Rimanto

do you have one PCB and chip forSG4 , for sell? Rimantas

Ralphf,Thanks Seth, I will redirect any future requests for SG4 chips from US users in your direction.

do you have one PCB and chip forSG4 , for sell? Rimantas

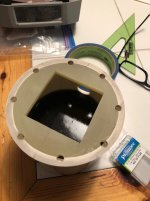

Working on the motor pod. There's a five pound disk of lead in the bottom.

Attachments

The tube is 4" PVC pipe. The sheet material is 1/8" fiberglass PC board with the copper stripped off, single layer in the bottom and two layers for top you see here. The inserts are brass hex spacers that I spun on my drill press and filed round. The black goop is electronics potting epoxy.

I have very limited shop tools so it's always an exercise in creativity to figure out how to make stuff without having to pay a machinist.

I have very limited shop tools so it's always an exercise in creativity to figure out how to make stuff without having to pay a machinist.

Very nice job!

Since the motor pod is non-metallic, you may need to watch the drive level and the temp of the motor since the pod will not act as much of a heat sink. You could also fill the void in the pod with lead or steel shot to help dissipate heat (make sure to seal the bottom of the motor with tape to prevent the shot from entering the motor housing).

Since the motor pod is non-metallic, you may need to watch the drive level and the temp of the motor since the pod will not act as much of a heat sink. You could also fill the void in the pod with lead or steel shot to help dissipate heat (make sure to seal the bottom of the motor with tape to prevent the shot from entering the motor housing).

Good point; I didn't think of that. Hopefully under steady-state conditions the power dissipation will be much lower than the rated value and heat won't be an issue.

Hmmm. The bottom of the pod is an inch of solid lead so it might absorb some heat but again it's inside the plastic housing and isn't in contact with the motor housing so it's unclear how much that would help. If it's a problem I can make an aluminum top cover.

It was always my grand plan to have a house with a machine shop in the basement. Instead I have no basement, no machine shop, and I make things on the kitchen table, LOL.

Edit: Looks like an option is Front Panel Express which will do a cover for about $45.

Hmmm. The bottom of the pod is an inch of solid lead so it might absorb some heat but again it's inside the plastic housing and isn't in contact with the motor housing so it's unclear how much that would help. If it's a problem I can make an aluminum top cover.

It was always my grand plan to have a house with a machine shop in the basement. Instead I have no basement, no machine shop, and I make things on the kitchen table, LOL.

Edit: Looks like an option is Front Panel Express which will do a cover for about $45.

Last edited:

The starting voltage for the motor was determined for rated power (12W); if run at that level for extended periods, the motor case temp will exceed 140°F. The SG4 has the capability to reduce the voltage after initial start up and the recommended levels will reduce the power to ~9W IIRC. With a metal housing the temp should stabilize ~110-115°F; not sure what they will be with a non-metallic case. The motor will certainly run at higher temps (AA recommends to keep the case temp below 175°F), but it becomes a balancing act of temp vs torque (power). Anything you can do to get the heat off the motor will make the balancing act easier.

- Home

- Source & Line

- Analogue Source

- DIY 4 Phase Sinewave Generator for Turntable Motor Drive