Thanks gpapag. That is little difficult to understand. But I presume the base tone frequency is FM Modulated and less of that modulation is preferred. the spectrum shows modulations at narrow band of low frequencies rest is perfect.Inset in Lucky's words

George

or

in other words unibody tonearms are good.

Right ?

Regards.

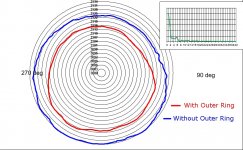

Here's a polar plot for those SME20 files - both on the same image for easy comparison. Blue is without the outer ring, red is with it. Spectrum inset is for the red channel, with the ring.Hi Luckydog,

I ripped two 3150 Hz tracks today. Would you please do plots for me?

I have a 6 lbs outer ring. One track is with the outer ring and another is without outer ring. The outer ring is heavy and I would like to see if it has any impact on the stability of the turn table.

My table is SME20, diy air bearing arm and Denon DL-103r cartridge.

Dropbox - 3150 with outer ring.wav

Dropbox - 3150 without outer ring.wav

Thank you!

Jim

That TT is running slow, and slows down further with the ring. Also rotational stability appears overall worse with the ring, one can see regions around the 1 thru 4 o'clock for example where something odd is going on, perhaps slipping?

The blue trace, without the ring, is pretty good really IMO. Some eccentricity once per revolution stuff, but the arm/cart combination looks stable - I've seen good results from the DL103 before, perhaps due to its damping?

HTH, and thanks for the interesting samples.

LD

Attachments

My table is SME20, diy air bearing arm and Denon DL-103r cartridge.

Jim, I can only admire your commitment to diy vinyl playback.

Respect

DIY Air Bearing Linear Arm

Question. The files you provided are with or without engaging the mechanical and the hydraulic dampers?

George

Hi Luckythedog,

Thank you for doing these plots for me!

I used a cheap laser photo tachometer to measure the speed. It looks like it is not accurate at all. I adjusted the speed with the outer ring again by using Feickert PlatterSpeed.

I understand that the ring makes things worse, but I have no choice because the arm/cartridge resonance. I did the arm/cartridge resonance test. My arm has Lateral resonance frequency: 3.97 Hz(left), 3.84 Hz(right) and Vertical resonance frequency: 4.37 Hz(left), 4.37 Hz(right).

These frequencies are within the 2-5 Hz warp resonance frequencies. So, an outer ring or other device is needed to reduce warp. From listening, the outer ring makes the sound better, too.

In the area of 1-4 clock, it can be caused by old belt. My belt is about 15 years old now. Maybe it is time to change the belt. I am just wondering if I can use belt conditioner for auto repair to increase the friction of turn table belt. Or it is because the heavy outer ring. The motor doesn’t have enough torque and lost its grip.

You said arm/cart combination looks stable. How do you find it out from this plot?

I didn’t use the damping device.

Jim

Thank you for doing these plots for me!

I used a cheap laser photo tachometer to measure the speed. It looks like it is not accurate at all. I adjusted the speed with the outer ring again by using Feickert PlatterSpeed.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I understand that the ring makes things worse, but I have no choice because the arm/cartridge resonance. I did the arm/cartridge resonance test. My arm has Lateral resonance frequency: 3.97 Hz(left), 3.84 Hz(right) and Vertical resonance frequency: 4.37 Hz(left), 4.37 Hz(right).

These frequencies are within the 2-5 Hz warp resonance frequencies. So, an outer ring or other device is needed to reduce warp. From listening, the outer ring makes the sound better, too.

In the area of 1-4 clock, it can be caused by old belt. My belt is about 15 years old now. Maybe it is time to change the belt. I am just wondering if I can use belt conditioner for auto repair to increase the friction of turn table belt. Or it is because the heavy outer ring. The motor doesn’t have enough torque and lost its grip.

You said arm/cart combination looks stable. How do you find it out from this plot?

I didn’t use the damping device.

Jim

Jim, I can only admire your commitment to diy vinyl playback.

Respect

DIY Air Bearing Linear Arm

Question. The files you provided are with or without engaging the mechanical and the hydraulic dampers?

George

Thank you George! I think I have too much of space time. I need to do something to kill time.

No. I didn't use the damping device.

Jim

I would also like to know Arm/cartridge stability evaluation from plots.

I am loosing connection with different thread. All are very interesting. It was mentioned in some thread about relationship of tonearm damping and speed stability. By damping tonearm what does it mean ? The tonearm itself by using various material and design or some Damping fluid like SME tonearms and Townshend Turntable ? Are we talking about vibrations in various elements of tonearm or specific resonance ?

Thanks and regards.

I am loosing connection with different thread. All are very interesting. It was mentioned in some thread about relationship of tonearm damping and speed stability. By damping tonearm what does it mean ? The tonearm itself by using various material and design or some Damping fluid like SME tonearms and Townshend Turntable ? Are we talking about vibrations in various elements of tonearm or specific resonance ?

Thanks and regards.

You're welcome, Jim, and thanks for providing files from such an interesting rig.I understand that the ring makes things worse, but I have no choice because the arm/cartridge resonance. I did the arm/cartridge resonance test. My arm has Lateral resonance frequency: 3.97 Hz(left), 3.84 Hz(right) and Vertical resonance frequency: 4.37 Hz(left), 4.37 Hz(right).

These frequencies are within the 2-5 Hz warp resonance frequencies. So, an outer ring or other device is needed to reduce warp. From listening, the outer ring makes the sound better, too.

In the area of 1-4 clock, it can be caused by old belt. My belt is about 15 years old now. Maybe it is time to change the belt. I am just wondering if I can use belt conditioner for auto repair to increase the friction of turn table belt. Or it is because the heavy outer ring. The motor doesn’t have enough torque and lost its grip.

You said arm/cart combination looks stable. How do you find it out from this plot?

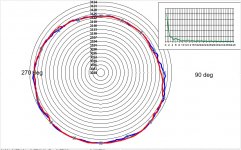

Attached is a polar plot showing two consecutive revolutions (red and blue) from your 'without outer-ring' recording. This is with the fascinating air bearing arm and DL-103r, and no arm damping.

You can see that it is really very good - the biggest contribution to pitch instability by far is once per platter variation that mimics eccentricity. This could be simply record centering, the most common cause. Even then, I've seen far worse.

That aside, overall cartridge-arm stability looks very good - it would show up as short term pitch variation, normally as a settle response involving natural resonant frequencies. But you can see from the plot, and from the inset spectrum, that amplitude of short term pitch variation is very small, near as good as it gets IME. And from the inset spectrum, there's no suggestion that the cart-arm resonant frequencies you mention show up to any extent - There's a small sort of quasi-random variation that has no real spectral focus, I would say. But no sign of cart-arm instability.

There does seem to be a platter/drive issue between 1 and 4 o'clock, even without the ring, that gets worse when the ring is fitted. Could be belt slip/stretch, could be bearing drag........if you sorted this, then apparently fitting the ring offers an improvement to stability, but from a very good base anyway.

Interesting that you prefer the sound with the ring fitted - I do believe a small amount of pitch variation can be euphonic............. I wonder if fixing the 1-4 o'clock problem might change that perception for better or worse ?

Anyways, nice rig. And I hope this might provide some pointers to fixing the rotational problem, if that's what you choose to do. Happy to run another plot or two should you wish, if you decide to fix or further investigate the cause.

LD

Attachments

Last edited:

Hi Luckythedog,

Thank you for your very informative explanation!

I am just amazed by your software and how much it can do.

I have SME table for more than 15 years now. The irregularity in 1-4 o’clock area may be a sign of aging bearing. But I am not able to do anything with bearing. SME bearing is sealed unless I completely change the bearing. The outer ring doesn’t create the irregularity of 1-4 o’clock problem, but makes it worse. It indicates it is a drive problem because the outer ring basically adds weight on platter. It makes the motor to work harder and magnifies the existing problem. One thing I can do is to change a new belt. However, I am not sure how much improvement a new belt can contribute.

From your plots, one thing makes me feel good is the arm-cartridge stability looks good. I have done many versions of head shells, counter weight, etc and have no instruments to analyze the improvements. All I did was to listen and to observe the movements of the arm, then to try to improve the arm. I am lucky to get good final result.

I recently did some frequency sweeps to see the arm-cartridge resonance frequencies. The results surprised me a bit. The lateral and vertical resonance frequencies are extremely close. I am not going to further elaborate here since it is off topic.

If you decide to develop and to commercialize your software to benefit diy enthusiasts one day, I will be the first in line.

Jim

Thank you for your very informative explanation!

I am just amazed by your software and how much it can do.

I have SME table for more than 15 years now. The irregularity in 1-4 o’clock area may be a sign of aging bearing. But I am not able to do anything with bearing. SME bearing is sealed unless I completely change the bearing. The outer ring doesn’t create the irregularity of 1-4 o’clock problem, but makes it worse. It indicates it is a drive problem because the outer ring basically adds weight on platter. It makes the motor to work harder and magnifies the existing problem. One thing I can do is to change a new belt. However, I am not sure how much improvement a new belt can contribute.

From your plots, one thing makes me feel good is the arm-cartridge stability looks good. I have done many versions of head shells, counter weight, etc and have no instruments to analyze the improvements. All I did was to listen and to observe the movements of the arm, then to try to improve the arm. I am lucky to get good final result.

I recently did some frequency sweeps to see the arm-cartridge resonance frequencies. The results surprised me a bit. The lateral and vertical resonance frequencies are extremely close. I am not going to further elaborate here since it is off topic.

If you decide to develop and to commercialize your software to benefit diy enthusiasts one day, I will be the first in line.

Jim

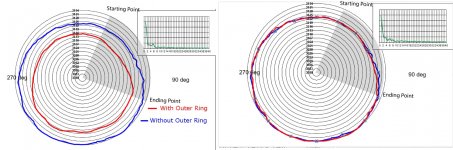

Super, I don't see from the latest plot how the ring makes things worse. Maybe that little slow down around 2:00-3:00 bothers you? Otherwise the speed looks the same as without the ring, just a bit smoother.

Hi Pano,

Please see attached image and pay attention to the shadowed areas. The frequency was suddenly shifted at starting point and back to normal at ending point. And, both plots with and without the outer ring seems to be very similar.

Jim

Attachments

Jim, is your platter/rim combo balanced and do you have a mark where you always put the combo so you know its a constant ?

Regards

David

David,

No. There is no mark. I put it on without any reference point at all. The platter and rim combo has never been balanced.

Jim

Hi LD,

I just received the new belt. Would you please do 2 plots for me? Thank you!

https://www.dropbox.com/s/3v0cnngu4mmuevv/new belt with ring.wav?dl=0

https://www.dropbox.com/s/axwcz8zyk1wluwv/new belt without ring.wav?dl=0

Jim

I just received the new belt. Would you please do 2 plots for me? Thank you!

https://www.dropbox.com/s/3v0cnngu4mmuevv/new belt with ring.wav?dl=0

https://www.dropbox.com/s/axwcz8zyk1wluwv/new belt without ring.wav?dl=0

Jim

Last edited:

Haven't tried it, but if you want to try optical methods, the free alignment template and strobe generator on my site will made strobe discs of any number of lines and of any size. If your printer has any sort of "resolution enhancement", turn it off, as it will blur and change the duty cycle of finer lines. Modern printers are extremely accurate, the expansion or shrinkage of the media being the largest contributor of errors.

the expansion or shrinkage of the media being the largest contributor of errors.

Unfortunately (I ran a print shop for a while) this is a real problem with paper so bad that 300dpi screens might not line up day to day. One should be able now to find special media for this, probably a few free samples in 8.5 X 11.

EDIT - It's funny how technology moves on, Google had no suggestions when I mistyped molleton roller, which was used to apply water to an offset plate to resist the ink which was applied next.

Last edited:

I use The Ultimate Test LP and Behringer USB audio interface to put 3150 Hz signal into PlatterSpeed for iPad. It has been working for many years and I like it very much. It worked several days ago. But it didn’t work last night, I have no idea what happened. It can be new iOS causes problem.

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Turntable speed stabilty