Anyone else have some kind of visible vapor come out from underneath the first time they use the heater on their ultrasonic tank? Is that something that will stop with regular usage, or something about which I should be concerned? I'll be sending a message to the manufacturer as well, but I wanted to check here first in case anyone else has experienced this.

Ghetto-tastic Trial Run

So, I gave it a go with the parts that I have so far. As my ServoCity parts have not arrived, I bought a 1/4" wooden dowel that I could turn by hand, and since the cork stoppers from the UK are obscenely priced once you factor in shipping, I got some smaller ones for cheap at Ikea. I was going for the cork coasters, which I'd planned on doubling up and gluing together, but they were out, so the stoppers were good enough for $2.

Here's the rack and dowel assembly:

And here's the whole contraption so far:

Here's the records in question, with my playback gear, for those that are remotely interested:

These two records are beat to hell, lousy later pressings, but albums that I still adore from my youth. The Nilsson is a 1978 repressing that I ruined with repeated plays on some cheap, hand-me-down equivalent to the groove-grinding Crosleys of today, only probably worse. Give me a break, I was 5 or 6 years old! My mom's "fancy" turntable was merely a Pioneer PL-200 (still have it, got me started on the vinyl resurgence a couple of years back). But I digress, this record was not treated well, was stored in a basement that flooded a couple of times over the years, so I had low expectations and less concern should it get damaged. I'm not sure if the Jarre came from the same batch of records-inherited-from-mom, but it was in worse condition, and I have an earlier pressing in better shape, so I used the crappy one for testing. Neither had yet been cleaned since I inherited them.

While distorted, sibilant, and hissy from a likely combo of lousy late-generation master source and excessive playback on a groove-grinder, there was a startling lack of rice krispies on the Nilsson. Since the distortion got noticeably worse on the inner groove, an issue that I really don't have with the Dynavector on the Audiomods mounted with the recommended protractor, I figured it was just a wrecked pressing. Again, not surprising. What was surprising was that there were fewer pops and ticks than some mint pressings that I've cleaned on the KAB EV-1 with the AIVS No 15 and Ultra Pure water.

The Jarre, however, still sounded terrible. One thing that I noticed while turning the record in the ultrasonic bath was that water stayed in the grooves of the Jarre much longer than it did on the Nilsson. I've seen stated on an Audiogon forum post that some garage sale finds can still benefit from an AIVS wash before going into the ultrasonic bath, and this may be a good example of that. To me fair, I was VERY conservative with my use of 91% isopropyl alcohol, pouring a mere two or three capfuls into the tank before degassing, as I was concerned that 2+ oz (ie: 2+ shot glasses) per gallon might be excessive, so perhaps upping the concentration of that will help. I'd REALLY like to avoid having to use the KAB EV-1 any more, as it is a major pain in the ***, but if it winds up only being necessary once per record, and only for really nasty ones, then I can cope. I'll try two shot glasses of Iso per gallon on my next pass, and hopefully the PhotoFlo that I ordered from Amazon will arrive this week. I will have to try out both the Jarre again along with another record that I've already cleaned on the KAB, so that I can know if I'm making matters worse or not.

Regarding the heat, I tried turning on the heater a couple more times, but never for long, as that weird vapor comes out every time. That being said, after a 10 minute degassing followed by about 15 minutes of cleaning time, I took the temperature of the water and it was about 105 Fahrenheit! While a tiny bit more heat might be helpful, maybe it won't be necessary, and maybe I won't have to send the thing back. We'll see. It WOULD be nice to have a FULLY functioning unit after paying more than $500 on the thing.

The MakerBeam stuff was fidgity but fun. I'm sure I could have accomplished the same goal for cheaper, but this rack arrangement looks kind of neat, IMO. Totally different than my originally intended goal, but without a motor or stronger spindle, I needed support on both sides of the tank. I got lucky with the dimensions. One side of this at least will definitely change once the ServoCity parts arrive, but for now at least this is functional.

All feedback and suggestions are welcome!

So, I gave it a go with the parts that I have so far. As my ServoCity parts have not arrived, I bought a 1/4" wooden dowel that I could turn by hand, and since the cork stoppers from the UK are obscenely priced once you factor in shipping, I got some smaller ones for cheap at Ikea. I was going for the cork coasters, which I'd planned on doubling up and gluing together, but they were out, so the stoppers were good enough for $2.

Here's the rack and dowel assembly:

An externally hosted image should be here but it was not working when we last tested it.

And here's the whole contraption so far:

An externally hosted image should be here but it was not working when we last tested it.

Here's the records in question, with my playback gear, for those that are remotely interested:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

These two records are beat to hell, lousy later pressings, but albums that I still adore from my youth. The Nilsson is a 1978 repressing that I ruined with repeated plays on some cheap, hand-me-down equivalent to the groove-grinding Crosleys of today, only probably worse. Give me a break, I was 5 or 6 years old! My mom's "fancy" turntable was merely a Pioneer PL-200 (still have it, got me started on the vinyl resurgence a couple of years back). But I digress, this record was not treated well, was stored in a basement that flooded a couple of times over the years, so I had low expectations and less concern should it get damaged. I'm not sure if the Jarre came from the same batch of records-inherited-from-mom, but it was in worse condition, and I have an earlier pressing in better shape, so I used the crappy one for testing. Neither had yet been cleaned since I inherited them.

While distorted, sibilant, and hissy from a likely combo of lousy late-generation master source and excessive playback on a groove-grinder, there was a startling lack of rice krispies on the Nilsson. Since the distortion got noticeably worse on the inner groove, an issue that I really don't have with the Dynavector on the Audiomods mounted with the recommended protractor, I figured it was just a wrecked pressing. Again, not surprising. What was surprising was that there were fewer pops and ticks than some mint pressings that I've cleaned on the KAB EV-1 with the AIVS No 15 and Ultra Pure water.

The Jarre, however, still sounded terrible. One thing that I noticed while turning the record in the ultrasonic bath was that water stayed in the grooves of the Jarre much longer than it did on the Nilsson. I've seen stated on an Audiogon forum post that some garage sale finds can still benefit from an AIVS wash before going into the ultrasonic bath, and this may be a good example of that. To me fair, I was VERY conservative with my use of 91% isopropyl alcohol, pouring a mere two or three capfuls into the tank before degassing, as I was concerned that 2+ oz (ie: 2+ shot glasses) per gallon might be excessive, so perhaps upping the concentration of that will help. I'd REALLY like to avoid having to use the KAB EV-1 any more, as it is a major pain in the ***, but if it winds up only being necessary once per record, and only for really nasty ones, then I can cope. I'll try two shot glasses of Iso per gallon on my next pass, and hopefully the PhotoFlo that I ordered from Amazon will arrive this week. I will have to try out both the Jarre again along with another record that I've already cleaned on the KAB, so that I can know if I'm making matters worse or not.

Regarding the heat, I tried turning on the heater a couple more times, but never for long, as that weird vapor comes out every time. That being said, after a 10 minute degassing followed by about 15 minutes of cleaning time, I took the temperature of the water and it was about 105 Fahrenheit! While a tiny bit more heat might be helpful, maybe it won't be necessary, and maybe I won't have to send the thing back. We'll see. It WOULD be nice to have a FULLY functioning unit after paying more than $500 on the thing.

The MakerBeam stuff was fidgity but fun. I'm sure I could have accomplished the same goal for cheaper, but this rack arrangement looks kind of neat, IMO. Totally different than my originally intended goal, but without a motor or stronger spindle, I needed support on both sides of the tank. I got lucky with the dimensions. One side of this at least will definitely change once the ServoCity parts arrive, but for now at least this is functional.

All feedback and suggestions are welcome!

I know this thread is for Ultrasonic but VPI USA is working in a ultrasonic machine,

VPI new "Sharknado" Record Cleaning Machine, Ultrasonic | Steve Hoffman Music Forums

read well the thread because everybody understand that is a joke but is true!!

maybe they sell in a good price and not the overpriced audiodesk!

VPI new "Sharknado" Record Cleaning Machine, Ultrasonic | Steve Hoffman Music Forums

read well the thread because everybody understand that is a joke but is true!!

maybe they sell in a good price and not the overpriced audiodesk!

OK, got a response from Sonix:

That's a relief. I'll probably just take it outside this evening with some fluid in the tank and turn on the heater for a while to let the vapor out without choking me, my wife, or my pets. VERY glad that I asked, though.

VERY glad that I asked, though.

Meanwhile, my second test run has been a bit disappointing. I upped the alcohol concentration by putting a full 2 oz of 91% IPA per gallon, and again ran without the heater (this time the fluid didn't heat up at all, so I guess the heat from the first run was indeed due to the minute or so of the heater being turned on during degassing). This didn't seem to do much of anything. I retried the Equinoxe, and it still sounds like a wreck, and still held onto the fluid far longer than the other record. The other record this time was a stubborn pressing of 10,000 Maniacs - Blind Man's Zoo that I'd cleaned twice on the KAB EV-1 using AIVS No 15 and Ultra Pure water. There may be a slight veil lifted on the 10kM, but the clicks all still seem to be there. So adding IPA alone did jack. :/ Again, though, this was without applying any heat, but it was also approximately 15 minutes worth of cleaning, doing a just-visible turn of the record skewer every 10 seconds (approx 7-8 minutes total cleaning time for the records, as I did 2 total passes).

I will try both of them again with the heater turned on, now that I'm reassured about the vapor issue by the manufacturer, checking to make sure that the temp does not exceed 120F. We'll see if that's more effective. After that, I'll try the AIVS scrub & vac on the Equinoxe to see if that one is being held back by grime that the ultrasonic bath can't handle.

Spenser Hooks (Sonix 4 Ultrasonics)

Jan 19, 12:08

Thank you for contacting Sonix IV.

The issue you have described sometimes happens within a new unit as it is the result of excess adhesive burning off of the heater. This will not cause any damage and the unit should cease "smoking" within a few minutes of operation. Usually, 30 minutes of continuous operation with the heater turned on is more than enough time to remove any excess adhesive from the heater.

I hope this information is useful, and please contact me should the issue persist or if you need any additional information.

That's a relief. I'll probably just take it outside this evening with some fluid in the tank and turn on the heater for a while to let the vapor out without choking me, my wife, or my pets.

Meanwhile, my second test run has been a bit disappointing. I upped the alcohol concentration by putting a full 2 oz of 91% IPA per gallon, and again ran without the heater (this time the fluid didn't heat up at all, so I guess the heat from the first run was indeed due to the minute or so of the heater being turned on during degassing). This didn't seem to do much of anything. I retried the Equinoxe, and it still sounds like a wreck, and still held onto the fluid far longer than the other record. The other record this time was a stubborn pressing of 10,000 Maniacs - Blind Man's Zoo that I'd cleaned twice on the KAB EV-1 using AIVS No 15 and Ultra Pure water. There may be a slight veil lifted on the 10kM, but the clicks all still seem to be there. So adding IPA alone did jack. :/ Again, though, this was without applying any heat, but it was also approximately 15 minutes worth of cleaning, doing a just-visible turn of the record skewer every 10 seconds (approx 7-8 minutes total cleaning time for the records, as I did 2 total passes).

I will try both of them again with the heater turned on, now that I'm reassured about the vapor issue by the manufacturer, checking to make sure that the temp does not exceed 120F. We'll see if that's more effective. After that, I'll try the AIVS scrub & vac on the Equinoxe to see if that one is being held back by grime that the ultrasonic bath can't handle.

There are many sources of clicks and noise besides dirt. Ultrasonic cleaning can't fix damaged records or poor pressings (and there are those who think all Polydor pressings, which I assume your Equinoxe is, from that era are bad).

And LPs simply wear out if they're played a lot.

You're beating your head against the wall with repeated cleanings of the same record. I've had problem children like that, so I know you want them to improve! But, if things don't improve after two cleanings, accept it and move on to the next. Changing the amount of IPA will have limited effect.

Cheers,

B B

And LPs simply wear out if they're played a lot.

You're beating your head against the wall with repeated cleanings of the same record. I've had problem children like that, so I know you want them to improve! But, if things don't improve after two cleanings, accept it and move on to the next. Changing the amount of IPA will have limited effect.

Cheers,

B B

Of course. I'm not certain yet, given that I've yet to use a surficant or heating, that I've reached the maximum potential of this method. If they sound the same after trying those things out, then I've done all that I can. I'm not sure yet with either of these records. It's unlikely to make them worse (and if so, oh well), and I'm learning something about each addition to the process in the meantime.

And it will also be interesting to discover if, after trying all of this, an AIVS cleaning of the Equinoxe does actually improve things on that record. I actually hope NOT, as then at least I would know that it's just the vinyl that's junk, and not a need for a tedious extra step. If an ultrasonic bath can eliminate the vast majority of any need for vacuum washing or mask peeling (ala Record Revirginizer), then this will be a very worthwhile investment, but I have to test it all to make sure.

And it will also be interesting to discover if, after trying all of this, an AIVS cleaning of the Equinoxe does actually improve things on that record. I actually hope NOT, as then at least I would know that it's just the vinyl that's junk, and not a need for a tedious extra step. If an ultrasonic bath can eliminate the vast majority of any need for vacuum washing or mask peeling (ala Record Revirginizer), then this will be a very worthwhile investment, but I have to test it all to make sure.

Just to add my two cents, heat (105F - 110F) did make a dfference for me. Also the few drops of the triton x114 was also noticable for the sheeting action of the water. There were a couple of records of records where I needed to run twice but that was due to being very dirty and a spot or two of built up grime. A little hand wash on those spots before the second spin made a big differense.

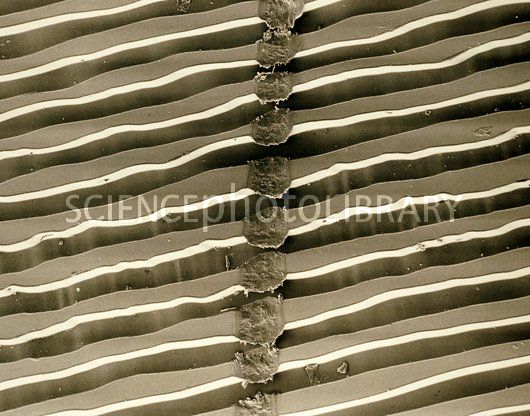

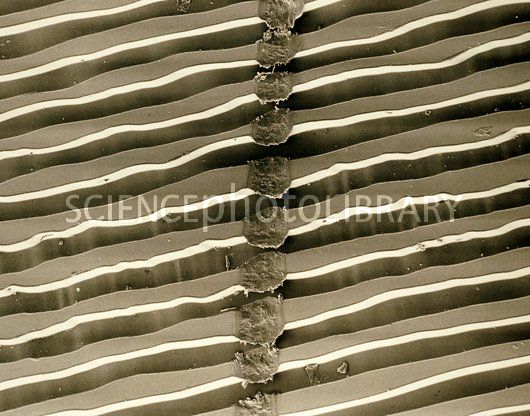

It may be my imagination but some of the scuffs and scratches seemed less visible after a cleaning.. I suspect US cleaning might be getting rid some of the burrs and curls that a scratch causes. Microscopic view of course.

It may be my imagination but some of the scuffs and scratches seemed less visible after a cleaning.. I suspect US cleaning might be getting rid some of the burrs and curls that a scratch causes. Microscopic view of course.

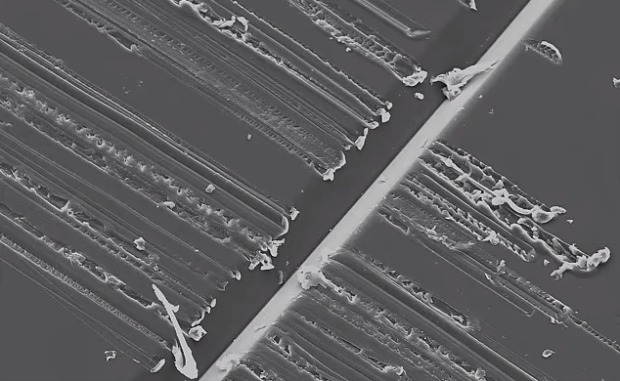

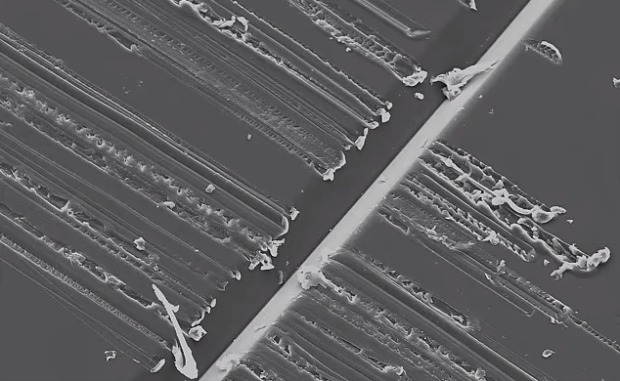

These images of a magnified record grooves with burrs and curls. I would think US cleaning might get rid of some of the vinyl debris because of the bubble implosions being enough to dislodge and seperate the smaller pieces. Any thoughts on this from anyone?

Higher power view below. The groove is the diagonal line going from lower left to upper right.

Higher power view below. The groove is the diagonal line going from lower left to upper right.

Last edited:

BBFTX, PLEASE share your idea on magnetic coupler and 9/32" shaft. That's the way I have wanted to go, but it's hard for me to figure those things out (the MS doesn't allow me to use that part of my brain as well anymore). I have a full wood shop and can make a lot of cool stuff, so I'm sure I can do a mag coupler. I bought that inexpensive motor that you (or someone) turned us onto, so I should be good to go. Those sketch up pics you share are awesome. This way we can have one or two extra ones already set up to go. I found some 1/2" cork costers that I will glue together to get 1" in between record surfaces. Thanks looking forward to seeing your new idea.

Hey Sooner!

I've got all the parts ordered for a different, free-standing system. I've modified that simple drawing I posted and gone away from the t-slot extrusions. I should probably wait to share the complete setup to make sure I've got the right components selected for the mag coupling.

I'm using a strong neodymium magnet, and there is always the question of how powerful a magnet to get, balancing the ability to support the records, spacers and spindle, but not so strong as to make the spindle hard to remove. I've made an educated guess and should know shortly after the components arrive whether I've spec'd the right one. It's a very simple, 2 part magnetic setup that won't require additional machining if all goes right for the spindle/magnet/steel coupler. But I'd hate to create confusion by mentioning specific parts and then find out they're not the right ones.

I've also found a potentially better spacer solution than the cork!

Please be patient and I'll report here as soon as I have a workable selection of components.

Cheers,

B B

I've got all the parts ordered for a different, free-standing system. I've modified that simple drawing I posted and gone away from the t-slot extrusions. I should probably wait to share the complete setup to make sure I've got the right components selected for the mag coupling.

I'm using a strong neodymium magnet, and there is always the question of how powerful a magnet to get, balancing the ability to support the records, spacers and spindle, but not so strong as to make the spindle hard to remove. I've made an educated guess and should know shortly after the components arrive whether I've spec'd the right one. It's a very simple, 2 part magnetic setup that won't require additional machining if all goes right for the spindle/magnet/steel coupler. But I'd hate to create confusion by mentioning specific parts and then find out they're not the right ones.

I've also found a potentially better spacer solution than the cork!

Please be patient and I'll report here as soon as I have a workable selection of components.

Cheers,

B B

Sorry for the lousy pictures in advance. My version of the US cleaner using magnetic coupling. Most parts came from Servo city and All electronics. The spacer are made from 1" HDPE which are a bitch to drill out as the low melt point causes the hole saw (4 1/4) to stick.

Last edited:

That's pretty slick, Zg! My own ServoCity parts and Synchro motor (from a different source, as Herbach was out of stock until Feb.) have arrived, but I haven't had another chance to tinker yet. Still need to get a box for the motor itself, and wire everything up, hopefully not frying the motor before I have a chance to test it.  Then reworking the stand to secure the motor in such a way that it can be easily lifted away from the tank. Hopefully I'll find some tinker time this weekend...

Then reworking the stand to secure the motor in such a way that it can be easily lifted away from the tank. Hopefully I'll find some tinker time this weekend...

Hi Zg,

Looks great. I think I'll have a spacer solution that avoids the problem of working with HDPE, and is much much lighter. I'm also designing to a much shorter spindle length which might should require less beef in the magnet, bearings and shafting.

What was your magnet choice (Neod. category Nxx and lbs. force?) and what does it mate with?

Thanks,

B B

Looks great. I think I'll have a spacer solution that avoids the problem of working with HDPE, and is much much lighter. I'm also designing to a much shorter spindle length which might should require less beef in the magnet, bearings and shafting.

What was your magnet choice (Neod. category Nxx and lbs. force?) and what does it mate with?

Thanks,

B B

Hey BB. I used a 1/2" x 1/2" neodymium magnet from www.apexmagnets.com part number M12x12CYL. I can't remember if it is 28 or 35 lbs pull. The magnet protrudes out about 1/4" from the backing plate (see image). On the record side there is a 1/2" recess on the first disk where the disc assembly attaches to the metal plate (on the motor side) I'm using a 6" x 1/4" zinc coated bolt on the record holder. The 3/8" rod I use as the main shaft is longer on this unit so I can center on this large tank. Normally it would only be a 1/2" longer than 1" round housing for a 6" wide tank. All parts eith aluminum or stainless steel with the exception of the 1/4" bolt on the record holder.

Also notice that I use a clamping system to attach the apparatus to the cleaner. By changing the size of the threaded rod I can use on different width tanks.

Also notice that I use a clamping system to attach the apparatus to the cleaner. By changing the size of the threaded rod I can use on different width tanks.

Last edited:

About the magnets I used from www.apexmagnets.com Working well to hold 5 records + 4 4"Dia x 1" HDPE spacer + 2 4" Dia x 5/8" spacers + 1/4" x 6" bolt + 1/4" plastic knob (4.25 lbs. total weight)

Set of 4 ($12.99) magnets 1/2"diameter x 1/2" thick (12.7 mm x 12.7 mm) Material: Neodymium (NdFeB) Grade: N48 Coating: Nickel Magnetization:Axial Pull Force: 24.5 pounds SKU# M12x12CYL NEODYMIUM

Pack, The project box I used came from All Electronics. http://www.allelectronics.com/make-a-store/category/145/cases/1.html

Set of 4 ($12.99) magnets 1/2"diameter x 1/2" thick (12.7 mm x 12.7 mm) Material: Neodymium (NdFeB) Grade: N48 Coating: Nickel Magnetization:Axial Pull Force: 24.5 pounds SKU# M12x12CYL NEODYMIUM

Pack, The project box I used came from All Electronics. http://www.allelectronics.com/make-a-store/category/145/cases/1.html

Last edited:

Very cool....thanks, I can't wait to see what you come up with. I'm not a metal turner (wood turner), so I'm hoping it's something that is fairly easy to make. Can't wait.Hey Sooner!

I've got all the parts ordered for a different, free-standing system. I've modified that simple drawing I posted and gone away from the t-slot extrusions. I should probably wait to share the complete setup to make sure I've got the right components selected for the mag coupling.

I'm using a strong neodymium magnet, and there is always the question of how powerful a magnet to get, balancing the ability to support the records, spacers and spindle, but not so strong as to make the spindle hard to remove. I've made an educated guess and should know shortly after the components arrive whether I've spec'd the right one. It's a very simple, 2 part magnetic setup that won't require additional machining if all goes right for the spindle/magnet/steel coupler. But I'd hate to create confusion by mentioning specific parts and then find out they're not the right ones.

I've also found a potentially better spacer solution than the cork!

Please be patient and I'll report here as soon as I have a workable selection of components.

Cheers,

B B

yes, my goal here was to limit tools required, since that seems to be a common situation among interested folks. I think I've got it down to just a drill being required. Hacksaw is optional, as the framing vendor would cut the framing material for an added cost!

More to come soon.

B B

More to come soon.

B B

Pack, I find that a lab grade detergent at minimum concentration works fine. Then rinse under running water, and two more rinses has the water drain off like a newly waxed fender.

I ruined a few good records by cleaning them with bad water, and they were noisy to the point of unplayability, no matter how I cleaned them, until I used ultrasound. Now they are wonderful and dynamic - nearly mint from 1965!!

But make sure that you have enough space between the records for a full wave to develop. That means more than 0.75 inches for 80 KHz, 1.5 inches for 40KHz - and that's for the minimum distance between them. I like to clean them for 15 minutes, double for badly soiled. YMMV

I ruined a few good records by cleaning them with bad water, and they were noisy to the point of unplayability, no matter how I cleaned them, until I used ultrasound. Now they are wonderful and dynamic - nearly mint from 1965!!

But make sure that you have enough space between the records for a full wave to develop. That means more than 0.75 inches for 80 KHz, 1.5 inches for 40KHz - and that's for the minimum distance between them. I like to clean them for 15 minutes, double for badly soiled. YMMV

About the magnets I used from www.apexmagnets.com Working well to hold 5 records + 4 4"Dia x 1" HDPE spacer + 2 4" Dia x 5/8" spacers + 1/4" x 6" bolt + 1/4" plastic knob (4.25 lbs. total weight)

Set of 4 ($12.99) magnets 1/2"diameter x 1/2" thick (12.7 mm x 12.7 mm) Material: Neodymium (NdFeB) Grade: N48 Coating: Nickel Magnetization:Axial Pull Force: 24.5 pounds SKU# M12x12CYL NEODYMIUM

Pack, The project box I used came from All Electronics. Cases | All Electronics Corp.

This is the same setup used in my Vinyl Stack unit. I think the magnet is the way to go. It holds tight and is very easy to remove. The difference is that Vinyl Stack uses a 1/4" x 3" bolt and thinner spacers. My biggest criticism of the Vinyl Stack is that you can't raise the entire record out of the US bath (I would like to be able to drip dry while rotating since I'm usually not in a hurry). bbftz, will your telescoping design raise the bottom of the record at least 10" from the bottom of the tank feet?

00

- Home

- Source & Line

- Analogue Source

- My version of an Ultrasonic Record Cleaner