Ray: Ok will take another look. I like his train set. I hope to get mine out of storage should I ever get a house with a man cave.

I have the B&K paper you reference which I often go back to. They recommend 12-16Hz for the arm/cart resonance. This is non-trivial to achieve without $$$ spent (or a machine shop) and I keep looking at ebay ads for SME 3009 SIII and Moerch DP6 tonearms and thinking 'one day'. The Frankencartridge might be able to get me there by dropping compliance right down. No free lunch tho...

This optical pickup idea. We are talking about 1750 lines per revolution so we get a 3150Hz pulse train? if it was around the outside edge thats what, about 0.5mm line spacing? Should be able to laserprint than on film. At least if I can find A3 film. This is where I wish I could write postscript...

EDIT: those nice home robotics people have done it for us https://code.google.com/archive/p/wheel-encoder-generator/ .

I have the B&K paper you reference which I often go back to. They recommend 12-16Hz for the arm/cart resonance. This is non-trivial to achieve without $$$ spent (or a machine shop) and I keep looking at ebay ads for SME 3009 SIII and Moerch DP6 tonearms and thinking 'one day'. The Frankencartridge might be able to get me there by dropping compliance right down. No free lunch tho...

This optical pickup idea. We are talking about 1750 lines per revolution so we get a 3150Hz pulse train? if it was around the outside edge thats what, about 0.5mm line spacing? Should be able to laserprint than on film. At least if I can find A3 film. This is where I wish I could write postscript...

EDIT: those nice home robotics people have done it for us https://code.google.com/archive/p/wheel-encoder-generator/ .

Last edited:

This is where I wish I could write postscript...

Not that hard for simple projects. Takes a little getting used to, sort of reverse Polish C.

Laser printers tend to be much more accurate that inkjets horizontally. Constant speed rotation on the polygon mirror with some feedback for additional stability but vertically you're at the mercy of how smooth the paper goes through the thing but I imagine it still beats an inkjet due to motion being relatively constant rather than slow start-stop.

My turntables all have their strobe pattern wave back and forth, and looking like it happens once per rotation. I'm not sure if it is caused by eccentricity of the platter or something else...

Once I get some lubrication for the bearings and finetune the drive electronics I'll be able to provide some test records of 3150Hz test track on one soviet era test disc. One player is an interesting direct drive that cloned the setup from Fisher MT-6225 and another is a belt drive with low voltage three phase motor that runs at same rpm as the heavy platter (1:1 ratio). It'll be interesting to see how those perform, both were classified as the really high end stuff at the time they were made.

My turntables all have their strobe pattern wave back and forth, and looking like it happens once per rotation. I'm not sure if it is caused by eccentricity of the platter or something else...

Once I get some lubrication for the bearings and finetune the drive electronics I'll be able to provide some test records of 3150Hz test track on one soviet era test disc. One player is an interesting direct drive that cloned the setup from Fisher MT-6225 and another is a belt drive with low voltage three phase motor that runs at same rpm as the heavy platter (1:1 ratio). It'll be interesting to see how those perform, both were classified as the really high end stuff at the time they were made.

Last edited:

Thank you, diyrayk, that's very interesting and spot on, IMO. Here's my thoughts:The effects of speed stability cause a pitch fluctuation or Frequency Modulation (FM) of the audio signal in the groove. A bent motor shaft on an idler or belt drive turntable will have a similar effect on the sound as an eccentric capstan on a tape recorder or a bad drive component in a movie film projector. These are all mechanical reproducers and have rotating parts which can cause cyclic and/or transient speed variations. The topic has been extensively researched and documented in technical papers and journals. The British Broadcasting Company published an excellent research paper “The Subjective Discrimination of Pitch and Amplitude Fluctuations in Recording Systems” in 1955 in Britain, and reprinted in the US by the AES in 1957. The BBC research built on other research references dating back to at least 1941. The BBC researchers found that the sensitivity threshold for FM among groups of listeners was broadly centered in the range of about 4Hz to 10Hz. Many arm/cartridge combinations have a mass/compliance resonance frequency within the 4Hz to 10Hz range. Bruel & Kjaer published a paper “Audible Effects of Mechanical Resonances in Turntables” in 1970. B&K mounted three different tonearms on the same turntable. Using the same turntable/motor and same cartridge moved in turn to each of the three arms, the weighted % wow and flutter B&K measured varied by a factor of 3 to 1, depending on the tonearm being used in the test setup. If you were the manufacturer of that turntable, which wow and flutter number would you use for the spec’s in your sales brochure?

As an exercise, I modeled my SME 3009 in a CAD program and ‘flexed’ the arm sideways to empirically measure what the stylus point does in the groove under dynamic conditions:

....(..)....

For a sideways displacement of about the thickness of a credit card, give or take, about 40% of the sideways displacement of the stylus goes into scrubbing motion along the groove, causing FM distortion. At mass/compliance resonance frequencies the scrubbing-induced FM shows up as measurable, and often audible, flutter. The amount and character of the scrubbing depends on the magnitude of the displacement, arm geometry, and stylus shaft length.

The usual measure of turntable speed stability, i.e. wow and flutter, includes the mechanical stability effects of the tonearm/cartridge, and is a speed stability measure of the record player, not just the turntable by itself. The two contributions need to be analyzed separately. A single numerical value for the wow and flutter that’s going into the preamp is meaningless. Dynamic stylus drag variation could cause a transient pitch variation (FM) in the turntable drive or does the dynamic stylus drag variation cause a sideways displacement of the cantilever which translates into transient pitch variation (FM) from the resultant scrubbing? Each of these sources requires a different remedy.

Thoughts?

In an otherwise normal healthy and well adjusted rig, the most significant (and audible) contribution to pitch instability is often due to unwanted headshell displacement motion and associated induced FM, IME.

Headshell displacement of only 100um@10Hz, contributes about +/- 0.35% of pitch variation - very audible and about 3 tramlines on the polar plot.

Time domain response to an unwanted headshell displacement from any cause depends on the cart-arm spring/mass/damping system. Then so does pitch variation in the time domain. I think that's the key way to look at this.

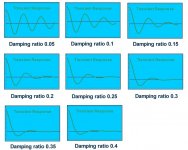

Attached is a set of plots showing time domain transient response of pitch variation to a small displacement in headshell position, for various damping ratios. Typical damping ratios in untreated rigs might be between 0.05 and 0.15.

Increasing cart-arm resonant f makes whatever damping there is available go further toward increasing the ratio. Low compliance cartridges also tend to provide more damping, the suspension being the same elastomer providing spring and damping.

There's no mechanical reason to choose exactly 10Hz as a target cart-arm resonant f: it seems some sort of common-lore of vinyl playback. Perhaps it has origin in being audibly better than lower frequencies in terms of pitch stability perception, or some vibrato might even be euphonic......? Or, more likely, maybe it's simply justified by plausible explanation of avoiding stimulus?

However, IMO the common focus on selecting cart-arm combinations based on resonant f alone is a distraction from the real issue of damping ratio - which almost always goes unaddressed and is where most of the performance opportunity lies.

Cart-arm selection is far more significant to pitch stability than motor speed variation in a the vast majority of normal healthy rigs out there, IME. Hence the B&K observation ! In many rigs, design of the cart-arm resonant system provides the best opportunity for improvement to pitch stability.

Counter-intuitive, but true !

LD

Attachments

Last edited:

The more times the same pattern appears, the stronger it’s freq component is.

1.8sec frame length is one revolution of the platter.

This way I can locate all the modulating components, i.e. the Cartesian Freq-level inset from Lucky’s analysis.

George

It's very interesting. I have another approach about modulating.HP53310A is modulation domain analyzer which can direcrly display FM.Vertical scale is frequency,horizontal is time.if scope,vertical is amplitude.

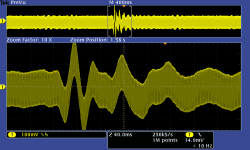

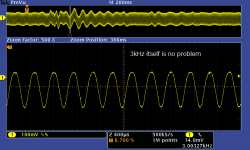

3kHz sinewave varies from 3.01k to 2.993k. Pk -Pk is 16.56Hz,almost 0.5%.Std-dev is 2.55Hz, almost 0.1%.I think this is ordinaly.But in practical use,there is some viblation around turntable,loudspeakers and so on.When I walk around the floor near turntable,frequency considerably jump like later 3 photo.

This is not the fault of turntable.Insulator usually has less isolation than one expect.I think digital solution is the best for this.It's better to digitalize record in calm circumstance,no loudspeaker,no walking around.But this is unpopular.

Attachments

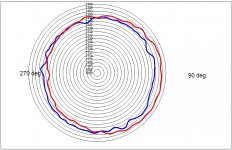

Here's a polar plot pitch stability contest between two well regarded healthy TTs: SL-1200 in red, and SP-10 in blue, displayed on the same chart.

One can see both are very good in the scheme of things, the SL-1200 especially so. In both cases, pitch stability appears to be dominated by record centering, and by cart-arm stability.

I don't have notes of arm/carts used, but I think one can see the principles at issue: it's probably mostly a matter of centering, and settle time following a headshell displacement event.

LD

One can see both are very good in the scheme of things, the SL-1200 especially so. In both cases, pitch stability appears to be dominated by record centering, and by cart-arm stability.

I don't have notes of arm/carts used, but I think one can see the principles at issue: it's probably mostly a matter of centering, and settle time following a headshell displacement event.

LD

Attachments

Last edited:

Thanks Ray.The advantage to your optical dots method is that it measures the pitch stability of the turntable, and is free from the mechanical stability effects of the tonearm/cartridge. By comparing the results of an optical method signal with the results from the arm/cartridge signal one could segregate the contribution of the turntable speed stability effects from the arm/cartridge resonance and mechanical stability effects. Put the printed dots pattern on the Feickert disc while running the test and both method signals could be measured simultaneously, as an added measure of controlling all the test variables. Now, if the Feickert discs were pressed with the dots printed right on the disc label, or stamped or laser etched on the outer perimeter lead-in area, hmmm…

Ray K

I guess heavy platter with some constant load heavier than other tonearm+cartridge criteria which affects speed stability (like spool tapes having felt disc ) can somewhat stabilize the speed. Isn't it ?

An example...

Regards

However, IMO the common focus on selecting cart-arm combinations based on resonant f alone is a distraction from the real issue of damping ratio - which almost always goes unaddressed and is where most of the performance opportunity lies.

Cart-arm selection is far more significant to pitch stability than motor speed variation in a the vast majority of normal healthy rigs out there, IME. Hence the B&K observation ! In many rigs, design of the cart-arm resonant system provides the best opportunity for improvement to pitch stability.

Counter-intuitive, but true !

LD

Not only damping ratio, but also arm geometry. To compare the correlation of offset angle with scrubbing I modeled my own servo driven linear arm in a CAD program and ‘flexed’ the arm sideways to empirically measure what the stylus point does in the groove under dynamic conditions. Under dynamic conditions near mass/compliance resonance frequency, this linear arm also moves in an arc like the SME-3009 in my post #36, except that now the offset angle is zero:

For the same “credit card thickness” sideways displacement of the stylus, only about 13% of the sideways displacement of the stylus goes into scrubbing motion along the groove. This is about 1/3 that of my SME 3009.

In a comment within the caption under Figure 20 on page 7 of the B&K paper, they note that parallel tracking arms yielded better spec’s for the turntable. It should be apparent that a 12 inch pivoted arm would, with the same “credit card thickness” sideways displacement, exhibit less scrubbing and FM than a 9 inch pivoted arm. IMO, what aficionados of linear arms and the longer 12 inch pivoted arms are hearing over 9 inch pivoted arms is the reduction of FM distortion (aka relative speed instability), rather than the effects of reduced tracking error distortion. At the risk of drifting off topic, there are non-turntable/drive related issues which can affect measured wow and flutter values that are typically attributed to the turntable alone.

Ray K

Last edited:

Luckydog - when we look at your polar plots, we see a long period speed variation that is probably caused by off-center. We see that variation in a once around of the plot. But we also a shorter term instability, or FM of the tone (the wiggles). This varies from on TT to the next, and seems to fit in a range of ~28-41Hz.

What is the cause of this wiggle, in your opinion?

What is the cause of this wiggle, in your opinion?

I was made aware of the arm/cartridge contribution to pitch stability just last night while listening to some records. One had some nice piano notes and a bad scratch  . When the stylus hit the scratch there was noticeable flutter in the piano notes for about a second. Clearly the impulse excited cart/arm resonance.

. When the stylus hit the scratch there was noticeable flutter in the piano notes for about a second. Clearly the impulse excited cart/arm resonance.

Thanks, diyrayk, esp for the geometry images. It's bang on topic IMO, and typically the elephant in the room concerning pitch stability, rather than rotational stability of the platter. I agree - difference in pitch stability arising from reduced cart-arm FM is far more likely to be at the root of any audible changes, for reasons you describe.]In a comment within the caption under Figure 20 on page 7 of the B&K paper, they note that parallel tracking arms yielded better spec’s for the turntable. It should be apparent that a 12 inch pivoted arm would, with the same “credit card thickness” sideways displacement, exhibit less scrubbing and FM than a 9 inch pivoted arm. IMO, what aficionados of linear arms and the longer 12 inch pivoted arms are hearing over 9 inch pivoted arms is the reduction of FM distortion (aka relative speed instability), rather than the effects of reduced tracking error distortion. At the risk of drifting off topic, there are non-turntable/drive related issues which can affect measured wow and flutter values that are typically attributed to the turntable alone.

Yes. A click or scratch can clearly highlight the issue by causing sudden headshell displacement, and solo piano shows the effect nicely: there's no natural vibrato on a piano !I was made aware of the arm/cartridge contribution to pitch stability just last night while listening to some records. One had some nice piano notes and a bad scratch. When the stylus hit the scratch there was noticeable flutter in the piano notes for about a second. Clearly the impulse excited cart/arm resonance.

Moment to moment variation in stylus-groove friction is a continuous stimulus for unwanted headshell motion, and probably the largest overall contributor, IMO, in offset angle arms. As stylus drag varies, so does torque about the arm pivot, and Newton kindly has explained the rest. It can also happen in any arm where the pivot is not in the same vertical plane as the stylus-groove contact, including linear arms, of course.

On polar plots, this effect often seems synchronised with platter rotation, occuring at about the same location on successive revolutions IME. Perhaps because vinyl composition varies in the same way locally around a record ?

I recall a well respected builder of precison servo controlled ac motor controls submitted a few files for analysis, a few years back. At the time, this was blind for me because I didn't know which files were which, in an A/B test. The servo sensed platter rotation and controlled it very accurately, as reported. However, all polar plots still revealed dominant eccentricty and cart-arm FM to the point where it wasn't possible to tell which were fitted with the controller, IMO. Such is the nature of the elephant(s) in the room: record centring and cart-arm headshell motion induced FM.

LD

Last edited:

there's no natural vibrato on a piano !

There is.

Through added sympathetic resonances from the non struck strings.

This is achieved by raising the dampers, special techniques of pedaling. Mostly the sustain (right) but also the soft (left) pedal.

George

Hi Pano, thanks for arranging the side by side offset/linear geometry images.Luckydog - when we look at your polar plots, we see a long period speed variation that is probably caused by off-center. We see that variation in a once around of the plot. But we also a shorter term instability, or FM of the tone (the wiggles). This varies from on TT to the next, and seems to fit in a range of ~28-41Hz.

What is the cause of this wiggle, in your opinion?

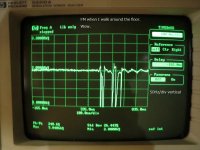

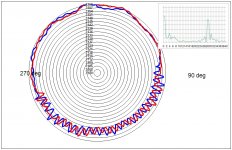

Having said that record centring, levelling, and cart-arm displacement FM typically dominates, many TT drives also have their own FM 'signature' depending on the nature of the drive. Particularly if they need repair or a bit of tlc.

AC synchronous motor cogging can turn up in the frequency range you mention, depending on the number of pole pairs and whether 50 or 60Hz mains. As can idler intermediate mechanics.

For interest, attached is a bad example of a Lenco idler TT with a clear fault that shows up for part of the revolution, at or about that frequency range. But one can see that even for the 'good' part of the revolution, a similar frequency pattern is there albeit at a lower level.

LD

Attachments

Yes. That's part of a natural piano like sound - whereas entire instrument pitch shift or pitch wobble isn't natural, that's what I mean.There is.

Through added sympathetic resonances from the non struck strings.

This is achieved by raising the dampers, special techniques of pedaling. Mostly the sustain (right) but also the soft (left) pedal.

George

Interestingly perhaps, a quality sampled piano instrument, such as a Nord, sounds lovely - more natural even - through a Leslie speaker rotating slowly, with a little bit of doppler shift induced FM at a few Hz. So perhaps a little bit of FM is euphonic - that is a part of vinyl sound for sure ?

BTW, I'm nearly done analysing your Stanton 150 play files on the mechanical resonance thread: will post results soon

LD

Last edited:

Is it worth me attaching the B&K paper here? It's freely available on the web, but not sure if we still need to be careful over copyright. Pano/George?

It is interesting that it all comes back to damping and centering, both things that were thrown away in the flat earth movement of the 80s. These have always been the elephants in the room but attempts to deal with them were generally ignored/rubbished as from Japan.

Ray: If you were going your linear tracker again, would you do it differently?

It is interesting that it all comes back to damping and centering, both things that were thrown away in the flat earth movement of the 80s. These have always been the elephants in the room but attempts to deal with them were generally ignored/rubbished as from Japan.

Ray: If you were going your linear tracker again, would you do it differently?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Turntable speed stabilty