hi Ralf

....followed by his servo rail... #2159

Not pushed, I had understood that, my compliments were precisely for that brilliant separation between the two actions, that I consider really revolutionary.

But moving an headshell of a few grams is different from a whole arm, especially if you have to apply the force from the wrong side of the linear bearing. (laterally)

I had designed the Syrinx counting on a stylus drag of 1 gr ca, as found on the web, but after the fault I measured with the pendulum 2-300 mgr at most.

Clarifying: this in practice means that the Side Force (up to 0,8 gr till skipping + lever) becomes greatly prevalent on the Stylus Drag which would act in the right direction for the linear bearing. Result: linear bearing blocked

ciao carlo

....followed by his servo rail... #2159

Not pushed, I had understood that, my compliments were precisely for that brilliant separation between the two actions, that I consider really revolutionary.

But moving an headshell of a few grams is different from a whole arm, especially if you have to apply the force from the wrong side of the linear bearing. (laterally)

I had designed the Syrinx counting on a stylus drag of 1 gr ca, as found on the web, but after the fault I measured with the pendulum 2-300 mgr at most.

Clarifying: this in practice means that the Side Force (up to 0,8 gr till skipping + lever) becomes greatly prevalent on the Stylus Drag which would act in the right direction for the linear bearing. Result: linear bearing blocked

ciao carlo

Last edited:

make head spin

It seems a pivot headshell can get people really confused about tangential tracking. It came to the point that whenever people see a headshell that can rotate, they immediately think it's tangential tracking. I blame the RS Labs people who never corrected this misinformation in any of the reviews of their arm or headshell, as if they are enjoying the financial fruition of this confusion.

Here's a review of the Nasotec swing headshell that totally misinterpreted its function. Below is the reviewer's interpretation.

Again, you would think the manufacturer would contact the reviewer to set the record straight, pun intended.

It seems a pivot headshell can get people really confused about tangential tracking. It came to the point that whenever people see a headshell that can rotate, they immediately think it's tangential tracking. I blame the RS Labs people who never corrected this misinformation in any of the reviews of their arm or headshell, as if they are enjoying the financial fruition of this confusion.

Here's a review of the Nasotec swing headshell that totally misinterpreted its function. Below is the reviewer's interpretation.

It has been a life-long objective of turntable manufacturers to create a system where the cartridge stylus tracks the record as close as possible to the way the grooves were originally laid. With a conventional pivoted arm this is not easy. At two points on the record the stylus will be perpendicular to the groove, but at all other times, it won’t track to grooves in the same manner as the record was created, using a tangential cutting lathe such as Neumann VMS80. At the start and particularly at the end of the record the stylus will track the groove at an angle. Doing so not only means that one leg of the signal will be slightly earlier adding phasing issues, but it also adds distortion and is not so good for the stylus. Luckily tangential arms have been around since Edison’s first cylinder player. Models from Harman Kardon, B&O, Revox, Clearaudio and Pre-Audio amongst others, have been a panacea for this lifelong conundrum, however, these can add other flaws that conventional arms don’t have to such a degree.

Some have devised other means of tackling the problem, including the famous Garrard Zero 100SB (and which led to their GT55P) Introduced in 1971. This turntable had a dual arm with zero tracking error by virtue of the constantly changing angle of the head-shell as it traversed the record due to the pair of parallel arms. Actually, that was an idea copied from an earlier arm design from another British company Burne Jones from thirteen years earlier. Much more recently this idea has been bettered by Thales. But, no one has yet succeeded in creating a device that can be retrofitted on any turntable using the universal SME head-shell connector. Until now.

What the Nasotec Swing Headshell 202A1 has done is allow the friction from the groove itself to force the head-shell to change angle as it plays.

Again, you would think the manufacturer would contact the reviewer to set the record straight, pun intended.

I blame the RS Labs people who never corrected this misinformation in any of the reviews of their arm or headshell, as if they are enjoying the financial fruition of this confusion.

Actually, I blame the reviewers for not calling this out, not RS Labs. In my reading of RS Labs PR material, I don't recall that they ever claimed their rotary head would correct for tracking error. The designer only claimed that the cartridge should be 'unrestrained', or something like that. Many reviewers gave glowing reports of how wonderful the arm was, despite the fact that it has boatloads of tracking error except at one null point in the middle. IMO those reviewers are 1) technically incompetent to not understand how the arm they observing in fact works and 2) of questionable hearing acuity in that they didn't comment on hearing any of the tracking error the arm has at the beginning and end of the record.

One thing the RS Labs arm does have going for it is that its geometry gives it a low susceptibilty to stylus scrubbing at resonance, and maybe that is what the reviewers were latching on to. I am working on a new thread about that topic - stay tuned.

Ray K

Last edited:

Again, you would think the manufacturer would contact the reviewer to set the record straight, pun intended. Dd

Sometimes I have expressed too tranchant opinions about some products, especially if very expensive ones, and I apologize.

In my defense consider please 40 years spent working in an advertising studio with small to medium client companies, advertisers in trade magazines. So let's say I know the backstage of this type of communication, at least here by us. Hoping, but not believing, that elsewhere things go differently.

Here it is normal for an advertiser who pays a certain number of ads to get the right to a certain number of editorial articles on his products, and that these articles well be "not malicious". Often it even happens that the content - texts and images - is transferred directly from the advertiser to the reviewers: a current practice in our profession.

This may still be understandable in business to business, since the reader is part of the game and knows how to take this kind of information, sometimes with technical contents too complex for the reviewers. But completely reprehensible for magazines that address to the end user, completely defenseless with respect to information he considers authoritative.

Now you may understand my intolerance, not so much to the claims of the manufacturers - perfectly legitimate commercially - as to the unfaithful opinions coming from sources that should instead properly inform and protect their readers.

forgive this personal and offtopic content

carlo

Sometimes I have expressed too tranchant opinions about some products, especially if very expensive ones, and I apologize.

In my defense consider please 40 years spent working in an advertising studio with small to medium client companies, advertisers in trade magazines. So let's say I know the backstage of this type of communication, at least here by us. Hoping, but not believing, that elsewhere things go differently.

Here it is normal for an advertiser who pays a certain number of ads to get the right to a certain number of editorial articles on his products, and that these articles well be "not malicious". Often it even happens that the content - texts and images - is transferred directly from the advertiser to the reviewers: a current practice in our profession.

This may still be understandable in business to business, since the reader is part of the game and knows how to take this kind of information, sometimes with technical contents too complex for the reviewers. But completely reprehensible for magazines that address to the end user, completely defenseless with respect to information he considers authoritative.

Now you may understand my intolerance, not so much to the claims of the manufacturers - perfectly legitimate commercially - as to the unfaithful opinions coming from sources that should instead properly inform and protect their readers.

forgive this personal and offtopic content

carlo

Last edited:

Rotating headshell

Overally, the idea of creating rotary headshell, able to correct angular mistake, seems to be very attractive and able to become a commercial success. Unfortunately, it seems to be kind of dead end, at least for normal pivot arms with their overhang and offset angle. Even if driven by special brush, as my rotary shell. It may work reasonably well as to keeping corect angle, if distance between stylus and brush (and thus, leverage) is very short (about 2-3mm), but it will bring extraordinary requirements to pivot bearing.

As to RS Labs, they seem to be discontinued making their contraversial arm long ago.Guess why?

Overally, the idea of creating rotary headshell, able to correct angular mistake, seems to be very attractive and able to become a commercial success. Unfortunately, it seems to be kind of dead end, at least for normal pivot arms with their overhang and offset angle. Even if driven by special brush, as my rotary shell. It may work reasonably well as to keeping corect angle, if distance between stylus and brush (and thus, leverage) is very short (about 2-3mm), but it will bring extraordinary requirements to pivot bearing.

As to RS Labs, they seem to be discontinued making their contraversial arm long ago.Guess why?

Real life got in the way of tonearms.

Ralf - my appreciation of your arm hasn't changed. My understanding is that you use deliberate skating which creates a side force to propel the arm and then to control that with the servo. I still think that's brilliant. My comment about stylus drag was about whether that force alone can move a sliding mechanism like I tried to build and Carlo designed for the Syrinx. I still think it's insufficient.

I've attached some larger photos which I hope show the arm more clearly. The carriage has two upper bearings which ride in a V track and one lower bearing, also in a V track, to control axial forces and keep the upper bearings from lifting. The original idea was to use a magnetic control, but because it had to be ahead of the carriage, it caused the rear upper bearing to lift. The torque also increased the friction of the other to bearings.

The fourth photo shows the trace the magnet needed to follow. I thought I might try to replace the magnet and relieve the stress with a two bearing control arm, but geometry got in the way.

In other words, I made a lot of problems for myself. Head banging, as Carlo says. It's possible someone may design and build a successful sliding extender PLT, but I got so discouraged, it probably won't be me.

Ralf - my appreciation of your arm hasn't changed. My understanding is that you use deliberate skating which creates a side force to propel the arm and then to control that with the servo. I still think that's brilliant. My comment about stylus drag was about whether that force alone can move a sliding mechanism like I tried to build and Carlo designed for the Syrinx. I still think it's insufficient.

I've attached some larger photos which I hope show the arm more clearly. The carriage has two upper bearings which ride in a V track and one lower bearing, also in a V track, to control axial forces and keep the upper bearings from lifting. The original idea was to use a magnetic control, but because it had to be ahead of the carriage, it caused the rear upper bearing to lift. The torque also increased the friction of the other to bearings.

The fourth photo shows the trace the magnet needed to follow. I thought I might try to replace the magnet and relieve the stress with a two bearing control arm, but geometry got in the way.

In other words, I made a lot of problems for myself. Head banging, as Carlo says. It's possible someone may design and build a successful sliding extender PLT, but I got so discouraged, it probably won't be me.

Attachments

Last edited:

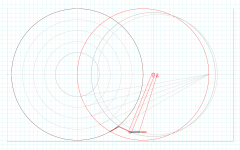

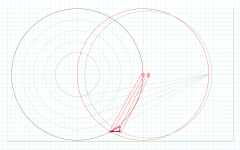

Thinking about the rear pivot of the sliding extender arm took me back to the Birch/Thales arms. The geometry of the extender was a bit different - I didn't start with the Thales circles, but instead started with a chosen arm length and did right angles off the front of that to the spindle. The point where the outter and inner lines cross is the pivot. The control arm pivot is derived from points on those lines.

I think Carlo did something similar in his drawings in #2146.

A serious problem with Birch/Thales arms is that the arm can't be parked very far away from the platter because the vertical bearing carrier bumps into the pivot. By using the geometry technique, it's possible to design the arm so that parking space is deigned in.

In the hasty drawing I've posted, the arm rests about 50 mm from the platter.

I think Carlo did something similar in his drawings in #2146.

A serious problem with Birch/Thales arms is that the arm can't be parked very far away from the platter because the vertical bearing carrier bumps into the pivot. By using the geometry technique, it's possible to design the arm so that parking space is deigned in.

In the hasty drawing I've posted, the arm rests about 50 mm from the platter.

Attachments

A serious problem with Birch/Thales arms is that the arm can't be parked very far away from the platter because the vertical bearing carrier bumps into the pivot. By using the geometry technique, it's possible to design the arm so that parking space is deigned in.

Just that nature suggests we can try a LONGER horizontal arm and SHORTER vertical arm, which makes it lower mass that might be moved by stylus drag? Since the swing arm needs clearance above the platter, it's best to make sliding arm/carriage hanging from the swing arm. I believe there's a sweet spot that the sliding arm/carriage is short and light enough to be moved by stylus drag and long enough not affected by warp. I also would prefer a guiding arm, instead of a magnetic track, that can "push" the carriage forward when pivoting clockwise (skating force?), that is, the cantilvered base in a Birch or Schroeder LT is not a guiding arm.

The above thinking out loud only dawns on me that once you start use linear bearing or any sliding mechanism it becomes not so different from a short parallel tracker a la Cantus style. Instead of moving 4 inches horizontally across record surface, the extending arm moves about 2 inches forward but with a lot more complication, geometrically and mechanically. The only plus side is, really, not having metal bars hovering over the record playing area.

Sliding extender . Hi Doug, you were even more optimistic than me: I was hoping that the Syrinx string gadget would make SF+SD collaborate (which instead nullifies each other), you that the TA would move with the SD alone, to guide it with a magnet. The Syrinx mk2 (# 1544) unfortunately showed that SD is totally insufficient.

No, we must be able to get the extension directly from rotation = 2 years of useless "head banging" (how do you say? here sbattere il naso, smashing the nose, like pets against a glass door)

Birch TAs parking: the Rabbit belt Birch can rest everywhere needed, since the CW can go even between the 2 cranks. (attachment)

The drawing #2146 tried only to show that the geometry deriving just from the tangency to the groove provides endless, and very different solutions.(all geometrically correct, but most with completely wrong points of control)

Therefore it is very unlikely not only to clone an LT, but also to talk about it without at least knowing its measures. I had praised the geometry found on that simulation (drawn interpreting the patent drawings) because it had a guide that was aligned with the cantilever (= <<skating) except to realize then that, in that way, the guide couldn't brake efficiently the advancement. Therefore the simulation is absolutely not that of an LT

The mockup instead shows that two very different solutions fail the string test quite the same way.

This poses serious problems, as we design these arms to avoid T.E.and Skating. Applying antiskating (weights, springs, magnets, pivot slanting) on PLTs may be something like the old trick of the rail tilting in the linear trackers - a remedy worse than the evil.

carlo

Dd: again a new challenging suggestion. The right recipe to start exploring another amusing project

No, we must be able to get the extension directly from rotation = 2 years of useless "head banging" (how do you say? here sbattere il naso, smashing the nose, like pets against a glass door)

Birch TAs parking: the Rabbit belt Birch can rest everywhere needed, since the CW can go even between the 2 cranks. (attachment)

The drawing #2146 tried only to show that the geometry deriving just from the tangency to the groove provides endless, and very different solutions.(all geometrically correct, but most with completely wrong points of control)

Therefore it is very unlikely not only to clone an LT, but also to talk about it without at least knowing its measures. I had praised the geometry found on that simulation (drawn interpreting the patent drawings) because it had a guide that was aligned with the cantilever (= <<skating) except to realize then that, in that way, the guide couldn't brake efficiently the advancement. Therefore the simulation is absolutely not that of an LT

The mockup instead shows that two very different solutions fail the string test quite the same way.

This poses serious problems, as we design these arms to avoid T.E.and Skating. Applying antiskating (weights, springs, magnets, pivot slanting) on PLTs may be something like the old trick of the rail tilting in the linear trackers - a remedy worse than the evil.

carlo

Dd: again a new challenging suggestion. The right recipe to start exploring another amusing project

Attachments

Last edited:

Don't stop!

I am in favor of continuing this thread. Direct Driver has overseen it as it became a resource, for which we are grateful. The many contributors, from the generous to the quirky, have only added to the pleasure.

Ask yourself: of the turntable, cartridge and arm, which would you improve first? Not the table (which paradoxically is the most cosmetic-driven). Maybe not the cartridge, which gets most of the press, and surely has the most audible effect. This thread says that we know that a good cartridge & stylus can be wasted with a less-good arm, and that is the norm, unfortunately.

We know that arms have been the main target for improvement since 1900. The sheer brainpower expended is enormous. We have seen inventors, engineers and scientists, but also writers, editors and even detractors, who have made positive contributions. If the thread stops, who will archive it for the future?

Which brings me to the first next entry: what is the technique for uploading copy and/or pix that doesn't require the newest & trickiest incompatible software? I miss some of the past entries that no longer survive their posting.

Andy

I am in favor of continuing this thread. Direct Driver has overseen it as it became a resource, for which we are grateful. The many contributors, from the generous to the quirky, have only added to the pleasure.

Ask yourself: of the turntable, cartridge and arm, which would you improve first? Not the table (which paradoxically is the most cosmetic-driven). Maybe not the cartridge, which gets most of the press, and surely has the most audible effect. This thread says that we know that a good cartridge & stylus can be wasted with a less-good arm, and that is the norm, unfortunately.

We know that arms have been the main target for improvement since 1900. The sheer brainpower expended is enormous. We have seen inventors, engineers and scientists, but also writers, editors and even detractors, who have made positive contributions. If the thread stops, who will archive it for the future?

Which brings me to the first next entry: what is the technique for uploading copy and/or pix that doesn't require the newest & trickiest incompatible software? I miss some of the past entries that no longer survive their posting.

Andy

Hoping to keep these posts for the future.

Hi, Carlo

See #519 for an example. Certain images apparently used software that ultimately disappeared, leaving this message:

"An externally hosted image should be here but it no longer works. Please upload images instead of linking to them to prevent this."

There were other posts that requested help in uploading content in general. A different post by DD made the same request that I did.

My writing style can be called "wordy." If "a picture is worth a thousand words," I might be advised to show a picture instead.

I hope this clarifies things.

Andy

Hi, Carlo

See #519 for an example. Certain images apparently used software that ultimately disappeared, leaving this message:

"An externally hosted image should be here but it no longer works. Please upload images instead of linking to them to prevent this."

There were other posts that requested help in uploading content in general. A different post by DD made the same request that I did.

My writing style can be called "wordy." If "a picture is worth a thousand words," I might be advised to show a picture instead.

I hope this clarifies things.

Andy

servo arm

While we're waiting for Ray's new thread on servo tonearms, what's your thought on this Dereneville servo tonearm introduced in another forum? We mentioned this arm before but only recently the designer participated in forums discussion the design and even included a whitepaper on the stepper motor design. They claim the arm can track eccentric records, detection time is 100 times per second. Is that a good idea? Whaddaya think?

I know it's off topic from this thread but what the heck!

I am working on a new thread about that topic - stay tuned.

While we're waiting for Ray's new thread on servo tonearms, what's your thought on this Dereneville servo tonearm introduced in another forum? We mentioned this arm before but only recently the designer participated in forums discussion the design and even included a whitepaper on the stepper motor design. They claim the arm can track eccentric records, detection time is 100 times per second. Is that a good idea? Whaddaya think?

I know it's off topic from this thread but what the heck!

They claim the arm can track eccentric records, detection time is 100 times per second. Is that a good idea? Whaddaya think?

I know it's off topic from this thread but what the heck!

I'm also waiting to see what Ray does. When I started scribbling about how I might build a linear tracker, considering a lot of parts are now easily avialable due to the makerbot hobby I looked at the idea of tracking eccentricity. I then looked carefully at Ray's Rabco controller and the simplicity and elegance of the controller struck me as ideal. Trying to track eccentricity without a guaranteed fixed groove pitch means you will be chasing your tail all the time.

All IMO.

They grossly mislead the readers by using the word, scanning. No. The arm doesn't scan the eccentricity at all. The arm follows the eccentricity after it happens.

Maybe it's semantics. I think he probably meant to use the word tracking instead of scanning. After all the designer is German and English is not his first language.

Trying to track eccentricity without a guaranteed fixed groove pitch means you will be chasing your tail all the time.

I agree.

While we are talking about servo arms, go check out Ralf's invention in this YouTube video.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms