It seems to be doing a pretty good job so far for my purposes which is bulk clean records for resale. The amount of debris in the solution is telling me it's working. A/B tests show impressive results. I was more or less wanting to know if anyone else is using them and their experience. Parts should be arriving this week for filtration system. Pretty solid.

Does anyone have experience using these to clean acetate records (nitrocellulose lacquers)? I bought an old medical grade 132khz, 8 transducer tank from my work when they replaced it with a newer model. It's been doing great for normal vinyl with my Tergitol, but I know acetates are very fragile, and I'm worried that the heat, surfactant, and/or ultrasonics will damage it

I see a lot of people in this thread saying 132khz is too weak, but it seem powerful enough to me. In just 10 minutes it made enough "aluminum glitter" from the foil test to easily cover someone's entire body haha.

I see a lot of people in this thread saying 132khz is too weak, but it seem powerful enough to me. In just 10 minutes it made enough "aluminum glitter" from the foil test to easily cover someone's entire body haha.

Ok. So here is my current setup thus far. Seems to be doing an effective job doing what I need it to do. I run a record store and we process a ton of used vinyl. I had to get this to dramatically cut the labor involved and it did just that. There is little to no information coming from other record stores as to how they clean vinyl efficiently, if they do at all. We insist on selling clean used vinyl so this is what I came up with.

-iSonic P4875II+MVR10 Motorized Ultrasonic Vinyl Record Cleaner, 110V (10-Records) 35000Hz.

-Bayite BYT-7A006 DC 12V Solar Hot Water Heater Circulation Pump Low Noise 3M Discharge Head 2.1GPM

-Hydronix HF3-10CLBK12PR 10" Clear Housing with Black Rib Cap, 1/2" Ports with Pressure Relief Button

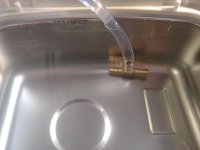

The basic setup is this. The ultrasonic has a 1/2" drain spout which I adapted to 3/8". I put in a T-barb in between for the addition of a skimmer later, if needed. Then the solution goes through the pump to the 1 micron filter and out a brass T-barb. I use the heater to get the solution just north of tepid and run 10 records on a 3 minute cycle. Then lock the spindle up at 45 degrees for drip dry with small fan assist. Usually dry within 2-5 min. The solution used is your typical distilled water, 91% iso, couple drops Jet Dry. After every 10 record batch the filtration system runs for 10-15 minutes. I've used this process for about the last 250 records with great results. Is it as effective as a $4k machine? No. But like I said for my purposes it seems to be fitting the bill.

-iSonic P4875II+MVR10 Motorized Ultrasonic Vinyl Record Cleaner, 110V (10-Records) 35000Hz.

-Bayite BYT-7A006 DC 12V Solar Hot Water Heater Circulation Pump Low Noise 3M Discharge Head 2.1GPM

-Hydronix HF3-10CLBK12PR 10" Clear Housing with Black Rib Cap, 1/2" Ports with Pressure Relief Button

The basic setup is this. The ultrasonic has a 1/2" drain spout which I adapted to 3/8". I put in a T-barb in between for the addition of a skimmer later, if needed. Then the solution goes through the pump to the 1 micron filter and out a brass T-barb. I use the heater to get the solution just north of tepid and run 10 records on a 3 minute cycle. Then lock the spindle up at 45 degrees for drip dry with small fan assist. Usually dry within 2-5 min. The solution used is your typical distilled water, 91% iso, couple drops Jet Dry. After every 10 record batch the filtration system runs for 10-15 minutes. I've used this process for about the last 250 records with great results. Is it as effective as a $4k machine? No. But like I said for my purposes it seems to be fitting the bill.

Attachments

Interesting, but who is Dr. Vince?

I first came across this name at message #1420 on this thread. I know very little about the original writer, but the content made sense to me. I see now that it strays a bit from this thread's area of interest, so I will move it to a new thread, something more focused on DIY record cleaning fluids.

Thank you BB for creating and maintaining this thread and thanks to Cal Weldon for his guidance.

Six.

What a fantastic thread! A huge thank you to bbftx for all your efforts and sharing. And thanks to Tima who's DIY articles lead me to this great thread and who's distillation I am implementing.

I have collected all the main items for my setup, Elmasonic P 120H, Kuzma RD rotisserie, Bayite BYT-7A015 DC 12V Solar Hot Water Heater Circulation Pump, Pentek 158116 ¼” #10 Slim Line filter housing & 0.35 micron Watts FM-0.35-975 2-1/2” x 9-3/4” Pleated Filters. Now I need to connect it all up.

I wish to replace the plastic elbow coupler that comes with the Elma and fits in the threaded female drain duct on the back so that I can connect a tube with an internal diameter of 3/8". I will have to order over the Internet and need the precise size of the male thread of this coupler. I estimate that it is 15mm. It looks a little smaller than 5/8" but maybe I am wrong. It would be great if anyone knows the precise dimension and can share it.

Many thanks!

I have collected all the main items for my setup, Elmasonic P 120H, Kuzma RD rotisserie, Bayite BYT-7A015 DC 12V Solar Hot Water Heater Circulation Pump, Pentek 158116 ¼” #10 Slim Line filter housing & 0.35 micron Watts FM-0.35-975 2-1/2” x 9-3/4” Pleated Filters. Now I need to connect it all up.

I wish to replace the plastic elbow coupler that comes with the Elma and fits in the threaded female drain duct on the back so that I can connect a tube with an internal diameter of 3/8". I will have to order over the Internet and need the precise size of the male thread of this coupler. I estimate that it is 15mm. It looks a little smaller than 5/8" but maybe I am wrong. It would be great if anyone knows the precise dimension and can share it.

Many thanks!

Interesting approach! Overall pretty cool. I like how you locked everything down and kept it all tight and contained. I also like how handled the rotisserie. Very clever there.Ok. So here is my current setup thus far. Seems to be doing an effective job doing what I need it to do. I run a record store and we process a ton of used vinyl. I had to get this to dramatically cut the labor involved and it did just that. There is little to no information coming from other record stores as to how they clean vinyl efficiently, if they do at all. We insist on selling clean used vinyl so this is what I came up with.

-iSonic P4875II+MVR10 Motorized Ultrasonic Vinyl Record Cleaner, 110V (10-Records) 35000Hz.

-Bayite BYT-7A006 DC 12V Solar Hot Water Heater Circulation Pump Low Noise 3M Discharge Head 2.1GPM

-Hydronix HF3-10CLBK12PR 10" Clear Housing with Black Rib Cap, 1/2" Ports with Pressure Relief Button

The basic setup is this. The ultrasonic has a 1/2" drain spout which I adapted to 3/8". I put in a T-barb in between for the addition of a skimmer later, if needed. Then the solution goes through the pump to the 1 micron filter and out a brass T-barb. I use the heater to get the solution just north of tepid and run 10 records on a 3 minute cycle. Then lock the spindle up at 45 degrees for drip dry with small fan assist. Usually dry within 2-5 min. The solution used is your typical distilled water, 91% iso, couple drops Jet Dry. After every 10 record batch the filtration system runs for 10-15 minutes. I've used this process for about the last 250 records with great results. Is it as effective as a $4k machine? No. But like I said for my purposes it seems to be fitting the bill.

Some comments/concerns: First, it might not be ideal to have something touching the bottom of the tank, though @VibratoLLC could probably tell if this is actually a problem or not. Anything submerged in the tank will count against the transducer power available for record cleaning anyway, so you may want to remove that when doing actual cleaning (if you aren't already doing so).

Also, that might be too many records at once for the power level of that tank for truly effective cleaning. Depending on the frequency, you may also want to space them out more. You could probably get more effective cleaning also with a slower rotation, but since the goal seems to be primarily just a quick clean to prevent anything from being too nasty when sold, this is probably just fine. I'd expect it to be better than the results of a Spin Clean alone.

Overall a pretty cool setup! Kudos!

Only just arrived here and what a wonderful forum. I am about to embark on making a US and the information on this thread is so helpful. I have a couple of questions but forgive me if these have already been answered. 1. I cannot find a parts list anywhere - it is not on the page quoted. 2. has anyone used a linear actuator for the record lift function. 3. I think I just about understand cavitation and see how a single record gets maximum "blast". Is the cavitation effect reduced or changed when more than one record is immersed. Many thanks.

Hi Vinyldobby,

A moderator deleted this whole thread by mistake some time back, and with that, all the attachments disappeared. Here is parts list for version 3 and version 2 of my URC. Some of these parts aren't available any more, but various substitutes have been found.

Cheers,

B B

A moderator deleted this whole thread by mistake some time back, and with that, all the attachments disappeared. Here is parts list for version 3 and version 2 of my URC. Some of these parts aren't available any more, but various substitutes have been found.

Cheers,

B B

Attachments

Thank you so much for this. I thought it was my usual inability to see the obvious but pleased it was the "dreaded moderators" who fouled things up! (only joking mods!) You are such a talented person and this thread you started is packed with really good advice. I just hope I can build the thing! Thanks again.

Yesterday, I tried to look up Sonix4 and found that their website and numerous social media accounts had been closed.

It's a bit sad to see, as a former employee, but also not surprising.

-Louis

Louis, what's your timing for making the 60Hz models available again?

Yesterday, I tried to look up Sonix4 and found that their website and numerous social media accounts had been closed.

It's a bit sad to see, as a former employee, but also not surprising.

-Louis

Why not surprising? I thought they had decent products other than the rebranded Chinese crap they were recently selling.

Louis, what's your timing for making the 60Hz models available again?

We just reordered the sheet-metal this morning, which takes about 3 weeks to arrive.

-Louis

Zg

The patriarch died a couple of years ago, and in my view, the widow was not up to the task of running the company.

Cheers,

B B

Daisy, the widow, was the downfall of Sonix4. To hear her on the phone with customers was atrocious! Not to mention her treatment of employees!

But I digress...

Louis

On my second try I found success. The first $100 Chinese US didn't do anything except make noise. After more research I decided to purchase the Elma P60H dual frequency and another filter setup for .35 microns and another pump running on AC, the 115v 33-Series Diaphragm Water Pump which has quite a bit of pressure and will blow hoses off if not clamped. I choose the filter housing for 1/4 NPT because I have those fittings. If I where to do it again I would choose 1/2 NPT for a more convenient hose arrangement. I have re cleaned six records from the first attempt and now am very pleased with the results using distilled water with a few ounces of 99% isopropyl alcohol with a few drops of triton X-100 and Hepastat 256. I may stop using Hepastat 256.

The music just seems deeper now, clearer and considerably less pops and clicks.

Thank you to all that have contributed to this great thread.

The music just seems deeper now, clearer and considerably less pops and clicks.

Thank you to all that have contributed to this great thread.

- Home

- Source & Line

- Analogue Source

- My version of an Ultrasonic Record Cleaner