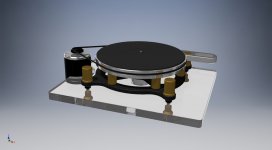

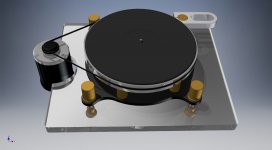

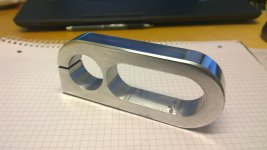

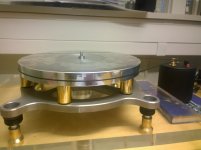

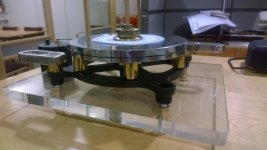

Hello I am new on this forum. I have this DIY Turntable I build 30 years ago. Then I moved a view times and it vanished in a box. Now I want to rebuild it up again and make some changes. Not so much in the design more technical like magnetic bearing and change the motor. I used an Thorens synchronous motor which was far too weak. Last weekend I put the parts out of the box measured them and mad some CAD models. Her is what I came up with and I hope my old turntable will look similar to this when I am ready with the project. I can take some pics of the status quo if interested. Hope I get some feedback and advice from you.

Attachments

Looks gorgeous! Looking forward to seeing the completed new one. Good luck!Hello I am new on this forum. I have this DIY Turntable I build 30 years ago. Then I moved a view times and it vanished in a box. Now I want to rebuild it up again and make some changes. Not so much in the design more technical like magnetic bearing and change the motor. I used an Thorens synchronous motor which was far too weak. Last weekend I put the parts out of the box measured them and mad some CAD models. Her is what I came up with and I hope my old turntable will look similar to this when I am ready with the project. I can take some pics of the status quo if interested. Hope I get some feedback and advice from you.

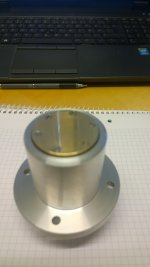

Hei, thank you all for replying. My plater is about 5 kg in comparison to 1.5 kg the platter of an Thorens. It needed always a helping hand for getting the rotation started. I am going for an BLDC solution. I thought about buying the motor from Jasmin Audio, because i take me to long research to come to solution. But i build my own housing around it. Hilsen Joschi

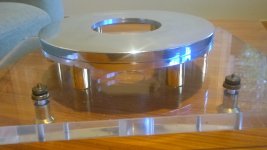

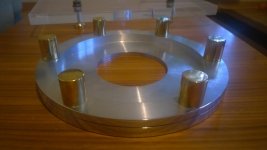

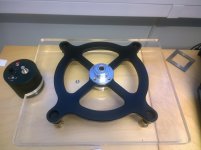

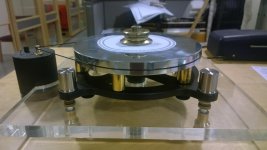

New Pics

I am getting closer. Have some problems with testing lubrication for the bearing. Found very different opinons in forums, was not very helpfull Will do some more tests the next days. Magnetic vertical bearing works fine.

Will do some more tests the next days. Magnetic vertical bearing works fine.

Still a lot to do!

Jochen

I am getting closer. Have some problems with testing lubrication for the bearing. Found very different opinons in forums, was not very helpfull

Still a lot to do!

Jochen

Attachments

Last edited:

Reply

Since I am the nearly the only one who replied on my thread it make no sense for me to go on with it. In the beginning I thought it might be an interesting project not just for me, since this is a diy forum. It's not that I am dissapointed, because I had wrong expectation. It is just boring to answer your own thread.

Since I am the nearly the only one who replied on my thread it make no sense for me to go on with it. In the beginning I thought it might be an interesting project not just for me, since this is a diy forum. It's not that I am dissapointed, because I had wrong expectation. It is just boring to answer your own thread.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Refurbishing my old Diy Turntable