I shall make something, measure, listen and see what i have! - work starts in the coming days and i will update after, you have the "before" screen shots, "after" will follow.

I'm looking forward to seeing these results!

Mike, one can add colour without filling (with hydrated alumina). After all, acrylic can coloured, but is not filled.

Hugh, something very wrong with detecting 5kHz, way outside the accelerometer's range. I suspect computer/interface interference. The pvb came today, will try to send it off in the next few days!

Hugh, something very wrong with detecting 5kHz, way outside the accelerometer's range. I suspect computer/interface interference. The pvb came today, will try to send it off in the next few days!

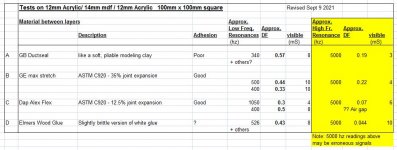

Ok, I've added a disclaimer to the revised chart (attached) about suspect measurements at 5000 hz.

It looks like the Acrylic/mdf/Acrylic combination you've suggested is a good one. Each of the 4 types of adhesive seemed to give good results. "B" and "C" ( Caulking for Vinyl Windows) are the ones that actually give reasonable adhesion.

Hugh

It looks like the Acrylic/mdf/Acrylic combination you've suggested is a good one. Each of the 4 types of adhesive seemed to give good results. "B" and "C" ( Caulking for Vinyl Windows) are the ones that actually give reasonable adhesion.

Hugh

Attachments

I should have added... I used C Clamps to squeeze out the excess caulking and get a very thin layer. The clamps were on for a few days while the caulking cured.

On item "C" I may have over clamped a bit. When I was taking it apart, I noticed a few areas at two edges where the caulking separated from the Acrylic.

I did get a peak at the ASTM C920 spec. It defines the properties required for standing up as a Window caulking. It says ISO 11600 and ISO 11618 are similar for those in Europe.

On item "C" I may have over clamped a bit. When I was taking it apart, I noticed a few areas at two edges where the caulking separated from the Acrylic.

I did get a peak at the ASTM C920 spec. It defines the properties required for standing up as a Window caulking. It says ISO 11600 and ISO 11618 are similar for those in Europe.

Last edited:

Theoretically, if a material could be designed to have a Phononic bandgap at a preferred frequency range and a natural frequency in another or same range, what would be the most advantageous ranges for those 2 properties?

Is it logical for the 2 to be the same somewhere in the audio band for the best outcome?

Is it logical for the 2 to be the same somewhere in the audio band for the best outcome?

2wice,

I had to use Google to find " Phononic bandgap". Looks interesting.

There's a KEF White paper on one of their speakers - the LS50 maybe. I think their philosophy was that Loudspeaker panels should not resonate much in the peak band for human hearing (around 3 khz). Outside that band is less audible.

My thinking is that the same would be good for plinths, tonearms, platters,etc. If anything rings in that zone, it should be well damped so it decays quickly.

Hugh

I had to use Google to find " Phononic bandgap". Looks interesting.

There's a KEF White paper on one of their speakers - the LS50 maybe. I think their philosophy was that Loudspeaker panels should not resonate much in the peak band for human hearing (around 3 khz). Outside that band is less audible.

My thinking is that the same would be good for plinths, tonearms, platters,etc. If anything rings in that zone, it should be well damped so it decays quickly.

Hugh

I suppose the sensitive areas for hearing are the inverse of these curves:

Equal-loudness contour - Wikipedia

In my TT and LTA project, I'll be trying to damp those reagions as much as I can. I haven't built it yet, so I can't comment on how effective it is.

Equal-loudness contour - Wikipedia

In my TT and LTA project, I'll be trying to damp those reagions as much as I can. I haven't built it yet, so I can't comment on how effective it is.

I suppose the sensitive areas for hearing are the inverse of these curves:

Equal-loudness contour - Wikipedia

In my TT and LTA project, I'll be trying to damp those regions as much as I can. I haven't built it yet, so I can't comment on how effective it is.

I wouldn't bother, Hugh, even if you could devise a way of damping those frequencies.

