I have a Teres table w/ a Verus motor and a solid acrylic platter. I love my table, but I’d love it more if I could experiment with other platter options. I’m not willing to mod my existing 3” platter. Has anyone machined a platter for a Teres bearing (of late)? I’d like to try a platter with much more mass (yet still looks “high-end”).

I don’t frequent this forum much - I’m generally found at the ‘gon or AudioCircle. If anyone stumbles on this post and has suggestions feel to hit me at nrenter (at) alumni (dot) northwestern (dot) edu.

Thanks!

- Nicholas

I don’t frequent this forum much - I’m generally found at the ‘gon or AudioCircle. If anyone stumbles on this post and has suggestions feel to hit me at nrenter (at) alumni (dot) northwestern (dot) edu.

Thanks!

- Nicholas

Last edited:

I am currently developing an outer-platter ring made from Corrian, as far as I know that is the same as Delrin but just another brand.

They are both made from different polymers. Not the same at all.

jeff

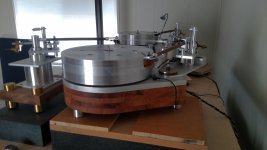

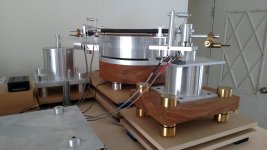

I built 4 different platters for teres and red point bearings. The 2 I liked the best are lead loaded aluminum at 32lbs and 38 lbs. I am also using PVC mats one with lead sheet sandwich.

I did not use acrylic but had the red point PVC platter. The heavier aluminum lead stood out in 3 areas. Drive/dynamics, pitch, and decay. I needed the money or I would have lead loaded the PVC for another comparison. It only weighed in at 16lbs. Met Chris at a show and we had a long talk. He stated weight is your friend with belt drive platters.

If you can build electronics, look on this site and get a sgt4 kit. Bill even has a motor and amp thread too. Run mylar tape 1/2 / 3/4 or 1 inch.

Here are the 2 platters I am using now.

Enjoy the ride

Tom

I did not use acrylic but had the red point PVC platter. The heavier aluminum lead stood out in 3 areas. Drive/dynamics, pitch, and decay. I needed the money or I would have lead loaded the PVC for another comparison. It only weighed in at 16lbs. Met Chris at a show and we had a long talk. He stated weight is your friend with belt drive platters.

If you can build electronics, look on this site and get a sgt4 kit. Bill even has a motor and amp thread too. Run mylar tape 1/2 / 3/4 or 1 inch.

Here are the 2 platters I am using now.

Enjoy the ride

Tom

Attachments

I had a Teres 255 (monkey wood plinth, lead-loaded platter, belt drive) back in the day. However, grad school in 2005 forced a sale of that beauty. When I got back into the game (2007-ish), Chris put together a package for me that I couldn't refuse - cocobolo plinth, solid acrylic platter and a Verus motor. He didn't have any lead-loaded (or derlin or wood) remaining. So, I took what I could get and was thrilled to be (again) part of the Teres family.

If you ever get inspired to craft a 3" platter for the Teres bearing, keep me in mind. For my aesthetic it would be cool to have the aluminum platter power coated black.

If you ever get inspired to craft a 3" platter for the Teres bearing, keep me in mind. For my aesthetic it would be cool to have the aluminum platter power coated black.

Here are the 2 platters I am using now.

Wow, that's quite the rig. You make the arms?

jeff

Wow some great posts and ideas...

Those lead loaded aluminium platters look the business, would love to procure one of them... Tom you wouldn't happen to have the drawings or schematics you would be happy to share?? Might try and find someone here in Aus to make something similar

Harold, you wouldn't happen to be able to get delrin from a supplier over there in new Zealand?? Although from my limited reading machining delrin is quite a specialised process???

Those lead loaded aluminium platters look the business, would love to procure one of them... Tom you wouldn't happen to have the drawings or schematics you would be happy to share?? Might try and find someone here in Aus to make something similar

Harold, you wouldn't happen to be able to get delrin from a supplier over there in new Zealand?? Although from my limited reading machining delrin is quite a specialised process???

I did not make any drawings but depending on bearing and pulley size they could all be different. So default size would be 12" diameter. Height would be based on looks, weight and what you did with the bearing/plinth pairing. From there you see how the bearing wants to mate to platter(teres wants slide fit with 90 degree shoulder).

Now you bore your underside hole to clear the bearing and put the shoulder on platter for the bearing mating. On adding weight( brass, SS, lead etc) drill the holes (with CNC or by hand with rotary table. You want to keep things balanced and the more on the outside the better for inertia. Then figure out how you want to cap the holes if you use lead shot (counter sink with cap is one way). Gram scale the weights to keep things in balance.

How the machine shop goes at this will depend on his machines.

Hope this helps

Tom

Now you bore your underside hole to clear the bearing and put the shoulder on platter for the bearing mating. On adding weight( brass, SS, lead etc) drill the holes (with CNC or by hand with rotary table. You want to keep things balanced and the more on the outside the better for inertia. Then figure out how you want to cap the holes if you use lead shot (counter sink with cap is one way). Gram scale the weights to keep things in balance.

How the machine shop goes at this will depend on his machines.

Hope this helps

Tom

Matt

Google teres and red point bearing, there are pictures and discussions about them. Red point is a little larger with a long threaded body, which allows for easy adjustment of platter height. They use a stainless spindles and brass bodies. Suppose to be .0002 clearance. Never measured either one.

My experience with large mass platters and turntables is the bearing is important but not as much as getting a big heavy platter. You can play around with how you mate the platter and bearing and lower ball bearing and thrust plate. In a perfect world you could press fit or loctite 609 the spindle on to the platter, then machine the spindle. Now platter changing very involved.

Hope this helps some.

Tom

Google teres and red point bearing, there are pictures and discussions about them. Red point is a little larger with a long threaded body, which allows for easy adjustment of platter height. They use a stainless spindles and brass bodies. Suppose to be .0002 clearance. Never measured either one.

My experience with large mass platters and turntables is the bearing is important but not as much as getting a big heavy platter. You can play around with how you mate the platter and bearing and lower ball bearing and thrust plate. In a perfect world you could press fit or loctite 609 the spindle on to the platter, then machine the spindle. Now platter changing very involved.

Hope this helps some.

Tom

Those are my arms. They are around 12.5 inches. They are Jewel unipivot with oil damping. Tried alum, carbon fiber, and various wood arm tubes. Wood won the fight in my system. Still playing with different woods.

Very nice Tom.

jeff

Chris @ Teres Audio sent me a .pdf of the platter dimensions that fits the Teres bearing. PM me at nrenter (at) alumni (dot) northwestern (dot) edu if you'd like me to forward.

Now I'm trying to find a machinist to make me a couple platters - one out of solid black Delrin, and another out of solid black Delrin that has 2 (or 3) rows of 2.5" deep holes around the perimeter of the underside so I can lead-load them (and cap w/ an epoxied friction-fit cap). The diameters of said holes are TBD. I've reached out to a couple in the Dallas / Ft. Worth area (in the United States), but haven't received a response (they're probably not interested in making a whopping 2 platters for some nut-job audiophile).

Now I'm trying to find a machinist to make me a couple platters - one out of solid black Delrin, and another out of solid black Delrin that has 2 (or 3) rows of 2.5" deep holes around the perimeter of the underside so I can lead-load them (and cap w/ an epoxied friction-fit cap). The diameters of said holes are TBD. I've reached out to a couple in the Dallas / Ft. Worth area (in the United States), but haven't received a response (they're probably not interested in making a whopping 2 platters for some nut-job audiophile).

Per a suggestion...I downloaded the CAD software from CNC Manufacturing, Prototyping, Fast Quotes & Free CAD | eMachineShop and began to design a Delrin platter to the Teres specs (plus holes to lead-load it - need to determine the best way to cap the holes and incorporate the caps into the design). If we could get 10 people together (and could agree on the design) the cost would drop to around $500 per-platter. For a one-off, it's closer to $1200 (if I recall correctly). The software package is relatively easy to use, but I'm not confident in my CAD skills, so if we can find enough people to place an order, we may want to collaborate on the design.

I just got a quote for an aluminum platter milled to the Teres drawing (kindly supplied by nrenter) exactly i.e., no lead shot holes, from a shop in New Haven CT., USA. $748.00 + shipping. He’s quoting the same in black Delrin with 12 holes tapped for caps as nothing sticks to Delrin so a glued in option is out of the question. Haven’t received the Delrin quote yet.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Teres platter options