Can you make a recording of the noise? Perhaps with your cell phone.

I think it is probably just the noise that all stepper motors make when they start up. But I would like to hear it.

I think it is probably just the noise that all stepper motors make when they start up. But I would like to hear it.

Hi at all!

the turntable works superbly ..

I have one doubt:

when I turn it on, the engine "creaks" for a few seconds, until it reaches the speed.

and the same thing, when I turn it off.

During operation is extremely quiet.

The same thing happens when I turn on the engine without the belt, so it can not be the cause. (The spindle is perfect, so I suspect a motor issue..)

I wonder if it is normal, this noise during the accelerations phase ...

Some experience?

Does anyone have a schematic of the controller for the 200 step motor of the model 1?

The manual doesn’t contain one and non of the upgrade sheets

Will call JB if no one comes thru.

If these are too expensive, I will more than likely just replace the entire motor assembly with a 3 phase one.

I understand the stock one has the RFI issues

Regards

David

The manual doesn’t contain one and non of the upgrade sheets

Will call JB if no one comes thru.

If these are too expensive, I will more than likely just replace the entire motor assembly with a 3 phase one.

I understand the stock one has the RFI issues

Regards

David

Last edited:

Does anyone have a schematic of the controller for the 200 step motor of the model 1?

The manual doesn’t contain one and non of the upgrade sheets

Will call JB if no one comes thru.

If these are too expensive, I will more than likely just replace the entire motor assembly with a 3 phase one.

I understand the stock one has the RFI issues

Regards

David

Why, did you win the auction for the bits and pieces of a 1.0 that Hobson was selling on ebay?

Yes

It was a record warehouse in LA and the owners Elite AV, but met up with someone else handling the ebay sale. He didn’t know a lot about it though.

I knew the control box was gone but everything else and the upgrade pcs were there.

The right front silver disc suspension pc was missing in the pics but was underneath the table.

The arm shaft looked terrible in the photo, but polishing it up removed whatever it was nicely.

The head shell was badly oxidized so dropped it in some aluminum prep acid to remove it and relapped /refinished all surfaces

Bear said it best, the stepper design were all the rage back when JB designed it

since JB had knowledge of microprocessor design so why not be different and unique ? From that point of view it makes sense why he went in that direction.

I will probably gut the stepper design for a more practical synchronous 3 phase

Other than the bearing, all the suspension discs and even the tonearm mount are just glued in. Not even bolted. At this late stage I would question owners now to modify theirs or at least check theirs. One might just pop off and damage a cartridge or hit the shaft. Realize your table has been just sitting there for 25 years against this glue interface. I will drill and tap the top discs for security

The suspension design and the Well tempered style bearing design is counter productive in that you need a a strong pull for the totem pole shaft centering.

The suspension should be a hanging one instead of the plinth resting on top of the springs in compression.

With the motor pulling in line with the hanging spring point a better non invasive style would work out better IMO . I think it would be the lesser of 2 evils. 2 of the springs should be counter wound at the same time

If any of you kids has a schematic it would help so I could at least get the info to the timing steps for everything this side of the motor control.

Regards

David

It was a record warehouse in LA and the owners Elite AV, but met up with someone else handling the ebay sale. He didn’t know a lot about it though.

I knew the control box was gone but everything else and the upgrade pcs were there.

The right front silver disc suspension pc was missing in the pics but was underneath the table.

The arm shaft looked terrible in the photo, but polishing it up removed whatever it was nicely.

The head shell was badly oxidized so dropped it in some aluminum prep acid to remove it and relapped /refinished all surfaces

Bear said it best, the stepper design were all the rage back when JB designed it

since JB had knowledge of microprocessor design so why not be different and unique ? From that point of view it makes sense why he went in that direction.

I will probably gut the stepper design for a more practical synchronous 3 phase

Other than the bearing, all the suspension discs and even the tonearm mount are just glued in. Not even bolted. At this late stage I would question owners now to modify theirs or at least check theirs. One might just pop off and damage a cartridge or hit the shaft. Realize your table has been just sitting there for 25 years against this glue interface. I will drill and tap the top discs for security

The suspension design and the Well tempered style bearing design is counter productive in that you need a a strong pull for the totem pole shaft centering.

The suspension should be a hanging one instead of the plinth resting on top of the springs in compression.

With the motor pulling in line with the hanging spring point a better non invasive style would work out better IMO . I think it would be the lesser of 2 evils. 2 of the springs should be counter wound at the same time

If any of you kids has a schematic it would help so I could at least get the info to the timing steps for everything this side of the motor control.

Regards

David

Last edited:

I spoke with Scot Markwell (Kuzma dist) who was listing it for Mike (nee Classic Records, High Fidelity, etc) while the auction was running.

The platter bearing is ceramic as you've found out, the two opposing discs are self centering (it shouldnt flop around like the well tempered design, but I understand the analogy). There's a special grease used for it. It does not spin freely like a normal thrust bearing, it intentionally uses drag in its design. The stepper motor is of the high torque variety and drives the platter easily, JB will argue they were designed to be used as a 'system' if you go w/ a 3 phase (or DC) motor or other route it will also have to be of similar torque.

The head shell is not Aluminum its Magnesium and a special dye was used to turn it black. The corrosion is not unusual and many Versas in the field have this issue. JB recommends removing the pitting with wet-dry 400 grit sand paper. 3m77 spay glue works well to adhere the sand paper to a flat straight surface then relap the flat sides of the head shell back and forth. lube it with water and a few drops of hand soap.

The tone arm is very clever and IMHO the best part of the design but requires high air pressure to run, Its an annular air bearing with a very small gap (extremely tight tolerance compared to say something like the Eminent Tech ET-2 arm). because the 'arm is short coupled it will amplify warp wow to the degree it will render the design useless if the LP being played is not tightly coupled to the platter. This design is incapable of working properly w/o vacuum hold-down. keep that in mind when you think about the restoration. If you're going to try and get it up and running you will need to speak with JB at some point, I seriously doubt schematics are floating around for what you need. John charges for his time, manuals, drawings, specs and anything and everything needed to help you put it back into service.

The platter bearing is ceramic as you've found out, the two opposing discs are self centering (it shouldnt flop around like the well tempered design, but I understand the analogy). There's a special grease used for it. It does not spin freely like a normal thrust bearing, it intentionally uses drag in its design. The stepper motor is of the high torque variety and drives the platter easily, JB will argue they were designed to be used as a 'system' if you go w/ a 3 phase (or DC) motor or other route it will also have to be of similar torque.

The head shell is not Aluminum its Magnesium and a special dye was used to turn it black. The corrosion is not unusual and many Versas in the field have this issue. JB recommends removing the pitting with wet-dry 400 grit sand paper. 3m77 spay glue works well to adhere the sand paper to a flat straight surface then relap the flat sides of the head shell back and forth. lube it with water and a few drops of hand soap.

The tone arm is very clever and IMHO the best part of the design but requires high air pressure to run, Its an annular air bearing with a very small gap (extremely tight tolerance compared to say something like the Eminent Tech ET-2 arm). because the 'arm is short coupled it will amplify warp wow to the degree it will render the design useless if the LP being played is not tightly coupled to the platter. This design is incapable of working properly w/o vacuum hold-down. keep that in mind when you think about the restoration. If you're going to try and get it up and running you will need to speak with JB at some point, I seriously doubt schematics are floating around for what you need. John charges for his time, manuals, drawings, specs and anything and everything needed to help you put it back into service.

Last edited:

I do like the bearing design and have the fluorocarbon gel made by NYE.

I made an air bearing years ago and still have it and might try it, but some drag against a known force is the way to go now

The drag on it is slight and beneficial here.

Magnesium, no wonder it reacted to the acid the way it did.

Surprised it didn’t catch fire grinding on it !

Inspired by the Versa years ago I reworked a ET2 with the same azimuth adjustment.

It will be interesting, low pressure vs high pressure necessary for the small surface area.

I will speculate the noise from high pressure and the tubing on the moving mass might be an issue but will find out sooner or later.

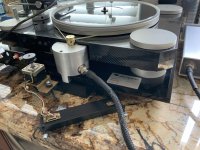

You can see the perimeter glue on the discs and those that own these, should double check theirs

I made an air bearing years ago and still have it and might try it, but some drag against a known force is the way to go now

The drag on it is slight and beneficial here.

Magnesium, no wonder it reacted to the acid the way it did.

Surprised it didn’t catch fire grinding on it !

Inspired by the Versa years ago I reworked a ET2 with the same azimuth adjustment.

It will be interesting, low pressure vs high pressure necessary for the small surface area.

I will speculate the noise from high pressure and the tubing on the moving mass might be an issue but will find out sooner or later.

You can see the perimeter glue on the discs and those that own these, should double check theirs

Last edited:

Need help! Manual, schematics and/or just basic setup information. This thread has gone on with updates for a long long time. Congrats to all who work to preserve these classics. Anyone know if John is still alive and if so any contact info? Anyone have a new platter pad around for sale? How did those work out bye the way?

Theres an intact Versa Dynamics 2.0 up for auction on ebay at the moment and one of you deserving slobs should buy it  I exchanged emails with Rob (seller) when it failed to sell the first time at $3,800 (a HUGE bargain if there was one--esp for the money). I have a feeling now it will sell for more. The 2.0 is the mac daddy in the Versa range and the superior to the 1.0 in all areas esp sonics. I've had both, and looking at the pictures this is one is very complete and needs little massaging to get up and running.

I exchanged emails with Rob (seller) when it failed to sell the first time at $3,800 (a HUGE bargain if there was one--esp for the money). I have a feeling now it will sell for more. The 2.0 is the mac daddy in the Versa range and the superior to the 1.0 in all areas esp sonics. I've had both, and looking at the pictures this is one is very complete and needs little massaging to get up and running.

Versa Dynamics Model 2.0. Turntable - Air Bearning Tangential Tracking Tonearm | eBay

Versa Dynamics Model 2.0. Turntable - Air Bearning Tangential Tracking Tonearm | eBay

Last edited:

Need help! Manual, schematics and/or just basic setup information. This thread has gone on with updates for a long long time. Congrats to all who work to preserve these classics. Anyone know if John is still alive and if so any contact info? Anyone have a new platter pad around for sale? How did those work out bye the way?

John is alive and well in New Mexico, he will not willfully give info for FREE, verbal, print or otherwise. The orig platter mats are long gone, but there's a substitute out there. it's not exactly the same, a bit thicker and less pliable.

I own Two Versa-Dynamics Record Players

....a 1.2 and a modified 2.3. I am interested in creating a list of Versa owners so that we can share information about modifications and problem solving. Please email LSchwarz@purdue.edu

I am interested in creating a list of Versa owners so that we can share information about modifications and problem solving. Please email LSchwarz@purdue.edu

....a 1.2 and a modified 2.3.

A couple of mods for the model 1.2

Viscous damping adjustable button like the ET 2 arm tonearm

Still working on the trough design as its a tight fit. A mini blind is shown above picture and debating on this..

I machined the tonearm base to attach to the bottom sandwich to avoid any vibrations coming from what attaches to the top sandwich -the 4 springs and platter bearing

The tonearm mount doesn’t touch the top section at all.

Lose the stepper design for 3 phase control

Regards

David

Last edited:

It's very easy to reach him- the phone number is on the Versalab.com website.

If you call 505.771.9177 his partner Laura usually answers the phone. I wouldn't rely on email.

I've ordered from them before and they are very responsive.

I own the Bicht-designed Versalab M3 espresso grinder. Much like the Versa Dynamics tables, the M3 is a classic piece of industrial design that performs really well.

If you call 505.771.9177 his partner Laura usually answers the phone. I wouldn't rely on email.

I've ordered from them before and they are very responsive.

I own the Bicht-designed Versalab M3 espresso grinder. Much like the Versa Dynamics tables, the M3 is a classic piece of industrial design that performs really well.

Hello,

Thank you very much for the information.

I am French and unfortunately my English is extremely bad and I cannot hold a conversation properly.

I have sent back an email hoping for an answer.

If someone here can help me contact Versalab it would be great !

I'll wait and hope.

Thank you very much for the information.

I am French and unfortunately my English is extremely bad and I cannot hold a conversation properly.

I have sent back an email hoping for an answer.

If someone here can help me contact Versalab it would be great !

I'll wait and hope.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Versa Dynamics TT owners - calling all!