Without going into the math (which I 'probably' used to be able to do, but not so sure nowadays), might it be possible to use the belt idea, but to have the bearing points offset from the center of circular pulleys? Alternatively might ellipsoidal (egg shaped) pulleys provide a practical solution?

I appreciate that it would be ideal if a perfect solution could be found, but many of us would probably be satisfied if a solution with an order of magnitude less error than the traditional offset headshell were feasible.

I appreciate that it would be ideal if a perfect solution could be found, but many of us would probably be satisfied if a solution with an order of magnitude less error than the traditional offset headshell were feasible.

I think I have found a solution for the pulleys & idler, and it might be applicable to the 2 pulley belt system also.

It is also not bound by the geometry anymore and could be placed nearly anywhere near the rim, subject to the tonearm length and start angle between the fixed and moving pivot.

From Doug's experiments, I might try to get that angle more obtuse, but I'm going ahead with the current angle just because to recalculate it is a mission, and an obtuse angle would increase the distance between the pivots.

ATM the fixed pivot can be a circle, but the profile of the idler and moving pivot has to change, took a looooong time but you can calculate the profile of the contact area between the idler and moving pivot to give you an increasing and decreasing angular acceleration required to keep the stylus on the tangential line.

It's incredibly weird but that profile can be nearly any shape as long as the mesh distance is the same and the transition is smooth. A congruent mesh will mean no slipping at all.

As it stands I think Hiten's Rolamite idea is the strongest for me because of the very low friction, no slipping and it's cheap to make, the belt could be cut from 0.05mm Stainless shimstock and could be one continuous length going around all the pulleys. Pulleys can be laser cut for the price of a hamburger. I'm still busy with the profile and will post as soon as it looks good.

It is also not bound by the geometry anymore and could be placed nearly anywhere near the rim, subject to the tonearm length and start angle between the fixed and moving pivot.

From Doug's experiments, I might try to get that angle more obtuse, but I'm going ahead with the current angle just because to recalculate it is a mission, and an obtuse angle would increase the distance between the pivots.

ATM the fixed pivot can be a circle, but the profile of the idler and moving pivot has to change, took a looooong time but you can calculate the profile of the contact area between the idler and moving pivot to give you an increasing and decreasing angular acceleration required to keep the stylus on the tangential line.

It's incredibly weird but that profile can be nearly any shape as long as the mesh distance is the same and the transition is smooth. A congruent mesh will mean no slipping at all.

As it stands I think Hiten's Rolamite idea is the strongest for me because of the very low friction, no slipping and it's cheap to make, the belt could be cut from 0.05mm Stainless shimstock and could be one continuous length going around all the pulleys. Pulleys can be laser cut for the price of a hamburger. I'm still busy with the profile and will post as soon as it looks good.

Yes both will get you close enough.but to have the bearing points offset from the center of circular pulleys? Alternatively might ellipsoidal (egg shaped) pulleys provide a practical solution?

Offset shafts cause a bit of drift though.

Eccentric Elliptical pulleys are probably ideal as you get a fixed centre distance but acceleration calculations are a nightmare because there are no accurate circumference equations for an ellipse. I've given up on finding an algebraic solution.

circumference of an ellipse.

The Web is very confusing here, as are their sources.

If you Google "What is the perimeter of an ellipse," you will get some pretty good formulas: few calculations, and the closer the ellipse is to a circle, the better. You can go for however many decimal places you like.

The problem comes when you ask the difference between circumference and perimeter. For circles, there is no difference. For most regular geometric shapes, you use circumference. For an outside path which may be slightly irregular or even segmented, you need perimeter. (that last bit isn't perfect, but may make some sense)

This is where I expect someone to tell me I am completely wrong, but I have faith.....

Andy

The Web is very confusing here, as are their sources.

If you Google "What is the perimeter of an ellipse," you will get some pretty good formulas: few calculations, and the closer the ellipse is to a circle, the better. You can go for however many decimal places you like.

The problem comes when you ask the difference between circumference and perimeter. For circles, there is no difference. For most regular geometric shapes, you use circumference. For an outside path which may be slightly irregular or even segmented, you need perimeter. (that last bit isn't perfect, but may make some sense)

This is where I expect someone to tell me I am completely wrong, but I have faith.....

Andy

Last edited:

Hi Ralphfcooke.

I think that an eccentric circular pulley can not turn around a fixed one, because it should stretch the belt - but please look at the chart of post 1620: there is no need because it is enough to mount the vert. pivot eccentrically with respect of the pulley to be on the elliptical geometry. Maybe not needed because those errors are smaller that mounting tolerances of cartridge on arm and arm on plinth. Imho design problems listed along with the drawings are still more relevant

carlo

I think that an eccentric circular pulley can not turn around a fixed one, because it should stretch the belt - but please look at the chart of post 1620: there is no need because it is enough to mount the vert. pivot eccentrically with respect of the pulley to be on the elliptical geometry. Maybe not needed because those errors are smaller that mounting tolerances of cartridge on arm and arm on plinth. Imho design problems listed along with the drawings are still more relevant

carlo

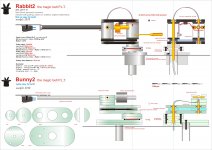

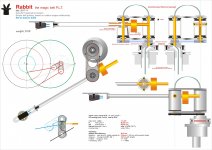

Another step in Rabbit&Son design; trying to make my life easier, at least in this.

