5V is sensitive but 50mV low won't matter. That you can't get higher than 50mV is tell-tale of a issue, as is the overheating - seems something is drawing too much current.

My PSU overheating ! ALSO got these issues : when i press the 75 rpm button (the turntable is stoped) the strob looks a little weak.

The other issue is that speed looks to waves a little back and forth (at all speeds) but maybe this is because the platter looks very very little bented (the motor to be honest)

YouTube

4 months ago I bought an SP10 mk2a in a decent condition all is working well and I haven't use it a lot in the last 4 months because I haven't got a plinth for it. I've recently made a plinth for it So I spend a bit of time to do clean up and oiling.

After oiling the bearing (2 drops of sp10 original oil) There is some scraping sound so I dismantle and motor and checked the bearing. looks like it's almost dry with some green coloured grease (I assume this is a mixture of the old oil and debris from the trust pad). The thrust pad looks a bit worn (though I forgot to take pictures). I clean up the bearing well and put 3 drop of oil directly on the well and resit the bearing cap test. It's now silent on 33 and 45 but it's scraping sound is back on 78. and after it's running on 78 the scraping sound comes back on 33,45 but it disappear again after I lift and resit the bearing.

So this is my conclusion. When I first got it was originally bone dry and was hold by greased up oiled debris and when I put in the new oil it just flushed the debris and showed up the issue with trust bearing.

I've ordered a replacement torlon thrust pad so I hope it will resolve the issue even with the 78 speed. Anyone has experience similar issue? or pointer on what I should check next while waiting for the thrust pads to arrive?

After oiling the bearing (2 drops of sp10 original oil) There is some scraping sound so I dismantle and motor and checked the bearing. looks like it's almost dry with some green coloured grease (I assume this is a mixture of the old oil and debris from the trust pad). The thrust pad looks a bit worn (though I forgot to take pictures). I clean up the bearing well and put 3 drop of oil directly on the well and resit the bearing cap test. It's now silent on 33 and 45 but it's scraping sound is back on 78. and after it's running on 78 the scraping sound comes back on 33,45 but it disappear again after I lift and resit the bearing.

So this is my conclusion. When I first got it was originally bone dry and was hold by greased up oiled debris and when I put in the new oil it just flushed the debris and showed up the issue with trust bearing.

I've ordered a replacement torlon thrust pad so I hope it will resolve the issue even with the 78 speed. Anyone has experience similar issue? or pointer on what I should check next while waiting for the thrust pads to arrive?

ra 7

A bit of a long shot, could you look at the drive to each of the 3 motor coils. Sometimes one driver transistor is down and that can make it run but cause all sorts of issues.

Also what are you using to measure the 5.0V line ? Also with the PSU disconnected what is the voltage ?

A bit of a long shot, could you look at the drive to each of the 3 motor coils. Sometimes one driver transistor is down and that can make it run but cause all sorts of issues.

Also what are you using to measure the 5.0V line ? Also with the PSU disconnected what is the voltage ?

Last edited:

Thanks Dave I at the moment it's stable and no noise on 33 and 45 and I'm reluctant to try 78 before putting in the new thrust pad. Regarding scrape marks yes I can see scrape mark on the raised ring around the bearing well but strangely not on the spindle cup but doesn't look like there is any scraping on the motor coils. But enough for me not to try to reproduce the issue without new parts.

Regarding small piece of plastic (I assume to simulate thicker trust pad) I'm worried it would get stuck in there and make things worse unless you have suggestions on some same material to use

Regarding small piece of plastic (I assume to simulate thicker trust pad) I'm worried it would get stuck in there and make things worse unless you have suggestions on some same material to use

Regarding small piece of plastic (I assume to simulate thicker trust pad) I'm worried it would get stuck in there and make things worse unless you have suggestions on some same material to use

Yes, but if it worries you wait until the proper one comes ?

Dave

Yes, but if it worries you wait until the proper one comes ?

Dave

I bought the new thrust pad 2 days ago so hoping it arrives next week meanwhile I'm monitoring the table every day. until now it's still no noise so hopefully it's safe to keep using it. In an event this doesn't solve it Any other known common bearing issue with sp10? Bearing well has been cleaned and lubricated with original sp10 oil

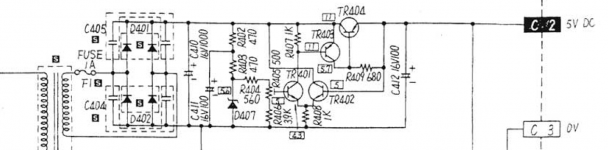

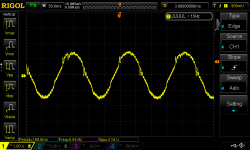

Hi Dave, I checked the waveforms on A1, A2, and A3, and basically they were garbage. It looks like a sine wave, but it is very distorted.

I also checked the 5V with a Fluke DMM, and it was dead on 5V. Earlier I was using a cheapo no-name DMM, but in the past it has read quite close to the Fluke.

Unfortunately, as I was measuring the 5V under the table I shorted between C2 and C4 or something, saw a spark, and now the table won't rotate. One of the fuses was hot and looks almost burnt. Will replace and see if it works. Really bummed I did that.

I also checked the 5V with a Fluke DMM, and it was dead on 5V. Earlier I was using a cheapo no-name DMM, but in the past it has read quite close to the Fluke.

Unfortunately, as I was measuring the 5V under the table I shorted between C2 and C4 or something, saw a spark, and now the table won't rotate. One of the fuses was hot and looks almost burnt. Will replace and see if it works. Really bummed I did that.

Hi Dave, I checked the waveforms on A1, A2, and A3, and basically they were garbage. It looks like a sine wave, but it is very distorted.

.

Were all 3 the same ? Is the PSU now OK ? and under load ?

Dave

Armboard material

Newbie question here. A few months ago I got an obsidian plinth

for a sp10 Mk2, without an armboard. The original armboard with the

metal mounting bracket seems difficult/expensive to acquire.

I'm wondering if a suitably sized piece of wood would be something to

try.

What material would you suggest?

Thanks,

Dennis

Newbie question here. A few months ago I got an obsidian plinth

for a sp10 Mk2, without an armboard. The original armboard with the

metal mounting bracket seems difficult/expensive to acquire.

I'm wondering if a suitably sized piece of wood would be something to

try.

What material would you suggest?

Thanks,

Dennis

These guys have an all-wood replacement: Acoustand Complete Armboard For Technics SP10 Original Obsidian Plinth - Acoustand Audio

I may have a corroded frame. If you want it I'll check.

I may have a corroded frame. If you want it I'll check.

This is the drive waveform from a healthy 'table.

Were all 3 the same ? Is the PSU now OK ? and under load ?

Dave

All 3 were the same. JP's waveforms give me hope. Mine weren't too dissimilar, but I need to readjust the scope. Although, it is not starting anymore after the short. PS voltages appear to be OK.

My days are getting pretty busy, so I am not sure when I can pick this back up.

Does anybody repair these things in the US? I am in the bay area, CA.

Hi ra7

That's sort of good news on the waveforms. The "short" issue should be easy to find. I know of only two people who repair these and I'm one ! I don't touch anything that has been looked at before and in any case both of us are expensive.

Hopefully there are others and they will respond to you request here ?

Regards

Dave

That's sort of good news on the waveforms. The "short" issue should be easy to find. I know of only two people who repair these and I'm one ! I don't touch anything that has been looked at before and in any case both of us are expensive.

Hopefully there are others and they will respond to you request here ?

Regards

Dave

Plinth for the 10

I received a custom made plinth for the Sp-10 today, it makes the same sound as rapping ones knuckles on the armoured hull of a tank. Solid as.

Time to mount the SME V and have a listen.

I received a custom made plinth for the Sp-10 today, it makes the same sound as rapping ones knuckles on the armoured hull of a tank. Solid as.

Time to mount the SME V and have a listen.

Attachments

Dave, JP, others,

I am now getting 4.8 something volts on the 5V line. Walking through the PS, all the voltages check out except for TR404, which is the transistor mounted to the sink. There is a replacement available, but I'm thinking of nixing these old boards and building a new PS. Thinking of going with Pete's board and shoving it into the existing PS chassis. I really would like to keep the same chassis, and even reuse the same transformer. I'll see if there is enough space tomorrow.

Low Voltage Regulator

Aleks, super cool plinth. I like the aesthetics! If I ever get to the plinth, I would like to make something similar, and I would make the top of the SP-10 flush with the rest of the plinth, so that only the platter sticks out.

I am now getting 4.8 something volts on the 5V line. Walking through the PS, all the voltages check out except for TR404, which is the transistor mounted to the sink. There is a replacement available, but I'm thinking of nixing these old boards and building a new PS. Thinking of going with Pete's board and shoving it into the existing PS chassis. I really would like to keep the same chassis, and even reuse the same transformer. I'll see if there is enough space tomorrow.

Low Voltage Regulator

Aleks, super cool plinth. I like the aesthetics! If I ever get to the plinth, I would like to make something similar, and I would make the top of the SP-10 flush with the rest of the plinth, so that only the platter sticks out.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread