Many thanks. That is what I'm using. I have a 10 L tank, so I assume that would equate to 4 to 7 drops of Triton-X 100. Along with 6 oz of alcohol?

And none of the Ilford Ilfotol to assist in drying?

I am currently using only a drop or two. I have tried eliminating altogether but feel the water doesn't sheet as well. I would start with the least amount and work up if needed. I haven't needed a drying agent.

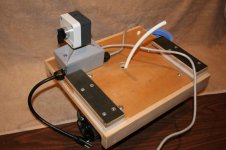

Completed Station, first cut

I have been interested in the Ultrasonic approach for cleaning records for a while. I bought the Sonix4 machine several years ago while I was still working. Life got in the way and I never got very far on the project. A month or two ago I was listening to some records and was just not satisfied with the cleaning I was able to do with a DIY record cleaner I built years ago. Time to dust off the ultrasonic machine.

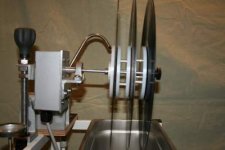

I read much of the thread and saw a lot of terrific variations for the machines. I know the original intent was to create a portable set up that can be put away when not needed. I have a large collection of vinyl (5000+) and vacant horizontal surfaces can be hard to find in casa electrovice. I opted to create a free standing cleaner set up with a filter all mounted on a compact movable stand. I went with a sturdy elevator mechanism and a fixed spindle.

The stand was originally a bar stool that I found in a thrift store. The elevator mechanism is horizontal clamp that was an accessory for a Ridgid miter saw also found in a thrift store. The pump, used from eBay, is a proper diaphragm pump with plenty of pressure and volume. The faucet is used and was a rescue from a recycling bin at a former job. The balance of it was either stuff I had laying around in the shop or purchases from the local ACE hardware.

Hopefully the pictures are not too compressed to show what I have created. The first picture needs to be rotated 90 degrees, sorry.

John

I have been interested in the Ultrasonic approach for cleaning records for a while. I bought the Sonix4 machine several years ago while I was still working. Life got in the way and I never got very far on the project. A month or two ago I was listening to some records and was just not satisfied with the cleaning I was able to do with a DIY record cleaner I built years ago. Time to dust off the ultrasonic machine.

I read much of the thread and saw a lot of terrific variations for the machines. I know the original intent was to create a portable set up that can be put away when not needed. I have a large collection of vinyl (5000+) and vacant horizontal surfaces can be hard to find in casa electrovice. I opted to create a free standing cleaner set up with a filter all mounted on a compact movable stand. I went with a sturdy elevator mechanism and a fixed spindle.

The stand was originally a bar stool that I found in a thrift store. The elevator mechanism is horizontal clamp that was an accessory for a Ridgid miter saw also found in a thrift store. The pump, used from eBay, is a proper diaphragm pump with plenty of pressure and volume. The faucet is used and was a rescue from a recycling bin at a former job. The balance of it was either stuff I had laying around in the shop or purchases from the local ACE hardware.

Hopefully the pictures are not too compressed to show what I have created. The first picture needs to be rotated 90 degrees, sorry.

John

Attachments

-

IMG_6724__1540329275_50.54.140.127.jpg11 KB · Views: 609

IMG_6724__1540329275_50.54.140.127.jpg11 KB · Views: 609 -

IMG_6725__1540329518_50.54.140.127.jpg26.2 KB · Views: 619

IMG_6725__1540329518_50.54.140.127.jpg26.2 KB · Views: 619 -

IMG_6726__1540329691_50.54.140.127.jpg11.7 KB · Views: 619

IMG_6726__1540329691_50.54.140.127.jpg11.7 KB · Views: 619 -

IMG_6728__1540329788_50.54.140.127.jpg12.8 KB · Views: 618

IMG_6728__1540329788_50.54.140.127.jpg12.8 KB · Views: 618 -

IMG_6720__1540330617_50.54.140.127.jpg43.4 KB · Views: 611

IMG_6720__1540330617_50.54.140.127.jpg43.4 KB · Views: 611 -

IMG_6721__1540330724_50.54.140.127.jpg43.1 KB · Views: 294

IMG_6721__1540330724_50.54.140.127.jpg43.1 KB · Views: 294 -

IMG_6723__1540329118_50.54.140.127.jpg48.2 KB · Views: 297

IMG_6723__1540329118_50.54.140.127.jpg48.2 KB · Views: 297 -

IMG_6729__1540329878_50.54.140.127.jpg12 KB · Views: 316

IMG_6729__1540329878_50.54.140.127.jpg12 KB · Views: 316

Very nice, John! Love the free-standing unit.

The use of the miter clamp is very clever. I assume it's one of those where you can release the threaded rod so you can more quickly slide the clamp up and down, lock it in, and then rotate the threaded assembly to fine tune the positioning?

Cheers,

B B

The use of the miter clamp is very clever. I assume it's one of those where you can release the threaded rod so you can more quickly slide the clamp up and down, lock it in, and then rotate the threaded assembly to fine tune the positioning?

Cheers,

B B

In my application the knob doesn't turn. To raise the motor assembly, you just pull up on the knob. To lower the unit, you release the clamp and guide it down while holding the knob. The all thread of this mechanism is a standard 5/8-11 thread. I took advantage of that and used nuts to create stops that limit the movement up and down. The knob is now "fixed" and helps the user to guide the mechanism up and down. It is a very "mechanical" mechanism but it works fine.

The saw clamp can still be purchased for about $45. I found mine for $1.50. Perhaps rummaging tool bins in pawn shops or used tool stores may yield similar mechanisms. A DeStaco type of clamp might also be used to hold the motor assembly on a vertical shaft. Lots of options.

John

The saw clamp can still be purchased for about $45. I found mine for $1.50. Perhaps rummaging tool bins in pawn shops or used tool stores may yield similar mechanisms. A DeStaco type of clamp might also be used to hold the motor assembly on a vertical shaft. Lots of options.

John

Regarding the faucet. The base of the faucet has a collimator device that focuses the water as it comes out. It is a dense column of water that doesn't get aerated. If aeration should prove to be a problem I could either relocate the faucet to a lower level so the spout is nearer the water level or I could just attach a length of flex hose to the faucet end. The faucet is also used to pump out the tank.

As I mentioned before, this is my first cut at the ultrasonic cleaner. All suggestions appreciated.

John

As I mentioned before, this is my first cut at the ultrasonic cleaner. All suggestions appreciated.

John

Regarding the faucet. The base of the faucet has a collimator device that focuses the water as it comes out. It is a dense column of water that doesn't get aerated. If aeration should prove to be a problem I could either relocate the faucet to a lower level so the spout is nearer the water level or I could just attach a length of flex hose to the faucet end. The faucet is also used to pump out the tank.

As I mentioned before, this is my first cut at the ultrasonic cleaner. All suggestions appreciated.

John

Wow, nice setup. Well done, John!

@Zg925 - hmm... any more suggestions for units? This was the one that bbtx had suggested a long time ago - granted, the supplier for these Chinese units, hardware, etc. is always changing, so quality control seems impossible... I know Vibratto is popular, but soooo expensive out of the gate. Do they still even do anything under 600?

flatearth:

I just did a quick DuckDuckGo search comparing prices of 80khz Ultrasonic Cleaners and found that the average price ranges from $1200 to $4000 from other suppliers (which all appear to be manufactured by the same Chinese company).

Our prices are considerably lower for these specialty, higher frequency Ultrasonic Cleaners.

Just wanted to throw that out there.

-Louis

I just came across this interesting product (I am not affiliated with them) - its a ready-made record holder system for ultrasonic cleaners!

https://www.cleanervinyl.com/

It come in a simple edge-hanging model, and a more extensive "pro" version which can lift the mechanism out of the bath.

Looks like they also make a fan-holder for drying and a micron-filter system, also.

Worth checking out?

-Louis

https://www.cleanervinyl.com/

It come in a simple edge-hanging model, and a more extensive "pro" version which can lift the mechanism out of the bath.

Looks like they also make a fan-holder for drying and a micron-filter system, also.

Worth checking out?

-Louis

I just came across this interesting product (I am not affiliated with them) - its a ready-made record holder system for ultrasonic cleaners!

https://www.cleanervinyl.com/

It come in a simple edge-hanging model, and a more extensive "pro" version which can lift the mechanism out of the bath.

Looks like they also make a fan-holder for drying and a micron-filter system, also.

Worth checking out?

-Louis

Interesting. It's nice to see that they're expanding on their options, but the pricing is nuts, especially for that filter. $399 for an in-tank filter that would have to be removed from the tank before cleaning a record since it would get in the way AND be too much surface area for the transducers to properly clean. My external system was something like $60 total including pump (though not a great option if there's no external drain on your tank). Seems they're pushing hard into Vinyl Stack Ultra Spin Kit territory when all the matching features are added up. Seems like the Vinyl Stack would be less of a hassle. The base CleanerVinyl One is a bit more accessible, price-wise, but I'm not sure worth the tradeoff for something that still seems to have a lot of DIY-like tradeoffs.

The CleanerVinyl Micron filter looks great. But I also had sticker shock. The pricing is nuts.

I tabulated the cost for a filter system I employ, nearly identical to what Tima shows on The Vinyl Press website. The entire kit was less than $100. Best of all it can filter to 0.35 microns. Further, if you employ the Harmsco 801 10" filter that bbftx pointed out, it is reusable after a rinsing.

My initial success with a Pentek 10" Slimline housing and Max Flow filter (0.35) is very encouraging. I've changed USC now and I am still working out how best or should I say optimally to filter the cleaning solution. I'm considering adding a second filter of 1 micron in front of the 0.35 filter, perhaps using it instead or even in addition to the 0.35 micron filter. I know bbftx has had terrific success with just a 1 micron filter so anything more may be overkill.

I don't want to over complicate my new set up, but I have experienced redeposition of USC debris on my records. I think part of the issue is flow in the Pentek that may have been compromised somehow. So I have a new housing that I have yet to connect. Also, the USC I now employ has a rather small drain hole (1/4") in the bottom of the tank and on the opposite end from the drain valve. I've considered that the Sicce 170 gallon per hour aquarium pump (actually measured with filtering is 1.2 gallons per minute, less than half of rating) is not turning over the cleaning solution quickly enough in my 10L tank or not sweeping all of the debris out through the drain hole. Some debris stays near the surface. So I moved the return flow to just below the surface on the opposite side as the drain hole. That has helped.

But this leads me to a question for the community.

Has anyone connected the filter before their pump? Typically I see the filter after the pump. But I want to know if anyone has tried the filter right out of the tank, so that the pump has to pull instead of pushing the liquid. Also, has anyone tried using two filters in line?

I know an obvious question is why use two filters. My thinking is that the 1 micron filter catches most of the debris, leaving the 0.35 micron filter for final filtering. That way, the 1 micron filter can be changed out leaving the 0.35 micron filter for longer duty. Bbftx has showed a well known chart illustrating that an 80kHz USC, which I use, is much more effective at removing sub-1 micron debris from a record.

I would consider trying two filters to eliminate redeposition of debris on records that I have experienced.

Thanks.

I tabulated the cost for a filter system I employ, nearly identical to what Tima shows on The Vinyl Press website. The entire kit was less than $100. Best of all it can filter to 0.35 microns. Further, if you employ the Harmsco 801 10" filter that bbftx pointed out, it is reusable after a rinsing.

My initial success with a Pentek 10" Slimline housing and Max Flow filter (0.35) is very encouraging. I've changed USC now and I am still working out how best or should I say optimally to filter the cleaning solution. I'm considering adding a second filter of 1 micron in front of the 0.35 filter, perhaps using it instead or even in addition to the 0.35 micron filter. I know bbftx has had terrific success with just a 1 micron filter so anything more may be overkill.

I don't want to over complicate my new set up, but I have experienced redeposition of USC debris on my records. I think part of the issue is flow in the Pentek that may have been compromised somehow. So I have a new housing that I have yet to connect. Also, the USC I now employ has a rather small drain hole (1/4") in the bottom of the tank and on the opposite end from the drain valve. I've considered that the Sicce 170 gallon per hour aquarium pump (actually measured with filtering is 1.2 gallons per minute, less than half of rating) is not turning over the cleaning solution quickly enough in my 10L tank or not sweeping all of the debris out through the drain hole. Some debris stays near the surface. So I moved the return flow to just below the surface on the opposite side as the drain hole. That has helped.

But this leads me to a question for the community.

Has anyone connected the filter before their pump? Typically I see the filter after the pump. But I want to know if anyone has tried the filter right out of the tank, so that the pump has to pull instead of pushing the liquid. Also, has anyone tried using two filters in line?

I know an obvious question is why use two filters. My thinking is that the 1 micron filter catches most of the debris, leaving the 0.35 micron filter for final filtering. That way, the 1 micron filter can be changed out leaving the 0.35 micron filter for longer duty. Bbftx has showed a well known chart illustrating that an 80kHz USC, which I use, is much more effective at removing sub-1 micron debris from a record.

I would consider trying two filters to eliminate redeposition of debris on records that I have experienced.

Thanks.

Last edited:

Hi Bend

You're asking a bit much of your pump. That Sicce has a max head rating of 4 ft. if I am looking at the right unit (Sicce 0.5). 4' of head equates to about a 2 psi pressure drop. Your filter and housing, and then having to pump the fluid up and back into the tank offer almost that much resistance on their own at a couple of gallons per minute. I don't think you'd be able to add a second filter to this setup --- the pump probably isn't powerful enough and you'd end up with just a trickle of fluid.

Also, a 2 filter solution really doesn't make sense here. These filters are designed for whole-home use and are spec'd to filter thousands of gallons before needing to be cleaned or replaced. You don't need 2 of them. Definitely overkill.

Also, let me explain gph ratings on pumps: The rating is the absolute max flow rate possible under ideal conditions at sea level at 0' head lift (no resistance). Since you are going through a filter, a housing, and raising the fluid back into the tank, there is lift required from the pump and it will pump less than the rating, as you've discovered.

Finally, you really can't put the filter before the pump. These pumps push better than they pull. Putting filter ahead of pump will likely lead to cavitation in the pump and it won't be able to pull the fluid across the filter. And you'll probably shorten the life of the pump by doing this.

If you think you've compromised your housing or your filter, replace them. And replace your fluid periodically. A filter setup doesn't allow never-ending recycling of your cleaning fluid. It just extends the life of it beyond what it would be without the filter.

Cheers,

B B

You're asking a bit much of your pump. That Sicce has a max head rating of 4 ft. if I am looking at the right unit (Sicce 0.5). 4' of head equates to about a 2 psi pressure drop. Your filter and housing, and then having to pump the fluid up and back into the tank offer almost that much resistance on their own at a couple of gallons per minute. I don't think you'd be able to add a second filter to this setup --- the pump probably isn't powerful enough and you'd end up with just a trickle of fluid.

Also, a 2 filter solution really doesn't make sense here. These filters are designed for whole-home use and are spec'd to filter thousands of gallons before needing to be cleaned or replaced. You don't need 2 of them. Definitely overkill.

Also, let me explain gph ratings on pumps: The rating is the absolute max flow rate possible under ideal conditions at sea level at 0' head lift (no resistance). Since you are going through a filter, a housing, and raising the fluid back into the tank, there is lift required from the pump and it will pump less than the rating, as you've discovered.

Finally, you really can't put the filter before the pump. These pumps push better than they pull. Putting filter ahead of pump will likely lead to cavitation in the pump and it won't be able to pull the fluid across the filter. And you'll probably shorten the life of the pump by doing this.

If you think you've compromised your housing or your filter, replace them. And replace your fluid periodically. A filter setup doesn't allow never-ending recycling of your cleaning fluid. It just extends the life of it beyond what it would be without the filter.

Cheers,

B B

Last edited:

BB: I agree. I think I have identified the issue with my filter system. The seal at the top of the Max Flow filter was not complete. A "washable" Harmsco 10" filter is on the way, so I experiment still.

The issue I've experienced is debris deposits in what I call a "tideline" on one half of the record, and only on the outside of the two end lps in the four Vinyl Stack set up. Then I see isolated debris spots on the other lps.

To solve most of that issue, I now use the pump when US cleaning. Then I have moved the return flow line to just below the surface near where the tidelines occur. I see now that the return flow moves along the tank end and in between the four stacked records, minimizing that debris deposition. Also, I raised the rotation speed from the slowest to the next to the slowest.

The cleaning solution I use includes Ilfotol, a wetting agent. The formula I use is the same as used by Tima, see his articles on The Vinyl Press. I've been somewhat surprised that the debris does not remain in solution to be cleaned out by the filtering system.

Clearly the pump at a measured 1.2 gallons per minute is insufficient to circulate all of the liquid with debris into and through the filter in the 20 minute cycle. Part of that may be the 1/4" drain hole size in the molded tank of my 80kHz USC. That drain hole is also offset from the tank's center line and on the opposite side of the tank from the drain valve. That means the cleaning solution must transit the tank length (i.e., under it) to exit through the drain valve.

I experiment on.

Thank you.

The issue I've experienced is debris deposits in what I call a "tideline" on one half of the record, and only on the outside of the two end lps in the four Vinyl Stack set up. Then I see isolated debris spots on the other lps.

To solve most of that issue, I now use the pump when US cleaning. Then I have moved the return flow line to just below the surface near where the tidelines occur. I see now that the return flow moves along the tank end and in between the four stacked records, minimizing that debris deposition. Also, I raised the rotation speed from the slowest to the next to the slowest.

The cleaning solution I use includes Ilfotol, a wetting agent. The formula I use is the same as used by Tima, see his articles on The Vinyl Press. I've been somewhat surprised that the debris does not remain in solution to be cleaned out by the filtering system.

Clearly the pump at a measured 1.2 gallons per minute is insufficient to circulate all of the liquid with debris into and through the filter in the 20 minute cycle. Part of that may be the 1/4" drain hole size in the molded tank of my 80kHz USC. That drain hole is also offset from the tank's center line and on the opposite side of the tank from the drain valve. That means the cleaning solution must transit the tank length (i.e., under it) to exit through the drain valve.

I experiment on.

Thank you.

The skimming for floaters is a good idea. I typically allow the pump to run for about 30 minutes after a session to filter the cleaning solution. Then I degas for 15 minutes prior to a session also with the pump on.

Your first part I don't understand. The tank on the USC I use has a small drain hole on the opposite side of the tank from the drain valve. Therefore, the exit from the tank in the circulation path is from that leftside drain hole, across the base of the tank (that is under the tank), and out the drain valve on the right. From there, the cleaning solution is in tubing into the Sicce pump, then into the Pentek filter housing, out of that via tubing that is routed to just under the surface on the drain valve side of the tank. That is to say, the return via tubing comes into the tank at the top, on the right, while the drain hole in the tank bottom is on the left side of the tank.

Your first part I don't understand. The tank on the USC I use has a small drain hole on the opposite side of the tank from the drain valve. Therefore, the exit from the tank in the circulation path is from that leftside drain hole, across the base of the tank (that is under the tank), and out the drain valve on the right. From there, the cleaning solution is in tubing into the Sicce pump, then into the Pentek filter housing, out of that via tubing that is routed to just under the surface on the drain valve side of the tank. That is to say, the return via tubing comes into the tank at the top, on the right, while the drain hole in the tank bottom is on the left side of the tank.

So here's a fun thing that I discovered regarding the 1 micron filter: It was filtering out my cleaning agent.

For some time now, on the rare occasions that I get around to cleaning records, I've been using TergiKleen (ie: Tergitol in a smaller package) dilution as my tank fluid, with 2 rinse/vac steps on my Okki Nokki. This has been very effective in general. Most recently, I got some mint records and cleaned them after running my old fluid through the filter for a few minutes. I was underwhelmed by the results: murky sound mostly. So I ditched the fluid and made a new batch with deionized water from Whole Foods. Not only did the fluid look cloudy again after I mixed in the TergiKleen, unlike the fluid I sent through the 1 micron filter, but the cleaning results were a substantial improvement.

As such, I'm likely going to pass on using the filter going forward, unless I mix up a separate set of tank fluid with isopropyl for shorter cleaning sessions. Maybe even a separate tank for pre-cleaning really nasty stuff. Definitely not compatible with keeping Tergitol in the tank solution, though.

For some time now, on the rare occasions that I get around to cleaning records, I've been using TergiKleen (ie: Tergitol in a smaller package) dilution as my tank fluid, with 2 rinse/vac steps on my Okki Nokki. This has been very effective in general. Most recently, I got some mint records and cleaned them after running my old fluid through the filter for a few minutes. I was underwhelmed by the results: murky sound mostly. So I ditched the fluid and made a new batch with deionized water from Whole Foods. Not only did the fluid look cloudy again after I mixed in the TergiKleen, unlike the fluid I sent through the 1 micron filter, but the cleaning results were a substantial improvement.

As such, I'm likely going to pass on using the filter going forward, unless I mix up a separate set of tank fluid with isopropyl for shorter cleaning sessions. Maybe even a separate tank for pre-cleaning really nasty stuff. Definitely not compatible with keeping Tergitol in the tank solution, though.

I believe that the Tergitol is just so sticky that it wants to bind to the filter, even if it might be "small" enough to get through. So I'm not really surprised. Wish I'd thought of it earlier.

Not all Whole Foods stores have the water dispensers. Our old one didn't, but they did after they moved to a newer, larger location. The water itself is 39 cents per gallon, but they charge obscene amounts for their own gallon jugs ($9.99 each!?). They're sturdier than the standard milk jug, though, so I sprung for a couple that were mislabeled as $7.99.

Not all Whole Foods stores have the water dispensers. Our old one didn't, but they did after they moved to a newer, larger location. The water itself is 39 cents per gallon, but they charge obscene amounts for their own gallon jugs ($9.99 each!?). They're sturdier than the standard milk jug, though, so I sprung for a couple that were mislabeled as $7.99.

So here's a fun thing that I discovered regarding the 1 micron filter: It was filtering out my cleaning agent.

...on the rare occasions that I get around to cleaning records, I've been using TergiKleen (ie: Tergitol in a smaller package) dilution as my tank fluid, with 2 rinse/vac steps on my Okki Nokki. This has been very effective in general. Most recently, I got some mint records and cleaned them after running my old fluid through the filter for a few minutes.

Pack,

How long had the fluid been sitting around? I throw mine away after every session, even when filtering. I don't use TergiKleen. Water with a little IPA.

B B

So here's a fun thing that I discovered regarding the 1 micron filter: It was filtering out my cleaning agent. . . .For some time now, on the rare occasions that I get around to cleaning records, I've been using TergiKleen (ie: Tergitol in a smaller package) dilution as my tank fluid, with 2 rinse/vac steps on my Okki Nokki. . . .

I think it is unlikely that your filter actually separated out Tergitol. I shared your post with a chemical engineer, and here is his response:

> "Reading this, I don’t understand the basis for the claim that a 1 micron filter would separate the surfactant. Surfactants are colloidal, meaning they can be as small as 1/1000 of a micron. Technically some of the largest colloidal particles approach one micron in diameter, but I don’t think detergents or wetting agents are nearly that big. The following is a definition of a colloid. Note it states that ordinary filtering will not separate them out.

> Colloid: a homogeneous noncrystalline substance consisting of large molecules or ultramicroscopic particles of one substance dispersed through a second substance. Colloids include gels, sols, and emulsions; the particles do not settle, and cannot be separated out by ordinary filtering or centrifuging like those in a suspension."

- Home

- Source & Line

- Analogue Source

- My version of an Ultrasonic Record Cleaner