Bunny2 e.g. can be made with simple tools always at hand: laser cutters or cnc mills, water jets, 3d printers... Rabbit2 instead needs still some lathing.

To be continued. (all those damn ball bearings...)

carlo

Bunny2 e.g. can be made with simple tools always at hand: laser cutters or cnc mills, water jets, 3d printers... Rabbit2 instead needs still some lathing.

To be continued. (all those damn ball bearings...)

carlo

Attachments

This Windows application looks like it could be useful in designing pivoted linear tracking arms.

Linkage Mechanism Designer and Simulator | Dave's Blog

Linkage Mechanism Designer and Simulator | Dave's Blog

Very useful link Jcarr, thanks; and thanks to the author of that really smart shareware program.

However, imho, the problem is not as much to imagine (and graphically verify) the pattern of movement of these simple mechanisms (and they must be simple, with that kind of forces) as to know the torque resulting in the various joints. The program menu mentions a "use momentum" instruction (maybe to overcome eventual dead spots) but does not seem to give this type of results. Is there any way to get them?

carlo

However, imho, the problem is not as much to imagine (and graphically verify) the pattern of movement of these simple mechanisms (and they must be simple, with that kind of forces) as to know the torque resulting in the various joints. The program menu mentions a "use momentum" instruction (maybe to overcome eventual dead spots) but does not seem to give this type of results. Is there any way to get them?

carlo

A noob idea.acceleration calculations are a nightmare because there are no accurate circumference equations for an ellipse. I've given up on finding an algebraic solution.

Can a jig be set up in such a way that the main pivot is fixed, the horizontal line across the vinyl is fixed by a track can be placed on which the jig dummy headshell can be moved. and the ellipse part would have sharp marker; so when we move the dummy headshell across the record it traces the ellipse ?

Regards

I've basically done this digitally to calculate the perpendicular point between the idler and moving cam for every degree of the tonearm arm rotation. It's working on paper so far.A noob idea.

Can a jig be set up in such a way that the main pivot is fixed, the horizontal line across the vinyl is fixed by a track can be placed on which the jig dummy headshell can be moved. and the ellipse part would have sharp marker; so when we move the dummy headshell across the record it traces the ellipse ?

Regards

Maybe Walter, but I can give you just an answer: try it.

Instead that's why using a rubber belt: a belt has no motion relative to the pulleys. so it does not have friction - on the contrary we need that does not slip with respect to the pulleys, with the least possible tension (load on the bearings). The force dispersed (2- 3%) is only the deformation of the material of the belt (and the more rigid, the worst).

That's how it behaves in the prototype: in respect to the tracking forces (0.1 - 0.2 gr) the belt is completely rigid, the elasticity comes into play only with discs with marked eccentricity, in my opinion softening stresses in a positive way. With a rigid driving system this job should be done by the cantilever, with probable damages.

The problems of these arms - as reported by Doug - are: off-axis loads, inevitably relevant horizontal mass - complex mechanics and consequent frictions - use of ball-bearings.

I add another one: the relationship between side force and stylus drag that moves these Birch based arms varies between external and internal gooves, and I still could not analyze correctly the resulting force. With a normal or a test record the thing is not perceptible, but I am convinced that there are some consequences in tracking.

Hiten: long time ago Doug had done something similar to find the right pattern of the magnetic guide, with Schroeder's approval. Linkage, the program linked by Jcarr seems a great tool to explore geometries.

carlo

Instead that's why using a rubber belt: a belt has no motion relative to the pulleys. so it does not have friction - on the contrary we need that does not slip with respect to the pulleys, with the least possible tension (load on the bearings). The force dispersed (2- 3%) is only the deformation of the material of the belt (and the more rigid, the worst).

That's how it behaves in the prototype: in respect to the tracking forces (0.1 - 0.2 gr) the belt is completely rigid, the elasticity comes into play only with discs with marked eccentricity, in my opinion softening stresses in a positive way. With a rigid driving system this job should be done by the cantilever, with probable damages.

The problems of these arms - as reported by Doug - are: off-axis loads, inevitably relevant horizontal mass - complex mechanics and consequent frictions - use of ball-bearings.

I add another one: the relationship between side force and stylus drag that moves these Birch based arms varies between external and internal gooves, and I still could not analyze correctly the resulting force. With a normal or a test record the thing is not perceptible, but I am convinced that there are some consequences in tracking.

Hiten: long time ago Doug had done something similar to find the right pattern of the magnetic guide, with Schroeder's approval. Linkage, the program linked by Jcarr seems a great tool to explore geometries.

carlo

Last edited:

addendum

What I know from previous tests (Schroeder mentioned it as one of the merits of his solution) is that the guide must be elastic, otherwise at the first eccentric LP (do you have one that is not?) goodbye cartridge.

Hi guys,

about the above: not quite... any decoupling(rubber band, magnetic coupling...) in the horizontal plane will lower the eff. mass in the horizontal plane and , when tuned properly, act as an antiresonator, reducing the lateral arn/cart resonance frequency peak substantially. Rigid coupling would not kill you cart upon playing an eccentric record...

Did anyone check out the arm that I took to the Munich High End Show in 2016? Didn't receive much notice, but it proved that there is more than one path leading to Rome, - and it utilizes a rubber belt..

The orientation of the lever is different but the functioning principle is identical to what was discussed here lately.

A video is available here:

Innovator Tone Arm Designer Frank Schroder Explains The Workings of the Rare Neumann Turntable | Analog Planet

All the best,

Frank

Rigid coupling would not kill you cart upon playing an eccentric record...

Best news I've heard the whole day.

I'd near given up on the Rolamite idea.

.... so good, Doug!

I'm glad the rabbits started to grow and multiply, what are your first impressions?

And I'm also glad to discover that I've reinvented the wheel, if it's a Schroeder's wheel: at least I'm sure it's a round wheel. You know what happened with the square one of the Syrinx.

At this point I would like if Frank Schroeder could give us some more information about that arm, because from the linked video does not look like a Birch based (P. forward hor. pivot?)

Rigidity vs elasticity: effectively that statement was melodramatic (I am italian, guys) so after I have always spoken just of possible damages: seing a stylus bending always worries me, and my favorite records detest the skipping. Imho it's the arm that has to deal with the eccentricity, not the cartridge.

carlo

I'm glad the rabbits started to grow and multiply, what are your first impressions?

And I'm also glad to discover that I've reinvented the wheel, if it's a Schroeder's wheel: at least I'm sure it's a round wheel. You know what happened with the square one of the Syrinx.

At this point I would like if Frank Schroeder could give us some more information about that arm, because from the linked video does not look like a Birch based (P. forward hor. pivot?)

Rigidity vs elasticity: effectively that statement was melodramatic (I am italian, guys) so after I have always spoken just of possible damages: seing a stylus bending always worries me, and my favorite records detest the skipping. Imho it's the arm that has to deal with the eccentricity, not the cartridge.

carlo

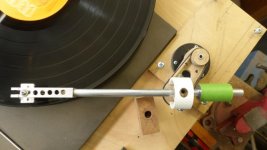

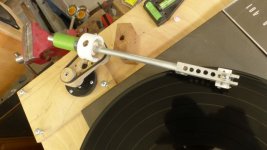

Hi all - Rabbit tonearm (almost) done.

Working on stiffness and lightness complicated a bit the construction. I gave up with the lifter in order to have a sturdy double crank system (design modified from previous). A small spring counterweight saves about 40 grams, so the total weight of moving masses is below 120 gr, which is an acceptable value for normal tonearms.

The most difficult things to build without a mill are the cranks and the vertical pivot: with my pillar drill I got a 0.12 mm error for the axes distance, and it took me a lot of patience to get there.

Ball bearings now are loaded almost properly, so having 4 instead of 2 does not increase frictions. Now it's easy to set up (leveling, spindle distance, proper angling are all fine tunable) and quite comfortable to place precisely on every trace of the record.

Some experiment are needed for cables that, being exposed on top, must be more resistant than those used on test-Bunny, but still very flexible.

carlo.

Working on stiffness and lightness complicated a bit the construction. I gave up with the lifter in order to have a sturdy double crank system (design modified from previous). A small spring counterweight saves about 40 grams, so the total weight of moving masses is below 120 gr, which is an acceptable value for normal tonearms.

The most difficult things to build without a mill are the cranks and the vertical pivot: with my pillar drill I got a 0.12 mm error for the axes distance, and it took me a lot of patience to get there.

Ball bearings now are loaded almost properly, so having 4 instead of 2 does not increase frictions. Now it's easy to set up (leveling, spindle distance, proper angling are all fine tunable) and quite comfortable to place precisely on every trace of the record.

Some experiment are needed for cables that, being exposed on top, must be more resistant than those used on test-Bunny, but still very flexible.

carlo.

Attachments

addendum

Did anyone check out the arm that I took to the Munich High End Show in 2016? Didn't receive much notice, but it proved that there is more than one path leading to Rome, - and it utilizes a rubber belt..

The orientation of the lever is different but the functioning principle is identical to what was discussed here lately.

A video is available here:

Innovator Tone Arm Designer Frank Schroder Explains The Workings of the Rare Neumann Turntable | Analog Planet

All the best,

Frank

Outstanding

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms