Hugh,

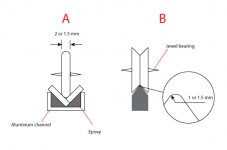

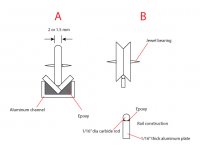

Here are two proposals if I would make a mechanical linear arm. Both proposals are highly diy friendly.

A. You may use two pieces of glass plates to form a rail and make two wheels same as Niffy’s. If you can find a pre-made glass angle channel, it would be even better.

B. Using two v groove ball bearings and modifying the v groove bearings by using jewel bearings. The rail can be hard metal or glass. I think even regular stainless steel will work well, too.

I did cut c shape of glass tubing myself. However, I would not recommend this kind of arm. If you still want to build this kind of arm, I will be happy to explain it in detail.

Jim

Here are two proposals if I would make a mechanical linear arm. Both proposals are highly diy friendly.

A. You may use two pieces of glass plates to form a rail and make two wheels same as Niffy’s. If you can find a pre-made glass angle channel, it would be even better.

B. Using two v groove ball bearings and modifying the v groove bearings by using jewel bearings. The rail can be hard metal or glass. I think even regular stainless steel will work well, too.

I did cut c shape of glass tubing myself. However, I would not recommend this kind of arm. If you still want to build this kind of arm, I will be happy to explain it in detail.

Jim

Attachments

Hi, hjam

You can get carbide flat stock . As an example, get 2 pieces of 1/8" x 1/2" and glue them together forming a V channel. You can then set your V rail in epoxy for rigidity.

Carbide Flat Blanks – Centennial Carbide: Carbide Blanks, Rod and End Mills

Joe

You can get carbide flat stock . As an example, get 2 pieces of 1/8" x 1/2" and glue them together forming a V channel. You can then set your V rail in epoxy for rigidity.

Carbide Flat Blanks – Centennial Carbide: Carbide Blanks, Rod and End Mills

Joe

Hugh,

I checked the link Joe provided here. Thanks Joe! You may make a rail by using 1/16” dia carbide rod for my proposal B. Please see the image.

Btw, I would suggest the total mass of carriage should be around 60 or 70 g.

Jim

I checked the link Joe provided here. Thanks Joe! You may make a rail by using 1/16” dia carbide rod for my proposal B. Please see the image.

Btw, I would suggest the total mass of carriage should be around 60 or 70 g.

Jim

Attachments

Last edited:

Hi Jim,

Picture B is pretty much exactly what I made for my first rail and wheels. I used a 1mm steel rod for the knife edge.

With either option I would recommend having the angle of the V greater than 90°, I think that 120-140° is optimal though this angle will be more difficult to make.

Even with my very short arm and 2mm wide wheels the amount that the wheel moves on the rail is very small. This is helped by having a very effective clamping system. During normal use the wheels will slide by less than 10um around the rods. That's less than 20 arc minutes which is pretty much a straight line. In reality there isn't really any difference between using round rods and flat bars except that it is much easier to build a straight level rail from round rods. It is also much easier to get a more obtuse contact angle.

I think that one of the reasons that knife edge bearings can work well sonically is that they have a very narrow contact line. I found that having a smaller radius on the edge of the wheel sounded slightly better than a fully rounded edge, as shown in picture A. The smaller edge radius will result in a narrower contact line.

Niffy

Picture B is pretty much exactly what I made for my first rail and wheels. I used a 1mm steel rod for the knife edge.

With either option I would recommend having the angle of the V greater than 90°, I think that 120-140° is optimal though this angle will be more difficult to make.

Even with my very short arm and 2mm wide wheels the amount that the wheel moves on the rail is very small. This is helped by having a very effective clamping system. During normal use the wheels will slide by less than 10um around the rods. That's less than 20 arc minutes which is pretty much a straight line. In reality there isn't really any difference between using round rods and flat bars except that it is much easier to build a straight level rail from round rods. It is also much easier to get a more obtuse contact angle.

I think that one of the reasons that knife edge bearings can work well sonically is that they have a very narrow contact line. I found that having a smaller radius on the edge of the wheel sounded slightly better than a fully rounded edge, as shown in picture A. The smaller edge radius will result in a narrower contact line.

Niffy

I cannot comment on where you find info on air bearings, I can however comment on air bearing in precision grinding spindles. On your typical "Pope" air bearing it's all you can do to turn the spindle without pressure on it. Apply 4 bar of clean dry air and the spindle seemingly floats and turns without any outside interference.

TIR on runout typically less than 3 microns. That said the trick is constant air flow, pulses from a piston pump would be a deal breaker.

TIR on runout typically less than 3 microns. That said the trick is constant air flow, pulses from a piston pump would be a deal breaker.

I cannot comment on where you find info on air bearings, I can however comment on air bearing in precision grinding spindles. On your typical "Pope" air bearing it's all you can do to turn the spindle without pressure on it. Apply 4 bar of clean dry air and the spindle seemingly floats and turns without any outside interference.

TIR on runout typically less than 3 microns. That said the trick is constant air flow, pulses from a piston pump would be a deal breaker.

If you are interested in air bearing arms, you may check my thread.

DIY Air Bearing Linear Arm

You should start from the last page since there are so many changes since my 1st version.

Hi Niffy,

For the rail as yours, two rods, there may be only one set of optimal parameters, such as the thickness of the wheels, the diameter of rods and the radius of wheel edge. For example, if we assume the thickness of the wheel is 2 mm, the damping in the vertical plane can change dramatically once the thickness of the wheel is less than 2 mm. But the rail as I proposed, it may be very flexible. For an optimally designed arm with the rail as yours, and for an arm with the rail as mine, I don't think there will be a lot of difference.

Jim

For the rail as yours, two rods, there may be only one set of optimal parameters, such as the thickness of the wheels, the diameter of rods and the radius of wheel edge. For example, if we assume the thickness of the wheel is 2 mm, the damping in the vertical plane can change dramatically once the thickness of the wheel is less than 2 mm. But the rail as I proposed, it may be very flexible. For an optimally designed arm with the rail as yours, and for an arm with the rail as mine, I don't think there will be a lot of difference.

Jim

yes, i agree. i can fashion some pretty good stuff on the chinese rubber lathe but there is no substitute for a bit of weightcarlo

Beautiful, rock solid lathe, Warrjon, especially compared with my poor chinese 9x20.

Hugh,

I checked the link Joe provided here. Thanks Joe! You may make a rail by using 1/16” dia carbide rod for my proposal B. Please see the image.

Btw, I would suggest the total mass of carriage should be around 60 or 70 g.

Jim

Jim, hottattoo, Niffy,

Thanks very Much!

Looking forward to this project.

Hugh

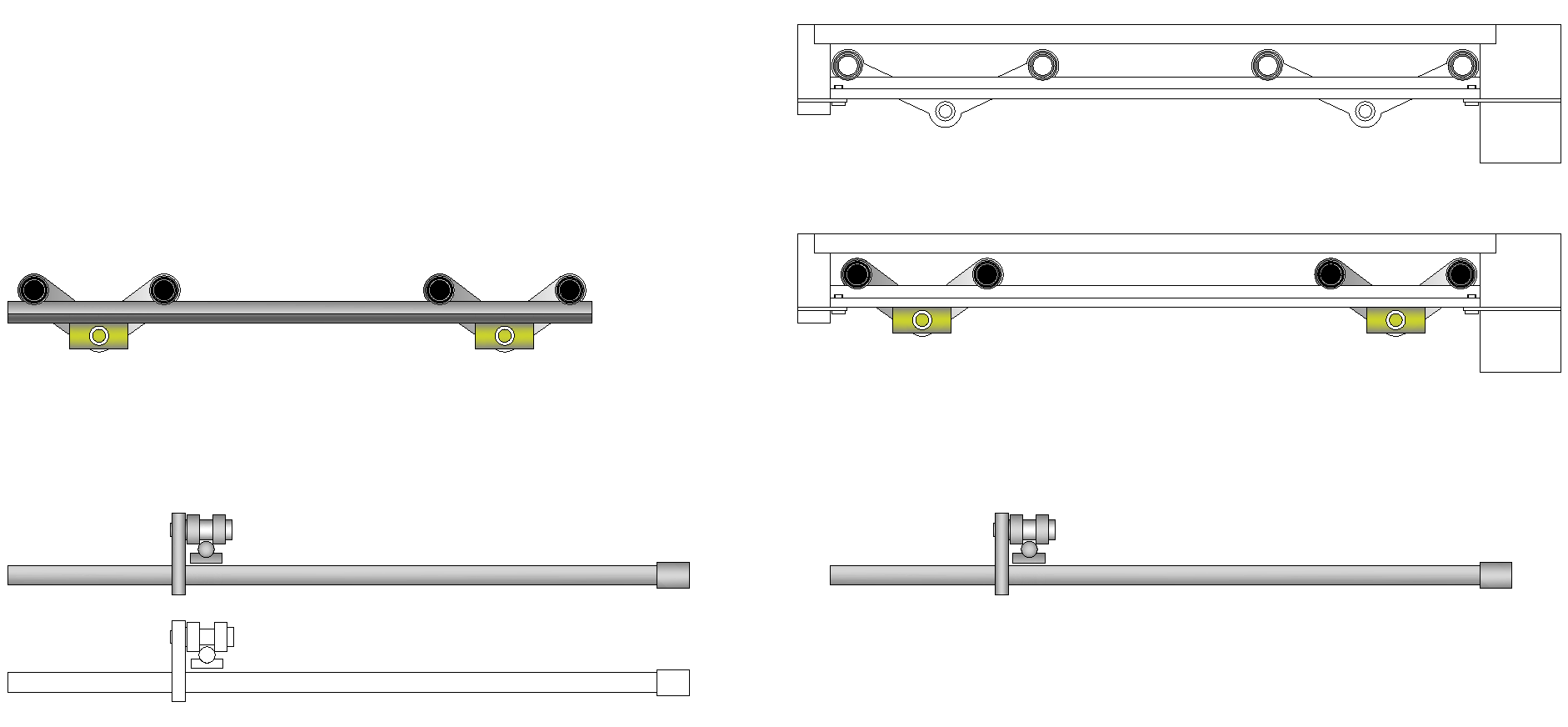

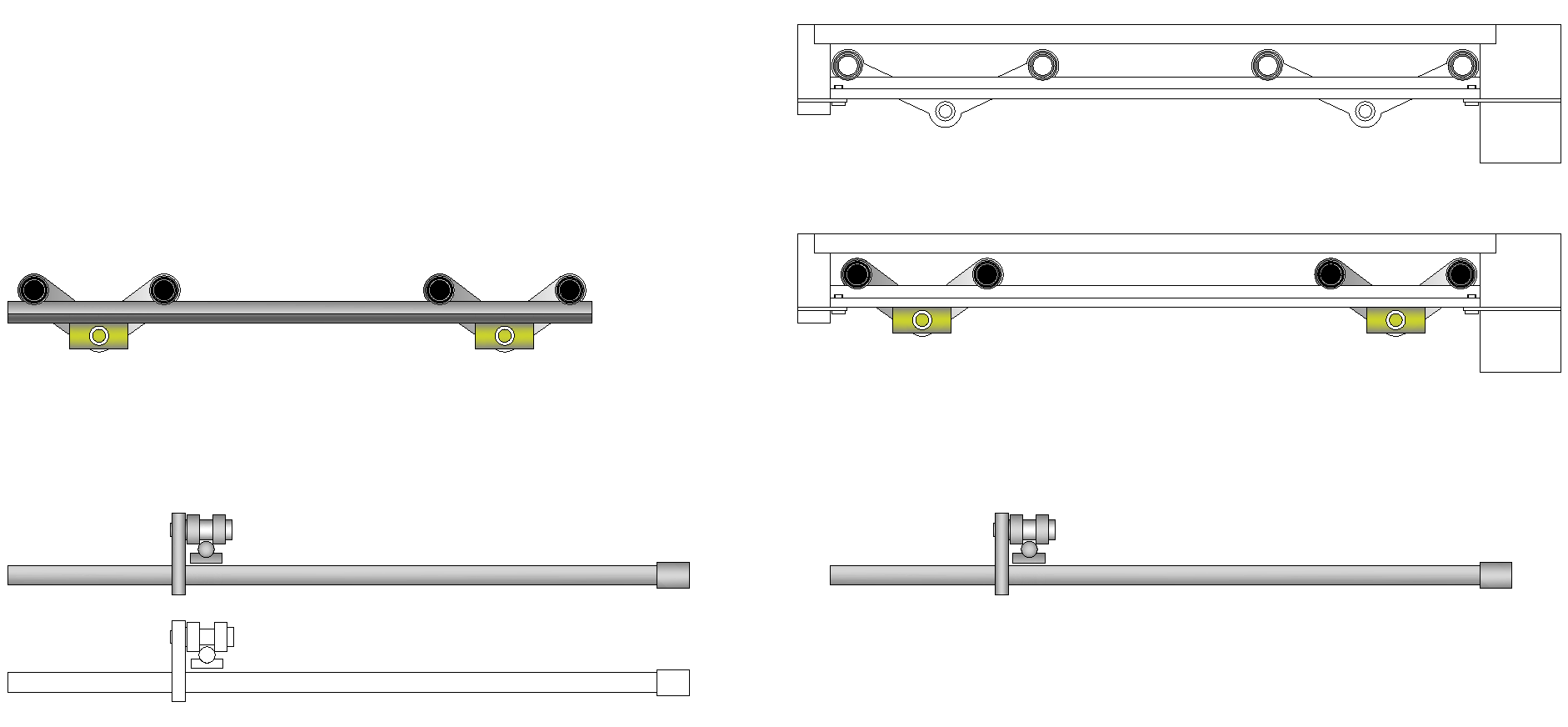

So I have started of with some drawings and done some searching and came up with two videos that tells me to skip this project all together.

So a question to you who have built this kind of arm would be, is this what would be expected from the project as it looks now ?

I have sourced abec-9 4x9x4mm ball bearings and a 5mm K10 carbide tungsten rod so far.

Arm tube is a titanium 6x4x200mm tube (13,5gr).

Bigger picture:

http://www.dahlbergaudiodesign.se/images/linear_4.png

Clearaudio can't make it work or it isn't set up right ?

YouTube

A video from "warrjon".

YouTube

So a question to you who have built this kind of arm would be, is this what would be expected from the project as it looks now ?

I have sourced abec-9 4x9x4mm ball bearings and a 5mm K10 carbide tungsten rod so far.

Arm tube is a titanium 6x4x200mm tube (13,5gr).

Bigger picture:

http://www.dahlbergaudiodesign.se/images/linear_4.png

Clearaudio can't make it work or it isn't set up right ?

YouTube

A video from "warrjon".

YouTube

Last edited:

That last one is my video, and is the before I added the larger diameter rings.

The cartridge I use a Stanton 881s and very high compliance 30um/mN. So it took me a while to get it to track properly. I machined a set of rings to increase the diameter of the wheels, this made a significant improvement to tracking. The cartridge now tracked without jumping. Installing the brush improved it further.

I did back to back listening between my Technics EPA100 and this linear, and have the same type cartridge installed in both arms so all I need to do is swap the stylus. The linear arm smoked the EPA100.

A lower compliance cartridge would be easier to set up. Niffy uses an Ortofon 2M Black 22um/nM and I'm sure this would track well now in my arm.

The cartridge I use a Stanton 881s and very high compliance 30um/mN. So it took me a while to get it to track properly. I machined a set of rings to increase the diameter of the wheels, this made a significant improvement to tracking. The cartridge now tracked without jumping. Installing the brush improved it further.

I did back to back listening between my Technics EPA100 and this linear, and have the same type cartridge installed in both arms so all I need to do is swap the stylus. The linear arm smoked the EPA100.

A lower compliance cartridge would be easier to set up. Niffy uses an Ortofon 2M Black 22um/nM and I'm sure this would track well now in my arm.

Attachments

Last edited:

Thanks. So maybe of to the drawing board again.

What I have at hand is a:

Denon DL-304 Phono Cartridge Specifications:

- Type: Moving coil

- Output voltage: 0.18mV

- Frequency response: 20Hz-75kHz

- Recommended load impedance: Over 100 ohms

- Channel balance @ 1kHz: < 1.5db

- Channel separation @ 1kHz: > 28dB

- Stylus tip: 0.07 x 0.1mm special elliptical solid diamond

- Compliance: 14 x 10-6 cm/dyne

- Recommended tracking force: (1.2g +/- 0.2g)

- Color: Gold

- Weight: 7 g

And an Ortofon MC-30 supreme:

MC Supreme series

What I have at hand is a:

Denon DL-304 Phono Cartridge Specifications:

- Type: Moving coil

- Output voltage: 0.18mV

- Frequency response: 20Hz-75kHz

- Recommended load impedance: Over 100 ohms

- Channel balance @ 1kHz: < 1.5db

- Channel separation @ 1kHz: > 28dB

- Stylus tip: 0.07 x 0.1mm special elliptical solid diamond

- Compliance: 14 x 10-6 cm/dyne

- Recommended tracking force: (1.2g +/- 0.2g)

- Color: Gold

- Weight: 7 g

And an Ortofon MC-30 supreme:

MC Supreme series

Here a summary of the carriages known to me, that can allow the double articulation, so as to be able to evaluate their advantages and disadvantages, from a geometric point of view. To highlight it was used an angle of 10°: obviously in the reality there will be at most a tenth, on worst warps; if not, better to throw away the disc.

hope this helps - carlo

"rubbery lathes": perfect definition.

Maybe it's more a problem of bad materials: my 9x20 weighs more than 100 kg, when a Schaublin 70 just a third ...

hope this helps - carlo

"rubbery lathes": perfect definition.

Maybe it's more a problem of bad materials: my 9x20 weighs more than 100 kg, when a Schaublin 70 just a third ...

Attachments

Carbide tipped pivots

Hi Niffy,

Partial good news... It seems that True Point will still supply the pivots you used. I described them as P12 modified with 3mm threads and a 0.125 mm radius tip. (Hope that's an accurate description). Charles said yes.

Hugh

Hi Hugh,

I've just had a quick look and can't find anyone on either amazon or eBay currently selling any jeweled bearing components. Even true point don't seem to be listing any other than the replacement for the pink triangle main bearing which is probably a bit big for this application. They didn't have any pivots that I could see. It might be worth contacting them directly to see if they can help. Most of the other suppliers, like bird, only seem to have trade accounts.

Sorry I can't be of much help. I'll keep an eye open for any other suppliers and let you know if anything shows up.

Niffy

Hi Niffy,

Partial good news... It seems that True Point will still supply the pivots you used. I described them as P12 modified with 3mm threads and a 0.125 mm radius tip. (Hope that's an accurate description). Charles said yes.

Hugh

Hi Niffy,

For the rail as yours, two rods, there may be only one set of optimal parameters, such as the thickness of the wheels, the diameter of rods and the radius of wheel edge. For example, if we assume the thickness of the wheel is 2 mm, the damping in the vertical plane can change dramatically once the thickness of the wheel is less than 2 mm. But the rail as I proposed, it may be very flexible. For an optimally designed arm with the rail as yours, and for an arm with the rail as mine, I don't think there will be a lot of difference.

Jim

Hi Jim,

You make a very good point. With your design, with the flat sided V channel, it would be much simpler to experiment with vertical damping, all you need to do is make a different thickness of wheel. With my design I would have to make a whole new rail as well.

Niffy

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm