Hi Warrjon,

Tool steel is considerably stiffer than carbon fibre. The main advantage of carbon fibre is its stiffness to weight ratio. Weight isn't important for the rail so the heavier stiffer material was preferred. Also the stiffest carbon fibre would be unidirectional which isn't very strong across the grain. The rail does have unidirectional carbon battons and the steel tubes as well as the tungsten carbide. The combination of the different materials will act to damp the bending of the rail making it very inert.

Niffy

Tool steel is considerably stiffer than carbon fibre. The main advantage of carbon fibre is its stiffness to weight ratio. Weight isn't important for the rail so the heavier stiffer material was preferred. Also the stiffest carbon fibre would be unidirectional which isn't very strong across the grain. The rail does have unidirectional carbon battons and the steel tubes as well as the tungsten carbide. The combination of the different materials will act to damp the bending of the rail making it very inert.

Niffy

Hi Carlo,

In your last post you said "The only thing that still does not convince me is the vertical articulation on the two bars".

The obvious choice would have been to use a knife edge rail and wheels with a V groove. As long as the edge of the knife is not so sharp as to cause the contact pressure to exceed the strength of the materials used the lateral friction should be very similar to that of my current rail system. The vertical friction would be reduced to almost nothing. It would seem sensible to aim for the lowest possible vertical friction but there is a problem with this approach.

As a record is being played the arm will want to bounce at the resonant frequency of the compliance/effective mass tuning, normally around 10hz. This is true of all types of arm be they linear or pivoted. The arm will naturally want to bounce in line with the main restorative force which in the case of our arms is gravity. This means that the arm tendency is to bounce vertically. This is made worse by the fact that warps can occur within an octave of the vertical tuning frequency and can excite this tendency. Eccentricity occurs 3-4 octaves below the lateral tuning frequency so don't tend to excite the arm to anywhere near the same degree.

Even though the bouncing is occurring outside of audio band it still has negative sonic effects most noticeably in speed stability due to stylus scrubbing. In order to control this bouncing the arm needs to be damped. More damping is required in the vertical plane.

With my arm the damping is applied by the friction in the bearings. With the knife edge you have very little friction vertically so very little damping vertically. You could apply the vertical damping by adding a silicone fluid damping trough. This type of damping system will also add lateral damping. The lateral friction of the bearing hasn't been reduced by using a knife edge so neither has its level of damping. By adding a silicone damping trough you will end up overdamping the arm laterally.

By using the rail and wheel profiles that I have chosen I have greater friction and therefore damping in the vertical plane. I think that I probably have the optimum level of damping with my current design. It is possible that using 3mm rods and 1.5mm wide wheels might be a bit better. These would reduce vertical friction by about 25%.

When using steel wheels on glass rods I found that a smaller radius edge to the wheel sounded very slightly better. You can only do so much prototyping so I used the smaller edge radius when I built the tungsten carbide wheels.

Niffy

In your last post you said "The only thing that still does not convince me is the vertical articulation on the two bars".

The obvious choice would have been to use a knife edge rail and wheels with a V groove. As long as the edge of the knife is not so sharp as to cause the contact pressure to exceed the strength of the materials used the lateral friction should be very similar to that of my current rail system. The vertical friction would be reduced to almost nothing. It would seem sensible to aim for the lowest possible vertical friction but there is a problem with this approach.

As a record is being played the arm will want to bounce at the resonant frequency of the compliance/effective mass tuning, normally around 10hz. This is true of all types of arm be they linear or pivoted. The arm will naturally want to bounce in line with the main restorative force which in the case of our arms is gravity. This means that the arm tendency is to bounce vertically. This is made worse by the fact that warps can occur within an octave of the vertical tuning frequency and can excite this tendency. Eccentricity occurs 3-4 octaves below the lateral tuning frequency so don't tend to excite the arm to anywhere near the same degree.

Even though the bouncing is occurring outside of audio band it still has negative sonic effects most noticeably in speed stability due to stylus scrubbing. In order to control this bouncing the arm needs to be damped. More damping is required in the vertical plane.

With my arm the damping is applied by the friction in the bearings. With the knife edge you have very little friction vertically so very little damping vertically. You could apply the vertical damping by adding a silicone fluid damping trough. This type of damping system will also add lateral damping. The lateral friction of the bearing hasn't been reduced by using a knife edge so neither has its level of damping. By adding a silicone damping trough you will end up overdamping the arm laterally.

By using the rail and wheel profiles that I have chosen I have greater friction and therefore damping in the vertical plane. I think that I probably have the optimum level of damping with my current design. It is possible that using 3mm rods and 1.5mm wide wheels might be a bit better. These would reduce vertical friction by about 25%.

When using steel wheels on glass rods I found that a smaller radius edge to the wheel sounded very slightly better. You can only do so much prototyping so I used the smaller edge radius when I built the tungsten carbide wheels.

Niffy

Hi Niffy, that feeling was because - for relevant angles - the support on the two bars becomes not symmetrical, apparently tending to slide lower. But I said also that things must be tried before judging: it's one of the few things learned by making various TAs. Hornets do fly, and some mechanical nonsenses of the past sound better than some perfect designs; who knows why.

Maybe I'm still nostalgic for my 3009 (cursed be the day when I swapped), but I still consider the knife-blade the most "musical" bearing. I tried to use it even vertically, on a magnet ...

Personally, I do not use damping, not even on my last unipivot. There is no need when masses and pivot are in the right place, but it took 3 of them built to learn that sometimes "xe péso el tacon del buso" as people say in Venice - the patch is worse than the hole.

Warrion, poltruded carbon fibre isn't always really straight: for the rail of the lil casey I had to roll a dozen tubes on the bench to find an acceptable one: the kite shop assistant was about to call a psychiatrist. HSS for tools is instead well rectified; but you certainly know this better than me

carlo

Maybe I'm still nostalgic for my 3009 (cursed be the day when I swapped), but I still consider the knife-blade the most "musical" bearing. I tried to use it even vertically, on a magnet ...

Personally, I do not use damping, not even on my last unipivot. There is no need when masses and pivot are in the right place, but it took 3 of them built to learn that sometimes "xe péso el tacon del buso" as people say in Venice - the patch is worse than the hole.

Warrion, poltruded carbon fibre isn't always really straight: for the rail of the lil casey I had to roll a dozen tubes on the bench to find an acceptable one: the kite shop assistant was about to call a psychiatrist. HSS for tools is instead well rectified; but you certainly know this better than me

carlo

Hello,

Im slowly building up the parts to make a Niffy arm.

I was thinking instead of using a toolsteel flat as the rail support could the whole support not be made as a channel? to make it alot more rigid. It would have to be deep enough to accomodate the counter weight.

Im slowly building up the parts to make a Niffy arm.

I was thinking instead of using a toolsteel flat as the rail support could the whole support not be made as a channel? to make it alot more rigid. It would have to be deep enough to accomodate the counter weight.

Warrion, poltruded carbon fibre isn't always really straight: for the rail of the lil casey I had to roll a dozen tubes on the bench to find an acceptable one: the kite shop assistant was about to call a psychiatrist. HSS for tools is instead well rectified; but you certainly know this better than me

carlo

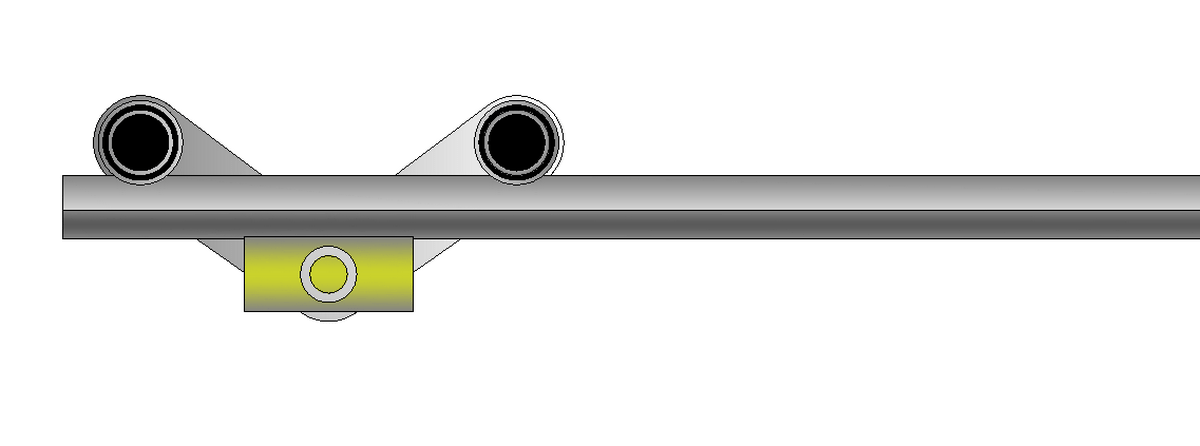

I've decided to use 316 flat bar for the rail base. This is available where I live in the size I need. HSS or O1 is difficult to get in the correct length. I am going to use 3x20mm and machine a 2mm deep channel down the centre for the tungsten rods to sit in.

Hello,

Im slowly building up the parts to make a Niffy arm.

I was thinking instead of using a toolsteel flat as the rail support could the whole support not be made as a channel? to make it alot more rigid. It would have to be deep enough to accomodate the counter weight.

I can see why Niffy did it the way he did, because bonding different materials will make the rail more inert. A bonded rail will still be very stiff, and the carbon fibre strip will provide some CLD.

If the rail was a single piece of say stainless steel channel it would ring.

Sapphire Vees

Hi Niffy,

I'm very thankful for all the work you've put into this fantastic thread! I'm now scheming my second Linear arm based on yours.

The quote above is from 2016 page 217.

The True Point web site shows tips similar to your 2016 post. But, I don't see any 0.25mm radius Vee's on Amazon right now. Is it the ratio of tip to cup that counts? (i.e 1:2 ?) Any suggested sources for the Vee's in any suitable size?

Thanks,

Hugh

Hi all, ....

One important point. The pivots have a tip radius of 0.125mm and the vees a cup radius of 0.25mm. I would recommend not changing this.

The pivots were purchased from true point in GB. The vees were purchased from small parts, part of Amazon in the US. The vees are actually metric but are in inches on the Amazon website.

I hope this helps.

Niffy

Hi Niffy,

I'm very thankful for all the work you've put into this fantastic thread! I'm now scheming my second Linear arm based on yours.

The quote above is from 2016 page 217.

The True Point web site shows tips similar to your 2016 post. But, I don't see any 0.25mm radius Vee's on Amazon right now. Is it the ratio of tip to cup that counts? (i.e 1:2 ?) Any suggested sources for the Vee's in any suitable size?

Thanks,

Hugh

Hi Hugh,

I've just had a quick look and can't find anyone on either amazon or eBay currently selling any jeweled bearing components. Even true point don't seem to be listing any other than the replacement for the pink triangle main bearing which is probably a bit big for this application. They didn't have any pivots that I could see. It might be worth contacting them directly to see if they can help. Most of the other suppliers, like bird, only seem to have trade accounts.

Sorry I can't be of much help. I'll keep an eye open for any other suppliers and let you know if anything shows up.

Niffy

I've just had a quick look and can't find anyone on either amazon or eBay currently selling any jeweled bearing components. Even true point don't seem to be listing any other than the replacement for the pink triangle main bearing which is probably a bit big for this application. They didn't have any pivots that I could see. It might be worth contacting them directly to see if they can help. Most of the other suppliers, like bird, only seem to have trade accounts.

Sorry I can't be of much help. I'll keep an eye open for any other suppliers and let you know if anything shows up.

Niffy

I highly recommend Niffy's style linear arm. However, I personally prefer angle rail. In my opinion, angle rail provides consistent damping in the vertical plane. Round bar rail may not provide same damping as angle rail due to the size of round bars and thickness of the wheels.

Another thing is very important, too. On Niffy's arm, the carriage won't drop off the rail due to a protection mechanism. If you want to copy Niffy's arm, you need to add a protection mechanism, too. Otherwise, it is very dangerous for your cartridge. I made a ball bearing and glass tube linear arm a long time ago. The carriage dropped off the glass rail on a running table. It almost destroyed my $2000 ZYX cartridge. This was why I changed the rail to Clear Audio kind and never want to make glass tube rail again.

Another thing is very important, too. On Niffy's arm, the carriage won't drop off the rail due to a protection mechanism. If you want to copy Niffy's arm, you need to add a protection mechanism, too. Otherwise, it is very dangerous for your cartridge. I made a ball bearing and glass tube linear arm a long time ago. The carriage dropped off the glass rail on a running table. It almost destroyed my $2000 ZYX cartridge. This was why I changed the rail to Clear Audio kind and never want to make glass tube rail again.

Attachments

I was googling for bearings and found this supplier and a bearing in the search function (3x8x4mm , abec-7).

SMR693C-ZZ #7 LD by Boca Bearings :: Ceramic Bearing Specialists

Prices around 20$ each + ? + ? + ?

Just found it so if someone else who has better knowledge what to look for.....

Edit: Went (almost) through checkout and it settled @ 96$ for 4pc incl shipping to Sweden

SMR693C-ZZ #7 LD by Boca Bearings :: Ceramic Bearing Specialists

Prices around 20$ each + ? + ? + ?

Just found it so if someone else who has better knowledge what to look for.....

Edit: Went (almost) through checkout and it settled @ 96$ for 4pc incl shipping to Sweden

Last edited:

Where would I find some info about air bearings? I want to try and replace air with some type of oil. With a engine, the oil makes it so that the steel and bearing don’t even touch each other and help keep it cool

That way you can have a gap in between the bearings and no need for a loud air pump

You would only need a 1/4lbs of pressure or less

If someone has tried this please let me know

Thanks

Carl

That way you can have a gap in between the bearings and no need for a loud air pump

You would only need a 1/4lbs of pressure or less

If someone has tried this please let me know

Thanks

Carl

Where would I find some info about air bearings? I want to try and replace air with some type of oil. With a engine, the oil makes it so that the steel and bearing don’t even touch each other and help keep it cool

That way you can have a gap in between the bearings and no need for a loud air pump

You would only need a 1/4lbs of pressure or less

If someone has tried this please let me know

Thanks

Carl

It is not a good idea since oil has resistance. In addition to that, it is not easy to seal oil. You create an even bigger problem than an air pump.

I was googling for bearings and found this supplier and a bearing in the search function (3x8x4mm , abec-7).

SMR693C-ZZ #7 LD by Boca Bearings :: Ceramic Bearing Specialists

Prices around 20$ each + ? + ? + ?

I used these

ABU REPLACEMENT 4 X 9 X 4 CERAMIC BEARINGS ABEC 9'S | eBay

I highly recommend Niffy's style linear arm. However, I personally prefer angle rail. In my opinion, angle rail provides consistent damping in the vertical plane. Round bar rail may not provide same damping as angle rail due to the size of round bars and thickness of the wheels.

Another thing is very important, too. On Niffy's arm, the carriage won't drop off the rail due to a protection mechanism. If you want to copy Niffy's arm, you need to add a protection mechanism, too. Otherwise, it is very dangerous for your cartridge. I made a ball bearing and glass tube linear arm a long time ago. The carriage dropped off the glass rail on a running table. It almost destroyed my $2000 ZYX cartridge. This was why I changed the rail to Clear Audio kind and never want to make glass tube rail again.

Hi Super10018,

That angle rail looks appealing too. I will likely try to build something that lets me try all three styles.

What did you use for the angle rail and where did you buy it?

How did you cut the Boroscillicate tubing?

I'm guessing you described these in earlier posts, so how far back? I don't wish to make you re-type it all.

Thanks for the tips!

Hugh

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm