Thanks for your answer!

My problem here would be the usual Ali approach: how do you know, what are you exactly buying, and receiving? I mean, there is a list of 50 different models... which one are they selling? E.g. there are transmitters with 4800pF capacity from 67 to 120 kHz frequency. The only parameter to distinguish between them is the height: 1mm difference...

Same for that generator: they write 80kHz 300W in the advertisement, and there is no such model in the list. There is one 300W, with max. frequency 40kHz; OR a high frequency model which goes from 300W up to 1200W - why would they advertise with the minimum power???

My problem here would be the usual Ali approach: how do you know, what are you exactly buying, and receiving? I mean, there is a list of 50 different models... which one are they selling? E.g. there are transmitters with 4800pF capacity from 67 to 120 kHz frequency. The only parameter to distinguish between them is the height: 1mm difference...

Same for that generator: they write 80kHz 300W in the advertisement, and there is no such model in the list. There is one 300W, with max. frequency 40kHz; OR a high frequency model which goes from 300W up to 1200W - why would they advertise with the minimum power???

Hi, I'm reading up on the frequency subject and i wonder if there's any concensus on this. Some say higher is best, some (kirmuss) say 35 khz and not higher, some say i doesn't matter much. I have no hands-on experience with any rcm, only manual cleaning. My goal is to be able to remove remains from wet played records like lenco fluids and the more common dirty records of second hand sources. So i wondered if the more experienced members can give their recommendations regarding the frequency requirements.

TIA, Vincent

TIA, Vincent

Hi, I'm reading up on the frequency subject and i wonder if there's any concensus on this. Some say higher is best, some (kirmuss) say 35 khz and not higher, some say i doesn't matter much. I have no hands-on experience with any rcm, only manual cleaning. My goal is to be able to remove remains from wet played records like lenco fluids and the more common dirty records of second hand sources. So i wondered if the more experienced members can give their recommendations regarding the frequency requirements.

TIA, Vincent

That's a very reasonable Qu, Vincent - trouble is, I doubt you will get consensus on the answer!

Having read a lot of articles over the last 5 years or so, my view is that:

* 40kHz is better for cleaning bad gunk off the records than 80kHz

* but, because of this, the 'bubble explosion' action is harder on the grooves, at 40kHz.

So I'm not prepared to use a 40kHz tank - mine is 60kHz.

The other point you have to remember is that, for optimum cleaning, you need 1 clear wavelength between the sides of the record and the tank sides ... and between LPs if you clean several, simultaneously.

The required spacings are:

* 1" for 60kHz, but

* 1 1/2" for 40kHz.

Andy

Do you have experience with lenco clean removal as well?

Vincent

Sorry, Vincent - I have no idea what "lenco clean removal" is.

As far as I know ... Lenco is a TT mfr?

Andy

This is Lencoclean:

The solution is pure ethylalcohol and distilled water. Wet playing reduces friction and pops by keeping any contamination in the grooves floating. The issue is that after drying the debris sticks to the groove walls. At the next wet playing it will float again. But any consequent dry playing has more noise and pops than before, because the particles remain stick to the groove walls. Basically once you wet played, you should do so forever.

I think US cleaning will loosen up and remove the dirt left by Lencoclean.

The solution is pure ethylalcohol and distilled water. Wet playing reduces friction and pops by keeping any contamination in the grooves floating. The issue is that after drying the debris sticks to the groove walls. At the next wet playing it will float again. But any consequent dry playing has more noise and pops than before, because the particles remain stick to the groove walls. Basically once you wet played, you should do so forever.

I think US cleaning will loosen up and remove the dirt left by Lencoclean.

This is Lencoclean:

The solution is pure ethylalcohol and distilled water. Wet playing reduces friction and pops by keeping any contamination in the grooves floating. The issue is that after drying the debris sticks to the groove walls. At the next wet playing it will float again. But any consequent dry playing has more noise and pops than before, because the particles remain stick to the groove walls. Basically once you wet played, you should do so forever.

I think US cleaning will loosen up and remove the dirt left by Lencoclean.

Aaah, wet playing. Yes, popular for a while.

An US cleaning process will certainly remove whatever crud remains in the groove, after Lenco 'cleaning'!

Andy

Well i guess i will try a 40khz first on a few to see what results can be obtained. 60khz or higher is too expensive for these records. No collectors items between them so I'll take risk.

As said before, all frecuencies have their pros and cons on the debate.

A friend of mine with a very very revealing system has a KL-Audio US that retails for something like us$4.000 and it uses 35hz! We have done lots of testing and no signs of sound deterioration due the the 35hz washing.

I just went with a 40hz machine miself.

I'm reading up on the frequency subject and i wonder if there's any concensus on this.

TIA, Vincent

Vincent, I posted on this topic early in the thread. There is plenty of published work from ultrasonic experts on this topic. It's valuable to hear anecdotes from vinyl aficionados, but subject matter expert opinion should also be considered. Here is a very good primer that includes simple guidelines on frequency selection:

Ultrasonic Cavitations and Precision Cleaning by: Sami B Awad

The calculations for pressure and localized temperature at 20kHz are something to which, I personally, would not want to expose my favorite LPs. And please note the sections about sub micron cleaning and delicate cleaning at 60-80kHz. Excerpt:

"Cavitations are generated in the order of microseconds. At the 20 kHz frequency, it is estimated that the pressure is about 35-70 K Pascal and the transient localized temperatures are about 5000°C, with the velocity of micro streaming around 400 Km/hr (Figure 2).

Several factors have great influence on the cavitation's intensity and abundance in a given medium. Among these factors are the ultrasonic wave form, its frequency and the power amplitude. Other determining factors are the colligative properties of the liquid medium, including viscosity, surface tension, density and vapor pressure; the medium temperature and the liquid flow, whether static or dynamic or laminar; and dissolved gases.

In general, at low frequencies (20-30 kHz), a relatively smaller number of cavitations with larger sizes and more energy are generated. At higher frequencies (60-100 kHz), much denser cavitations with moderate or lower energies are formed. Low frequencies are more appropriate for cleaning heavy and large-size components, while high frequency (60-80 kHz) ultrasonics is recommended for cleaning delicate surfaces and for the rinsing step.

For example, at 68 kHz, the cavitation abundance is high enough and mild enough to remove detergent films and remove submicron particles in the rinsing steps without inflicting damage on surfaces. The 35-45 kHz frequency range was found to be appropriate for a wide range of industrial components and materials."

Awad's credentials are solid:

Dr. Sami Awad is VP of technology at Crest Ultrasonics (Trenton, NJ). He has more than 15 years experience in developing new chemistries and processes for precision cleaning, surface treatment and metal forming. Awad is the author of more than 25 scientific academic papers in organic synthesis and reaction mechanisms, and has served on the teaching faculties of Drexel University (Philadelphia, PA) and Cairo University, Egypt. Awad is a member of ACS, Ultrasonic Industrial Association (UIA), IDEMA and ASM. He holds a Ph.D. in organic chemistry.

Cheers,

B B

Vincent,

Many of the early attachments in this thread were deleted by a moderator's mistake.

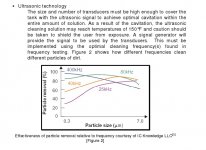

Another post I made on this topic earlier in the thread introduced this graphic into the URC discussion. It shows particle cleaning effectiveness as a function of frequency and particle size. As most of the particles to be cleaned from an LP surface are in the 1 to 5 micron range, the 80khz curve seems to show max effectiveness. One could presume a 60khz line would be somewhere in between the 40 and the 80 lines. Thus, 60khz and 80khz would be slightly advantageous for cleaning effectiveness vs. 40khz, and certainly better than 25khz.

Best,

B B

Many of the early attachments in this thread were deleted by a moderator's mistake.

Another post I made on this topic earlier in the thread introduced this graphic into the URC discussion. It shows particle cleaning effectiveness as a function of frequency and particle size. As most of the particles to be cleaned from an LP surface are in the 1 to 5 micron range, the 80khz curve seems to show max effectiveness. One could presume a 60khz line would be somewhere in between the 40 and the 80 lines. Thus, 60khz and 80khz would be slightly advantageous for cleaning effectiveness vs. 40khz, and certainly better than 25khz.

Best,

B B

Attachments

Update on Ultrasonic Record Cleaner

I built my ultrasonic record cleaner in 2013 using the version 2 design from bbftx as my guide. A simple and well thought out piece of engineering.In the last week I started using a Pro-Ject VC-E record cleaner for its vacuum stage to use following the cleaning with the ultrasonic cleaner. Very happy with the results. This morning I reviewed the posting I had on Vinyl Asylum from 9/23/13 after I had completed the original build. In my posting I mentioned that I felt that the cleaning was easier and better than with my VPI 16.5. That drew a response from HW from VPI.

In his posting, "Are we burnishing the grooves with the sandblasting effect?? Is it cleaner or is it just easier to track because we have rounded all the edges?? The gunk removed by the vibration does not immediately vanish from the fluid, it is there and is slammed into the surface over and over at 40 to 60 thousand times a second until it is removed from the fluid and nothing is removed immediately. Very similar to sandblasting in effect."

The only description of ultrasonic record cleaning I have read over the years on the analysis of what's occurring during cleaning with this conclusion.

I built my ultrasonic record cleaner in 2013 using the version 2 design from bbftx as my guide. A simple and well thought out piece of engineering.In the last week I started using a Pro-Ject VC-E record cleaner for its vacuum stage to use following the cleaning with the ultrasonic cleaner. Very happy with the results. This morning I reviewed the posting I had on Vinyl Asylum from 9/23/13 after I had completed the original build. In my posting I mentioned that I felt that the cleaning was easier and better than with my VPI 16.5. That drew a response from HW from VPI.

In his posting, "Are we burnishing the grooves with the sandblasting effect?? Is it cleaner or is it just easier to track because we have rounded all the edges?? The gunk removed by the vibration does not immediately vanish from the fluid, it is there and is slammed into the surface over and over at 40 to 60 thousand times a second until it is removed from the fluid and nothing is removed immediately. Very similar to sandblasting in effect."

The only description of ultrasonic record cleaning I have read over the years on the analysis of what's occurring during cleaning with this conclusion.

Harry wanted to continue selling 16.5 and 17 record cleaning machines as he had been.Toward the end of his post he concedes that ultrasonic cleaning works well on "used poorly cared for records". Never had a record sound worse after ultrasonic cleaning. Thinking of replacing my Sonix 4 tank with the Elma P60H. I like the electronic timer, thermostat temperature control and the 80 KHz capability

Update on Ultrasonic Record Cleaner

Anyone replace a 60khz ultrasonic tank with an 80khz and using that now to clean their vinyl? If so, did you have to make any changes in your routine during the ultrasonic process? My Sonix 4 is doing a great job of cleaning but the conveniences of the Elma with the digital timer and thermostat control are appealing. Just wonder about how the results of cleaning with 60khz vs 80khz may differ.

Anyone replace a 60khz ultrasonic tank with an 80khz and using that now to clean their vinyl? If so, did you have to make any changes in your routine during the ultrasonic process? My Sonix 4 is doing a great job of cleaning but the conveniences of the Elma with the digital timer and thermostat control are appealing. Just wonder about how the results of cleaning with 60khz vs 80khz may differ.

Adjustable Ultrasonic Cleaner

I found these on Alibaba:

Langee/OEM UC-8240L - 11Liter Ultrasonic Cleaner

Frequency(KHz): 53/68/80/100/120/132(optional)

China Discount Double Frequency Ultrasonic Cleaning Uses for Cleaning Tool Suppliers, Factory, Manufacturers - Wholesale Price - LANGEE

Single unit $453 with 2 week shipping - Mcu-sweep High Frequency Uc-8240l Adjustable Power Ultrasonic Cleaner 60khz 80khz - Buy Ultrasonic Cleaner 60khz,Ultrasonic Cleaner 80khz,High Frequency Ultrasonic Cleaner Product on Alibaba.com

$250.00 - 50 Pieces Langee 8240l 40khz 80khz 100khz High Frequency Ultrasound Vinyl Record Cleaning Cylinder Head 11liter Ultrasonic Tooth Cleaner - Buy Ultrasonic Tooth Cleaner,Ultrasonic Cleaner 11liter,Spare Parts Ultrasonic Cleaner Product on Alibaba.com

$230.00 +100 Pieces - Vinyl Vibrator Wash Tank Stainless Steel Heat Wave Circuit Board Cleaning Price 10l Industrial Chemical Lab Ultrasonic Cleaner - Buy Lab Ultrasonic Cleaner,Wave Circuit Board Cleaning Price 22l Ultrasonic Cleaning Machine,Vinyl Vibrator Wash Tank Heat Ultrasonic Cleanet Product on Alibaba.com

I found these on Alibaba:

Langee/OEM UC-8240L - 11Liter Ultrasonic Cleaner

Frequency(KHz): 53/68/80/100/120/132(optional)

China Discount Double Frequency Ultrasonic Cleaning Uses for Cleaning Tool Suppliers, Factory, Manufacturers - Wholesale Price - LANGEE

Single unit $453 with 2 week shipping - Mcu-sweep High Frequency Uc-8240l Adjustable Power Ultrasonic Cleaner 60khz 80khz - Buy Ultrasonic Cleaner 60khz,Ultrasonic Cleaner 80khz,High Frequency Ultrasonic Cleaner Product on Alibaba.com

$250.00 - 50 Pieces Langee 8240l 40khz 80khz 100khz High Frequency Ultrasound Vinyl Record Cleaning Cylinder Head 11liter Ultrasonic Tooth Cleaner - Buy Ultrasonic Tooth Cleaner,Ultrasonic Cleaner 11liter,Spare Parts Ultrasonic Cleaner Product on Alibaba.com

$230.00 +100 Pieces - Vinyl Vibrator Wash Tank Stainless Steel Heat Wave Circuit Board Cleaning Price 10l Industrial Chemical Lab Ultrasonic Cleaner - Buy Lab Ultrasonic Cleaner,Wave Circuit Board Cleaning Price 22l Ultrasonic Cleaning Machine,Vinyl Vibrator Wash Tank Heat Ultrasonic Cleanet Product on Alibaba.com

Well I picked up a 20/40KHz 10l system from one of the Chinese companies a few weeks ago. Been so busy with other projects I have not even taken it out of the box. Once I can get to it my first thing is probably going to be looking at the components on the boards and possibly replacing them. Than it will be onto the LP drive mechanism to get it up and cleaning some albums.

Third installment after purchasing a Lego Mindstorm set for €60 online.

Edge driven DIY lego record spinner for Ultrasonic Cleaning Vinyl. Version 3.0 using Lego Mindstorm. - YouTube

Really easy build as you can see with a whole set of new options.

Only 1 record because I noticed the Ultrasonic effect (ripples on water surface) degraded a lot when spinning 3 records at once.

Since this option makes spinning programmable, is there anyone who has some experience with a spin cycle where the records spin and then stop for a determined time to really get the cleaning going? Looking for most efficient cycle.....

Edge driven DIY lego record spinner for Ultrasonic Cleaning Vinyl. Version 3.0 using Lego Mindstorm. - YouTube

Really easy build as you can see with a whole set of new options.

Only 1 record because I noticed the Ultrasonic effect (ripples on water surface) degraded a lot when spinning 3 records at once.

Since this option makes spinning programmable, is there anyone who has some experience with a spin cycle where the records spin and then stop for a determined time to really get the cleaning going? Looking for most efficient cycle.....

Last edited:

- Home

- Source & Line

- Analogue Source

- My version of an Ultrasonic Record Cleaner