Hi Warren, VTF increases as the cartridge raises.

I am happy that its not a terrible fault and it plays well, however i know from handling the BB version and the Mylar version of the parallelogram when there is no load on them that there is gradual spring increase as the Mylar flexes either way from flat at larger displacements, therefore there must be also at the real and smaller displacements. when i chose the material i thought that would be negligible but seems i was wrong!

Actually building these things teaches a lot about being wrong!

M

I am happy that its not a terrible fault and it plays well, however i know from handling the BB version and the Mylar version of the parallelogram when there is no load on them that there is gradual spring increase as the Mylar flexes either way from flat at larger displacements, therefore there must be also at the real and smaller displacements. when i chose the material i thought that would be negligible but seems i was wrong!

Actually building these things teaches a lot about being wrong!

M

Hi Eduard

i agree its better to increase than decrease but i am uncomfortable with the variation, i will seek a solution.

Now i need another solution, my new cart moves too easily.

I shall have to fit some brakes.

The anodised rails and Zro2 spheres move so easily that as i launch the cue mechanism the cart skids off in the distance, didn't happen before?!

I shall have to go back to the old one or fit some brakes now

What to do?

Mike

i agree its better to increase than decrease but i am uncomfortable with the variation, i will seek a solution.

Now i need another solution, my new cart moves too easily.

I shall have to fit some brakes.

The anodised rails and Zro2 spheres move so easily that as i launch the cue mechanism the cart skids off in the distance, didn't happen before?!

I shall have to go back to the old one or fit some brakes now

What to do?

Mike

Attachments

Hi Warren, VTF increases as the cartridge raises.

M

Hi Mike, it's better that VTF increases as a decrease in VTF as the cartridge raises is a sign that COM is above the pivot and this causes instability in vertical tracking.

Increase in VTF can also be causes by the COM being much lower than the vertical pivot and the pivot point not being directly over the stylus. IIRC your pivot is off to one side of the stylus.

Hi Mike, it's better that VTF increases as a decrease in VTF as the cartridge raises is a sign that COM is above the pivot and this causes instability in vertical tracking.

Increase in VTF can also be causes by the COM being much lower than the vertical pivot and the pivot point not being directly over the stylus. IIRC your pivot is off to one side of the stylus.

Thanks Warren,

I don't understand the physics of those things but here i can show what is happening on my set up.

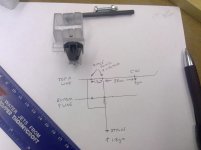

In the picture attached the fixed pivot line of my parallelogram warp acceptor is bang in line with the stylus, hence no lateral torque on that. one pic with mylar hinges (currently in use) and one with bearings in the same geometry but abandoned because of possibly rattily bearings and weight.

The position of the vertical pivot might be debatable as there are two, but with the cartridge below and the CW above one would guess its in the middle as well............?

Attachments

Hello guys

Just want to say and ask a question

Firstly, a ton of great ideas and work on this post. 99% is way over my skill set.

My question is this. Does anyone have a used tonearm, one that they would sell me on the cheap side? I don’t need anything fancy. Just one that I can build a mount for and have it next to my turntable motor . Here’s a photo of one that I want to use

And I have the said parts and motor for a 100% diy build

Also I’m in Florida and shipping is fine for me

I have a few carts and head shells for a tonearm

Thanks and sorry for jumping on this great diy build post

Just want to say and ask a question

Firstly, a ton of great ideas and work on this post. 99% is way over my skill set.

My question is this. Does anyone have a used tonearm, one that they would sell me on the cheap side? I don’t need anything fancy. Just one that I can build a mount for and have it next to my turntable motor . Here’s a photo of one that I want to use

And I have the said parts and motor for a 100% diy build

Also I’m in Florida and shipping is fine for me

I have a few carts and head shells for a tonearm

Thanks and sorry for jumping on this great diy build post

A problem i need some help with please.

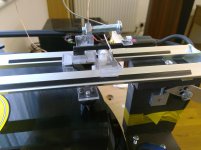

Following improvements to cart and rails the lateral friction is much reduced, levels and angles critical so i thought i would make more robust my rail mount and cueing device.

This remains a work in progress and i will soon develop a new arrangement, but i hope for some guidance in the right direction.

To set the scene, my TT is on a very rigid wall shelf made of a coupled layer damped plywood/rubber sandwich, it works really well with the normal arm and TT.

My lateral arm is clamped to this shelf, not the TT normal mount position.

It has always been evident that handling the arm and shelf induced a deep thudding noise.

As surface noise has reduced and i have made the connection of the arm to the shelf more rigid i am now hearing rumble at that same frequency on the lead in track.

I conclude i have successfully connected all the parts better as intended (!) and conducted that rumble to the cartridge, stylus and thence amplified it.

I tried some damping on the mount and that seemed to help a bit.

I don’t really want to start changing the shelf as it is very effective with the pivot arm set up, and seems to be right, what direction do i start?

Will making the arm mount more rigid make this worse or better?

Following improvements to cart and rails the lateral friction is much reduced, levels and angles critical so i thought i would make more robust my rail mount and cueing device.

This remains a work in progress and i will soon develop a new arrangement, but i hope for some guidance in the right direction.

To set the scene, my TT is on a very rigid wall shelf made of a coupled layer damped plywood/rubber sandwich, it works really well with the normal arm and TT.

My lateral arm is clamped to this shelf, not the TT normal mount position.

It has always been evident that handling the arm and shelf induced a deep thudding noise.

As surface noise has reduced and i have made the connection of the arm to the shelf more rigid i am now hearing rumble at that same frequency on the lead in track.

I conclude i have successfully connected all the parts better as intended (!) and conducted that rumble to the cartridge, stylus and thence amplified it.

I tried some damping on the mount and that seemed to help a bit.

I don’t really want to start changing the shelf as it is very effective with the pivot arm set up, and seems to be right, what direction do i start?

Will making the arm mount more rigid make this worse or better?

Attachments

Gents,

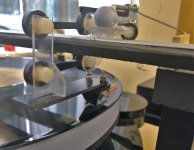

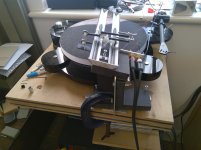

For less than £50 you can buy all the parts and have many spares left over for what seems to be a good radial rail TA, developed with input from many friends.

Pic attached.

You can make it look pretty with little effort, but imho it sounds great.

If someone wishes to build i will tell write an explanation sufficient for that.

Meanwhile i will continue to tap the brains on this site to develop further.

Comments or enthusiastic responses welcome!

M

For less than £50 you can buy all the parts and have many spares left over for what seems to be a good radial rail TA, developed with input from many friends.

Pic attached.

You can make it look pretty with little effort, but imho it sounds great.

If someone wishes to build i will tell write an explanation sufficient for that.

Meanwhile i will continue to tap the brains on this site to develop further.

Comments or enthusiastic responses welcome!

M

Attachments

enthusiasming! (my enthusiastic comment)

Jokes aside, Mike: you are doing a great innovative work, at great speed and always with great DIY spirit, but ... there is always a but.

50 £? including labor, I want to hope! but where will we end up, this way?

carlo

Good afternoon Carlo,

I am like everyone else when on a new road we don't know what is round the corner, so i cannot answer your question, but i am enthused by the idea that;

1. i can build something myself that works really well

2. I can make something that performs in the same realm as expensive commercially built items

3. This hobby doesn't break the bank, if i throw it away at the end it doesn't matter, but that's the only reason to limit the cost

4. It is an enthralling hobby that combines these things and

5. Allows me to enjoy listening to music in a different way than before, for example i was listening to Beethoven 6 this morning and it was probably the first time i have listened to that recording and grabbed my attention, made me smile.

So you have the journey and the destination.

Good news for me is that there are repeat iterations of both, where will it end, i guess it might not, so i have an enjoyable hobby long term, its always likely i can find something to improve.

My labour is not valuable ( look at the workmanship!) so £0 per hour, its £50 with or without!

My intention when mentioning the budget was to hope to encourage others to enjoy some of my points above and contribute to the thread.

I am currently wondering if my expenditure betters my mid level commercially purchased solution.

Now i am looking forward to finding out if your latest work delivers great results

Mike

the CorkScrew full radial tonearm

Well, it's done at last, almost.

The Corkscrew tracks ok, and passed my "crash test" (+ -1.5mm eccentricity + 3mm warp) smoothly. The cartridge cantilever is rather immobile, except for a slight compression at maximum warp; No skipping, not even giving a kick to the plinth ("hyper crash test").

But - there is always a but.

Vertical movement is better than feared, but it's hinge seems a bit too flexible for my tastes; maybe it can be stiffened, further improving the simmetric movement of the 2 arms without worsening too much the vertical articulation. So I can (no, have to) widen the "sandwich" holding the blade or probably even return to 2 blades, as in the original drawing (when I'll understand how the hell to cut them lengthwise, since are needed just two halves)

The carriage moves really well (you know what I mean) but has a mass similar to that of traditional carts (the damn CW on board) and it behaves like those with very low friction: that is, its inertia tends to push it beyond the eccentricity. Maybe without real consequences, but I don't like seeing it, maybe with the LC carts, weighing 1/3 of this one, I got used too well.

The comfort of use still leaves a lot to desire - I have to put a positioning bar (already previewed) on cart and prevent, with some end stoppers, the headshell from dropping down too much when the arm is raised

In short, a lot of details to improve (it is very different from what i have done so far) but knowing that it tracks correctly is already a good starting point, for a LTA.

carlo

drawings are re-posted due some dimensional changes, but more for a new lifter+rotation stop mechanism: now the lifter lifts up for 3-4 mm, and then rotates the rails 45° to change disc. a touch of luxury.

to resume the long Corkscrew genesis # 3762 - 3964 - 3975 - 4084 - 4144 - 4150 -

Well, it's done at last, almost.

The Corkscrew tracks ok, and passed my "crash test" (+ -1.5mm eccentricity + 3mm warp) smoothly. The cartridge cantilever is rather immobile, except for a slight compression at maximum warp; No skipping, not even giving a kick to the plinth ("hyper crash test").

But - there is always a but.

Vertical movement is better than feared, but it's hinge seems a bit too flexible for my tastes; maybe it can be stiffened, further improving the simmetric movement of the 2 arms without worsening too much the vertical articulation. So I can (no, have to) widen the "sandwich" holding the blade or probably even return to 2 blades, as in the original drawing (when I'll understand how the hell to cut them lengthwise, since are needed just two halves)

The carriage moves really well (you know what I mean) but has a mass similar to that of traditional carts (the damn CW on board) and it behaves like those with very low friction: that is, its inertia tends to push it beyond the eccentricity. Maybe without real consequences, but I don't like seeing it, maybe with the LC carts, weighing 1/3 of this one, I got used too well.

The comfort of use still leaves a lot to desire - I have to put a positioning bar (already previewed) on cart and prevent, with some end stoppers, the headshell from dropping down too much when the arm is raised

In short, a lot of details to improve (it is very different from what i have done so far) but knowing that it tracks correctly is already a good starting point, for a LTA.

carlo

drawings are re-posted due some dimensional changes, but more for a new lifter+rotation stop mechanism: now the lifter lifts up for 3-4 mm, and then rotates the rails 45° to change disc. a touch of luxury.

to resume the long Corkscrew genesis # 3762 - 3964 - 3975 - 4084 - 4144 - 4150 -

Attachments

Last edited:

the CorkScrew full radial tonearm

Vertical movement is better than feared, but it's hinge seems a bit too flexible for my tastes; (the damn CW on board) -

Carlo, can you kindly explain a little more the hinge mechanism? what i am seeing seems to have the flex part each side of the cartridge carrier plate and a counterweight outboard of the pivot, but the pivot itself and the brass weight in the hole confuse me.

Also is it equal resistance both sides that keeps verticality? in one photo (not completed) it is apparent that the cartridge is tipped, does it return vertical always by gravity and equilibrium?

As said for the previous prototypes, the CorkScrew is made up of 2 symmetrical normal CW arms, pivoted on blades, doing practically all the work in the usual way. The role of the flexible hinge is only to keep them aligned, and support the head shell. Being an elbow lever, its resistance is almost irrelevant for small angles.

The small counterweights are only for the fine tuning of the VTF (range 0 - 1/2 gr).

It is an extremely simple object. but also extremely difficult and delicate to build and improve properly for a diyer like me. While for a good, well equipped industry it could be a simple nylon single piece, molded with appropriate thickness hinges.

carlo

tipped? may be- but may also be a bit rotated - it's just the first rough shake down test, to see just if it tracks or not. Not a fine set up to listen, or to measure it

The small counterweights are only for the fine tuning of the VTF (range 0 - 1/2 gr).

It is an extremely simple object. but also extremely difficult and delicate to build and improve properly for a diyer like me. While for a good, well equipped industry it could be a simple nylon single piece, molded with appropriate thickness hinges.

carlo

tipped? may be- but may also be a bit rotated - it's just the first rough shake down test, to see just if it tracks or not. Not a fine set up to listen, or to measure it

Last edited:

tipped? may be- but may also be a bit rotated - it's just the first rough shake down test, to see just if it tracks or not. Not a fine set up to listen, or to measure it

Most probably even better news if it tracks fine without careful adjustment, nice and tolerant as well...

Good afternoon all, new lockdown here will probably lead to more TA experiments.

For now i have been in discussions for a while with fellow posters and implemented many ideas resulting from that.

Eventually I wondered if orienting the parallelogram warp accommodation movement that i use axially along the groove as proposed by them would work better than the transverse orientation i had adopted and dissociate the warp movement from the cart tracing and eccentrics.

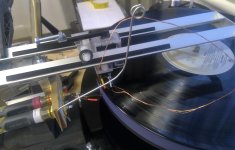

As per the pic you can see i have done that now, by using the old components that i made previously, but reassembled to wrap around the front rail.

Some parts remain a bit oversize and execution is not so neat.

However it tracks well and background noise is notably low, i have eliminated the bass resonance that was troubling me and it plays well.

You can see how i have kept the fixed pivot points in line with the stylus tip, wrapping the attachment pillar around the rail, there is some refinement available in the geometry, but its an interesting progress.

I would be interested in your feedback

Mike

For now i have been in discussions for a while with fellow posters and implemented many ideas resulting from that.

Eventually I wondered if orienting the parallelogram warp accommodation movement that i use axially along the groove as proposed by them would work better than the transverse orientation i had adopted and dissociate the warp movement from the cart tracing and eccentrics.

As per the pic you can see i have done that now, by using the old components that i made previously, but reassembled to wrap around the front rail.

Some parts remain a bit oversize and execution is not so neat.

However it tracks well and background noise is notably low, i have eliminated the bass resonance that was troubling me and it plays well.

You can see how i have kept the fixed pivot points in line with the stylus tip, wrapping the attachment pillar around the rail, there is some refinement available in the geometry, but its an interesting progress.

I would be interested in your feedback

Mike

Attachments

Dear all, I have silently followed this thread for some time and I'm absolutely thrilled with the advancements you all made on this path.

After building and enjoying for one year an air bearing linear TA and then (almost) building a Birch type tangential TA, you have made me start pondering on returning to the "first love" linear TA but this time on bearing balls

This concept is not new. I've seen it first some years ago but unfortunately, I can't locate it on Youtube anymore. It involved four steel balls rolling on two pairs of thick wire. The closest match I could find is this (which uses only two balls) diy tonearm + luxman l80 + sony turntable + shure m75 cartridge - YouTube.

Mike, to answer your feedback request, I really think THIS is the way to go. IMHO, it's much better to have the parallelogram along the grooves than across. As we all know, the parallelogram movement does not provide a perfect vertical movement but one following and arc centered at the bearings. It's much better to have this arc movement along the grooves than towards the groove walls.

After building and enjoying for one year an air bearing linear TA and then (almost) building a Birch type tangential TA, you have made me start pondering on returning to the "first love" linear TA but this time on bearing balls

This concept is not new. I've seen it first some years ago but unfortunately, I can't locate it on Youtube anymore. It involved four steel balls rolling on two pairs of thick wire. The closest match I could find is this (which uses only two balls) diy tonearm + luxman l80 + sony turntable + shure m75 cartridge - YouTube.

Mike, to answer your feedback request, I really think THIS is the way to go. IMHO, it's much better to have the parallelogram along the grooves than across. As we all know, the parallelogram movement does not provide a perfect vertical movement but one following and arc centered at the bearings. It's much better to have this arc movement along the grooves than towards the groove walls.

Dear all, I have silently followed this thread for some time and I'm absolutely thrilled with the advancements you all made on this path.

Mike, to answer your feedback request, I really think THIS is the way to go. IMHO,

Consty, great to see your reply.

I got really valuable contributions from various people to help me when i first started and ongoing but the thread had gone quiet. I keep in touch with some others who've been helpful and we thought it was because people didn't like these ideas.

I feel i should go on posting because the thread helped me so much.

Everyone goes to their various constructions and designs for different reasons and its great to be able to pick up other peoples work and use all or part of it.

I would urge anyone who reads these to contribute, having a great big design team out there is really useful.

So right now i am pretty convinced the rail and cart side i currently have is one good way to go, the orientation of the P is good but its execution needs further development. i am looking at better pivots for it.

Picture of slightly tidier latest version attached.

Also if anyone has further interest i have partly written a guide to Mikes arm with some explanations and reasons because one poster expressed interest to consider building it, if you would like that please send me a private message and i will copy you in, meanwhile i will keep working on that document and ask some friends to critique it.

All feedback very welcome,

M

Attachments

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm