Is there anyway to add a very small fan blade at the bottom of the motor? And drill some slots or holes in the case for air flow?

One way is to glue a small shaft at the bottom of the motor to use as a bearing and

Install the small fan blade onto that and run it using the magnetic field of the motor to spin the fan blade ? Crazy? Yes/no

Just thinking outside the box

One way is to glue a small shaft at the bottom of the motor to use as a bearing and

Install the small fan blade onto that and run it using the magnetic field of the motor to spin the fan blade ? Crazy? Yes/no

Just thinking outside the box

Well, it's up and running and works fine. Thanks, Phoenix.

After playing two albums the motor isn't warm at all (I can touch the mounting flange through the hole in the top cover). I don't think heat is going to be a problem. A fan is definitely not needed and if heat did become an issue passive heat sinking ought to be more than adequate.

One thing I notice is the amplifier is causing some hum in the speakers. Unplugging the motor cable and turning off the SG4 doesn't make a difference. I assume putting everything in a shielded enclosure will help.

After playing two albums the motor isn't warm at all (I can touch the mounting flange through the hole in the top cover). I don't think heat is going to be a problem. A fan is definitely not needed and if heat did become an issue passive heat sinking ought to be more than adequate.

One thing I notice is the amplifier is causing some hum in the speakers. Unplugging the motor cable and turning off the SG4 doesn't make a difference. I assume putting everything in a shielded enclosure will help.

Attachments

The starting voltage for the motor was determined for rated power (12W); if run at that level for extended periods, the motor case temp will exceed 140°F. The SG4 has the capability to reduce the voltage after initial start up and the recommended levels will reduce the power to ~9W IIRC. With a metal housing the temp should stabilize ~110-115°F; not sure what they will be with a non-metallic case. The motor will certainly run at higher temps (AA recommends to keep the case temp below 175°F), but it becomes a balancing act of temp vs torque (power). Anything you can do to get the heat off the motor will make the balancing act easier.

Forgive me if I misunderstand but I was under the impression that motor power dissipation is a function of mechanical load as well as supply voltage. Once the platter is spun up the power to maintain rotation is minimal and so the winding current should drop significantly due to back EMF opposing the supply voltage.

Anyway, as I said so far the motor is running quite cool. I'll keep an eye on it.

Forgive me if I misunderstand but I was under the impression that motor power dissipation is a function of mechanical load as well as supply voltage. Once the platter is spun up the power to maintain rotation is minimal and so the winding current should drop significantly due to back EMF opposing the supply voltage.

Anyway, as I said so far the motor is running quite cool. I'll keep an eye on it.

The amount of torque the motor delivers is a function of the load and will affect the angle between the rotating field and the magnetic rotor; at no load, the field and rotor are aligned, and maximum torque is produced when the rotor is 90° behind the field. The available torque will remain nearly constant. The electrical power consumption of the motor changes very little with load, until the motor stalls. The power consumption is a function of the winding resistance and the back EMF; the faster the motor spins, the higher the back EMF, the higher the apparent impedance and the higher the drive voltage needed to maintain constant power. If the motor stalls at high RPM, the back EMF disappears and the current draw (now equal to supply voltage/winding resistance) could be enough to reset the wall wart.

I noticed that you have 2 power supplies: one for the MA-3D and one for the SG4. You can power the SG4 using the 2 unused outputs on the MA-3D (marked 12V and Gnd) so you only need one wall wart.

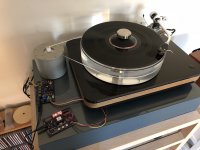

Beautiful table BTW.

I measured the current in one of the motor leads. It's about 90mA with no load and increases to about 180mA when driving the platter. So three times 3.2V times 180mA is about 1.7W. Of course, some of that power is coming out as mechanical work and the motor isn't a purely resistive load so the actual dissipation will be lower, maybe a watt? It seems like it should be ok.

Thanks for the compliment on the turntable. If you're not familiar, the parts came from the original Teres group buy, maybe fifteen years ago. The plinth is Corian and baltic birch with lead shot inside.

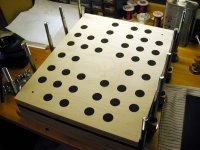

I need to put the motor drive in a box and get some proper drive belts. I also have one of the SDP/SI flat belt pulleys so want to give that a try. The dental floss works but the grip on the pulley isn't great.

Oh, about the wall warts. I forgot to buy another barrel connector when I was at the electronics store yesterday. I didn't want to sacrifice the cord on the small power supply so for now I am using both wall warts.

Thanks for the compliment on the turntable. If you're not familiar, the parts came from the original Teres group buy, maybe fifteen years ago. The plinth is Corian and baltic birch with lead shot inside.

I need to put the motor drive in a box and get some proper drive belts. I also have one of the SDP/SI flat belt pulleys so want to give that a try. The dental floss works but the grip on the pulley isn't great.

Oh, about the wall warts. I forgot to buy another barrel connector when I was at the electronics store yesterday. I didn't want to sacrifice the cord on the small power supply so for now I am using both wall warts.

Attachments

Last edited:

The DS1833-10+ is now obsolete @ Mouser. Can you recommend a suitable replacement part?

See discussion here:

https://www.diyaudio.com/forums/ana...tor-turntable-motor-drive-62.html#post5439643

The DS1833-10+ is now obsolete @ Mouser. Can you recommend a suitable replacement part?

DS1833-15+ Maxim Integrated | Mouser

Hello Pyramid. My SG4 controller was built up months ago and performance wise, its immaculate. There's been only one fault I cannot solve and been bothering me. I play records regularly and operate it all as usual. Once a while when I power it up at the AC mains push button on the front panel, it will trigger to 68hz (45rpm mode) for no reason. Most of the time it should start in STBY. This happen once a while or at random. My config is simple, SG4 to Class D module, only mains power switch and wired momentary push button switch and latching switch for 33/45 change. I've not installed any rotary encoder. What could cause it to trigger at random, I've checked the SG4 board through and through and cannot find anything faulty. Its very perplexing to me

Last edited:

coolmaster- The SG4 powers up not in standby, but in 45 RPM running mode? Is the 33/45 switch in 45 position when this happens?

The only thing I can think of that could cause this, is static discharge (carpet shock) when you touch the power switch. Are you using a reset controller (DS1833, MCP101, etc.) or a capacitor on the reset line? A reset controller should prevent any abnormal start up, even if the DC supply is slow rising or noisy.

If you extended the 3 push buttons on the front panel with longer wires, you may want to try clamping the inputs on the PCB with reverse connected diodes (1N914 or equiv) to ground and VCC.

The only thing I can think of that could cause this, is static discharge (carpet shock) when you touch the power switch. Are you using a reset controller (DS1833, MCP101, etc.) or a capacitor on the reset line? A reset controller should prevent any abnormal start up, even if the DC supply is slow rising or noisy.

If you extended the 3 push buttons on the front panel with longer wires, you may want to try clamping the inputs on the PCB with reverse connected diodes (1N914 or equiv) to ground and VCC.

Hi Pyramid. The 33/45 switch is in the 33 position most of the time as I rarely spin at 45. All parts onboard are exactly as specified without any alternatives used. The reset is a DS1833 device. Only standby button and 33/45 switch have been extended out remotely of the controller to beside the turntable. Its been carefully cabled out. I will try the diode clamp idea. Thanks a lot. Lee

That's very strange. Even if there was a power glitch on the speed select line and it booted up in 45 RPM mode, it should self clear once it sees the switch is still in 33 position. The firmware constantly checks to see if what it thinks is the current speed matches the input from the speed switch. If they are out of synch, it debounces the input, then changes speed to match the hardware.

The symptoms are indicative of a false reading at the inputs (+/-/Stby/Speed) caused by static and/or a faulty reset mechanism.

One further question: When it powers up in the erroneous state, do the controls function as normal, or is it "locked up" and non-functional?

The symptoms are indicative of a false reading at the inputs (+/-/Stby/Speed) caused by static and/or a faulty reset mechanism.

One further question: When it powers up in the erroneous state, do the controls function as normal, or is it "locked up" and non-functional?

There's 2 symptoms at random when it happen, it can either lockup, needing a shutdown and switch on again or I press the start/stop switch to get it working normally.

Its all very strange and got me thinking more about tackling this issue. I intend to do a elimination process

1) Remove the remote switches entirely, operate the onboard tact switch to activate it, since its only at 33rpm mode mostly. I may replace the push button switch, I suspect its internal contact could be too close to Normally on position and trigger the SG4 (wild guess).

2) Replace the LM2596 buck converter (which power the SG4) to another good known LM317 module I have as spare. (this module have been consistent and working properly since Day1, doubt if it could be possible cause, but will do it anyway.

3) Lastly and reluctantly, suspect the DS1833-10 reset device and replace it to a new one.

Any of the above could be a cause hoping it is one of it, but may take time for this fault to resurface. Intermittent issues is always difficult to tackle.

Its all very strange and got me thinking more about tackling this issue. I intend to do a elimination process

1) Remove the remote switches entirely, operate the onboard tact switch to activate it, since its only at 33rpm mode mostly. I may replace the push button switch, I suspect its internal contact could be too close to Normally on position and trigger the SG4 (wild guess).

2) Replace the LM2596 buck converter (which power the SG4) to another good known LM317 module I have as spare. (this module have been consistent and working properly since Day1, doubt if it could be possible cause, but will do it anyway.

3) Lastly and reluctantly, suspect the DS1833-10 reset device and replace it to a new one.

Any of the above could be a cause hoping it is one of it, but may take time for this fault to resurface. Intermittent issues is always difficult to tackle.

Merry Christmas everyone!

Hi Bill, Just an update. Since my last call here, the problem persisted at will, nevermind. I spent some free time this evening, dug out my last spare MCP101 (was previously used but unsuited to the strobe project), replaced the DS1833 reset IC. I'm hoping that was the culprit. Circuitry function nicely when firing it up. I will monitor for any repetition of the issue and report back in good time. Wishing everyone Happy New Year 2019 too!

Lee

Hi Bill, Just an update. Since my last call here, the problem persisted at will, nevermind. I spent some free time this evening, dug out my last spare MCP101 (was previously used but unsuited to the strobe project), replaced the DS1833 reset IC. I'm hoping that was the culprit. Circuitry function nicely when firing it up. I will monitor for any repetition of the issue and report back in good time. Wishing everyone Happy New Year 2019 too!

Lee

- Home

- Source & Line

- Analogue Source

- DIY 4 Phase Sinewave Generator for Turntable Motor Drive