Quote: Undithered noisefloor.

Without dither, there is no noise-floor.

Of course i hear crackle and pop, but that is due to environment, say dirt, not the disc itself. When i had a big stereo, i noticed, that rumble is strong and takes a lot of effort to reduce properly {without filtering it all away}. But noise of hier frequency seems mostly an environmental issue to me.

Without dither, there is no noise-floor.

Of course i hear crackle and pop, but that is due to environment, say dirt, not the disc itself. When i had a big stereo, i noticed, that rumble is strong and takes a lot of effort to reduce properly {without filtering it all away}. But noise of hier frequency seems mostly an environmental issue to me.

You want to see vinyl background noise, listen to the few seconds before the music starts. Is there anyone here that doesn't hear this noise even at low volume?

Irreducible noise is mostly the 'roar' of 1/f noise, plus surface crackle pop. Both of which have their origin in stylus groove friction, and can be minimised by any means which miminises stylus groove friction. More strictly, reduces friction force as a fraction of VTF.

It puzzled me for ages why outer radii, ie low numbered tracks on a side, often have higher background noise, especially crackle pop and roar. Partly it can be wear, partly warm up time of cutting lathe perhaps. But it's mostly explained by the fact that faster vinyl-groove velocity has higher friction force as a fraction of VTF, so produces more noise.

LD

Member

Joined 2009

Paid Member

Wet playback, for example, works by lubrication and is highly effective

I never knew this - fascinating !

So why isn't this method used more often, couldn't we add a simple water 'mist' arm over the LP ahead of the stylus during play - just enough to reduce friction but not so much that it doesn't readily evaporate behind the stylus by the time we want to put the record away ?????

Looking at other discussions of the subject, I'd guess the problem would be something like, if you use plain water you'll eventually get a residue buildup on the vinyl like that on washed and air-dried glass.(waterspotting) If you add alcohol you'll eventually degrade/destroy the bonding of the stylus to cantilever. If you use plain distilled water, you'll eventually have fungus on the vinyl from putting it back in the sleeve slightly damp.

There is a problem with wet play. It's a one way street. For reasons no one has yet worked out, once you wet play a record you always have to wet play it.

Yes - it's because the act of using water as a lubricant permanently alters the friction surface for dry playback. Measured friction coefficient increases significantly for dry playback after playing wet, versus original condition. Whereas during wet playback the friction coefficient is very low indeed.

Why, I don't know. But I've measured and confirmed this. Ideally, one needs a lubricant that does not do this, or even better is permanent: the grail.

Interestingly, wet playback either significantly improves or does not degrade every aspect of measured playback performance. Frequency response, slew rate, thd, noise floor, you name it. Very counter-intuitive, but the audio results are self-evident too. After much thought, all that matters is that the stylus more accurately follows the locus of the groove base, and that must be happening, and at lower friction.

LD

If there are perfect clean records without scratches in use, there is still a very heavy hiss and noise audible between the tracks.

I guess that "heavy hiss" could be a subjective assessment, but I would suggest that you do have heavy hiss between tracks then there is something seriously wrong with your system. A good vinyl replay system does NOT have heavy hiss between tracks.

Some other posters have stated that noise floor of vinyl is higher than CD. I can't argue with that. But, a clean record on a good system will still demonstrate low noise between tracks.

Forget wet playing records etc. If you hear heavy hiss there is something fundamentally wrong.

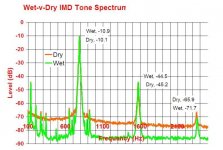

Here's a couple of measurements that show some of the advantages of reducing stylus-groove friction. In this case wet-versus dry, noise floor measured on a test record with IMD tones.

You can see significant improvement in the general noise floor, 10-15dB, even on a clean good condition test record.

LD

You can see significant improvement in the general noise floor, 10-15dB, even on a clean good condition test record.

LD

Attachments

Here's a couple of measurements that show some of the advantages of reducing stylus-groove friction. In this case wet-versus dry, noise floor measured on a test record with IMD tones.

You can see significant improvement in the general noise floor, 10-15dB, even on a clean good condition test record.

LD

Thanks, that's a great graphic. I experimented with wet-play 20 years ago or more, and to be honest didn't hear enough difference to continue. And now I can see why - I acknowledge that, based on this graph, that wet play can reduce noise by 10dB. But when the baseline noise is -70dB down, then you need a really quiet room to actually hear this reduction. Really, really, quiet.

And to my original point - this graphic demonstrates that a good system will have low noise between tracks. -70dB is pretty quiet in any scenario. There should NOT be heavy hiss between tracks as described by OP. Wet play is not the solution, for what is clearly a different problem.

Thanks, that's a great graphic. I experimented with wet-play 20 years ago or more, and to be honest didn't hear enough difference to continue. And now I can see why - I acknowledge that, based on this graph, that wet play can reduce noise by 10dB. But when the baseline noise is -70dB down, then you need a really quiet room to actually hear this reduction. Really, really, quiet.

And to my original point - this graphic demonstrates that a good system will have low noise between tracks. -70dB is pretty quiet in any scenario. There should NOT be heavy hiss between tracks as described by OP. Wet play is not the solution, for what is clearly a different problem.

Yes. I'm not advocating wet playback, but it demonstrates the significant improvement to noise floor of reducing stylus groove friction via any means.

Those measurements were made using a test record in good clean condition. So yes, noise floor was already very good, yet nevertheless was improved significantly. 10dB or more improvement in noise floor is well worth having, it's available, and can make a great difference to perception of detail and clarity of playback even for records where noise is not an issue.

For records which do show high levels of surface noise due to high groove friction, ie crackle pop noise despite being in good clean condition, the improvement can be profound - perhaps 20-30dB or more - and that is a game changer in recovering otherwise written off records.

In a real system, without using lubricants, reducing stylus-groove friction is mostly about choice of stylus/cartridge and choice of alignment. Strictly, what matters is friction force as a fraction of VTF, so VTF doesn't really factor, nor does cartridge suspension much. Whereas azimuth, SRA/VTA and tangential alignment can make a big difference, depending on stylus profile. Stylus quality, accuracy of manufacture, and polish can be a factor too.

I agree about the OP report of hiss being abnormal, but assumed it meant crackle-pop-roar surface noise, which is common, and the subject of my comments about friction.

LD

Last edited:

Here's a couple of measurements that show some of the advantages of reducing stylus-groove friction. In this case wet-versus dry, noise floor measured on a test record with IMD tones.

You can see significant improvement in the general noise floor, 10-15dB, even on a clean good condition test record.

LD

Hi LD,

A very interesting measurement.

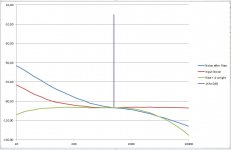

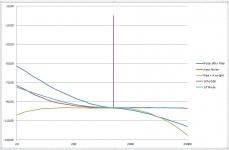

Looking at the flatness of the noise spectrum, it must have been recorded without RIAA correction.

I recorded the spectrum of a 1 Khz 0dB signal from a test record.

Then I applied an anti Riaa curve to get a flat recording, which should be comparable to your recording, this is the line in red in my figure.

I also calculated a third curve, being A-weighted + Riaa correction.

With this curve I could calculate that the A-weighted S/N related to the 0 dB 1Khz was 63 dB.

This figure is very close to the 66 dB theoretical maximum achievable with a state of the art LP master cutter.

So to conclude, the noise in my recording is even below your wet recording, so I'm a bit puzzled how to interpret your results.

Hans

Thank you, Hans. My measurements were made a few years ago, but yes, I am sure to have taken care of RIAA correction when preparing the plots.

You can see from my dry plot that the noise floor roughly has a 1/f or -6dB per octave slope, which is characteristic of flicker noise from a friction source, BTW. And you can see that slope is absent in the wet plot, when friction is very low.

As to the absolute noise floor for the wet playback case, for my plots I suspect it may have been limited by pre-amp noise floor, and this might be better in your case.

In your plot, it seems odd that all the expected harmonic distortion peaks are absent ? Otherwise, at first sight, I would interpret it as you have a low friction test record/setup, on a low noise cartridge/preamp.

As to the cutter's role in groove friction, I suppose it must be a factor in determining vinyl wall surface smoothness, along with many other manufacturing process factors, not least vinyl composition itself? I guess a cutter S/N spec would be based on what is achievable with it, given good manufacturing processes ?

LD

You can see from my dry plot that the noise floor roughly has a 1/f or -6dB per octave slope, which is characteristic of flicker noise from a friction source, BTW. And you can see that slope is absent in the wet plot, when friction is very low.

As to the absolute noise floor for the wet playback case, for my plots I suspect it may have been limited by pre-amp noise floor, and this might be better in your case.

In your plot, it seems odd that all the expected harmonic distortion peaks are absent ? Otherwise, at first sight, I would interpret it as you have a low friction test record/setup, on a low noise cartridge/preamp.

As to the cutter's role in groove friction, I suppose it must be a factor in determining vinyl wall surface smoothness, along with many other manufacturing process factors, not least vinyl composition itself? I guess a cutter S/N spec would be based on what is achievable with it, given good manufacturing processes ?

LD

just curious.

What about compliance of cartridges ? For a moment if we ignore tracking ability and resonances, will a high compliance cartridge will have low noise ?

Also I guess direct metal mastered vinyls will have low noise isn't it ? I have one Alan Parson's Project Ammonia Avenue direct metal master vinyl which sounds good.

Thanks and regards.

What about compliance of cartridges ? For a moment if we ignore tracking ability and resonances, will a high compliance cartridge will have low noise ?

Also I guess direct metal mastered vinyls will have low noise isn't it ? I have one Alan Parson's Project Ammonia Avenue direct metal master vinyl which sounds good.

Thanks and regards.

You are right about the absence of harmonics in my figure.Thank you, Hans. My measurements were made a few years ago, but yes, I am sure to have taken care of RIAA correction when preparing the plots.

You can see from my dry plot that the noise floor roughly has a 1/f or -6dB per octave slope, which is characteristic of flicker noise from a friction source, BTW. And you can see that slope is absent in the wet plot, when friction is very low.

As to the absolute noise floor for the wet playback case, for my plots I suspect it may have been limited by pre-amp noise floor, and this might be better in your case.

In your plot, it seems odd that all the expected harmonic distortion peaks are absent ? Otherwise, at first sight, I would interpret it as you have a low friction test record/setup, on a low noise cartridge/preamp.

As to the cutter's role in groove friction, I suppose it must be a factor in determining vinyl wall surface smoothness, along with many other manufacturing process factors, not least vinyl composition itself? I guess a cutter S/N spec would be based on what is achievable with it, given good manufacturing processes ?

LD

I have only transferred the 1kHz 0db value plus the noise spectrum from a blank trace on my test record to an excel sheet for further calculations.

I have left all the harmonics, in total close to -40 dB, because I just wanted to calculate the maximum dynamic A-weighted range.

I can show the original spectra, but they give no extra information regarding surface noise.

I also made a recording of the noise spectrum with running platter but the arm in the air. At all frequencies noise was more than 12 dB below the surface noise, so preamp noise did not interfere with the surface noise.

To support your statement about 1/f noise with 6dB/oct, I have now also included the spectrum of 1/f noise with a corner frequency at 250 Hz in light blue. The calculated max dynamic range without this 1/f noise, only improves by 0.4 dB. Not a very big deal or something to worry about.

I suppose the theoretical 66dB max dynamic range that Neumann specifies is based on using the best possible vinyl quality.

Hans

Not a very big deal or something to worry about.

This is because, for whatever reason, you are not observing any 1/f noise in that setup with that test record - whereas my measurements did.

As to absolute level of noise floor, that depends on sample resolution of course - broad spectrum noise being divided into discrete buckets in the spectrum, and the absolute level depends on the resolution or 'width' of each bucket. This probably explains the difference in absolute levels between our measurements, and unfortunately I didn't note on mine because I wasn't interested in absolute levels at the time, just relative between wet and dry.

Unfortunately, to run a measurement with wet playback ruins the test disc. So this is something I did once only, and still would stand by the result, and it sits well with listening tests and other measurements from that time.

IME, there is always notable and measurable difference in noise performance between wet and dry playback. Sometimes profoundly so !

LD

Hi LD,

I did observe 1/f noise, look at the red curve of the input noise as compared to a simulated 1/f noise with 6 dB/oct and a corner frequency of 250 Hz in light blue.

The two curves are almost identical !

I recorded my spectra with "buckets" of 1.5 Hz, and indeed a larger filter width will increase the noise level. When your filter width is a guessed 10 Hz, noise level will be 8 dB higher, but that is not the point.

What I was trying to understand is that a dry record in my case showed a dynamic range of 63 dBA, very close to the theoretical max of 66 dBA.

Your recording suggests that a wet record can lower the noise figure by 10-15 dB, however that would mean going way beyond the theoretical maximum.

And if wet recording only removes the 1/f noise, gain will only be 0.4 dB which is below the hearing limit.

Hans

I did observe 1/f noise, look at the red curve of the input noise as compared to a simulated 1/f noise with 6 dB/oct and a corner frequency of 250 Hz in light blue.

The two curves are almost identical !

I recorded my spectra with "buckets" of 1.5 Hz, and indeed a larger filter width will increase the noise level. When your filter width is a guessed 10 Hz, noise level will be 8 dB higher, but that is not the point.

What I was trying to understand is that a dry record in my case showed a dynamic range of 63 dBA, very close to the theoretical max of 66 dBA.

Your recording suggests that a wet record can lower the noise figure by 10-15 dB, however that would mean going way beyond the theoretical maximum.

And if wet recording only removes the 1/f noise, gain will only be 0.4 dB which is below the hearing limit.

Hans

I did observe 1/f noise, look at the red curve of the input noise as compared to a simulated 1/f noise with 6 dB/oct and a corner frequency of 250 Hz in light blue.

The two curves are almost identical !

Hi Hans, the floor of 1/f noise should have a -6dB/octave gradient if it is there and dominant, but neither your measured nor calculated curves show this. I don't understand where the idea of a 250Hz corner comes from, but you can see in my measured dry plot there is no corner: the line pretty much follows -6dB/octave.

What I was trying to understand is that a dry record in my case showed a dynamic range of 63 dBA, very close to the theoretical max of 66 dBA.

Your recording suggests that a wet record can lower the noise figure by 10-15 dB, however that would mean going way beyond the theoretical maximum.

I can't verify that calculation, but yes I believe it is plausible that achievable S/N spec of cutters assumes normal (dry) playback, and so, under abnormal (low friction) conditions, it might be possible to outperform spec limit?

That's how it seems at face value, I think.

LD

What about compliance of cartridges ? For a moment if we ignore tracking ability and resonances, will a high compliance cartridge will have low noise ?

Unfortunately, I think it makes little difference, Hiten. What matters most is the ratio of friction force to applied tracking force. Varying tracking force doesn't help or hinder much because the friction force is derived from it via the ratio, if that makes sense? So varying VTF, for example, doesn't alter surface noise by much if at all, and the same is true for compliance, all other things being equal.

LD

- Home

- Source & Line

- Analogue Source

- Reducing Record Surface Noise - I want to know all Approaches