You may assume it was centred. I look forward to your results for W&F sensitivity to torque settings.

I didn't volunteer to take any. I hate dealing with centering test records, tracking down variables, etc. to get proper results. It wouldn't surprise me in the least if wow worsened with a lower torque setting, and I find the data interesting which is why I'm asking about the test hygiene. I love a good murder mystery game, but not tonight.

If you provide a wav file I'd be happy to give you a polar plot so you can start to piece together the nuance of your test record.

I look forward to your results for W&F sensitivity to torque settings.

@ JP

I appreciate the test results and advice. However, do you have any data on the effect of torque settings on speed stability? Even if the effect is minuscule, it would be useful to see if there is a trend.

My main turntable, a DD linear tracker, has these posted specs, which I personally confirmed with the shop's test equipment years ago....

3LB rotating platter mass

W/F 0.025% (WRMS)

0.05% DIN

S/N (rumble) DIN 40dB (A)

DIN 75dB (B)

I see nothing there to consider worthy of upgrading.

3LB rotating platter mass

W/F 0.025% (WRMS)

0.05% DIN

S/N (rumble) DIN 40dB (A)

DIN 75dB (B)

I see nothing there to consider worthy of upgrading.

I see nothing there to consider worthy of upgrading.

The overall noise and so called groove noise is less on the 10R. Plus you can fit the world's best tonearms and cartridges.

BTW JP is of course correct on W&F, I worked with Noel Keywood of HiFi World magazine. We both have multiple copies of "DIN 45 545", "Denon XG-7004" and "JVC TRS-1007".

The challenge of centering and finding a good copy of a good test record is huge. Then there is which weighting, repeatability and cartridge/arm selection.

It is not easy at all YMMV

Dave

The clearly stated intention of my post #55, was to provide data on the effect of the 10R torque settings on speed stability. The data is actually supported by the August 2018 Hi Fi World review of the 10R, in which Dave was closely involved. The pdf of the review can be found online at the Hi Fi World site. Some quotes from the review:

"Torque can be reduced in the control unit and this improves speed stability even further."

"Reducing torque to minimum (Torque 1) brought obvious improvement, surprisingly cutting basic rate variation at 0.55Hz by half, as our analysis shows."

"Torque can be reduced in the control unit and this improves speed stability even further."

"Reducing torque to minimum (Torque 1) brought obvious improvement, surprisingly cutting basic rate variation at 0.55Hz by half, as our analysis shows."

Hi Bon

I'm not disagreeing with anything here, just adding an additional perspective. Both HiFi News and HiFi World test reports are here Technics SP-10R

The HiFi World test was on a unit configured and supplied by me. I delivered and collected it in person from their office. It was in conjunction with Panasonic UK and won turntable of the year award.

The HiFi News review has some interesting things mentioned on general noise.

Dave

I'm not disagreeing with anything here, just adding an additional perspective. Both HiFi News and HiFi World test reports are here Technics SP-10R

The HiFi World test was on a unit configured and supplied by me. I delivered and collected it in person from their office. It was in conjunction with Panasonic UK and won turntable of the year award.

The HiFi News review has some interesting things mentioned on general noise.

Dave

"Reducing torque to minimum (Torque 1) brought obvious improvement, surprisingly cutting basic rate variation at 0.55Hz by half, as our analysis shows."

The very next sentence is important for context. I wouldn’t hold it against them for throwing in some doubt; a variation once per revolution would be very odd to be caused by the torque setting.

BTW, even when centered with my TX-1000, many test records I have still show a slight 0.555Hz variation.

Fully quoting the very next sentence, not paraphrasing it as you have done:The very next sentence is important for context. I wouldn’t hold it against them for throwing in some doubt; a variation once per revolution would be very odd to be caused by the torque setting.

BTW, even when centered with my TX-1000, many test records I have still show a slight 0.555Hz variation.

"This variation I thought was down to residual factors such as disc eccentricity (even though it is carefully centred using the locked groove) and cutting lathe variation – but perhaps not. The SP-10R produced its best result in speed stability tests at Torque 1 – and they are exceptionally low values, beyond all else."

Do I sense some dancing?

An escape hatch, perhaps. I interpret it as saying 'here's what the measurements say, which don't appear to make sense, but I can't find an explanation for it'. Fair enough.

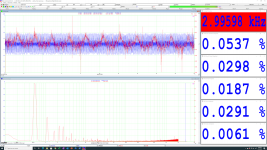

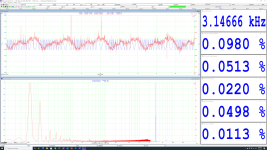

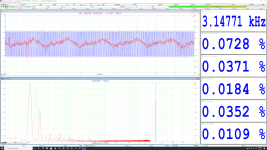

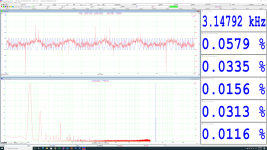

Attached is what I was talking about yesterday. Red is FM demodulated. The numbers are slightly different as I pushed the FFT up to 4M points. What's dominating the result is obvious.

Attached is what I was talking about yesterday. Red is FM demodulated. The numbers are slightly different as I pushed the FFT up to 4M points. What's dominating the result is obvious.

Attachments

About these "torque" observations related to W/F measurements....

As my previous post #64 states, my turntable has a relatively "light" platter, anchored by a very well made spindle and bearing assembly.

The DD motor is also quite "weak" compared to the Technics SP's discussed here.

In fact, it takes a full revolution or so, to "lock in" to the desired speed, which is not an issue.

Once running, it also has just enough torque to remain stable under stylus drag/loading (1.5G VTF).

The combination works extremely well, which is why the W/F ratings are so low for what it is.

The intensity of the magnetic pulses/cogging effects are minimal enough to not interfere with smooth rotation.

The bottom line, or "sweet spot" of it all is that there is a point at which too much torque is overkill, and relates to platter mass and related inertia.

This is, of course, for "home use" playing a record normally, not DJ-ing duty.

I believe that the adjustable torque on the Technics was provided for the reasons of versatility in these areas.

If it were me, I'd set the adjustment low in home use.

As my previous post #64 states, my turntable has a relatively "light" platter, anchored by a very well made spindle and bearing assembly.

The DD motor is also quite "weak" compared to the Technics SP's discussed here.

In fact, it takes a full revolution or so, to "lock in" to the desired speed, which is not an issue.

Once running, it also has just enough torque to remain stable under stylus drag/loading (1.5G VTF).

The combination works extremely well, which is why the W/F ratings are so low for what it is.

The intensity of the magnetic pulses/cogging effects are minimal enough to not interfere with smooth rotation.

The bottom line, or "sweet spot" of it all is that there is a point at which too much torque is overkill, and relates to platter mass and related inertia.

This is, of course, for "home use" playing a record normally, not DJ-ing duty.

I believe that the adjustable torque on the Technics was provided for the reasons of versatility in these areas.

If it were me, I'd set the adjustment low in home use.

Last edited:

I interpret it as saying 'here's what the measurements say, which don't appear to make sense, but I can't find an explanation for it'. Fair enough.

My interpretation is different. It says to me, “despite extreme care in centering the test LP and accounting for production errors, there is still a variation with torque setting”.

The facts are that the low torque setting is mentioned at least three times in the review, that the test format and conditions were the most rigorous in an English language periodical, the format and the test results were approved by the UK importer (Timestep), my own results confirm the torque settings stability variation. That is sufficient confirmation for me. I will be using Torque setting 1.

YMMV (Sorry for the borrowing, Dave)

I don't see any mention of conditions or rigor. The only detail shared was the test record. No mention of the equipment, calibration, number of measurements, if taken at the same place on the test record, the method used to center the record, the tolerance thereof, etc.

There's simply not enough evidence or data provided in either case to draw a conclusion.

There's simply not enough evidence or data provided in either case to draw a conclusion.

Case in point: DIN 45 545 test record tracks B1, B3, and B5. All I did was move the needle.

Attachments

Case in point: DIN 45 545 test record tracks B1, B3, and B5. All I did was move the needle.

A major component of the Scientific Method that has served western society so well for the last 500 years, is replicability or reproducibility.

Reproducibility - Wikipedia

Any experiment or test procedure that that has outcomes sensitive to small change in the input parameters, is poorly designed or flawed in its execution.

Case in point: DIN 45 545 test record tracks B1, B3, and B5. All I did was move the needle.

Moving the stylus to a different track is a COMPLETELY DIFFERENT MEASUREMENT. Why would you expect the results to be even related? You might as well measure different turntables.

A while ago I saw the video JP posted on Youtube about his repaired EPA-100 tonearm. JP replaced the broken rubis bearing with ceramic balls, and got this excellent result.

For years I had this damaged EPA-100, got rob by some seller in Japan, a long story... Just to say that the arm was useless. I tried to find a place to have it repair, but no success, or at least some place that were not recommended to me. Except for the bearings the rest of the tonearm was perfect (VTA, antiskating, counterweight, etc...)

I decided to ask JP is he would be interested, and he agreed. I sent him the tonearm, and after his inspection, the horizontal axis (L/R) bearing was all destroyed, damaged retaining hats, even some marks on the adjustments pins plating, and needed complete rebuilt. The vertical axis (Up/Down) still had rubis bearing ball, but the top bearing plate was damaged by incorrect pin adjustment... It was bad.

JP completly rebuilt both axis, installed new ceramic balls, repaired the plate and polished the adjustments pins plating. While working on the tonearm, also rewired the arm with new Litz wires. He did extenive tests on the repaired tonearm, and sent me detailled tests results, including tests results showing no parasit resonnance. The arm was tracking perfectly, and sounds great.

Received the tonearm 2 weeks later in perfect condition, listening to it right now, and everything is perfect, I got my EPA-100 back!

Thanks again JP for your help, couldn't have done myself...

If you need to have your EPA-100 repair, JP is your guy!

SB

For years I had this damaged EPA-100, got rob by some seller in Japan, a long story... Just to say that the arm was useless. I tried to find a place to have it repair, but no success, or at least some place that were not recommended to me. Except for the bearings the rest of the tonearm was perfect (VTA, antiskating, counterweight, etc...)

I decided to ask JP is he would be interested, and he agreed. I sent him the tonearm, and after his inspection, the horizontal axis (L/R) bearing was all destroyed, damaged retaining hats, even some marks on the adjustments pins plating, and needed complete rebuilt. The vertical axis (Up/Down) still had rubis bearing ball, but the top bearing plate was damaged by incorrect pin adjustment... It was bad.

JP completly rebuilt both axis, installed new ceramic balls, repaired the plate and polished the adjustments pins plating. While working on the tonearm, also rewired the arm with new Litz wires. He did extenive tests on the repaired tonearm, and sent me detailled tests results, including tests results showing no parasit resonnance. The arm was tracking perfectly, and sounds great.

Received the tonearm 2 weeks later in perfect condition, listening to it right now, and everything is perfect, I got my EPA-100 back!

Thanks again JP for your help, couldn't have done myself...

If you need to have your EPA-100 repair, JP is your guy!

SB

Attachments

Last edited:

Case in point: DIN 45 545 test record tracks B1, B3, and B5. All I did was move the needle.

"5 modulated bands per side to measure wow and flutter at different positions."

IF I have the correct record, this is for measuring wow and flutter on five different places on the record. He measured the inside groove, middle groove and outside groove. A experienced tester like JP (his measurements are all over the web) would be able to learn a lot by comparing them.

BUT he did not give us enough information to tell us what he was up to ! Which is the lesson I think.( And I too might have missed his point entirely)

- Home

- Source & Line

- Analogue Source

- The Incredible New Technics SP-10R Thread