Ever thought about titanium Joe ? its non magnetic, doesn't corrode and the aerospace grade 6ALV barstock is pretty dimensionally constant with a surface finish which is quite good. Would be roughly a third of the cost of tungsten carbide.

trading hardness for a smoother surface is not a good trade in my opinion. The performance of the arm design with a Pyrex tube is already above just about any arm money can buy. It is the hard glass which provides the improved performance due to the low friction. If you are looking to run in the tube I suppose that you could hone the tube without much trouble if you really wanted to. Flat window glass could be lapped one piece on another to a precision surface without a lot of trouble. In this way a very fine open bottom "V" could be made and you could experiment with any angle you like with steeper being better IMO. This could just as easily be flipped over and you could run on the outside. A tube is not necessary. Hope this is of interest. Best regards Moray James.

Hi.

Siddley:

I am sure you could use titanium without hurting the design. But why settle for a Yugo when you can have a Mercedes. Both will drive you from point A to point B ( at least most of the time ha,ha). You could probably use hard anodized precision aluminum tubing. To do a proper job imho using titanium or aluminum you would have to machine/grind/polish to make sure it is straight with a nice finish. The carbide rod I have now is precision ground and polished within .0005 with a mirror finish. No need to look any further for me.

Life is short, I am not going to "cheap" out for a couple of dollars in materials. I figure it may cost me $200 or so in materials but this arm should rival the performance of tonearms that cost thousands. Still a bargain in my book. I realize this just a passing experiment for some folks here and that is fine. Not everyone can spend lots of money on a project like this. I am in the process of finishing off a 4 way horn system and home theater room so when The time come I will give this arm a serious try.

Joe

Siddley:

I am sure you could use titanium without hurting the design. But why settle for a Yugo when you can have a Mercedes. Both will drive you from point A to point B ( at least most of the time ha,ha). You could probably use hard anodized precision aluminum tubing. To do a proper job imho using titanium or aluminum you would have to machine/grind/polish to make sure it is straight with a nice finish. The carbide rod I have now is precision ground and polished within .0005 with a mirror finish. No need to look any further for me.

Life is short, I am not going to "cheap" out for a couple of dollars in materials. I figure it may cost me $200 or so in materials but this arm should rival the performance of tonearms that cost thousands. Still a bargain in my book. I realize this just a passing experiment for some folks here and that is fine. Not everyone can spend lots of money on a project like this. I am in the process of finishing off a 4 way horn system and home theater room so when The time come I will give this arm a serious try.

Joe

Point taken gentlemen, I'm just throwing ideas around.

Moray - the amateur telescope making guys can actually lap glass to accuracies which are measured in fractions of the wavelength of light, so I'm sure there is a lot of merit in your suggestion.

Siddley,

Last night I set up some 9" ground steel parallels on a surface plate and positioned a dial indicator to measure for out of round, bow and any irregularities which could show up. Rolling the 10mm glass tube on the surface plate did show up the out of roundness and that measured no more than .002 inches. The same was true for bow over the 9" length. All deviations were smooth and gradual. IMO it will be impossible to hear any effect on musik playback.

Friction is something which I feel is thrown around with reckless abandon and really it shows a great lack of knowledge. My own lack of knowledge

included. So I took a good look at the Wikipedia entries. May I suggest that all the folks involved in this project spend some time learning about friction and all its types. Very enlightening and a better understanding of the subject will answer a lot of questions and clear up some misunderstandings.

BillG

Siddley,

Last night I set up some 9" ground steel parallels on a surface plate and positioned a dial indicator to measure for out of round, bow and any irregularities which could show up. Rolling the 10mm glass tube on the surface plate did show up the out of roundness and that measured no more than .002 inches. The same was true for bow over the 9" length. All deviations were smooth and gradual. IMO it will be impossible to hear any effect on musik playback.

BillG

Great stuff, no arguing with that. I think I'll return to just lurking on this thread for now because I'm not sure I'm helping

much.

Hi.

Siddley:

I am sure you could use titanium without hurting the design. But why settle for a Yugo when you can have a Mercedes. Both will drive you from point A to point B ( at least most of the time ha,ha). You could probably use hard anodized precision aluminum tubing. To do a proper job imho using titanium or aluminum you would have to machine/grind/polish to make sure it is straight with a nice finish. The carbide rod I have now is precision ground and polished within .0005 with a mirror finish. No need to look any further for me.

Life is short, I am not going to "cheap" out for a couple of dollars in materials. I figure it may cost me $200 or so in materials but this arm should rival the performance of tonearms that cost thousands. Still a bargain in my book. I realize this just a passing experiment for some folks here and that is fine. Not everyone can spend lots of money on a project like this. I am in the process of finishing off a 4 way horn system and home theater room so when The time come I will give this arm a serious try.

Joe

The real question is will what you are doing make any REAL measurable difference in the sound that you can actually perceive? If that floats your boat, go for it.

Hi,

bgruhn:

Wow that is good news, that glass tubing is definitely good for this project. I cut some 17mm pyrex test tubes I had and found a .002 to ,003 run out which would also be good. I guess it depends on who makes the glass and where it comes from. It is a good idea to check or have checked the tubing you are going to use.

Joe

bgruhn:

Wow that is good news, that glass tubing is definitely good for this project. I cut some 17mm pyrex test tubes I had and found a .002 to ,003 run out which would also be good. I guess it depends on who makes the glass and where it comes from. It is a good idea to check or have checked the tubing you are going to use.

Joe

Hi:

Lexx21:

That is the $64,000 question ( I am showing my age ).

If your system is hi-rez enough you can tell the difference between tonearms fairly easily. In this particular case I have not built this arm yet so I can not say.

What I can say is I can hear the difference between copper wound output transformers and silver wound transformers. The differences between various 45, 2a3, 300b output tubes is also pretty easy to hear. The main question is if what you are hearing is actually better or just different---which maybe totally subjective. Most of the times the differences are subtle and sometimes they are not. For 80 percent of the people the differences don't mean a thing. Most young people today are happy with the sound of their I-Pod and that is fine with me. I will stick with my 4 way horn system using a mix Tad and field coil drivers. That floats my boat !!!!

Joe

Lexx21:

That is the $64,000 question ( I am showing my age ).

If your system is hi-rez enough you can tell the difference between tonearms fairly easily. In this particular case I have not built this arm yet so I can not say.

What I can say is I can hear the difference between copper wound output transformers and silver wound transformers. The differences between various 45, 2a3, 300b output tubes is also pretty easy to hear. The main question is if what you are hearing is actually better or just different---which maybe totally subjective. Most of the times the differences are subtle and sometimes they are not. For 80 percent of the people the differences don't mean a thing. Most young people today are happy with the sound of their I-Pod and that is fine with me. I will stick with my 4 way horn system using a mix Tad and field coil drivers. That floats my boat !!!!

Joe

Maybe another material which is possible :

ROD10/200-4B1 - FERROXCUBE - FERRITE CORE, CYLINDRICAL | element14 Australia

The ferroxcube rod.

I don't know the geometrical accuracy nor finish, but it is cheap, easily available and it has a very hard skin.

ROD10/200-4B1 - FERROXCUBE - FERRITE CORE, CYLINDRICAL | element14 Australia

The ferroxcube rod.

I don't know the geometrical accuracy nor finish, but it is cheap, easily available and it has a very hard skin.

What am I missing here. What exactly is the problem with the glass tubing? When we talk tolerance of other materials along what dimension are we referring? Why is glass inferior? Most standard tubing is actually smoother than a super machined surface or mechanically polished surface on a dimension which will impact friction.

Want precision dimensions contact a tubing supplier or go to a local university with a decent size chem research group. Their glass blower can hook you up with good stuff that probably can exceed expectations.

The truth is this arm, as designed by the OP is 1) VERY easy to build 2) VERY cheap 3) uses material that is easy to find and 4) Most Importantly sounds STUPID GOOD for the effort. The ideal DIY project.

This arm, as designed by the OP, is on par with some top arms out there. I have a TriPlaner VI on a Blank Onyx TT. And this arm with a Denon 103r on a homemade TT (aka the Phoenix posted on this site) sounds good enough to be on my main system.

My suggestion is to build it as designed, (no loss in trying), and then upgrade as you see fit, evaluating each of the changes. It will make you smile as you do. This way you can be listening to some pretty good music while you build the ultimate arm of your dreams. The original design and materials are a pretty good match and in my honest opinion what make this arm what is is.

Happy Listening

Want precision dimensions contact a tubing supplier or go to a local university with a decent size chem research group. Their glass blower can hook you up with good stuff that probably can exceed expectations.

The truth is this arm, as designed by the OP is 1) VERY easy to build 2) VERY cheap 3) uses material that is easy to find and 4) Most Importantly sounds STUPID GOOD for the effort. The ideal DIY project.

This arm, as designed by the OP, is on par with some top arms out there. I have a TriPlaner VI on a Blank Onyx TT. And this arm with a Denon 103r on a homemade TT (aka the Phoenix posted on this site) sounds good enough to be on my main system.

My suggestion is to build it as designed, (no loss in trying), and then upgrade as you see fit, evaluating each of the changes. It will make you smile as you do. This way you can be listening to some pretty good music while you build the ultimate arm of your dreams. The original design and materials are a pretty good match and in my honest opinion what make this arm what is is.

Happy Listening

Attachments

That 0.002" deviation? is that with the tubing on the flat surface, end to end?

Suggest hanging one end OFF the end of the precision flat by an inch or so and seeing if the deviation is in the center of the tubing or because of the way it is made or cut and held at the ends??

I would think light shining from the rear and looking at the edge on the flat would tell the story visually.

IF the thing is bowed like a mild parabola it might impact the tracking at the center as it would look like a mild "uphill". Otoh if these are merely surface undulations, maybe not much of an issue.

Titanium or other solid rod will have some ringing issues, and may be harder to damp than a hollow rod or tube. Just a thought.

Suggest hanging one end OFF the end of the precision flat by an inch or so and seeing if the deviation is in the center of the tubing or because of the way it is made or cut and held at the ends??

I would think light shining from the rear and looking at the edge on the flat would tell the story visually.

IF the thing is bowed like a mild parabola it might impact the tracking at the center as it would look like a mild "uphill". Otoh if these are merely surface undulations, maybe not much of an issue.

Titanium or other solid rod will have some ringing issues, and may be harder to damp than a hollow rod or tube. Just a thought.

Hi,

bear :

It is funny that you mention how the deviations were measured. You are right on point.

This morning I took the samples of the tubing I have on hand and put into a Hardidge 5c collet and hand spun them in my lathe. The results were not pretty !!!! It was like spinning a " banana ", you did not need a dial indicator to see what was going on. I would not use any of these tubes for this project. Period.

Not only that, but visible distortion while shining a light through the tubes and a newspaper placed behind the tube was obvious. Most people here do not have the ability to measure their tubes but this a critical part of this arm. Some people here think this extreme but I beg to differ. I believe tube quality will separate a " very good arm " that " works " from an excellent arm.

When molten glass is extruded gravity will take its toll.

SGregory:

There is nothing wrong using glass tubing so long as the tube is round and straight and as a matter of fact it is a great choice if properly checked. You can not assume this with a casual look.

The Tri-planer is one of the best arms out there. I listened to one for a couple of months and can borrow one anytime for the asking. I spoke with Mr.Tai Mai at the Rocky Mountain Audiofest for about a half hour last year about the construction of his arm. He said the most important thing about his arm was the super quality of the bearings used and claimed they were aero-space quality and almost impossible to buy and I believe him. I tried to measure for any bearing deviation in my friends Tri-planer arm and was unable to because the bearing were better then my measuring equipment I have.

You mentioned " Good enough " Most people would say that a properly tuned Rega arm is " good enough ". The Tri-planer arm you have does not have bearing that are " good enough " they are superb !!! And that is one reason why people pick this arm over others and are willing to pay for it.

Joe

bear :

It is funny that you mention how the deviations were measured. You are right on point.

This morning I took the samples of the tubing I have on hand and put into a Hardidge 5c collet and hand spun them in my lathe. The results were not pretty !!!! It was like spinning a " banana ", you did not need a dial indicator to see what was going on. I would not use any of these tubes for this project. Period.

Not only that, but visible distortion while shining a light through the tubes and a newspaper placed behind the tube was obvious. Most people here do not have the ability to measure their tubes but this a critical part of this arm. Some people here think this extreme but I beg to differ. I believe tube quality will separate a " very good arm " that " works " from an excellent arm.

When molten glass is extruded gravity will take its toll.

SGregory:

There is nothing wrong using glass tubing so long as the tube is round and straight and as a matter of fact it is a great choice if properly checked. You can not assume this with a casual look.

The Tri-planer is one of the best arms out there. I listened to one for a couple of months and can borrow one anytime for the asking. I spoke with Mr.Tai Mai at the Rocky Mountain Audiofest for about a half hour last year about the construction of his arm. He said the most important thing about his arm was the super quality of the bearings used and claimed they were aero-space quality and almost impossible to buy and I believe him. I tried to measure for any bearing deviation in my friends Tri-planer arm and was unable to because the bearing were better then my measuring equipment I have.

You mentioned " Good enough " Most people would say that a properly tuned Rega arm is " good enough ". The Tri-planer arm you have does not have bearing that are " good enough " they are superb !!! And that is one reason why people pick this arm over others and are willing to pay for it.

Joe

duran-group precision-bore-tubing

We manufacture our precision bore tubing with optimal precision by heating glass tubes and vacuum heat shrinking them onto precision mandrels.

This technique enables the DURAN Group to manufacture precision bore tubing with a defined inside diameter with the smallest possible tolerances in the micrometre (μm) range.

We manufacture our precision bore tubing with optimal precision by heating glass tubes and vacuum heat shrinking them onto precision mandrels.

This technique enables the DURAN Group to manufacture precision bore tubing with a defined inside diameter with the smallest possible tolerances in the micrometre (μm) range.

Hi,

You mentioned " Good enough " Most people would say that a properly tuned Rega arm is " good enough ". The Tri-planer arm you have does not have bearing that are " good enough " they are superb !!! And that is one reason why people pick this arm over others and are willing to pay for it.

Joe

If I understand the OP's intention. The ideas was that you obtain better than "good enough" with basic available materials that don't break the bank, easy to assemble, and don't require a ultra precision aerospace machine shop to construct.

After building this arm I can can attest that one does not have to pursue the "HOLY Grail" in order to achieve better than good enough results. Where one takes it is their choice. But HAVING BUILT ONE and comparing to a great arm, I want to encourage people that have a more frugal DIY mind to build this and not fear splitting 0.002" as a failure in design or criteria to be successful.

This arm works Great, not average, as originally designed. That is just my 0.02c. And no I don't want to discredit those in pursuit of perfection. I have that bug too

Last edited:

Wow things are heating up  ,

,

I'd say if those want to go with aerospace, or NASA shuttle materials that is definately their choice . However as SGregory has very correctly stated that for little money involved one has a chance to build a DIY linear arm that will work very well and easily slay as designed and of those Regas and mid level audiophile arms, since I haven't heard the upper end I cannot comment there. I can say it does what any great arm should do, easily wipe the floor on a good pressing of its cd equivalent

. However as SGregory has very correctly stated that for little money involved one has a chance to build a DIY linear arm that will work very well and easily slay as designed and of those Regas and mid level audiophile arms, since I haven't heard the upper end I cannot comment there. I can say it does what any great arm should do, easily wipe the floor on a good pressing of its cd equivalent  .

.

Colin

I'd say if those want to go with aerospace, or NASA shuttle materials that is definately their choice

Colin

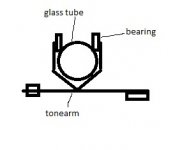

This thread has been very inspiring. While reading it twice I was wondering about the way the bearing->tonearm connection is made. This is similar to the Cantus tonearm, basicly the connecting T-bar+bearing is a C-shape. That form is a must in the Cantus because the bearing is inside the glass tube. Now with this 4-bearing design, doesn't the bearing on the side of the "T-bar" take more/most of the stress of the weight.

This C-shape of course makes it easier to remove the tonearm from the glass tube for more fiddling, but it also makes me a bit scared that a clumsy user, like me, could drop the whole structure off of the glass tube.

So, how about a U-shape structure like in the attached drawing? This woud prevent the dropping of tonearm and it would give all 4 bearings same load.

Although not in the image, you still could make the bearing assembly with the brass shim etc. like the original desing has.

I hope somebody undestood...

This C-shape of course makes it easier to remove the tonearm from the glass tube for more fiddling, but it also makes me a bit scared that a clumsy user, like me, could drop the whole structure off of the glass tube.

So, how about a U-shape structure like in the attached drawing? This woud prevent the dropping of tonearm and it would give all 4 bearings same load.

Although not in the image, you still could make the bearing assembly with the brass shim etc. like the original desing has.

I hope somebody undestood...

Attachments

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm