Scott re vibrations

I would suggest to start with the electrical part of your ac motor.

Find the optimum operating voltage and the optimum phasing capacitor value for minimum motor vibration.

Use a stethoscope or a screwdriver touching your ear or a piezo disk on oscilloscope as vibration sensors directly on the motor (motor can be dismantled from the TT)

Then target the vibration path from motor to plinth, to platter, to disk.

1. You have to add some compliance between the motor and the plynth.

Suspending the motor with a small rubber belt as Rega has done is easy and very effective, better than the rubber grommets.

2. Add some compliance between platter and disk.

Use a softer platter mat. Make one from a piece of velvet fabric, it’s good.

You can search ebay for felt, silicone or sorbothane mat.

Note. A soft mat does change the playback sound, makes it softer. Test with a record having lute, classical guitar, piano. Notice mostly the attack of a note.

Motor suspension and driving belt softness/tension also affect the sound in that respect but less than what the mat does.

I think you won’t have to go further than this.

Technical curiosity may drag you toward difficult paths (building another plinth with different materials, making a separate housing for the motor away from the TT plinth ect). You will risk becoming an audio fetishist.

George

I would suggest to start with the electrical part of your ac motor.

Find the optimum operating voltage and the optimum phasing capacitor value for minimum motor vibration.

Use a stethoscope or a screwdriver touching your ear or a piezo disk on oscilloscope as vibration sensors directly on the motor (motor can be dismantled from the TT)

Then target the vibration path from motor to plinth, to platter, to disk.

1. You have to add some compliance between the motor and the plynth.

Suspending the motor with a small rubber belt as Rega has done is easy and very effective, better than the rubber grommets.

2. Add some compliance between platter and disk.

Use a softer platter mat. Make one from a piece of velvet fabric, it’s good.

You can search ebay for felt, silicone or sorbothane mat.

Note. A soft mat does change the playback sound, makes it softer. Test with a record having lute, classical guitar, piano. Notice mostly the attack of a note.

Motor suspension and driving belt softness/tension also affect the sound in that respect but less than what the mat does.

I think you won’t have to go further than this.

Technical curiosity may drag you toward difficult paths (building another plinth with different materials, making a separate housing for the motor away from the TT plinth ect). You will risk becoming an audio fetishist.

George

Attachments

Bill

I just received two beauties.

Pm me your address and I will send you one of the two.

Hans

Attachments

Last edited:

I'm a bit lost.@LD: It would be comforting if all the cartridges showed similar peaks. The fact that they don't does suggest to be a resonance showing up. Another string to pull on at some point.

If we mean the peaks c. 3kHz/9kHz/? series that Scott and Hans found in crosstalk, I have not seen those before and that seems to be a widespread test record issue.

The series of peaks that runs c 15-25kHz/40-50kHz/? is almost certainly cantilever self resonance IMHO. This does vary between carts and shows up on all records in principle. I suppose it could happen at lower f, but that would not be good, though colourful...….

LD

Hans: thank you. Will pm as soon as I get on the computer without my little helper!

LD:LD: was referring to the fact that the miller measurements show a distortion peak at 6-7kHz which might infer a resonance at 12 or 18kHz. The Jo #5 shows this peak at a much higher frequency. Something doesn't quite stack up.

LD:LD: was referring to the fact that the miller measurements show a distortion peak at 6-7kHz which might infer a resonance at 12 or 18kHz. The Jo #5 shows this peak at a much higher frequency. Something doesn't quite stack up.

I agree.I disagree with the explanation of resolution between pink noise and sweeps. Coherent detection techniques with sweeps give good results, I posted some here.

Whilst it's possible to muck up post-playback analysis, it's also very possible to get it right.

LD

The series of peaks that runs c 15-25kHz/40-50kHz/? is almost certainly cantilever self resonance IMHO. This does vary between carts and shows up on all records in principle

There has to be one more playback with a laser beam turntable (ELP) before there will be some certainty on what is in the grooves and what is due to playback cartridge.

George

Ah, got it. You mean the DS-W2 report: there's much about that looks plain odd and not in a good way...………………..LD: was referring to the fact that the miller measurements show a distortion peak at 6-7kHz which might infer a resonance at 12 or 18kHz. The Jo #5 shows this peak at a much higher frequency. Something doesn't quite stack up.

I suppose it could be cantilever impedance dip at 6-7kHz...…….whatever it looks like mistracing/mistracking around that band, recovering at higher f. But the f response looks weird too...…..??

Those carts don't track too well, do they ? Should have a two horse race on measurements versus the S-120

LD

I'm a bit lost.

If we mean the peaks c. 3kHz/9kHz/? series that Scott and Hans found in crosstalk, I have not seen those before and that seems to be a widespread test record issue.

Let's not get too off track here with my experiments. I was curious to see how different pink noise tracks behaved and the artifacts I found I think are real.

I agree.

Whilst it's possible to muck up post-playback analysis, it's also very possible to get it right.

If you start talking >10% distortion fundamental suppression can factor in. I don't think I have any -8dB sweeps and PN on the same makers disks.

Scott re vibrations

I would suggest to start with the electrical part of your ac motor.

Find the optimum operating voltage and the optimum phasing capacitor value for minimum motor vibration.

Thanks all good ideas but the motor is 24V AC no mains. I have a good miniature accelerometer to scope out were it's coming from, and I'm thinking some lead sheets and Ed's double sticky tape might help.

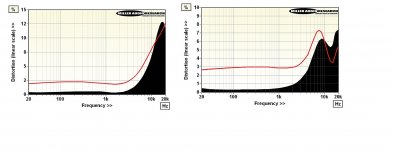

Attached might explain a bit more what I was getting at. This is the Kiseki blue vs EAT Jo 5. Source Miller audio research.

The Kiseki is a 5x120um (Gyger?) and the EAT is 8x40um (shibata?) so both should be as low as tracing distortion can get. Haven't had a chance to adjust the graphs for scale differences so it should be noted up front that they both have about the same distortion at 8kHz but after that behave very differently.Also odd is that the kiseki has a very un-MC like frequency response with a peak in output lining up with the dip around 15kHz. .

If the diamond is pulling 500G in this test I can help thinking of a metal ruler held against a table and being twanged, although an epee is probably close to it .

.

Now PM usually puts in a comment about these peaks being due to extended frequency response, so I can only assume he's measuring 2nd to 4th harmonic in this test. But without more information on the measurement setup this is guessing. Something interesting is shown there, just not sure what at the moment.

The Kiseki is a 5x120um (Gyger?) and the EAT is 8x40um (shibata?) so both should be as low as tracing distortion can get. Haven't had a chance to adjust the graphs for scale differences so it should be noted up front that they both have about the same distortion at 8kHz but after that behave very differently.Also odd is that the kiseki has a very un-MC like frequency response with a peak in output lining up with the dip around 15kHz. .

If the diamond is pulling 500G in this test I can help thinking of a metal ruler held against a table and being twanged, although an epee is probably close to it

Now PM usually puts in a comment about these peaks being due to extended frequency response, so I can only assume he's measuring 2nd to 4th harmonic in this test. But without more information on the measurement setup this is guessing. Something interesting is shown there, just not sure what at the moment.

Attachments

Those carts don't track too well, do they ? Should have a two horse race on measurements versus the S-120

LD

Reminds me, I don't suppose you have a worn out S-120 you would swap for a new one? I need a donor and it'll take an age for me to wear one out in normal use.

Whilst OT. Have you checked out the concorde Mk2 range? Sensible compliance and very similar tracking ability as S-120 without the donut. Sadly only available in concorde shape and different moulding so no using on older OM bodies.

No kidding! The comment on no hum was interesting. I did an experiment last night since my new place is dead quiet compared to the last. My re-wired TT is very quiet in differential mode (remarkable for a Grado) but when playing an LP there is audible mains related noise, so I tried letting the motor run with no belt and listened stylus up vs. down. The noise is actually mechanically transmitted through the plinth and not any kind of magnetic coupling.

This is bad because now it bothers me, I see $$$ down the rabbit hole.

Interesting. I got a Project T/T over here about 4 years ago. The PSU was one of those wall warts. Reasonably quiet with the platter rotating and stylus off the record. Put the stylus down and the LF 'hum' was really bad. I googled around a bit an discovered these T/T's have mechanical noise problems due to the motor rotational vibration coupling up onto the platter. I ended up buying a special kit from the local importer (Henley here in the UK) that included a new belt, some rubber washers etc for about $35. I fitted them and there was a substantial drop in the noise.

However, I felt I'd been screwed with a bad product. My son got it and I bought a Michel Gyrodec (beautiful). No noise - absolutely silent but at 3x the price. The motor is mounted off board and not coupled to the platter in anyway other than through the belt.

One of the very cool looking VPI's was on my shortlist, but I felt the London made Michel (about £1700 without an arm) was better bang for the buck over here (import duties etc) and that's what swung me. Besides, the Michel is seriously retro - 30 year old design but still golden IMO.

I bought a 40 kg piece of gravestone head marble from a local monumental mason who drilled 4 holes in the base so I could mount some large rubber bumpers. The whole thing sits on the marble so no vibration can get to the T/T other than whatever can move the plinth around (very little given its weight). I've used high carbon content rubber discs between the Michel feet and the marble base plate - I figured any vibration would be turned to heat energy - no science in it, just a wild guess.

(BTW @billshurv that's how I got to get the Ortofon Black - from the Protect T/T all in for c. £600. The Black is about £250 if you buy it on its own. Still using the Black stylus in a Red body - works a treat.)

Last edited:

Attached might explain a bit more what I was getting at. This is the Kiseki blue vs EAT Jo 5. Source Miller audio research.

The Kiseki is a 5x120um (Gyger?) and the EAT is 8x40um (shibata?) so both should be as low as tracing distortion can get. Haven't had a chance to adjust the graphs for scale differences so it should be noted up front that they both have about the same distortion at 8kHz but after that behave very differently.Also odd is that the kiseki has a very un-MC like frequency response with a peak in output lining up with the dip around 15kHz. .

If the diamond is pulling 500G in this test I can help thinking of a metal ruler held against a table and being twanged, although an epee is probably close to it.

Now PM usually puts in a comment about these peaks being due to extended frequency response, so I can only assume he's measuring 2nd to 4th harmonic in this test. But without more information on the measurement setup this is guessing. Something interesting is shown there, just not sure what at the moment.

Do you know if they measure both channels? And what test record they use? I can surely see differences in the HF region that is not consistent between channels.

I ended up buying a special kit from the local importer (Henley here in the UK) that included a new belt, some rubber washers etc for about $35. I fitted them and there was a substantial drop in the noise.

Mine is the same with belt off and motor running so first line of attack is motor mount. The chance of me doing $3000 + for anything audio is nil, just my upbringing, my father's creed was don't pay anyone good money for something you can do yourself and don't pay interest on anything.

Thanks all good ideas but the motor is 24V AC no mains. I have a good miniature accelerometer to scope out were it's coming from, and I'm thinking some lead sheets and Ed's double sticky tape might help.

If the motor is a synchronous two coil (four wire out) , all the suggestion for the main’s motors is applicable to it too.

Alternatively, a new world of possibilities opens up

YouTube

George

Scott, try using a sound card to help with the noise identification and analysis. In the Project case more pliant rubber motor mounts and a new type of belt dropped the noise about 15-20 dB.

Loosening the motor mounting screws also helped ( the motor was suspended on thick rubber bands IIRC - these were not changed in the upgrade kit).

You’re an engineer, you could of course remove the motor and mount it off board - just ‘sayin

Loosening the motor mounting screws also helped ( the motor was suspended on thick rubber bands IIRC - these were not changed in the upgrade kit).

You’re an engineer, you could of course remove the motor and mount it off board - just ‘sayin

Last edited:

You’re an engineer, you could of course remove the motor and mount it off board - just ‘sayin

I hope you guys realize I'm having a little fun with you here.

The risk of physical injury when handling this product due to strong force of magnets can damage your fingers and skin that gets caught between the magnets and metal.

People with heart pacemakers are not allowed to handle the apparatus or operate the platter.

heart pacemaker may switch to test mode causing improper functioning.

heart defibrillator may stop working.

do not come closer than one meter to the turntable.

warn others, who are wearing such devices, not to come closer than one meter from the apparatus.

Additionally, if you have MC cartridges, keep them away from the ML1.

Finally, for our readers who have reel-to-reel (or even cassette) tapes, please keep all tapes as far away as possible from the ML1. In fact, magnetic media of all kinds should be kept at a safe distance from this turntable.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Cartridge dynamic behaviour