genius, but an effort that took a number of years to refine. However, the aha moment is occurring now, and it is not a moment but an ongoing occurrence. I've been listening to all of my favorite LPs for several months now and all I can say is that, if there were a cloud higher than cloud nine, I would be on it. And last but not least, considering all the kind comments I've gotten, make that cloud ninety.

Sincerely,

Ralf

Last edited:

strange offset - errata corrige

Further investigating I discovered that it is not (only) a problem of side-force: it is more a problem of geometry, innovative and advantageous.

I do not post these new graphs, maybe I have already exaggerated with "reverse engineering" and I apologize to Ralf: there are already too many copycats around.

carlo

this arm is always surprising

Further investigating I discovered that it is not (only) a problem of side-force: it is more a problem of geometry, innovative and advantageous.

I do not post these new graphs, maybe I have already exaggerated with "reverse engineering" and I apologize to Ralf: there are already too many copycats around.

carlo

this arm is always surprising

strange offset - errata corrige

Further investigating I discovered that it is not (only) a problem of side-force: it is more a problem of geometry, innovative and advantageous.

I do not post these new graphs, maybe I have already exaggerated with "reverse engineering" and I apologize to Ralf: there are already too many copycats around.

carlo

this arm is always surprising

Hello Carlo,

Thank you, and there is no need to apologize.

I should have a video ready later in the week.

Sincerely,

Ralf

Ralf,

How does it deal with the runout groove at the end of the record?

Does the servo keep up?

Ray K

Hello Ray K,

The run_out groove turns into a circle at ~ R2.080" and my tone arm follows it just fine, no issues.

Remember, the servo does not "drive" the tone arm, it just relaxes its hold_back. Sort of like restraining a dog with one of those spring loaded dog leashes. If you want him to go, you just push a button.

As mentioned above, I should have a video ready by the end of the week.

Sincerely,

Ralf

Last edited:

- Home

- Source & Line

- Analogue Source

- A Revolutionary Pivoting Tangential Tone Arm