"provando e riprovando"

it's since Galileo times that revealed truths have no longer been liked: whoever affirms something must prove it with experiments and, by fully publishing his materials, enable others to repeat them, to validate or refute.

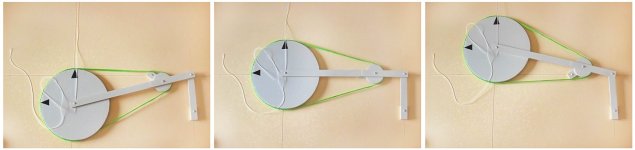

Not being able to replicate the simulation #5037 of the linear movement despite some hints from Alighiszem (mine are all locking on the horizontal) i went back to the dear old wooden mockups of the past.

The string test confirms that the mechanism works fine with the Side Force (no lock up -some variable traction) while it it doesn't start at all with the Stylus Drag, totally dissipating it

I've also completed the Twin Peaucellier mockup with the two strings of the simulation #5029, and it works smoothly: string tension is ok, no lever needed. Sooner or later i'll have to build a working prototype...

carlo

Trying to better understand the vector breakdown I made this lever version simulation, for those allergic to pulleys...

it's since Galileo times that revealed truths have no longer been liked: whoever affirms something must prove it with experiments and, by fully publishing his materials, enable others to repeat them, to validate or refute.

Not being able to replicate the simulation #5037 of the linear movement despite some hints from Alighiszem (mine are all locking on the horizontal) i went back to the dear old wooden mockups of the past.

The string test confirms that the mechanism works fine with the Side Force (no lock up -some variable traction) while it it doesn't start at all with the Stylus Drag, totally dissipating it

I've also completed the Twin Peaucellier mockup with the two strings of the simulation #5029, and it works smoothly: string tension is ok, no lever needed. Sooner or later i'll have to build a working prototype...

carlo

Trying to better understand the vector breakdown I made this lever version simulation, for those allergic to pulleys...

Attachments

The double Peaucellier cell is overdetermined. .... #5030

Alighiszem is always generous of precious hints, but for me it is not that easy to understand which ones.

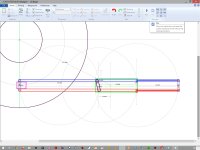

Reducing joints&levers meant imprecision, and an almost impossible TA to build up; but - waiting for 2 dozen chinese BBs - a doubt came up: do we really need mathematical precision? eliminating some joints could be much more practical.

Playing with simulations #5029 and #5042 now lots of pieces are left over like when dismantling toys; the geometry has to be tuned too, but N°3 starts looking a tonearm..

have fun - carlo

Alighiszem is always generous of precious hints, but for me it is not that easy to understand which ones.

Reducing joints&levers meant imprecision, and an almost impossible TA to build up; but - waiting for 2 dozen chinese BBs - a doubt came up: do we really need mathematical precision? eliminating some joints could be much more practical.

Playing with simulations #5029 and #5042 now lots of pieces are left over like when dismantling toys; the geometry has to be tuned too, but N°3 starts looking a tonearm..

have fun - carlo

Attachments

I showed in #5011 which parts are not needed.The double Peaucellier cell is overdetermined. .... #5030

Alighiszem is always generous of precious hints, but for me it is not that easy to understand which ones.

This is more than a hint.

And for that I thanked you, just as previously I congratulated you on the brilliant geometries with pulleys (and every time i met remarkable projects from others from which to learn).

The difference is that I try to design tone arms that can be built and work, these attempts try to go on that path. Hoping someone could be interested to that goal too

c

The difference is that I try to design tone arms that can be built and work, these attempts try to go on that path. Hoping someone could be interested to that goal too

c

This is an absolutely intriguing subject and i can sometimes keep up with developments, so for me, full and clear explanations are wonderful and most helpful, thanks all.

By the way Alighiszem, what deck and arm do you use, did you do a self build, this may be apparent somewhere else but i haven't seen it, many thanks, mike

By the way Alighiszem, what deck and arm do you use, did you do a self build, this may be apparent somewhere else but i haven't seen it, many thanks, mike

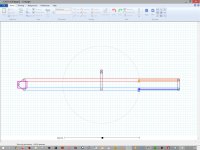

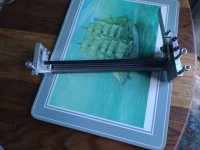

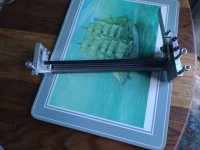

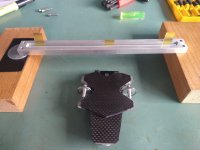

after #5044 simulation tuning, back to reality

..more than a mockup, (much) less than a prototype...

but equally surprising, because also done in this rough way with aluminum rivets on wooden bearings (!) this gadget doesn't skip, and bypasses the +1,5 -1,5 mm eccentric test - not trivial even for many Cantus clones LTAs. Of course with visible cantilever bending, but without skipping the AT 95 with 2.0 gr VTF. - Attachment 1, 2

Also the geometry is near perfect - the pencil lead tracing shows a nice straight line. - Attachment 3

Frankly I hadn't hopes for it, so I was laughing alone while wondering about that behavior, like when seeing first time the radial rail in action.

What would Monsieur Peaucellier think after 150 years? Maybe that this lame son spoils the beauty of his perfect mathematical achievement, but will the same be able to earn an honest living playing vinyl.

Thanks for your patience - c

if someone is interested i may collect some infos about geometry tuning - forces in action - tests observation/thoughts for a serious design and realization of such a nowheels true linear.

..more than a mockup, (much) less than a prototype...

but equally surprising, because also done in this rough way with aluminum rivets on wooden bearings (!) this gadget doesn't skip, and bypasses the +1,5 -1,5 mm eccentric test - not trivial even for many Cantus clones LTAs. Of course with visible cantilever bending, but without skipping the AT 95 with 2.0 gr VTF. - Attachment 1, 2

Also the geometry is near perfect - the pencil lead tracing shows a nice straight line. - Attachment 3

Frankly I hadn't hopes for it, so I was laughing alone while wondering about that behavior, like when seeing first time the radial rail in action.

What would Monsieur Peaucellier think after 150 years? Maybe that this lame son spoils the beauty of his perfect mathematical achievement, but will the same be able to earn an honest living playing vinyl.

Thanks for your patience - c

if someone is interested i may collect some infos about geometry tuning - forces in action - tests observation/thoughts for a serious design and realization of such a nowheels true linear.

Attachments

Thanks Alighiszem: maybe a first step, but the road is still long... and crowded with bearings.

String test - sure, it's mainly done for that. Confirms the favorable simulations in Algodoo: the SD behavior is complex, I'll talk about it after further checks

CW + vert. articulation- the answer in the drawings #5048; in the mockup there is a brass Cw simply glued under the main body, and a small VTF tuning on the rear.

Hoecken or who knows - I once compared we TA diyers to potato peeler inventors: there's nothing to invent in mechanics, just to see the solutions right under our nose: a bit like the famous A. Poe's "Purloined letter"

ciao - carlo

String test - sure, it's mainly done for that. Confirms the favorable simulations in Algodoo: the SD behavior is complex, I'll talk about it after further checks

CW + vert. articulation- the answer in the drawings #5048; in the mockup there is a brass Cw simply glued under the main body, and a small VTF tuning on the rear.

Hoecken or who knows - I once compared we TA diyers to potato peeler inventors: there's nothing to invent in mechanics, just to see the solutions right under our nose: a bit like the famous A. Poe's "Purloined letter"

ciao - carlo

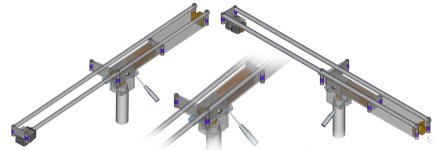

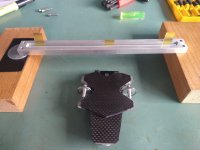

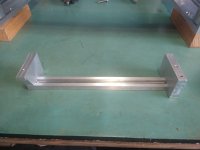

Here made a new version (thanks Carlo again!), wider carriage for lighter counter weight, total 28g without cart.

Using anodized rails (polished) and abec-9 bearing, wiring from kabusa.

Using anodized rails (polished) and abec-9 bearing, wiring from kabusa.

Attachments

Thanks to you for trusting again my "strange" tonearms.

Nice realization and flawless tracing on eccentric - a quite difficult test for best usual linear trackers too.

Cables seem a bit too thick, imo - try very thin enameled wire (from small inductor/tx from old PC boards on neon lamps)

Are Abec 9 BB ok? no play? it's a practical question because i'm going to use too many on this new "nowheels" linear experiment

c

ps - EASY P - short lever seems to work ok.

Nice realization and flawless tracing on eccentric - a quite difficult test for best usual linear trackers too.

Cables seem a bit too thick, imo - try very thin enameled wire (from small inductor/tx from old PC boards on neon lamps)

Are Abec 9 BB ok? no play? it's a practical question because i'm going to use too many on this new "nowheels" linear experiment

c

ps - EASY P - short lever seems to work ok.

Thanks Carlo, don't have same skill so trying best to make it easy

The cable is actually softer than most magnet wire (have to hang it there otherwise it drops down), pure copper litz sounds nice too (compare to silk/cotton covered 7x44ga litz)

ABEC-9 got from aliexpress is very smooth and no play (was using abec-3), it's not rust proof though as first batch was a disaster after cleaning up the oil.

Looking forward to your new experiment.

Cheers, Wei

The cable is actually softer than most magnet wire (have to hang it there otherwise it drops down), pure copper litz sounds nice too (compare to silk/cotton covered 7x44ga litz)

ABEC-9 got from aliexpress is very smooth and no play (was using abec-3), it's not rust proof though as first batch was a disaster after cleaning up the oil.

Looking forward to your new experiment.

Cheers, Wei

I use 8 strands of 0.08mm magnet wire 2 strands per run. This is far better and has less influence on carriage movement than the flexible wire I used previously.

2 strands are twisted together then cut to make to make the 4 runs. each channel L & R are then twisted together. I also wind the leftover around both channels which becomes the shield for the open wiring and is connected to the ground in the cable and the phono pre.

2 strands are twisted together then cut to make to make the 4 runs. each channel L & R are then twisted together. I also wind the leftover around both channels which becomes the shield for the open wiring and is connected to the ground in the cable and the phono pre.

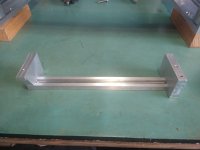

I rebuilt the rail and rail carrier for my LTA to increase rigidity and swapped the M3 setscrew Vees for sapphire. The improvement is quite noticeable. The biggest noticeable difference is in click/pop suppression.

The old rail made in the same was @niffy did his fell apart when I removed it. The epoxy had failed on the SS rods compromising rail rigidity. The new rail is solid 20x10mm aluminium with a pocket machined for the 2x 4mm carbide rods. The rail carrier was also increased in size from 20x10mm to 30x20mm with a beach laminated beam inserted up the center to damp as well as further increase stiffness.

Pics in order Original rail, new rail prior to gluing the rods, new rail and hangers, new rail and carrier mounted on the bridge, last 3 are the carriage with new sapphire Vee's

The old rail made in the same was @niffy did his fell apart when I removed it. The epoxy had failed on the SS rods compromising rail rigidity. The new rail is solid 20x10mm aluminium with a pocket machined for the 2x 4mm carbide rods. The rail carrier was also increased in size from 20x10mm to 30x20mm with a beach laminated beam inserted up the center to damp as well as further increase stiffness.

Pics in order Original rail, new rail prior to gluing the rods, new rail and hangers, new rail and carrier mounted on the bridge, last 3 are the carriage with new sapphire Vee's

Great job! The reduction in click/pop may be mainly attributed to the additional structure of the rails which damps the noise.I rebuilt the rail and rail carrier for my LTA to increase rigidity and swapped the M3 setscrew Vees for sapphire. The improvement is quite noticeable. The biggest noticeable difference is in click/pop suppression.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm