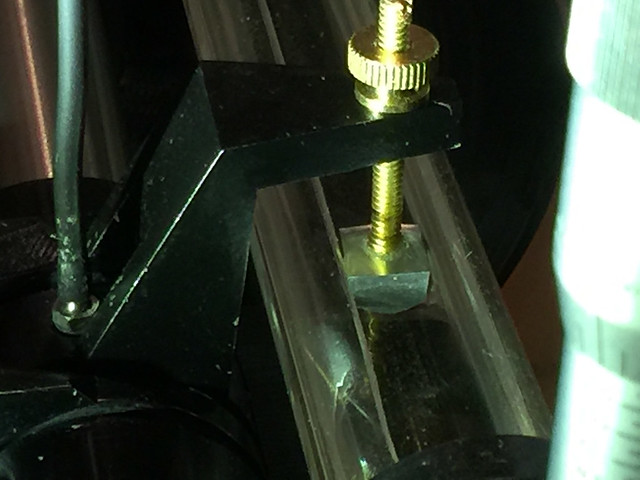

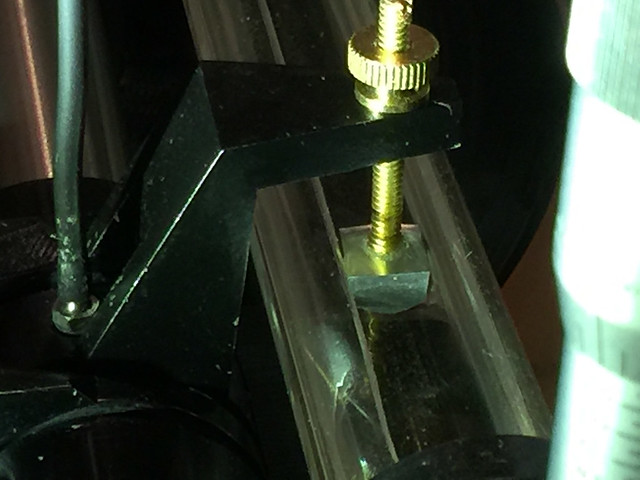

I made a new paddle for the damping device. The new paddle can damp both directions laterally, left and right, but can only damp up force vertically. In my opinion, it is good enough. It is no need to damp the down force of cartridge.

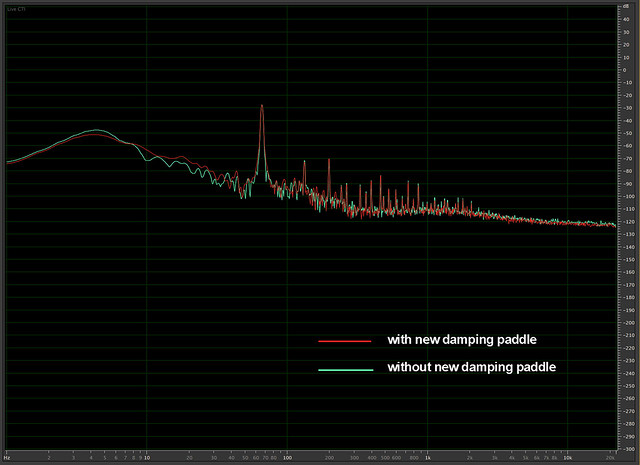

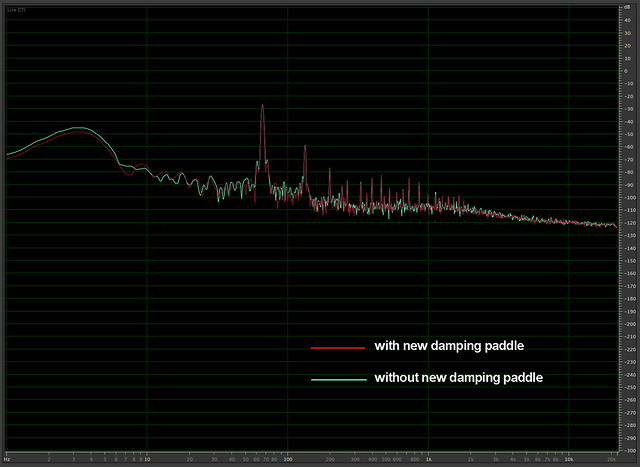

I also added some 22.5 CST silicone fluid to make the damping fluid is about 2000 CST now. It was about 3000 CST. Here are new testing results.

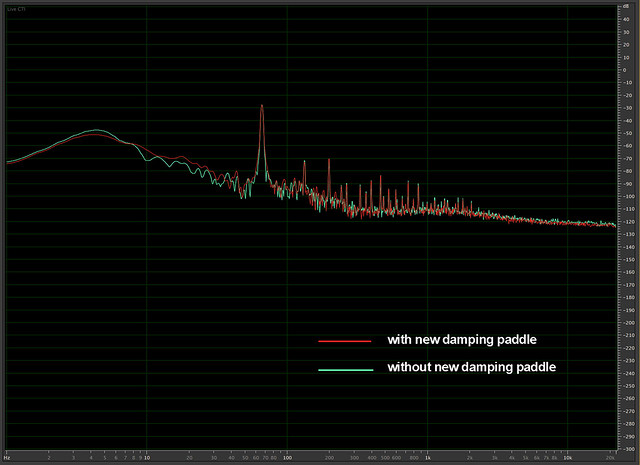

Lateral Testing Result

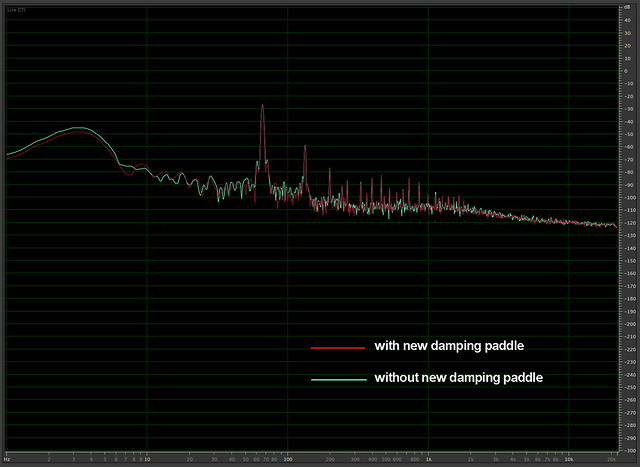

Vertical Testing Result

Both lateral and vertical damping reduce arm/cartridge resonance about 5 db. It seems that the new damping paddle is not as effective as old one. In fact, it is not true because the damping fluid has lower viscosity now. In other word, the damping force is reduced by almost half.

I also added some 22.5 CST silicone fluid to make the damping fluid is about 2000 CST now. It was about 3000 CST. Here are new testing results.

Lateral Testing Result

Vertical Testing Result

Both lateral and vertical damping reduce arm/cartridge resonance about 5 db. It seems that the new damping paddle is not as effective as old one. In fact, it is not true because the damping fluid has lower viscosity now. In other word, the damping force is reduced by almost half.

Last edited:

super10018, what technique do you use to balance your air bearing tonearm? Do you add weight to the counterbalance so the cartridge is floating with no downforce and then adjust level until cartridge stays in one place? Or do you adjust the level of the tonearm to achieve best tracking in both channels while playing a test record? When leveling an air bearing tonearm, is it necessary to take into consideration the slight slope found in the surface of most LPs or do you just want a static balance and let the tonearm/cartridge deal with the slope of the record?

super10018, what technique do you use to balance your air bearing tonearm? Do you add weight to the counterbalance so the cartridge is floating with no downforce and then adjust level until cartridge stays in one place? Or do you adjust the level of the tonearm to achieve best tracking in both channels while playing a test record? When leveling an air bearing tonearm, is it necessary to take into consideration the slight slope found in the surface of most LPs or do you just want a static balance and let the tonearm/cartridge deal with the slope of the record?

Disengage your damping device if you have one. Move the arm to most outer groove, Use arm lifter to lift arm 2 or 3 times to see if the needle always hits the same spot. Then move the arm to most inner groove, do the same thing. If the needle always hits the same spot, your bearing shaft is leveled.

The balance of output levels for two channels should not be used to adjust bearing shaft level.

No. You don't need to take the slope of record as a factor to adjust the level of bearing shaft, but you do need to adjust the level of your turntable as you normally would do.

Jim

Super10018

This is best thread so far about diy TT arm. I am following you since start and really enjoying your posts explanations and pictures. I think that air bearing linear tonearm is best solution for diyers who want their own TT assy. Pivoted tangential ones are harder to build. I am also thinking to build one like yours when i found time.

Can you explain to me though why to go with short arm in comparison to ie Kuzma airline arm. I was thinking to build simmilar to Kuzma one but with damped carbon tube and alu head shell with brass interface to carbon and be able to remove record without hassle when finish playing or to go with short arm and make all assy to rotate in order to free up space above platter to remove record?!

What is the cost for 1" air bushing and compatible steel shaft in length required?

Thanx mate and best wishes in your endeavours

Zz

This is best thread so far about diy TT arm. I am following you since start and really enjoying your posts explanations and pictures. I think that air bearing linear tonearm is best solution for diyers who want their own TT assy. Pivoted tangential ones are harder to build. I am also thinking to build one like yours when i found time.

Can you explain to me though why to go with short arm in comparison to ie Kuzma airline arm. I was thinking to build simmilar to Kuzma one but with damped carbon tube and alu head shell with brass interface to carbon and be able to remove record without hassle when finish playing or to go with short arm and make all assy to rotate in order to free up space above platter to remove record?!

What is the cost for 1" air bushing and compatible steel shaft in length required?

Thanx mate and best wishes in your endeavours

Zz

Zz,

Thanks for encouraging words!

In my opinion, a short arm has these advantages over long arm.

1, Reduce arm tube resonance. Niffy did some experiments and I think he knows it better than I do.

2, I think an air bearing is more sensitive to a short arm, especially, under the condition of eccentricity.

3, As you may see, I have done some tests to see how much the difference between vertical resonance and lateral resonance for an air bearing arm. The results indicated that both resonance was very close although the arm’s vertical and lateral masses are different. This result was done on a short arm. However, I don’t know how a long arm will behave.

The major disadvantage for a short arm is you need to build a mechanism to retract the arm.

I don’t know the price for a new 1” air bearing. Before 1” air bearing, I used a 3/4” air bearing and paid it for USD$265. I guess 1” will be little more expensive than 3/4”. I bought my 1” air bearings from eBay with great prices.

I bought my 1” shaft from Oav.com and paid about $150 for a 10” long one. I can’t remember the exact price for the shafts. Oav uses non magnetic stainless steel for the shaft. I bought the shaft for 3/4" air bearing with the air bearing together from motionusa.com. It was magnetic stainless steel. I found it out a year later when I was trying to build a magnetic damping device. I prefer non magnetic stainless.

The mass of my arm is about 200 g now. Heavy mass can certainly help bass section. However, I think 200 g may be a little bit too much. I probably would like to control the mass around 150-170 g. This is also what I have in my mind to try it out, but I have too much going on now. This will be my next attempt to refine the arm.

Hope this helps.

Jim

Thanks for encouraging words!

In my opinion, a short arm has these advantages over long arm.

1, Reduce arm tube resonance. Niffy did some experiments and I think he knows it better than I do.

2, I think an air bearing is more sensitive to a short arm, especially, under the condition of eccentricity.

3, As you may see, I have done some tests to see how much the difference between vertical resonance and lateral resonance for an air bearing arm. The results indicated that both resonance was very close although the arm’s vertical and lateral masses are different. This result was done on a short arm. However, I don’t know how a long arm will behave.

The major disadvantage for a short arm is you need to build a mechanism to retract the arm.

I don’t know the price for a new 1” air bearing. Before 1” air bearing, I used a 3/4” air bearing and paid it for USD$265. I guess 1” will be little more expensive than 3/4”. I bought my 1” air bearings from eBay with great prices.

I bought my 1” shaft from Oav.com and paid about $150 for a 10” long one. I can’t remember the exact price for the shafts. Oav uses non magnetic stainless steel for the shaft. I bought the shaft for 3/4" air bearing with the air bearing together from motionusa.com. It was magnetic stainless steel. I found it out a year later when I was trying to build a magnetic damping device. I prefer non magnetic stainless.

The mass of my arm is about 200 g now. Heavy mass can certainly help bass section. However, I think 200 g may be a little bit too much. I probably would like to control the mass around 150-170 g. This is also what I have in my mind to try it out, but I have too much going on now. This will be my next attempt to refine the arm.

Hope this helps.

Jim

Last edited:

Hey Super,.

Thanx for your kind reply,..

I think i will go with 20mm bearing,..It weight 49.1 gram while 25mm weight 22 gram more (total 72 gram). It cannot be that much of a difference in sound and i can save weight of total assy.

I got reply from OAV just half hour ago

OAV020MB air bushing $248 each

OAV20MB shaft x 250mm length $140 each.

This price suits me well, now i just hope European dealer have same price as folks in USA,..

Is there any particular reason you got NewWay air bush instead of OAV air bush?

No matter tollerances coz they are still in normal levels i think that one need to go with same manufacturers. I also sent mail to NewWay and waiting their reply.

I am engineer and machinist and in no way i know more behind science of moving stylus as you and Niffy but i am avid diyer and sound reproduction is my love and hobby, and i am ready for challenge with long arm

I plan to use alu or carbon bracket arround air bush with brass interface for alu or carbon tappered tube.,, I plan to make my design to be modular so i can easilly swap tubes and play with tube damping in order to get best from assy.

I will design headshell in CAD and will produce at least dozen of these

It is cheaper than just one so i will have enough material to play arround

I am in no rush,so i still learn from you guys on this wonderfull forum

Cheers mate and god bless you

I hardly wait for more from you guys.

Zz

Thanx for your kind reply,..

I think i will go with 20mm bearing,..It weight 49.1 gram while 25mm weight 22 gram more (total 72 gram). It cannot be that much of a difference in sound and i can save weight of total assy.

I got reply from OAV just half hour ago

OAV020MB air bushing $248 each

OAV20MB shaft x 250mm length $140 each.

This price suits me well, now i just hope European dealer have same price as folks in USA,..

Is there any particular reason you got NewWay air bush instead of OAV air bush?

No matter tollerances coz they are still in normal levels i think that one need to go with same manufacturers. I also sent mail to NewWay and waiting their reply.

I am engineer and machinist and in no way i know more behind science of moving stylus as you and Niffy but i am avid diyer and sound reproduction is my love and hobby, and i am ready for challenge with long arm

I plan to use alu or carbon bracket arround air bush with brass interface for alu or carbon tappered tube.,, I plan to make my design to be modular so i can easilly swap tubes and play with tube damping in order to get best from assy.

I will design headshell in CAD and will produce at least dozen of these

It is cheaper than just one so i will have enough material to play arround

I am in no rush,so i still learn from you guys on this wonderfull forum

Cheers mate and god bless you

I hardly wait for more from you guys.

Zz

Zz,

There is no particular reason not to get Oav bearing. The bearings I got from eBay were happen to be New Way’s. But in my case, the tolerance for the comb of 1” New Way air bushing and 1” Oav shaft is little tighter than the tolerance of my 3/4” air bushing and shaft both from New Way. Anyway, I think either ways should be fine.

Btw, where can do you get tapped carbon fiber tube? If I can, I would like to get a piece of tapped carbon fiber tube for a 12” pivot arm.

Jim

There is no particular reason not to get Oav bearing. The bearings I got from eBay were happen to be New Way’s. But in my case, the tolerance for the comb of 1” New Way air bushing and 1” Oav shaft is little tighter than the tolerance of my 3/4” air bushing and shaft both from New Way. Anyway, I think either ways should be fine.

Btw, where can do you get tapped carbon fiber tube? If I can, I would like to get a piece of tapped carbon fiber tube for a 12” pivot arm.

Jim

Super,

You can ask for tappered carbon tubes at:

Rock West Composites - Engineered Carbon Fiber, Fiberglass & Kevlar

Carbon Fiber Tubing : Carbon Fiber Products or

SkyShark tapered tubes at A Wind Of Change

There are manny mfgs and lot of them can roll on order but i still didnt ask fo rmy self

I am in no rush.

Zz

You can ask for tappered carbon tubes at:

Rock West Composites - Engineered Carbon Fiber, Fiberglass & Kevlar

Carbon Fiber Tubing : Carbon Fiber Products or

SkyShark tapered tubes at A Wind Of Change

There are manny mfgs and lot of them can roll on order but i still didnt ask fo rmy self

I am in no rush.

Zz

Sorry, its not A Wind Of Change but Sky Shark Tubes.

They can be contacted for custom wrapping, but i believe all of mfgs can custom roll on steel tapered mandrel acc to your specs.

They can be contacted for custom wrapping, but i believe all of mfgs can custom roll on steel tapered mandrel acc to your specs.

Okay guys,is it really necessery that every freaking post must go trough moderation??

I cant edit my previous post coz they wait approval

I am here for ten years and didnt log in for long time (life, job etc) and furthermore i had so many posts and all of them are deleted. Its like i never existed here

These can custom wrap anything tapered up to one inch of dia by your specs:

Goodwinds composites

Goodwinds.com: Wrapped Carbon Tubes - Carbon

Cheers

Zz

I cant edit my previous post coz they wait approval

I am here for ten years and didnt log in for long time (life, job etc) and furthermore i had so many posts and all of them are deleted. Its like i never existed here

These can custom wrap anything tapered up to one inch of dia by your specs:

Goodwinds composites

Goodwinds.com: Wrapped Carbon Tubes - Carbon

Cheers

Zz

OberonGT according to your profile, you joined in January 2007 and have a sum total of four posts. That is why you are still in Moderation, as every new poster is.

OberonGT according to your profile, you joined in January 2007 and have a sum total of four posts. That is why you are still in Moderation, as every new poster is. I would say that if you have been here for 10 years, with many posts then it must have been under a different username. If you can remember what it is and let us know (and we can verify by the registered email address) we will merge the accounts.

Tony.

Hey Winter,...

This is my only acc,..I just change E-mail address yesterday since i rarely use my web site e-mail acc. I know that i was posting in pass amps forum a years back regarding aleph 4 i was building and some others. Its a mystery to me really.

But never mind Life goes on and i am here

Life goes on and i am here

Cheers folks

Zz

This is my only acc,..I just change E-mail address yesterday since i rarely use my web site e-mail acc. I know that i was posting in pass amps forum a years back regarding aleph 4 i was building and some others. Its a mystery to me really.

But never mind

Cheers folks

Zz

It may have been suggested before : if you want to experiment with tapered carbon-fibre tubes , most fishingrod-repairshops or rodbuilders would have offcuts or broken tip-sections from flyrods or light spinning/casting rods sitting around . Might be worth a try .

Cheers

Kim

Cheers

Kim

It may have been suggested before : if you want to experiment with tapered carbon-fibre tubes , most fishingrod-repairshops or rodbuilders would have offcuts or broken tip-sections from flyrods or light spinning/casting rods sitting around . Might be worth a try .

Cheers

Kim

Great idea! Thanks, Kim.

It may have been suggested before : if you want to experiment with tapered carbon-fibre tubes , most fishingrod-repairshops or rodbuilders would have offcuts or broken tip-sections from flyrods or light spinning/casting rods sitting around . Might be worth a try .

Cheers

Kim

Great idea! Thanks, Kim.

Please note, even the low-end fishing supply shops would have the, for the lack of a better word, end-pieces for fishing rods available for sale. I have seen them for as cheap as $5 for a 1m piece.

In most cases, these are not the "traditional aesthetic" but more typically called "unidirectional tubing", like this:

Unidirectional Carbon Fiber Tubing - Unidirectional Composites

I would also suggest trying "round pultruded tubes":

Round Pultrusion Tube

...I have found these perform much, much better in tonearm applications than the "traditional aesthetic" that we so commonly see.

InSides,.

"traditional aesthetic" is only last layer for...well aesthetic purposes

Just to be clear, there are much to be researched from my side on resonance characteristic of various fiber materials (glass, carbon and possible Kevlar) their shape and cross section, but i doubt it is simple task to just use fishing pole to make effective tonearm wand.

Fishing poles tends to be flexible. We need high stiffness.

You are probably right about longitudinal fibers. They add strength throughout length and help to efficiently make energy transfer from cartridge to more massive carriage.

What i read by now the higher the taper ratio, the better reduction of ringing resonances and standing waves with different wall thickness throughout its length.

I really think that combination of these various materials would yield good result in wand creation.

Now, since manufacturers use same tapered stainless steel mandrel to roll different material prepregs, one can order several custom thin walled full length combinations to be surface sanded and stack&glue one tube inside another to get different wall thickness in different length. Glue filled in gaps between tubes can serve as damping and memory foam can be used for additional damping with not much impact on weight.

This is what i will do when time come.

This tonearm wand will be some 5-6 inches long, again glued onto root aluminum interface tube of same taper which will be fastened onto carriage block. Same interface but of brass will be glued inside tip of the wand and cnc-ed aluminum head shell will be fastened to this brass interface.

Does this sound to complicated to you guys

Oh and i will not waste these tubes if i failed coz i use them in RC model building anyway.

Now i am aware that there is not much of a science base in what i just wrote,

but i am of thinking that with addition of some drop of snake oil, bat wing and chicken leg dust, maybe the end result will be quite awesome

Zz

"traditional aesthetic" is only last layer for...well aesthetic purposes

Just to be clear, there are much to be researched from my side on resonance characteristic of various fiber materials (glass, carbon and possible Kevlar) their shape and cross section, but i doubt it is simple task to just use fishing pole to make effective tonearm wand.

Fishing poles tends to be flexible. We need high stiffness.

You are probably right about longitudinal fibers. They add strength throughout length and help to efficiently make energy transfer from cartridge to more massive carriage.

What i read by now the higher the taper ratio, the better reduction of ringing resonances and standing waves with different wall thickness throughout its length.

I really think that combination of these various materials would yield good result in wand creation.

Now, since manufacturers use same tapered stainless steel mandrel to roll different material prepregs, one can order several custom thin walled full length combinations to be surface sanded and stack&glue one tube inside another to get different wall thickness in different length. Glue filled in gaps between tubes can serve as damping and memory foam can be used for additional damping with not much impact on weight.

This is what i will do when time come.

This tonearm wand will be some 5-6 inches long, again glued onto root aluminum interface tube of same taper which will be fastened onto carriage block. Same interface but of brass will be glued inside tip of the wand and cnc-ed aluminum head shell will be fastened to this brass interface.

Does this sound to complicated to you guys

Oh and i will not waste these tubes if i failed coz i use them in RC model building anyway.

Now i am aware that there is not much of a science base in what i just wrote,

but i am of thinking that with addition of some drop of snake oil, bat wing and chicken leg dust, maybe the end result will be quite awesome

Zz

Using tappered tubes for tonearms is a good thing, place the highest rigidity where the bending moments are greatest and moving the mass closer to centre. Better still is to remove the arm tube completely as both Jim and I have done. If you have no arm tube you have no arm tube resonance. Directly connecting the headshell to the bearing yoke will give the highest possible rigidity and the lowest possible colouration due to bending modes.

Zz, one of the advantages of diy is that you can utilize a construction method that would be totally uneconomic for production but is fine for a one off.

Niffy

Zz, one of the advantages of diy is that you can utilize a construction method that would be totally uneconomic for production but is fine for a one off.

Niffy

Tapered tubes etc.

Here's another idea : Rather than using fishingrod tubing or pultruded/pulwinding cf-tubes with their relatively thick walls , use the prepreg cf tubes with a wall thickness of 0,5mm . Take an 8x9mm tube , slide a 7x8mm tube inside it , continue with a 6x7mm tube and a 5x6mm tube and so on . You can choose the outer diameter you need and work from there . Gives you a taper from the inside so to speak , and you can experiment with various taper-ratios to your hearts content . Using the proper quality of tubes , they'll fit very snugly inside each other and can be secured with a low viscosity glue . I've tried it , it works .

Cheers

Kim

Here's another idea : Rather than using fishingrod tubing or pultruded/pulwinding cf-tubes with their relatively thick walls , use the prepreg cf tubes with a wall thickness of 0,5mm . Take an 8x9mm tube , slide a 7x8mm tube inside it , continue with a 6x7mm tube and a 5x6mm tube and so on . You can choose the outer diameter you need and work from there . Gives you a taper from the inside so to speak , and you can experiment with various taper-ratios to your hearts content . Using the proper quality of tubes , they'll fit very snugly inside each other and can be secured with a low viscosity glue . I've tried it , it works .

Cheers

Kim

- Home

- Source & Line

- Analogue Source

- DIY Air Bearing Linear Arm