FWIW, I noticed the benefit of separate cleaning with vacuuming based on my own experiences, before joining the VPI thread. And long before owning anything from VPI.It's not surprising the VPI group was promoting a follow-up cleaning with a vacuum RCM. VPI makes vacuum RCMs, so they want to try to avoid becoming obsolete!

I have a VPI, and I don't notice any additional benefit from using it after ultrasonic cleaning.

Cheers

B B

Well the old adage "you get what you pay for" is proven again. Recall a few weeks ago I posted about not having great results using a cheap Chinese-made ULC I bought on ebay. Despite making lots of noise, sounding like it was working, I was always disappointed in the results. There was still visible grime on the vinyl, even after a full 60 minute cleaning.

I splurged for Christmas and bough an Elma P60H and the results have been nothing less than incredible. Very noticeable difference in the cleaning thoroughness compared to the cheaper version.

Now I have a new challenge – the scum floating at the top of the tank is clinging to the records when I pull them out. Anyone else have that problem and found a solution?

I splurged for Christmas and bough an Elma P60H and the results have been nothing less than incredible. Very noticeable difference in the cleaning thoroughness compared to the cheaper version.

Now I have a new challenge – the scum floating at the top of the tank is clinging to the records when I pull them out. Anyone else have that problem and found a solution?

Well the old adage "you get what you pay for" is proven again. Recall a few weeks ago I posted about not having great results using a cheap Chinese-made ULC I bought on ebay. Despite making lots of noise, sounding like it was working, I was always disappointed in the results. There was still visible grime on the vinyl, even after a full 60 minute cleaning.

I splurged for Christmas and bough an Elma P60H and the results have been nothing less than incredible. Very noticeable difference in the cleaning thoroughness compared to the cheaper version.

Now I have a new challenge – the scum floating at the top of the tank is clinging to the records when I pull them out. Anyone else have that problem and found a solution?

E, thanks for the update on the cheap Ultrasonic cleaner. As I've said before in this thread, this is not a surprise when it happens. "Lots of noise" is not a good sign from a USC. The higher quality machines, particularly if they are working at a higher frequency, make a lot less noise that is also less irritating in nature.

Regarding "floaters", you have a couple of options. I use the return tubing from my filtering system to rinse off any floaters if I have them as I remove the LPs from the tank. You could also just use a squeeze bottle with your choice of clean water to accomplish this task. After the LPs are removed, I use a fine mesh aquarium net to round up the floaters ---- $1.89 at your nearest pet store....

Another added option is to adapt a skimmer filter system to your tank, hanging off the side, although this might reduce your record cleaning capacity per load in a 6L tank that is already tight for space if you are trying to clean multiple records at a time. I have not felt the need to mount a skimmer, but if I was starting over, I'd probably go with a 10 liter tank that would allow me room to do this on the end of the tank.

Best

B B

Last edited:

I'm ready to buy a decent cleaner but am having problems finding something in Europe (preferably Germany)

I've opted for the VinylStack kit and would like to get a decent 60 or 80KHz machine but Elma units are €1250 and Sonix IV machines don't seem easy to get...

The Vibrato unit looks good but they're had none in stock for 6 weeks...

Any Europeans have a recommendation?

I've opted for the VinylStack kit and would like to get a decent 60 or 80KHz machine but Elma units are €1250 and Sonix IV machines don't seem easy to get...

The Vibrato unit looks good but they're had none in stock for 6 weeks...

Any Europeans have a recommendation?

I'm ready to buy a decent cleaner but am having problems finding something in Europe (preferably Germany)

I've opted for the VinylStack kit and would like to get a decent 60 or 80KHz machine but Elma units are €1250 and Sonix IV machines don't seem easy to get...

The Vibrato unit looks good but they're had none in stock for 6 weeks...

Any Europeans have a recommendation?

Ask this guy, he offered some demo-units while ago. I bought one and it works great. emmi-ultraschall-welt on eBay

Works- still figuring out the optimum nr of albums/distance between the albums for the "perfect" wash

My understanding is that you need an 1" between LPs (and from the outside LPs to the side of the tank) if your US frequency is 60Khz ... and 1 1/2" if you have a 40Khz machine.

Andy

Ask this guy, he offered some demo-units while ago. I bought one and it works great. emmi-ultraschall-welt on eBay

Cheers...got in touch but he only sells 40KHz units...I think I'd prefer a 60 or 80!

Hi all,

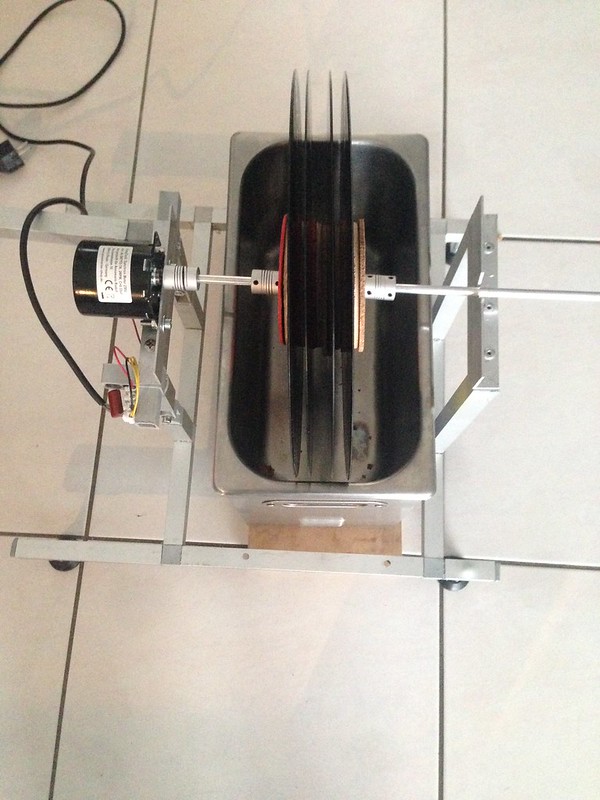

I've been floating around this thread for a while and have finally made the major components for my record cleaning machine. I definitely did not have the budget for a 60 or 80khz machine and had to settle for a 40khz unit. I have a 9ltr cleaner from GT Sonic. I decided to go for the larger capacity tank so that I could space the records greater than one wavelength apart and still fit three in the cleaner.

The record spacer/label protectors are made of 6mm acrylic discs with 20mm thick hubs. Luckily I had quite a lot of acrylic left over from building my record deck. The labels are protected with discs of 1mm thick neoprene closed cell foam. This setup spaces the records 54mm apart which should be ideal for a 40khz machine.

The axle is 1/4" stainless steel with 4mm pins at either end that sit into nylon pillow blocks that take the entire weight of the axle and records. The drive is applied via a gear attached to one end of the axle. The records are really easy to mount to the axle and are secured with a wing bolt. The axle with records fitted drops in and out of the pillow blocks dead easy.

The motor is 12volt dc worm drive rated at 0.6rpm (one revolution every 100seconds) which is about 6 times faster than recommend. As water is involved using low voltage dc has a definite safety advantage. The drive gears from the motor to axle give a 8:3 reduction decreasing rotational speed and increasing torque. To further reduce speed the motor is driven by a pulse width modulation motor controller (£1.50 from eBay). This allows me to select any speed from 4 1/2 minutes to 15 minutes per revolution. I've marked the position that gives 1 revolution every ten minutes. A separate switch allows easy start/stop. The motor and controller sit in a sealed acrylic box that hangs off the back of the cleaner.

The framework that supports the motor and all the other components sits on top of the cleaner and is also made of acrylic.

So far I have only done a quick test. I have a junk record that I use for cartridge alignment. As my arm is linear tracking it has a line scored on one side that makes alignment dead easy. This record doesn't live in a sleeve and hasn't been handled with care. It was filthy and covered in finger prints. I gave the unscored side a quick listen. The snap, crackle and pop almost drowned out the music. Ten minutes in the cleaner filled with plain tap water and a drop of dish soap. The difference was really quite dramatic. There is still a bit of pops but this is probably mainly due to scratches, as I said this record has been abused severely. The record was quite listenable, the level of surface noise was too low to be detracting. The real ear opener was in the run out groove. The fluid level in the tank was a bit lower than ideal and only covered half way up the run out groove. The stylus started the run out in near silence then hit the point where the water surface had been, the crackling was almost deafening in comparison. I have high hopes for proper cleaning with a proper cleaning solution.

I still have to make the components for the rinse and drying cycles. I don't see the point in making a batch of proper cleaning solution and cleaning a bunch of records until then. No point in half cleaning the records then having to clean them again.

I've actually made 4 axles. The extra work to do so was minimal once I was set up to make the first one. This way I can have one in an enzyme presoak (if necessary for really grubby records), one in the US cleaner, one in a distilled water rinse, and one in a dryer. This will allow me to run a production line style of cleaning maximizing the number of records cleaned in a session.

Here are some photos of the work so far.

View attachment 593207

View attachment 593208

View attachment 593209

View attachment 593210

View attachment 593211

Niffy

I've been floating around this thread for a while and have finally made the major components for my record cleaning machine. I definitely did not have the budget for a 60 or 80khz machine and had to settle for a 40khz unit. I have a 9ltr cleaner from GT Sonic. I decided to go for the larger capacity tank so that I could space the records greater than one wavelength apart and still fit three in the cleaner.

The record spacer/label protectors are made of 6mm acrylic discs with 20mm thick hubs. Luckily I had quite a lot of acrylic left over from building my record deck. The labels are protected with discs of 1mm thick neoprene closed cell foam. This setup spaces the records 54mm apart which should be ideal for a 40khz machine.

The axle is 1/4" stainless steel with 4mm pins at either end that sit into nylon pillow blocks that take the entire weight of the axle and records. The drive is applied via a gear attached to one end of the axle. The records are really easy to mount to the axle and are secured with a wing bolt. The axle with records fitted drops in and out of the pillow blocks dead easy.

The motor is 12volt dc worm drive rated at 0.6rpm (one revolution every 100seconds) which is about 6 times faster than recommend. As water is involved using low voltage dc has a definite safety advantage. The drive gears from the motor to axle give a 8:3 reduction decreasing rotational speed and increasing torque. To further reduce speed the motor is driven by a pulse width modulation motor controller (£1.50 from eBay). This allows me to select any speed from 4 1/2 minutes to 15 minutes per revolution. I've marked the position that gives 1 revolution every ten minutes. A separate switch allows easy start/stop. The motor and controller sit in a sealed acrylic box that hangs off the back of the cleaner.

The framework that supports the motor and all the other components sits on top of the cleaner and is also made of acrylic.

So far I have only done a quick test. I have a junk record that I use for cartridge alignment. As my arm is linear tracking it has a line scored on one side that makes alignment dead easy. This record doesn't live in a sleeve and hasn't been handled with care. It was filthy and covered in finger prints. I gave the unscored side a quick listen. The snap, crackle and pop almost drowned out the music. Ten minutes in the cleaner filled with plain tap water and a drop of dish soap. The difference was really quite dramatic. There is still a bit of pops but this is probably mainly due to scratches, as I said this record has been abused severely. The record was quite listenable, the level of surface noise was too low to be detracting. The real ear opener was in the run out groove. The fluid level in the tank was a bit lower than ideal and only covered half way up the run out groove. The stylus started the run out in near silence then hit the point where the water surface had been, the crackling was almost deafening in comparison. I have high hopes for proper cleaning with a proper cleaning solution.

I still have to make the components for the rinse and drying cycles. I don't see the point in making a batch of proper cleaning solution and cleaning a bunch of records until then. No point in half cleaning the records then having to clean them again.

I've actually made 4 axles. The extra work to do so was minimal once I was set up to make the first one. This way I can have one in an enzyme presoak (if necessary for really grubby records), one in the US cleaner, one in a distilled water rinse, and one in a dryer. This will allow me to run a production line style of cleaning maximizing the number of records cleaned in a session.

Here are some photos of the work so far.

View attachment 593207

View attachment 593208

View attachment 593209

View attachment 593210

View attachment 593211

Niffy

And a couple more.

View attachment 593218

View attachment 593219

View attachment 593220

View attachment 593221

Niffy

View attachment 593218

View attachment 593219

View attachment 593220

View attachment 593221

Niffy

Hi Niffy,

Congratulations on a job well done!

I have been following this thread with great interest. I am currently using VPI’s cleaning machine. VPI does ok job for cleaning and my arm is quiet, so I don’t have strong desire to build one yet.

The only concern I have is how effective the label protectors are. I don’t refer to your machine only but to all machines built by diyers here. If you take the record out of water, there are still some water on the record. The water may flow over the label if you take the protectors off without vacuuming the water.

Jim

Congratulations on a job well done!

I have been following this thread with great interest. I am currently using VPI’s cleaning machine. VPI does ok job for cleaning and my arm is quiet, so I don’t have strong desire to build one yet.

The only concern I have is how effective the label protectors are. I don’t refer to your machine only but to all machines built by diyers here. If you take the record out of water, there are still some water on the record. The water may flow over the label if you take the protectors off without vacuuming the water.

Jim

I've built an ultrasonic cleaner as per BBTfx design using a 0.6rpm motor can you post some me details of how you have slowed down the rotation in your version as I'm not sure if a 10 minute cleaning cycle with a 0.6rpm motor is giving enough cleaning time in the tank for each section of the LP

Hi Jim,

Almost all of my records are near silent on the surface noise front. (Some aren't, most of the noisy ones are second hand.) My wife has quite a large collection that has not been cared for with the fastidious care that mine have received. Restoring her records to a playable condition will positively expand our joint music library.

Additionally there are many reports that a good clean can improve the sound of even new records. I found this to be the case with my old hunt p2 record cleaning solution. Unfortunately it turned out that this stuff was pretty much pure CFC so was not very environmentally friendly.

My label protectors seem to work very well. I run a record under a tap when clamped with them and the label stayed perfectly dry. I'm not actually all that worried about a little bit of water getting onto the labels. My previous cleaning regime involved immersing the entire record in cleaning solution (soapy water) and cleaning with a carbon fibre brush when rinsing under a tap. Even with complete immersion I never had any problems with label damage.

Niffy

Almost all of my records are near silent on the surface noise front. (Some aren't, most of the noisy ones are second hand.) My wife has quite a large collection that has not been cared for with the fastidious care that mine have received. Restoring her records to a playable condition will positively expand our joint music library.

Additionally there are many reports that a good clean can improve the sound of even new records. I found this to be the case with my old hunt p2 record cleaning solution. Unfortunately it turned out that this stuff was pretty much pure CFC so was not very environmentally friendly.

My label protectors seem to work very well. I run a record under a tap when clamped with them and the label stayed perfectly dry. I'm not actually all that worried about a little bit of water getting onto the labels. My previous cleaning regime involved immersing the entire record in cleaning solution (soapy water) and cleaning with a carbon fibre brush when rinsing under a tap. Even with complete immersion I never had any problems with label damage.

Niffy

Hi Moko,

My 0.6rpm motor is a 12volt dc model. I have a 15tooth gear mounted on the output shaft of the motor that drives a 40tooth gear on the axle. This gives a 3:8 reduction reducing the speed to 0.225rpm. To slow the rotation further I use a pulse width modulation (PWM) motor controller that I purchased from eBay. A PWM controller gives lots of very short full voltage pulses to the motor. This works similar to reducing the supply voltage but has the advantage as it helps to maintain motor torque.

If you have connected your axle directly to the motor output shaft you could probably reduce rotational speed with a PWM to about 0.125rpm or once every 8minutes.

Niffy

My 0.6rpm motor is a 12volt dc model. I have a 15tooth gear mounted on the output shaft of the motor that drives a 40tooth gear on the axle. This gives a 3:8 reduction reducing the speed to 0.225rpm. To slow the rotation further I use a pulse width modulation (PWM) motor controller that I purchased from eBay. A PWM controller gives lots of very short full voltage pulses to the motor. This works similar to reducing the supply voltage but has the advantage as it helps to maintain motor torque.

If you have connected your axle directly to the motor output shaft you could probably reduce rotational speed with a PWM to about 0.125rpm or once every 8minutes.

Niffy

Thanks Niffy do you mean something like this 12V-40V 10A 13khz Pulse Width Modulation PWM DC Motor Speed Control Switch ZY | eBay

The motor I'm using is this one 0.6rpm Reversible High Torque Turbo Worm Geared Motor DC 12V Motor GW/GJY370 0.6-120RPM | eBay

The motor I'm using is this one 0.6rpm Reversible High Torque Turbo Worm Geared Motor DC 12V Motor GW/GJY370 0.6-120RPM | eBay

Hi Moko,

That's exactly the same motor that I'm using. The PWM controller you found is perfect for the job. The one I used is this one. Dc Motor 12V-36V Pulse Width Pwm Speed Control Ler Regulator Switch 12V 24V 3A E | eBay

It's basically the same but at a third the price.

Niffy

That's exactly the same motor that I'm using. The PWM controller you found is perfect for the job. The one I used is this one. Dc Motor 12V-36V Pulse Width Pwm Speed Control Ler Regulator Switch 12V 24V 3A E | eBay

It's basically the same but at a third the price.

Niffy

Hello Niffy

first of all, congratulations to your build! I have to say this is so far the best example ever seen of these BBQ-style machines, thumbs up! The quality of elaboration on those Acrylic components is phenomenal, you must have a lot of professional tools to perform this level of craftsmanship. Even the gears are of own production, or something stock?

As you are using a 40kHz machine as well, may I ask if you experienced excess temperature rise of the washing liquid, after several cleaning cycles?

Jano

first of all, congratulations to your build! I have to say this is so far the best example ever seen of these BBQ-style machines, thumbs up! The quality of elaboration on those Acrylic components is phenomenal, you must have a lot of professional tools to perform this level of craftsmanship. Even the gears are of own production, or something stock?

As you are using a 40kHz machine as well, may I ask if you experienced excess temperature rise of the washing liquid, after several cleaning cycles?

Jano

I've read through 10+ pages of this thread but can not find a parts list. I want to do it as cheaply as possible from parts I can get on ebay or my local hardware store. Not looking for anything pretty or precise. As long as it can hold 1 or 2 records and rotate them, it will do the job!

Is there a post that contains this info.?

Is there a post that contains this info.?

- Home

- Source & Line

- Analogue Source

- My version of an Ultrasonic Record Cleaner