Trying to understand the damping required...

(1) if lateral stylus movement creates 'tail wags the dog' effect, wouldn't a triangle shape tone arm piece counteract that. I mean Stylus/cartridge would be tip of the triangle and bottom two corners at a little distance would be air bearing. This way any lateral movement if stylus is creating would be resisted by the angle it will create with respect to axis of air bearing.

(2) would precise little by little drop in air pressure be advisable to create ideal balance between 'Too much free movement" and "Damping"

Regards.

(1) if lateral stylus movement creates 'tail wags the dog' effect, wouldn't a triangle shape tone arm piece counteract that. I mean Stylus/cartridge would be tip of the triangle and bottom two corners at a little distance would be air bearing. This way any lateral movement if stylus is creating would be resisted by the angle it will create with respect to axis of air bearing.

(2) would precise little by little drop in air pressure be advisable to create ideal balance between 'Too much free movement" and "Damping"

Regards.

Trying to understand the damping required...

(1) if lateral stylus movement creates 'tail wags the dog' effect, wouldn't a triangle shape tone arm piece counteract that. I mean Stylus/cartridge would be tip of the triangle and bottom two corners at a little distance would be air bearing. This way any lateral movement if stylus is creating would be resisted by the angle it will create with respect to axis of air bearing.

(2) would precise little by little drop in air pressure be advisable to create ideal balance between 'Too much free movement" and "Damping"

Regards.

Tail wagging dog happens because the air bearing is frictionless. Small force to move the cartridge will drag the bearing(large mass) side ways. So, even if the carriage is triangle, it won't help.

I think to low air pressure won't increase the friction. It will change the stiffness of air bearing. The higher pressure will make the bearing stiffer. High pressure will have effect on sound too. Too high pressure will cause the sound edgy. On my arm, the best sounding pressure is between 35 psi to 40 psi.

Last edited:

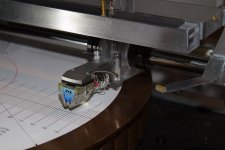

I have done some updates on my air bearing arm.

First, I added a silicone oil damping device. Please see the photo. I have tried 30 wt and 40 wt silicone oils. I prefer 40 wt. In the meantime, I reduced the weight of my own damping device, 1.2 g on right side and 1.4 g on left side. The silicone oil damping provides base while mine to compensate the difference of biasing.

I also did three different versions of carriages. From these carriages, I have learnt a simple but not so obviously fact. The tip of needle should be on same level as the center of air bearing or at least, to close to it as much as possible in order to improve the tracking ability. The carriage can be further improved by using aluminum. However, I don’t have tools to do it. If anyone has the access to a machine shop, please let me know.

Air tubing should be as flexible as possible. I tried three different kinds of air tubings. Air tubing has certain degree of damping function, but it is not good damping device because its resistance is not consistent while the cartridge is moving. It may introduce distortions, artifacts and peaks under certain conditions. Using air tubing as damping device is never a good option.

Pictured air tubing and carriage are not the latest ones.

My arm is very quiet now. Its sound is exceptional.

First, I added a silicone oil damping device. Please see the photo. I have tried 30 wt and 40 wt silicone oils. I prefer 40 wt. In the meantime, I reduced the weight of my own damping device, 1.2 g on right side and 1.4 g on left side. The silicone oil damping provides base while mine to compensate the difference of biasing.

I also did three different versions of carriages. From these carriages, I have learnt a simple but not so obviously fact. The tip of needle should be on same level as the center of air bearing or at least, to close to it as much as possible in order to improve the tracking ability. The carriage can be further improved by using aluminum. However, I don’t have tools to do it. If anyone has the access to a machine shop, please let me know.

Air tubing should be as flexible as possible. I tried three different kinds of air tubings. Air tubing has certain degree of damping function, but it is not good damping device because its resistance is not consistent while the cartridge is moving. It may introduce distortions, artifacts and peaks under certain conditions. Using air tubing as damping device is never a good option.

Pictured air tubing and carriage are not the latest ones.

My arm is very quiet now. Its sound is exceptional.

Attachments

Last edited:

Hi Super.

Good to see that you're still busy. The aluminium headshell in the photos looks very tidy. How does the current one differ and is it sonically superior? Did you consider a Townsend style trough where the trough sits in front of the cartridge and an outrigger extends the headshell. The Townsend trough was designed to damping arm resonance rather cantilever resonance but with your arm it might do both. (not that you're going to have much arm resonance with such a short arm so just a thought) The Townsend design used 10,000cts silicone fluid which is rather high on the viscosity scale.

Keep up the good work and keep us posted.

Still jealous of your entire system

Niffy

Good to see that you're still busy. The aluminium headshell in the photos looks very tidy. How does the current one differ and is it sonically superior? Did you consider a Townsend style trough where the trough sits in front of the cartridge and an outrigger extends the headshell. The Townsend trough was designed to damping arm resonance rather cantilever resonance but with your arm it might do both. (not that you're going to have much arm resonance with such a short arm so just a thought) The Townsend design used 10,000cts silicone fluid which is rather high on the viscosity scale.

Keep up the good work and keep us posted.

Still jealous of your entire system

Niffy

Hi Niffy,

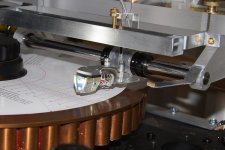

I can’t tell for sure how much the head shell improve the sound since I have been changing the arm frequently, but it adds convenience to change cartridge and to adjust azimuth. Here is a photo to show you the construction of damping device and how it attaches to the bearing. I ordered 60 wt(800 cst) silicone oil and am going to try it out. But I feel 40 wt should be fine.

This project is basically over now although I am still tweaking the arm. I think I am kind of addicted to building tonearms. I am thinking of building 2nd one. Its construction is same as Walker audio’s.

I can’t tell for sure how much the head shell improve the sound since I have been changing the arm frequently, but it adds convenience to change cartridge and to adjust azimuth. Here is a photo to show you the construction of damping device and how it attaches to the bearing. I ordered 60 wt(800 cst) silicone oil and am going to try it out. But I feel 40 wt should be fine.

This project is basically over now although I am still tweaking the arm. I think I am kind of addicted to building tonearms. I am thinking of building 2nd one. Its construction is same as Walker audio’s.

Attachments

Your design with short armwand reminds me of this tonearm.

YouTube video of Tritium Triphazer Linear Tonearm with Fluid Damping

I like how the whole assemble can be swung to the side without hanging over the platter.

YouTube video of Tritium Triphazer Linear Tonearm with Fluid Damping

I like how the whole assemble can be swung to the side without hanging over the platter.

Last edited:

I am thinking of building 2nd one. Its construction is same as Walker audio’s.

To keep a similar theme with short armwand, maybe something like this?

Or something like this.

Obviously you need a wide plinth or table space!

Or this one:

https://www.youtube.com/watch?v=-WPDKXlQL9I

Last edited:

They are very inspirational, especially, the Deconstrata table. This is what I have in my mind.

I would put the counterweight on the other side of the rod to balance the mass on both ends, similar to the Walker or ET approach.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Update 1,

I have been doing listening tests for my own damping device. Although I can see the there is unbalanced force between left and right channel on PC oscilloscope, the device does kill some soundstage and bass information. I finally decided not using my own damping device but using silicone oil damping only. The soundstage of my arm is truly 3D like now.

Update 2

I also changed 30 wt(350 cst) silicone oil to 60 wt(800 cst). I think 60 wt does better job than 30 wt. I also placed an order for 2000 cst and 5000 cst and will try 2000 cst, and different mixtures.

I have been doing listening tests for my own damping device. Although I can see the there is unbalanced force between left and right channel on PC oscilloscope, the device does kill some soundstage and bass information. I finally decided not using my own damping device but using silicone oil damping only. The soundstage of my arm is truly 3D like now.

Update 2

I also changed 30 wt(350 cst) silicone oil to 60 wt(800 cst). I think 60 wt does better job than 30 wt. I also placed an order for 2000 cst and 5000 cst and will try 2000 cst, and different mixtures.

I have been updating my two air bearing arms for over a year now. Now, I can say that both arms can rival the best arms in the market. I may still make some of small changes but basically I am done. Here are the major updates since I started this thread more than a year ago.

1. The first lesson I learnt is:

Do not make air compressor by using a refrigerator compressor.

Refrigerator compressor is not designed for continue use. It may be ok for air bushing but not for continue supply of compressed air. I had destroyed two brand new refrigerator compressors. I finally bought a Silentaire TC-50 and like it very much. The filter on the TC-50 is not fine enough. So, I added one .3 micron and one .01 micron filters. I also separated air supplies for different arm with different air pressure.

2.For MS(moving shaft) arm, I changed the shaft. I bought a aluminum shaft from Mac-Master Carr and had local machine shop drill a hole all the way through the shaft. It works very good. Here are two videos.

https://youtu.be/CzhJisSrX_w

https://youtu.be/SjvPHaGOMaU

3. For MB(moving bearing) arm, I used 1/2 inch air bearing at beginning, but changed it to 3/4 inch one. The 3/4” air bearing definitely sounds better than 1/2” one. Here are two videos.

https://youtu.be/KNTdIRB2aA4

https://youtu.be/Xy1fAO5rbwU

1. The first lesson I learnt is:

Do not make air compressor by using a refrigerator compressor.

Refrigerator compressor is not designed for continue use. It may be ok for air bushing but not for continue supply of compressed air. I had destroyed two brand new refrigerator compressors. I finally bought a Silentaire TC-50 and like it very much. The filter on the TC-50 is not fine enough. So, I added one .3 micron and one .01 micron filters. I also separated air supplies for different arm with different air pressure.

2.For MS(moving shaft) arm, I changed the shaft. I bought a aluminum shaft from Mac-Master Carr and had local machine shop drill a hole all the way through the shaft. It works very good. Here are two videos.

https://youtu.be/CzhJisSrX_w

https://youtu.be/SjvPHaGOMaU

3. For MB(moving bearing) arm, I used 1/2 inch air bearing at beginning, but changed it to 3/4 inch one. The 3/4” air bearing definitely sounds better than 1/2” one. Here are two videos.

https://youtu.be/KNTdIRB2aA4

https://youtu.be/Xy1fAO5rbwU

Yes. I have spent a lot of time to build the arms and put a lot of thoughts into the designs. It has been a process of fun and learning. There are many small updates I have tried which I never mentioned here. If anyone interested, please feel free to ask.

The paddle I use now is 5 mm x 6 mm rectangle. I am thinking of using different kind such as a 6 mm long and 7 mm diameter round rod. Doing this way will add damping vertically as well as horizontally. But for now, I don’t feel it will make big audible difference. However, this may be my next update.

For the damping silicone fluid, I tried 30 cst to 800 cst. I ended with a mixture of 30 cst and 3000 cst. I guess it is about 2000 cst.

The paddle I use now is 5 mm x 6 mm rectangle. I am thinking of using different kind such as a 6 mm long and 7 mm diameter round rod. Doing this way will add damping vertically as well as horizontally. But for now, I don’t feel it will make big audible difference. However, this may be my next update.

For the damping silicone fluid, I tried 30 cst to 800 cst. I ended with a mixture of 30 cst and 3000 cst. I guess it is about 2000 cst.

You got me thinking again. ;-) I am going to make a paddle as the drawing. This paddle can always have vertical damping. If I don't need horizontal damping, I can just turn the paddle 90 degrees as the red arrow indicates.

Attachments

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY Air Bearing Linear Arm