On the issue of stainless steel welds in US tanks, see page 188, post #1880 by bbftx.

"Where DI water can cause problems in stainless steel systems is where there are stainless steel welds that aren't done the proper way. This is why some people think DI water cannot be contained in stainless --- because the welding issue was misinterpreted to be a general stainless steel issue. Unless your tank has welds exposed to the DI water, there will not be issues."

In the welded Beijing Ultrasonic tank I received, the welds were exposed to DI water. The tank shown on BU website is one piece molded. The person I know that has a BU USC, his tank is one piece.

While the welded tank may never have an issue, the possibility of an issue was present.

"Where DI water can cause problems in stainless steel systems is where there are stainless steel welds that aren't done the proper way. This is why some people think DI water cannot be contained in stainless --- because the welding issue was misinterpreted to be a general stainless steel issue. Unless your tank has welds exposed to the DI water, there will not be issues."

In the welded Beijing Ultrasonic tank I received, the welds were exposed to DI water. The tank shown on BU website is one piece molded. The person I know that has a BU USC, his tank is one piece.

While the welded tank may never have an issue, the possibility of an issue was present.

Last edited:

Andy: I read it the other day, but now I cannot find it. So it is quite possible I misread the paper.

Most tabletop ultrasonic tanks are stamped out, not welded together. Stainless steel is a great material, while if the weld has nickel in it, it may be more susceptible to erosion.

Distilled water is considered a preferred liquid for cleaning in an ultrasonic tank. Water is a terrific solvent.

The reason why this came up was I was researching if having welds in the US tank was an issue. I found a statement in my search that led me to believe it could be. As I mentioned, I cannot now find that citation.

Thanks, Mike,

I must say that my Sonix IV tank (US mfrd tank from a couple of years ago) certainly looks like it's been stamped - not welded.

Now, I'd be interested in your input on using a 1 micron filter - and pump, obviously. From my own experiments:

* when I used an aquarium-type foam filter - and didn't vacuum the wet LP with my Nitty Gritty afterwards ... I heard hiss, after the cleaning process.

* but when I subsequently cleaned the LP with my NG ... this removed the hiss.

* so my assumption is ... the aquarium filter didn't take out the crap in suspension, in the cleaning liquid, so this remained at the bottom of the groove when the liquid evaporated (but the NG wet/vac clean got rid of it).

I then changed to a 1-micron cartridge filter ... this time, I heard no hiss - even without using my NG to vac-dry the LP.

So I continue to use the 1-micron filter!

My question to you is ... do you think running the filter circuit whilst the US tank is cleaning LPs, degrades the effectiveness of the US cleaning process? IOW you really should run a cleaning cycle - with X LPs on your spindle (where 'X' is determined by a) the width of your tank and b) the frequency) - and then run the filter cycle with the US vibrations switched off and no LPs in the tank?

(Which doubles the time taken to clean 'X' LPs, obviously!

Thanks,

Andy

"My question to you is ... do you think running the filter circuit whilst the US tank is cleaning LPs, degrades the effectiveness of the US cleaning process? IOW you really should run a cleaning cycle - with X LPs on your spindle (where 'X' is determined by a) the width of your tank and b) the frequency) - and then run the filter cycle with the US vibrations switched off and no LPs in the tank?"

Andy: See this website for general experience in use of USC: Questions and answers about Ultrasonic Cleaning. See this quote:

"You should run the filter at no more than 1-2 gallons per minute if you are using the ultrasonics at the same time. The pump in a filter system will introduce air into the liquid and lower the ultrasonic activity if it is run at a higher rate. It is better to run the filter between cleaning cycles."

In my setup, I use both the tank drain valve and a return valve to "trim" the filter return to below the rated 175 GPH (~3 GPM). At first, I used a "T" splitter fitting to return my DI cleaning solution to the US tank at the top of the tank. However, I noticed that doing so put air bubbles into the solution. Now I use a 90° angle fitting with a length of 3/8" flex tubing to return the solution into a corner above the tank bottom. So yes, I filter and clean at the same time.

Some users here clean their lps without the filter system running, then after a cleaning, they then run the filter to clear debris removed from the records. That tactic is recommended also in the quote above.

Full disclosure, I've never employed the 1.0 micron filter. As far as the effectiveness of the 0.35 micron filter: I find it to be very effective and I wrote about it a number of pages back. If I may recommend, read update #2 by Tima on The Vinyl Press on his experience with 1.0 and 0.35 micron filters in Pentek housings. Note, the 0.35 micron filter employs a 10" filter and Pentek housing to match, while the 1.0 micron filter is about half as tall and employing the suitable Pentek housing.

I've toyed with the idea of daisy chaining a 1.0 micron filter housing with the 0.35 micron filter housing, thereby catching larger particles in a filter than can be cleaned. Technically, the 0.35 micron Flow Max filter cannot be cleaned, while I still rinse it off after cleaning 40 records.

Andy: See this website for general experience in use of USC: Questions and answers about Ultrasonic Cleaning. See this quote:

"You should run the filter at no more than 1-2 gallons per minute if you are using the ultrasonics at the same time. The pump in a filter system will introduce air into the liquid and lower the ultrasonic activity if it is run at a higher rate. It is better to run the filter between cleaning cycles."

In my setup, I use both the tank drain valve and a return valve to "trim" the filter return to below the rated 175 GPH (~3 GPM). At first, I used a "T" splitter fitting to return my DI cleaning solution to the US tank at the top of the tank. However, I noticed that doing so put air bubbles into the solution. Now I use a 90° angle fitting with a length of 3/8" flex tubing to return the solution into a corner above the tank bottom. So yes, I filter and clean at the same time.

Some users here clean their lps without the filter system running, then after a cleaning, they then run the filter to clear debris removed from the records. That tactic is recommended also in the quote above.

Full disclosure, I've never employed the 1.0 micron filter. As far as the effectiveness of the 0.35 micron filter: I find it to be very effective and I wrote about it a number of pages back. If I may recommend, read update #2 by Tima on The Vinyl Press on his experience with 1.0 and 0.35 micron filters in Pentek housings. Note, the 0.35 micron filter employs a 10" filter and Pentek housing to match, while the 1.0 micron filter is about half as tall and employing the suitable Pentek housing.

I've toyed with the idea of daisy chaining a 1.0 micron filter housing with the 0.35 micron filter housing, thereby catching larger particles in a filter than can be cleaned. Technically, the 0.35 micron Flow Max filter cannot be cleaned, while I still rinse it off after cleaning 40 records.

Last edited:

Thanks, Mike,

I must say that my Sonix IV tank (US mfrd tank from a couple of years ago) certainly looks like it's been stamped - not welded.So I should be all right.

My question to you is ... do you think running the filter circuit whilst the US tank is cleaning LPs, degrades the effectiveness of the US cleaning process? IOW you really should run a cleaning cycle - with X LPs on your spindle (where 'X' is determined by a) the width of your tank and b) the frequency) - and then run the filter cycle with the US vibrations switched off and no LPs in the tank?

Thanks,

Andy

Hi Andy,

I've not seen a welded tank on any of the small ultrasonic units that people are using in this application. They're probably all stamped when you're talking about 6 liter tanks.

I've experimented with filtering while cleaning, and filtering while not cleaning. I don't believe filtering while cleaning degrades cleaning effectiveness. However, you need to make sure your pump is rated for a continuous duty cycle if you want to use it this way. My Little Giant pump, which was designed as a beverage pump, was really only designed for 50% duty cycle. It will get too hot and stop pushing much water if run for more than about 4 or 5 minutes. It needs to stop and cool down for several minutes after a filtering cycle.

A lot of these small little pumps people are using won't even have a duty cycle rating associated with them. I'd recommend not running them continuously because of that, or the pump will likely live a short life. And it's really not necessary to be filtering 100% of the time anyway. Every third or fourth cycle is plenty if you've got reasonably clean records to begin with.

Cheers,

B B

Last edited:

Folks,

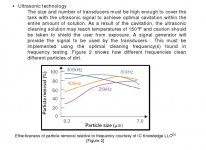

When considering filters, note that using a filter finer than 1 micron might or might not be overkill, particularly if you are using a 40 kHz ultrasonic cleaner. At 40 kHz, cleaners only remove about half the particles at a 0.35 micron particle size anyway, per the attached graphic.

If you feel the need to run a 0.35 micron filter, and you have a 60 or 80 kHz machine, and your pump can handle the pressure drop across a 0.35 micron filter, I'd recommend a cleanable, reusable one like this:

0.35 micron Harmsco Polyester filter

I use a 1 micron filter and get excellent results.

Cheers,

B B

When considering filters, note that using a filter finer than 1 micron might or might not be overkill, particularly if you are using a 40 kHz ultrasonic cleaner. At 40 kHz, cleaners only remove about half the particles at a 0.35 micron particle size anyway, per the attached graphic.

If you feel the need to run a 0.35 micron filter, and you have a 60 or 80 kHz machine, and your pump can handle the pressure drop across a 0.35 micron filter, I'd recommend a cleanable, reusable one like this:

0.35 micron Harmsco Polyester filter

I use a 1 micron filter and get excellent results.

Cheers,

B B

Attachments

For whatever it is worth, I have some practical experience with failing stainless steel welds when exposed to deionized water. For years I maintained a fleet of bulk water dispensers that dispensed DI water that was treated with UV light. The UV module was a stainless steel tube that had end caps welded on. The caps allowed the module to be plumbed and allowed the UV bulb to be in contact with the water. The bulb was lit 24/7 and the dispenser valve was after the UV module. This was the design I inherited. Over time I experienced numerous pin hole leaks developing in the weld seam. I grew weary of replacing the modules knowing that they would only fail again.

Because the water was dispensed randomly, the water in the module could become very hot and expand during periods when usage was low. The hot water would then be replaced with cool water when water was dispensed. I speculated that the temperature cycling, expansion of the water and water "hammering" were making the weld seams fail. I had not considered the chemistry of the DI water attacking the weld.

I reconfigured the system by placing the dispenser valve before the UV module. This allowed the water to freely vent to the atmosphere if it expanded due to high temperature. I never experience a weld seam failure after this change.

I cannot imagine a weld failure would be an issue with the Ultrasonic machines used for record cleaning. There would not be enough water contact time, pressure or temperature to affect any weld (if there is one).

John

Because the water was dispensed randomly, the water in the module could become very hot and expand during periods when usage was low. The hot water would then be replaced with cool water when water was dispensed. I speculated that the temperature cycling, expansion of the water and water "hammering" were making the weld seams fail. I had not considered the chemistry of the DI water attacking the weld.

I reconfigured the system by placing the dispenser valve before the UV module. This allowed the water to freely vent to the atmosphere if it expanded due to high temperature. I never experience a weld seam failure after this change.

I cannot imagine a weld failure would be an issue with the Ultrasonic machines used for record cleaning. There would not be enough water contact time, pressure or temperature to affect any weld (if there is one).

John

I've noticed that BendBond first referred to distilled water and then the discussion has shifted to deionized water. They are not the same thing. Distilled water should not pose any dangers to welds. I doubt that DI water will, either, if the welds are done properly. As John said, you should never have an issue in an ultrasonic cleaner in this record cleaning application. Your DI water will likely cease to be DI'ed about 10 seconds after you insert your LP. Even DI water sitting in the US cleaner will cease to be DI'ed pretty quickly as it will absorb free ions out of the air.

Years ago at my work our manufacturing floor used a Miele dishwasher (stainless steel insides and guts) to clean hybrid circuit modules. The Miele was fed DI water from our DI water system. When we shut down this process the Miele had seen continuous service (multiple cycles per day) 24x365 for over 20 years without a problem. As far as I know, it never had any issues related to DI water 'corrosion'.

Our audiophile US cleaners will never see that amount of service.

Years ago at my work our manufacturing floor used a Miele dishwasher (stainless steel insides and guts) to clean hybrid circuit modules. The Miele was fed DI water from our DI water system. When we shut down this process the Miele had seen continuous service (multiple cycles per day) 24x365 for over 20 years without a problem. As far as I know, it never had any issues related to DI water 'corrosion'.

Our audiophile US cleaners will never see that amount of service.

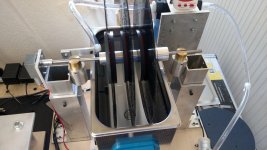

Though I would show my DIY Ultrasonic unit. This thread has been great. Used the pump on eBay that some have used and with a .35 micron filter it pumps 1.3 gpm. Put a pwm controller on the DC motor so I could get .25 to .5 rpm.

Only played with 12 albums so far. The Dynamics is really eye opening. Some congestion on some passages, major improvement. I have only used distill water with. 4 drops of dawn. Water temp has been around 85 degrees and been doing 3 revolutions per 9-10 minutes.

Also built vacuum turntable. Use a hand wand (Vinyl Vac) with it. Some distilled water, disc doctor brush, vacuum and done.

Would be nice if anyone else want to share experiences with cycles, speed, total time etc. And if they tried various cleaning formulas for the tanks. I am most interested on how it sounds than how it looks or if has a slight tick here or there.

This is a great thread, thought I would share my limited experience with the Ultrasonic stuff. Really impressed so far.

Enjoy the ride

Tom

Only played with 12 albums so far. The Dynamics is really eye opening. Some congestion on some passages, major improvement. I have only used distill water with. 4 drops of dawn. Water temp has been around 85 degrees and been doing 3 revolutions per 9-10 minutes.

Also built vacuum turntable. Use a hand wand (Vinyl Vac) with it. Some distilled water, disc doctor brush, vacuum and done.

Would be nice if anyone else want to share experiences with cycles, speed, total time etc. And if they tried various cleaning formulas for the tanks. I am most interested on how it sounds than how it looks or if has a slight tick here or there.

This is a great thread, thought I would share my limited experience with the Ultrasonic stuff. Really impressed so far.

Enjoy the ride

Tom

Attachments

Wow, TomWh, that is an insanely sturdy setup! For when you don't want a nearby tank to bend your stand!

I've shared by process before, but it may have changed a bit since I last mentioned anything here. I still use the same 5 RPH (12 minutes per rotation) motor. The bath temp generally gets up to about 105F to 110F when doing an extended cleaning session. I tend to just run one record at a time through the ultrasonic these days, for two full rotations (about 24 minutes), to make sure I'm getting maximum cleaning power, and minimal drying time between removal from the ultrasonic and vacuuming on the Okki Nokki. After an issue with damage caused by my brief stint with a Nitty Gritty, I now ALWAYS go straight into the ultrasonic before using any other tool (if I had a large sink with good water filtration, I might pre-wash with a GEM Dandy, but I don't have that option), to make sure that any hard grit is removed before getting stuck between the record and vacuum nozzle.

I have tried numerous tank solutions, alternately using 2 oz per gallon of 90% Isopropyl (as per original recommendation from bbftx), 0.8oz per gallon of Simple Green Crystal, 1oz per gallon of Sporicidin Enzymatic concentrate, and 10 drops per gallon of TergiKleen (a custom blend/repackaging of Tergitol), as well as just plain distilled water. I always use distilled water as the base. I have ultimately settled on the TergiKleen as the most generally effective and safest. I do occasionally still use the Sporicidin Enzymatic dilution in special cases, but it was counterproductive in the ultrasonic tank, and the Simple Green didn't seem to accomplish much. Isopropyl was definitely effective in my early tests, but anxiety about potential damage to the vinyl always nagged at my mind.

My experience has shown that both vacuum RCM and ultrasonic used in conjunction provides the best results. The ultrasonic loosens most of the crud, and 2 rinse passes on the vacuum RCM generally seem to remove the last of the crud and any remaining Tergitol residue as well (I'm not sure whether the more recent addition of the 1 micron filter has removed any of the Tergitol or not, so I may be down to mostly just re-filtered distilled water at this point). This is ESPECIALLY true when using the Sporicidin Enzymatic dilution for really moldy oldies, like a Brubeck Time Out six-eye that I recently tried to salvage. I ran through the ultrasonic first, as usual, but a lot of the moldy crud remained even after the 24 minute cleaning. So I went through multiple scrub/soak/rinse passes and one or two more ultrasonic passes to remove more junk. It could still use another pass, but it's considerably better. I wouldn't have wanted to be without either ultrasonic or vacuum RCM for this particular project. Both helped considerably.

Maybe that helps with your question, maybe it doesn't. But here's some before and after of the Brubeck (you can still see where another pass or two might help). Just remember: there is no magic bullet. Each fluid or tool solves a different problem.

I've shared by process before, but it may have changed a bit since I last mentioned anything here. I still use the same 5 RPH (12 minutes per rotation) motor. The bath temp generally gets up to about 105F to 110F when doing an extended cleaning session. I tend to just run one record at a time through the ultrasonic these days, for two full rotations (about 24 minutes), to make sure I'm getting maximum cleaning power, and minimal drying time between removal from the ultrasonic and vacuuming on the Okki Nokki. After an issue with damage caused by my brief stint with a Nitty Gritty, I now ALWAYS go straight into the ultrasonic before using any other tool (if I had a large sink with good water filtration, I might pre-wash with a GEM Dandy, but I don't have that option), to make sure that any hard grit is removed before getting stuck between the record and vacuum nozzle.

I have tried numerous tank solutions, alternately using 2 oz per gallon of 90% Isopropyl (as per original recommendation from bbftx), 0.8oz per gallon of Simple Green Crystal, 1oz per gallon of Sporicidin Enzymatic concentrate, and 10 drops per gallon of TergiKleen (a custom blend/repackaging of Tergitol), as well as just plain distilled water. I always use distilled water as the base. I have ultimately settled on the TergiKleen as the most generally effective and safest. I do occasionally still use the Sporicidin Enzymatic dilution in special cases, but it was counterproductive in the ultrasonic tank, and the Simple Green didn't seem to accomplish much. Isopropyl was definitely effective in my early tests, but anxiety about potential damage to the vinyl always nagged at my mind.

My experience has shown that both vacuum RCM and ultrasonic used in conjunction provides the best results. The ultrasonic loosens most of the crud, and 2 rinse passes on the vacuum RCM generally seem to remove the last of the crud and any remaining Tergitol residue as well (I'm not sure whether the more recent addition of the 1 micron filter has removed any of the Tergitol or not, so I may be down to mostly just re-filtered distilled water at this point). This is ESPECIALLY true when using the Sporicidin Enzymatic dilution for really moldy oldies, like a Brubeck Time Out six-eye that I recently tried to salvage. I ran through the ultrasonic first, as usual, but a lot of the moldy crud remained even after the 24 minute cleaning. So I went through multiple scrub/soak/rinse passes and one or two more ultrasonic passes to remove more junk. It could still use another pass, but it's considerably better. I wouldn't have wanted to be without either ultrasonic or vacuum RCM for this particular project. Both helped considerably.

Maybe that helps with your question, maybe it doesn't. But here's some before and after of the Brubeck (you can still see where another pass or two might help). Just remember: there is no magic bullet. Each fluid or tool solves a different problem.

Attachments

I've noticed that BendBond first referred to distilled water and then the discussion has shifted to deionized water. They are not the same thing. Distilled water should not pose any dangers to welds. I doubt that DI water will, either, if the welds are done properly.

Agree. I use distilled water, not DI water. When I got a welded tank and not the molded tank as advertised, I searched for potential issues. That is as far as it goes. I posted all I know. Highly unlikely welds would have been an issue. The tank being too small and smaller than advertised was the issue in my case.

I don't think many people understand the frustration in international shipping, or even domestic, for that matter!

I once sent a unit to California by USPS, which was delivered to a completely different address than the one on the label.

Even though USPS delivered to the wrong address and were unable to recover the item, they still denied my claim 3 times!!! (I had already refunded in full to the customer).

I had to email so much information, which USPS never made clear they needed to honor an insurance claim.

I finally received the insurance claim, but the experience made me so mad, I now use FedEx whenever I can.

I understand your pain!!!

-Louis

I once sent a unit to California by USPS, which was delivered to a completely different address than the one on the label.

Even though USPS delivered to the wrong address and were unable to recover the item, they still denied my claim 3 times!!! (I had already refunded in full to the customer).

I had to email so much information, which USPS never made clear they needed to honor an insurance claim.

I finally received the insurance claim, but the experience made me so mad, I now use FedEx whenever I can.

I understand your pain!!!

-Louis

It warped. And three attempts at increased process time on a Vinyl Flat were unable to remove the warp.

Now I set my temperature to 28°C and if the temperature climbs to 31°C, I allow the pump to circulate the solution until the temperature declines to what I believe is a safe level.

Long time lurker here - did a LOT of reading and built my kit, so I can't thank everyone enough, bbtx and now BendBound for all their posts.

I wish the above statement had come through clearer for me. I'd become confident in my process, and had a some early stellar results, but typing this out even now makes my stomach clench up and drop... I have now ruined a section of my collection due to warping by doing an extended cleaning session. I don't blame anyone but myself... and perhaps the maker of the US unit. But mostly myself.

For anyone that is just starting this journey to cleaning, let me introduce a new step in the process, especially if you think you've got it down pat -

STOP AND DO A SPOT CHECK ON YOUR VINYL. Take a cleaned disc, put it on the turntable, and spin it, even drop the needle on it. If that needle has started bouncing where there was no bounce before, STOP STOP STOP. I couldn't figure out where I'd gone wrong - was it the move to the home brew isopropyl mix? Was it the cleaning process using US instead of just vacuum? Was it the heat in the bath? I'm still not 100% sure so I'm putting this out there for help, but also as a very strong caveat. I've had records all my life, and I still prefer to sit down and listen end to end to an album, so have always preferred and cared for this format since I was a tyke, so let me reiterate - please don't make the mistake I made here.

Here's my bit about my own trip into cleaning. It's a long post, so feel free to skip, but I'm including as much info as I can to either give other folks info as well as to hopefully get some understanding and/or help before dipping back into ultrasonic cleaning.

Long kit list short -

Bath mix - 10% isopropyl/drops of triton x-100/distilled water final mix decided upon. I'd also tried tergikleen but found it leaving a higher noise floor after cleaning AND rinses so settled on the home brew. I also noticed it not removing hand/finger printed and other residue that the home brew took out easily.

Kit built up piece by piece over literally a decade - includes US cleaner (truSonik 10L that I'd seen a recommendation on and ordered off e-bay), temp set to 25C becaues it usually rose to about 32-36C during 20 min cleaning cycle, Vinyl Stack with only 2 records on spindle (I'd tried 4, but felt I wasn't getting results, so I chalked it up to the cheaper US unit since I couldn't afford the more expensive ones) 1 micron filter setup listed here with solar/heat resistant pump from amazon, which I'd run for 2-3 minutes after every 4-6 records with a longer return hose wrapped in a cut-off 1 gallon milk jug filled with ice to try and cool the water a bit (was still working on this part of design), quick spray rinse with new bug sprayer and distilled water followed by another rinse with SpinClean and distilled water followed by 1 rotation left and 1 right on a KAB vacuum clean to get most of remaining water off, then short air dry and into clean sleeves.

NOW the sickening part for me... during the session, I thought I'd heard a change in the sound of US unit - somehow not as loud, but I'd also noticed previously a different sound during degassing with the alcohol/triton water mix vs. the degassing with tergikleen, and stopped to check the 2 albums I'd cleaned. Somehow I thought it wasn't cleaning or maybe these records had been dirtier or more static-y (is that a word?) but I plowed ahead. I never noticed that the bath temp decided to lose control and start to go up to or above 46C during the clean, because I'd start the cleaner and then walk away due to noise, and confidence.

I'd read that there had been an experience where someone left an LP sitting without turning on the vinylstack and had no damage from the actual ultrasonic process, or from the exposure to the alcohol bath mix, so I suspect that something in this model went wrong and there was a source of extreme heat blasting into the LPs.

I am worried it's worse because in this batch of about 40 records, the heavier LPs weren't initially touched/wrecked due to the combination of vinyl weight (180 vs. thinner) as well as age of lp possibly. Then I got down to a copy of my morning jacket acoustic citsuoca. I'd just cleaning it, stopped for a while, and really wanted to hear it. Put it on the turntable, lowered the needle, and my heart fell out of my chest. The needle wouldn't stay in the groove on the outer edge of this heavy weight vinyl record. It bounced as if hitting a small very tightly placed series of waves.

The warp created on a lot of the washed LPs is odd - it's not a warped line across the lp as if dipped half into the bath and overheated, it's just on the outer edge of the record, causing a small area of extreme bounce as the record rotates. It's not a dish warp, or something that occurs all the way around. Records were never placed and left in the bath without rotating, and it's almost as if they'd been standing still, with a small single heat source blasting into this one area on the edge of the record. I couldn't explain it, but I've taken very cared for lp's and wrecked a fair amount of my collection because I didn't stop and check by actually spinning them on the turntable. I now have the sinking feeling that I may have caused more damage, and once I've buckled down I'll go back through the shelves I've already cleaned one by one and see if it's any worse than I now know.

I don't know what to do besides full stop. I don't want to scare anyone away from this process - again, I had some amazing early results. I know it can't repair scratched vinyl, but it did make some old records my parents had absolutely wonderful again.

So now I have to refer to wiser minds than myself. - I might have missed something, or gotten important steps lost in the deluge of info in here. I've debated whether or not to post under this thread or start a new one, but I decided here because others might find this result here whereas a separate thread might get missed in a forum search. But mods know best.

Any information or insight or other experiences are greatly appreciated. The cleaner is under warranty, and even with a new one I won't wash anything except bargain bin stuff as testers if I get a replacement but... music is my life. I don't want to risk any more of my collection until I get more info, or find out the cause or if anyone else has had this happen. And I definitely don't want anyone else to go through this either. I'm lucky it wasn't worse, but it's still dozens of examples of my stupidity staring up at me now from a box.

They even warble and cry a bit when I first try to play them as a reminder.

Help?

FE7:

So it's the same kind of damage across a number of different records? Could you post a picture? Just a guess, but there's probably something weird going on with a high amount of heat being applied to a localized area in your tank.

I frequently measure bath temp at various positions in my tank, near the top of liquid in the bath (heat rises, so this should be the warmest portion of the tank.) I routinely run my bath around 46°C (115°F); I've not had a single warped LP -- not one out of hundreds and hundreds cleaned. So, that temp in and of itself is not a problem. But wherever you measured it might not be the highest temp in your tank.

One gent in this forum found he wasn't filling his tank high enough. The heater, in his case on the side of the tank wall, was probably overheating the tank wall above the liquid level in the tank. Without fluid touching this hot metal to disperse the heat throughout the tank, he was exposing his nearby LP surfaces, just out of the bath, to very high temps. This would be extreme during times when the LPs were stationary and not spinning. Most vinyl used in LPs typically has a deformation temp roughly around 150°F . If a tank heater is not covered by the liquid level in the tank, it would be easy to run up the metal temp to unsafe level. Without LPs in your tank, get your system up and running and see if you can identify a localized hot spot that is appearing.

B B

So it's the same kind of damage across a number of different records? Could you post a picture? Just a guess, but there's probably something weird going on with a high amount of heat being applied to a localized area in your tank.

I frequently measure bath temp at various positions in my tank, near the top of liquid in the bath (heat rises, so this should be the warmest portion of the tank.) I routinely run my bath around 46°C (115°F); I've not had a single warped LP -- not one out of hundreds and hundreds cleaned. So, that temp in and of itself is not a problem. But wherever you measured it might not be the highest temp in your tank.

One gent in this forum found he wasn't filling his tank high enough. The heater, in his case on the side of the tank wall, was probably overheating the tank wall above the liquid level in the tank. Without fluid touching this hot metal to disperse the heat throughout the tank, he was exposing his nearby LP surfaces, just out of the bath, to very high temps. This would be extreme during times when the LPs were stationary and not spinning. Most vinyl used in LPs typically has a deformation temp roughly around 150°F . If a tank heater is not covered by the liquid level in the tank, it would be easy to run up the metal temp to unsafe level. Without LPs in your tank, get your system up and running and see if you can identify a localized hot spot that is appearing.

B B

bbftx -

Thank you for taking the time to read all that and throw out a very good suggestion! All I've got around the house is a drug store fever thermometer - do I need something else to check temps at various depths in the tank or keep it along the bath surface and tank edges?

I couldn't capture the effect in a picture, so here's a video clip of the type of warp being produced.

YouTube

It doesn't seem like much until the needle is placed on the groove, which is why I didn't feel or notice anything. I've kept the tank pretty much filled up to the 'max' line embossed on the back, refilling with distilled water while evaporation and/or bath loss was occurring from removing finished lps. Still waiting to hear back from the ebay seller about their warranty, but not having high hopes.

Thanks again

Thank you for taking the time to read all that and throw out a very good suggestion! All I've got around the house is a drug store fever thermometer - do I need something else to check temps at various depths in the tank or keep it along the bath surface and tank edges?

I couldn't capture the effect in a picture, so here's a video clip of the type of warp being produced.

YouTube

It doesn't seem like much until the needle is placed on the groove, which is why I didn't feel or notice anything. I've kept the tank pretty much filled up to the 'max' line embossed on the back, refilling with distilled water while evaporation and/or bath loss was occurring from removing finished lps. Still waiting to hear back from the ebay seller about their warranty, but not having high hopes.

Thanks again

You don't have the records IN the bath when you cycle the fluid through the filter to cool it down, do you? Mixing different temperatures of water with the records in the bath would be bad.

Also try just one record at a time, centered in the tank, to see if that reduces these issues.

Definitely turn off the heater when it gets to a target temp, since the transducers will increase the heat as it runs.

How long do you let the record drip dry before spraying it with your rinse water? You definitely want to give it a couple of minutes for the vinyl itself to cool back down to room temp.

How fast or slow is your rotation speed?

On a different note, how far into the record does that weird warp continue? If it's really only along the edge, then it might be salvageable with a Vinyl Flat.

I use a digital drug store thermometer to check the fluid temp. I sort of swirl it around at the top of the tank while degassing to help stir it around and even out fluid temp while getting the temperature. Don't do this if you're checking for a specific hot-spot in the tank, but it's good for general prep.

I'd also recommend doing the foil test again to make sure all the transducers are working properly.

Good luck.

Also try just one record at a time, centered in the tank, to see if that reduces these issues.

Definitely turn off the heater when it gets to a target temp, since the transducers will increase the heat as it runs.

How long do you let the record drip dry before spraying it with your rinse water? You definitely want to give it a couple of minutes for the vinyl itself to cool back down to room temp.

How fast or slow is your rotation speed?

On a different note, how far into the record does that weird warp continue? If it's really only along the edge, then it might be salvageable with a Vinyl Flat.

I use a digital drug store thermometer to check the fluid temp. I sort of swirl it around at the top of the tank while degassing to help stir it around and even out fluid temp while getting the temperature. Don't do this if you're checking for a specific hot-spot in the tank, but it's good for general prep.

I'd also recommend doing the foil test again to make sure all the transducers are working properly.

Good luck.

Might want to get Lazer temp gun. There 20.00 and up these days. Can shoot albums in various spots side of walls on tank etc. If localized heating is the problem you can at least check certain areas with this. Plus what a great tool to have for electronics, automotive, etc...

Enjoy the ride

Tom

Enjoy the ride

Tom

Packgrog and TomWh - thanks for reading too and for great suggestions, let me see if I can answer all the questions.

Vinylstack was set at 4.5V so 4.5 minutes for 1 rotation

I do not run the filter while records are in the tank, run 2 records at a time in 10L tank (that seemed to get the best results), didn't try 1 record except for a really really dirty bargain shop release, but that ended up being more damaged then dirty...!

I had been leaving the records on the spindle for about 2 minutes before spraying - I used that time to load up a 2nd spindle and set into the machine and start... maybe that's not enough time to cool? O man, I hope I didn't do this to myself. I feel dumb...

The heater is off - the room temp lists the liquid at 27C after I put the solution in, but I know the house isn't that hot and water jugs were stored at floor level. The temp rises VERY quickly the minute this machine is turned on, and then stays hot. I think evaporation has been the only cooling besides a 2 degree dip from the first movement of the water that's stuck in the filter between washing sets that is cooled by the ice. Then it's traveling too fast to cool through the thick tubing.

The warps don't continue in far - they are usually just that first inch in, and only on that one spot, each are the same in that respect. If it were simply the bath or putting them in too hot water, I'd expect the warp to be general or at least appear on 2 opposite sides?

I can see 4 dimples in the bottom of the tank, and whne I do degassing, that's where the swirls seem to emanate from.

I'll have to do the foil test again - but on that note, the seller on ebay finally contacted me back and asked me to unscrew the bottom and check if all the wires are connected? I thought this was strange, but they confirmed it won't invalidate teh warranty. In any case, connected or not, this unit is more a lava bath than ultrasonic bath.

TomWh - good idea! I'm strapped for $ but it's been put into the "GAS" line item in my budget - for now I'll have to do a temp test and foil test, and then will check the btm and report back. Thanks for the help everyone

Vinylstack was set at 4.5V so 4.5 minutes for 1 rotation

I do not run the filter while records are in the tank, run 2 records at a time in 10L tank (that seemed to get the best results), didn't try 1 record except for a really really dirty bargain shop release, but that ended up being more damaged then dirty...!

I had been leaving the records on the spindle for about 2 minutes before spraying - I used that time to load up a 2nd spindle and set into the machine and start... maybe that's not enough time to cool? O man, I hope I didn't do this to myself. I feel dumb...

The heater is off - the room temp lists the liquid at 27C after I put the solution in, but I know the house isn't that hot and water jugs were stored at floor level. The temp rises VERY quickly the minute this machine is turned on, and then stays hot. I think evaporation has been the only cooling besides a 2 degree dip from the first movement of the water that's stuck in the filter between washing sets that is cooled by the ice. Then it's traveling too fast to cool through the thick tubing.

The warps don't continue in far - they are usually just that first inch in, and only on that one spot, each are the same in that respect. If it were simply the bath or putting them in too hot water, I'd expect the warp to be general or at least appear on 2 opposite sides?

I can see 4 dimples in the bottom of the tank, and whne I do degassing, that's where the swirls seem to emanate from.

I'll have to do the foil test again - but on that note, the seller on ebay finally contacted me back and asked me to unscrew the bottom and check if all the wires are connected? I thought this was strange, but they confirmed it won't invalidate teh warranty. In any case, connected or not, this unit is more a lava bath than ultrasonic bath.

TomWh - good idea! I'm strapped for $ but it's been put into the "GAS" line item in my budget - for now I'll have to do a temp test and foil test, and then will check the btm and report back. Thanks for the help everyone

That's not the usual warp as the surface bounces but the edge remains fairly flat. Very odd. It looks to me like more intensive heat in a focused area. If so, it doesn't sound like the bath itself is the problem. Is it the same on both sides at the same place?

In any case, I'd stope everything with your good albums and watch carefully through the process on a disposable LP, watching for anyplace you might encounter heat. Also, if you have a disposable LP in your collection that's stored with the rest, I'd do a needle drop BEFORE cleaning to make sure it isn't a pre-existing problem...

In any case, I'd stope everything with your good albums and watch carefully through the process on a disposable LP, watching for anyplace you might encounter heat. Also, if you have a disposable LP in your collection that's stored with the rest, I'd do a needle drop BEFORE cleaning to make sure it isn't a pre-existing problem...

- Home

- Source & Line

- Analogue Source

- My version of an Ultrasonic Record Cleaner