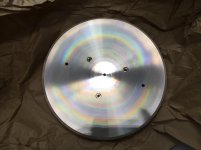

These were done by a local company called Titan machine. They have some TV reality show now about american made aerospace or something like that. This platter is easy compared to some of the things they do in exotic materials.

The MK 3 was a reference for us but the modified Mark 2 now is. Time to rework the 3.

The MK 3 was a reference for us but the modified Mark 2 now is. Time to rework the 3.

How important is the platter for any turntable? A better platter a better turntable?

Go to Titan America.

CNC Machine Shop located in Northern California | Titan America MFG

Go to Titan America.

CNC Machine Shop located in Northern California | Titan America MFG

A MKII with that platter, may both measure and sound better than the MKIII

Hi Wayne

Have you done any measurements at all ?

I have a MKIII here and the big difference is the platter. To be honest the electronics don't seem to be as good as the MKII. They used a simpler approach on the MKIII as the MKII was way too complex.

So it is quite possible that a MKII with that platter, may both measure and sound better than the MKIII ? and maybe better than anything past or present ?

My measurement lab is here How we test

My last article on Direct Drive is here http://www.soundhifi.com/FOURUMIMAGES/DC.pdf part II is the bit worth reading.

But I have a US Government Conference in Washington the week after next, everything will have to wait until after that. But with this information turning up, combined with my acquisition of an unmarked MKIII, it could be the turning point that we never expected ?

Thanks

Dave

Hi Wayne

Have you done any measurements at all ?

I have a MKIII here and the big difference is the platter. To be honest the electronics don't seem to be as good as the MKII. They used a simpler approach on the MKIII as the MKII was way too complex.

So it is quite possible that a MKII with that platter, may both measure and sound better than the MKIII ? and maybe better than anything past or present ?

My measurement lab is here How we test

My last article on Direct Drive is here http://www.soundhifi.com/FOURUMIMAGES/DC.pdf part II is the bit worth reading.

But I have a US Government Conference in Washington the week after next, everything will have to wait until after that. But with this information turning up, combined with my acquisition of an unmarked MKIII, it could be the turning point that we never expected ?

Thanks

Dave

Hi,

Dave, in Your article You say that "What made the SP-10 MkII special was cog free drive and a massive bearing. (p.102), and later on p.103 "The Direct Drive motor of the ‘1200 was almost identical to that of the SP-10 and was as near perfect and as cog free as it could be."

As I understand a slotted iron cored motor is not cog-free.

The amount of torque necessary to accelerate the platter so fast, requires a iron cored motor. Remark: compare for example to the Hall-commutated slotless and coreless DUAL motor EDS1000 et al.

There are of course means that reduce the amount of cogging as for example shown in the Matsushita patent: "Motor Core And Motor Using The Same", US6,774,524B2, Aug.10,2004.

I assume, that the associated electronics reduces any effect of the cogging to negligible values.

Unfortunately does googling for the White Paper of Yosumi San result in 0 hits.

Do You have the paper to share or a link?

Btw. there are papers from Pioneer called "The Tuning Fork".

Issues No. 2 and 5 contain valuable Information about DirectDrive Motors and the three basic speed control circuits (EMF-servo, FG-Servo, Quartz-PLL).

jauu

Calvin

Dave, in Your article You say that "What made the SP-10 MkII special was cog free drive and a massive bearing. (p.102), and later on p.103 "The Direct Drive motor of the ‘1200 was almost identical to that of the SP-10 and was as near perfect and as cog free as it could be."

As I understand a slotted iron cored motor is not cog-free.

The amount of torque necessary to accelerate the platter so fast, requires a iron cored motor. Remark: compare for example to the Hall-commutated slotless and coreless DUAL motor EDS1000 et al.

There are of course means that reduce the amount of cogging as for example shown in the Matsushita patent: "Motor Core And Motor Using The Same", US6,774,524B2, Aug.10,2004.

I assume, that the associated electronics reduces any effect of the cogging to negligible values.

Unfortunately does googling for the White Paper of Yosumi San result in 0 hits.

Do You have the paper to share or a link?

Btw. there are papers from Pioneer called "The Tuning Fork".

Issues No. 2 and 5 contain valuable Information about DirectDrive Motors and the three basic speed control circuits (EMF-servo, FG-Servo, Quartz-PLL).

jauu

Calvin

The platter makes the most significant upgrade to the sound of anything it is a huge difference. It is 17.5 Pounds about 8 Kilos.

Did you make any changes to the bearing (especially the thrust plate)? What does that increased mass do to bearing life?

The bearings are new and the electronics redone with caps etc. It may wear faster with the weight but probably not by much. We just have a half dozen or so of these around. They are cheap compared to some of the $50-100K stuff.

I haven't done any measurements but would like to, just need to figure out the equipment and see what Dave uses.

I do know somebody with lots of measurements of different tables I can talk to him and see what to look for. He makes very nice tables and knows his stuff.

I haven't done any measurements but would like to, just need to figure out the equipment and see what Dave uses.

I do know somebody with lots of measurements of different tables I can talk to him and see what to look for. He makes very nice tables and knows his stuff.

I use exactly the same testing methods as the magazine HiFi World, in fact I sourced some of their test equipment for them. When I'm measuring the MKII in two weeks time, it would be good to measure the new platter too ?

Many of the SP-10's I have seen, have had over 25 years of continuous service, that's nearly 1/4 million hours ! So a few hours a day in the home with a heavier platter isn't much at the end of the day ?

I could supply these "at cost" to diyaudio members of at least 6 months standing ?

Thanks

Dave

Many of the SP-10's I have seen, have had over 25 years of continuous service, that's nearly 1/4 million hours ! So a few hours a day in the home with a heavier platter isn't much at the end of the day ?

I could supply these "at cost" to diyaudio members of at least 6 months standing ?

Thanks

Dave

wayne,

How much does the platter cost? What is the platter made of? What information does Titan America need to make this platter. Some SP-10 owners may be interested in this platter.

I'm thinking that this is a perfect "group buy" opportunity, so that the NRE and setup can be amortized.

- Home

- Source & Line

- Analogue Source

- The Incredible Technics SP-10 Thread