A panel the size of a turntable plinth will have its fundamental resonance frequency in the 100 to 500 Hz region. The fundamental resonance has the largest amplitude, usually followed by all the rest. Higher frequencies will have much lower amplitudes, usually. So the real problem to solve is with the fundamental and lower harmonics.

Last edited:

I wouldn't bother, Hugh, even if you could devise a way of damping those frequencies.

A panel the size of a turntable plinth will have its fundamental resonance frequency in the 100 to 500 Hz region. The fundamental resonance has the largest amplitude, usually followed by all the rest. Higher frequencies will have much lower amplitudes, usually. So the real problem to solve is with the fundamental and lower harmonics.

Bryan,

I had a good look at some older tests on Plinth sized material. Looks like you're right about the lower frequencies dominating - especially if I ignore the suspect spikes above 3khz.

I also tried the Accelerometer on a speaker cone at different frequencies. It looks OK up to 2500 hz. (6db/oct slope). Then it drops like a rock above that.

I think I'll still have to concern myself with resonances above 500 hz for the Linear Arm. Some of the supports will be much smaller than a plinth.

Thanks again.

Hugh

A panel the size of a turntable plinth will have its fundamental resonance frequency in the 100 to 500 Hz region.

Does this mean there are no topologies possible in plinth sizes that have a fundamental around 3khz?

even a panel of ply 100mm thick (yes, they do exist!) has a fundamental resonance around 600 Hz, but very close to the critical frequency (so havoc would ensue!). The fourth, sixth and eighth harmonics would approach 3 kHz though, but at a much reduced amplitude, compared with the fundamental.

Note, as the fundamental resonance frequency and critical frequency are very close, it will mean that there is no (or very little) help from the mass controlled region, the very reason to add mass! Irony indeed.

Note, as the fundamental resonance frequency and critical frequency are very close, it will mean that there is no (or very little) help from the mass controlled region, the very reason to add mass! Irony indeed.

misko1989 said:I'm thinking... why mdf and acrylic if here chipboard has better DF? why not chipboard in the combo instead of mdf?

mdf 0.017

perspex (acrylic) 0.070

chipboard 0.228

logic says even acrylic glued to acrylic should be better than including mdf into plinth...

first up, damping factor is an intrinsic property, meaning it cannot be calculated, only measured, a bit like density. so that guessing at the damping factor of materials is just that, a guess. Surely, acrylic glued to acrylic is just thicker acrylic, which is not necessarily better from other perspectives (no pun intended). Damping factor will still be around 0.07.

I don't know where you are in the world, but in the UK, chipboard is an endangered species, and difficult to get hold of. It has been replaced by mdf for making loudspeakers because it is easier to work (machine) and is cheap! NOT better.

I have a Michell Focus 1 turntable that uses a (thin) plinth made of acrylic and chipboard, and although I have never measured it, sounds OK to me. Maybe they knew something all those years ago?

The damping factor of chipboard you reference is just one kind I measured, and other types may have different values. I don't know the provenance of the bit quoted.

Last edited:

first up, damping factor is an intrinsic property, meaning it cannot be calculated, only measured, a bit like density. so that guessing at the damping factor of materials is just that, a guess. Surely, acrylic glued to acrylic is just thicker acrylic, which is not necessarily better from other perspectives (no pun intended). Damping factor will still be around 0.07.

I don't know where you are in the world, but in the UK, chipboard is an endangered species, and difficult to get hold of. It has been replaced by mdf for making loudspeakers because it is easier to work (machine) and is cheap! NOT better.

I have a Michell Focus 1 turntable that uses a (thin) plinth made of acrylic and chipboard, and although I have never measured it, sounds OK to me. Maybe they knew something all those years ago?

The damping factor of chipboard you reference is just one kind I measured, and other types may have different values. I don't know the provenance of the bit quoted.

Surely chipboard flooring remains readily available in UK, or is that different to what you're thinking?

M

- Home

- Source & Line

- Analogue Source

- DIY CLD Plinth Design--A measured Approach