I'll try again lol

A great thread that helped give me a push towards an SP10 setup.

I’ve just finished putting this together.

SP10 MK2 deck, Phonomac Panzerholz Plinth, Puresound Tenuto Gunmetal mat, Fidelity Research FR64fx arm, Orsonic AV101s Headshell, Hana ML cartridge, Bigbottle Audio Spotfire cable.

A great thread that helped give me a push towards an SP10 setup.

I’ve just finished putting this together.

SP10 MK2 deck, Phonomac Panzerholz Plinth, Puresound Tenuto Gunmetal mat, Fidelity Research FR64fx arm, Orsonic AV101s Headshell, Hana ML cartridge, Bigbottle Audio Spotfire cable.

Beautiful! However the FX version of the FR64 is a lot different in sound character to the 'S' version. I have had both - but I tend toward very low compliance cartridges. Also, unless you need really minimal mass, the flat FR headshells are far more rigid even if a lot plainer to look at.

How does it sound to you and was it worth all of the effort?

How does it sound to you and was it worth all of the effort?

@warrjon....

Apologies for the erroneous (catty ) remarks a while back....I was not thinking clearly due to morphine painkillers.

) remarks a while back....I was not thinking clearly due to morphine painkillers.

My new plinth for my SP10 is static due to the virus - but I have now arranged for a machinist to help with the basic cutting and drilling. Will post pics when that is completed.

Apologies for the erroneous (catty

My new plinth for my SP10 is static due to the virus - but I have now arranged for a machinist to help with the basic cutting and drilling. Will post pics when that is completed.

@warrjon....

Apologies for the erroneous (catty) remarks a while back....I was not thinking clearly due to morphine painkillers.

Did I miss something

I made my plinth from resin/bentonite, the one on the right. The one on the left is a commercial plinth, still some kind of resin with a solid lead arm board. They both sound very good, although the one with the linear arm is 5 steps in front of the other with the EPA100 even though it still has a few issues to solve.

Attachments

Very nice job. `i had the Technics arm - the straight tube version...beautifully made but even with a med compliance MC was very indifferent...I sold it as an elderly Zeta sounded far better. Also sold a full obsidian plinth and - eventually - the deck itself.

I had x3 ex BBC MkIIP decks and also one with off board PS and electrics...that is the one which I am working on. One of the ex.BBC is on loan and the other was used as a donor.

I have had a few FR arms - all 64 versions incl. one FX....it sounded very lightweight compared to the 64S it lacked weight and solidity of sound whilst the treble was on the screechy side. Would love to get a 66S!!!

I had x3 ex BBC MkIIP decks and also one with off board PS and electrics...that is the one which I am working on. One of the ex.BBC is on loan and the other was used as a donor.

I have had a few FR arms - all 64 versions incl. one FX....it sounded very lightweight compared to the 64S it lacked weight and solidity of sound whilst the treble was on the screechy side. Would love to get a 66S!!!

Last edited:

Would that be the EPA500?

I kept the EPA100 as a reference while I build and test the linear. the LTA is so superior to any pivoting arm I have heard. I was a little skeptical when I built the first one but it inspired me to build something better. The very short stiff carriage lowers the noise floor significantly, at a guess I would say better than 3dB maybe even as much as 6dB, it is noticeable as soon as the needle drops into the lead in groove. Clicks and pops are a thing of the past and when I do hear them they are attenuated to the point of almost not noticing.

I kept the EPA100 as a reference while I build and test the linear. the LTA is so superior to any pivoting arm I have heard. I was a little skeptical when I built the first one but it inspired me to build something better. The very short stiff carriage lowers the noise floor significantly, at a guess I would say better than 3dB maybe even as much as 6dB, it is noticeable as soon as the needle drops into the lead in groove. Clicks and pops are a thing of the past and when I do hear them they are attenuated to the point of almost not noticing.

Hi Brian,

I assume you mean me. There are a few photos over on the DIY Linear tonearm thread.

Plinth was made the same way Bon made his (earlier in this thread) except I covered the whole plinth in fiberglass mat and then black gelcoat to smooth it as the bentonite tends to fall out and cause pock marks.

Here is a quick video

YouTube

I assume you mean me. There are a few photos over on the DIY Linear tonearm thread.

Plinth was made the same way Bon made his (earlier in this thread) except I covered the whole plinth in fiberglass mat and then black gelcoat to smooth it as the bentonite tends to fall out and cause pock marks.

Here is a quick video

YouTube

Well, I've got my SP-10MK2 completed. My inital post is here: The Incredible Technics SP-10 Thread

My apologies to 6L6, consider the complaint null and void...

I end up doing a full re-cap job on the deck and psu. I also replaced the bearing and went through the readjustment procedure. I really should have taken some in-progress pics. Everything went relatively smoothly that by the time I thought to take pictures, the deck was already back together.

The only issue I ran into was undoing a mod to make it compatible with the mixing deck used at the radio station. I had replaced IC8 with a 74LS73. I kept having weird start/stop switch de-bounce issues. I end up scavenging an old non LS series chip that worked flawlessly.

The new plinth is made from a 1.25" thick pane of Lexan. Instead of polishing out all the scratches, it was frosted instead. I think the frosted appearance looked better in the end anyways.

I am using a Jelco TS-550L. While a 10" arm would probably be better, I went with a 12" arm. Since I wasn't able to get a 10", and a 9" would be too short.

Sadly it looks like Jelco have decided to call it quits. From my research, Jelco definitely had best price to performance.

I also decided against refinishing the SP-10. While it would certainly look nicer, it would also erase some of it's history. I find it somewhat cool to see the thousands of missed needle drops made over the years. From the wear you can tell this deck outlived at least three different tonearms.

I thought I would post a little preview to my next turntable project as well, the rare and elusive SL-M3.

My apologies to 6L6, consider the complaint null and void...

I end up doing a full re-cap job on the deck and psu. I also replaced the bearing and went through the readjustment procedure. I really should have taken some in-progress pics. Everything went relatively smoothly that by the time I thought to take pictures, the deck was already back together.

The only issue I ran into was undoing a mod to make it compatible with the mixing deck used at the radio station. I had replaced IC8 with a 74LS73. I kept having weird start/stop switch de-bounce issues. I end up scavenging an old non LS series chip that worked flawlessly.

The new plinth is made from a 1.25" thick pane of Lexan. Instead of polishing out all the scratches, it was frosted instead. I think the frosted appearance looked better in the end anyways.

I am using a Jelco TS-550L. While a 10" arm would probably be better, I went with a 12" arm. Since I wasn't able to get a 10", and a 9" would be too short.

Sadly it looks like Jelco have decided to call it quits. From my research, Jelco definitely had best price to performance.

I also decided against refinishing the SP-10. While it would certainly look nicer, it would also erase some of it's history. I find it somewhat cool to see the thousands of missed needle drops made over the years. From the wear you can tell this deck outlived at least three different tonearms.

I thought I would post a little preview to my next turntable project as well, the rare and elusive SL-M3.

Attachments

Warren, yes, I meant you. Should have been more specific. I'll have to go check out the linear arm thread. Limited time has prevented from trying to catch up with that lengthy thread after missing much.

You definitely have a robust arm frame.

Good idea on the fiberglass coating over the plinth.

You definitely have a robust arm frame.

Good idea on the fiberglass coating over the plinth.

Hi Brian,

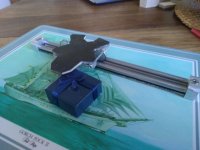

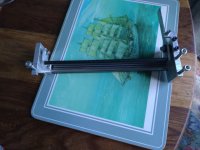

Here are few pics of the build.

The bridge was designed so I could change rails to different style if needed. The uprights have blocks with brass inserts running on 8mm linear shaft and are individually height adjustable.

The rail support is held to the blocks with m4 bolts that have 60deg points that hold in brass Vees. This allows a small amount of forward aft movement to fine tune the rail for tangent and a pivot that can be locked tight to enable to rail to pivot for leveling.

The carriage wheels are 1 piece aluminium with 2mm carbide wedding rings as tyres. It now uses Vee pivots the axles are made from 1.5mm drills with a 0.1mm radius and the Vees are m3 cup head grub screws that have a 0.5mm radius. The Vee's were forged in the grub screw with another drill ground to the correct radius.

The carriage is a copy of the one Niffy made and is carbon fibre/balsa composite.

How does it sound OMG I have never heard vinyl sound so quiet, background noise (stylus in groove) is extremely low, and clicks and pops are almost a thing of the past. Not quite digital quiet but the closest I've heard.

I summed this up in a few words - Bass response, dynamics and eerily quiet.

Is it perfect - No I still have some distortion on inner groove with some female voices, I'm working on this.

.

Here are few pics of the build.

The bridge was designed so I could change rails to different style if needed. The uprights have blocks with brass inserts running on 8mm linear shaft and are individually height adjustable.

The rail support is held to the blocks with m4 bolts that have 60deg points that hold in brass Vees. This allows a small amount of forward aft movement to fine tune the rail for tangent and a pivot that can be locked tight to enable to rail to pivot for leveling.

The carriage wheels are 1 piece aluminium with 2mm carbide wedding rings as tyres. It now uses Vee pivots the axles are made from 1.5mm drills with a 0.1mm radius and the Vees are m3 cup head grub screws that have a 0.5mm radius. The Vee's were forged in the grub screw with another drill ground to the correct radius.

The carriage is a copy of the one Niffy made and is carbon fibre/balsa composite.

How does it sound OMG I have never heard vinyl sound so quiet, background noise (stylus in groove) is extremely low, and clicks and pops are almost a thing of the past. Not quite digital quiet but the closest I've heard.

I summed this up in a few words - Bass response, dynamics and eerily quiet.

Is it perfect - No I still have some distortion on inner groove with some female voices, I'm working on this.

.

Attachments

-

P_20200205_143324.jpg688.2 KB · Views: 399

P_20200205_143324.jpg688.2 KB · Views: 399 -

P_20200114_120258.jpg953.2 KB · Views: 393

P_20200114_120258.jpg953.2 KB · Views: 393 -

P_20200208_170708.jpg577.9 KB · Views: 379

P_20200208_170708.jpg577.9 KB · Views: 379 -

P_20200226_095715.jpg600.5 KB · Views: 390

P_20200226_095715.jpg600.5 KB · Views: 390 -

P_20200615_092804.jpg577 KB · Views: 370

P_20200615_092804.jpg577 KB · Views: 370 -

P_20200615_092658.jpg574.4 KB · Views: 141

P_20200615_092658.jpg574.4 KB · Views: 141 -

P_20200615_092701.jpg697.6 KB · Views: 137

P_20200615_092701.jpg697.6 KB · Views: 137 -

P_20200627_124044.jpg599.7 KB · Views: 162

P_20200627_124044.jpg599.7 KB · Views: 162 -

P_20200627_124032.jpg607.4 KB · Views: 169

P_20200627_124032.jpg607.4 KB · Views: 169

Grab it while you can—they had full stock a month ago—the 10" is the best bang for buck I have found—fit and finish is top notch—I am comparing it to my SME IV. (Not sure if you are US or not—these guys are based in Canada—poke around and you will find their Canada site for intl shipping.) Jelco is out of business this year. It's too bad. In fact i have half a mind to pick up a 12" before the prices get nuts.

Audio Sensibility $US Store

Audio Sensibility $US Store

Attachments

Last edited:

Any recommendations for a less expensive tone arm for my SP-10? I’ve got an old Grace 714 wooden arm on it from the 80s!

I’ve gone for the old Audio Technica AT1503 mk.2 and mk.3. They can be found very cheap and sound incredible. Better than a Jelco SA750L or the SME’s I’ve owned.

Don't forget that the cartridge used will have great influence on arm choice...most low mass arms are totally unsuitable with low compliance cartridges - and visa versa!

You either choose can arm and then a cartridge to match, or choose the cartridge first and then the arm.

You either choose can arm and then a cartridge to match, or choose the cartridge first and then the arm.

Thanks [emoji4]@Mikeyb48 very beautifull your SP10II restored.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread