Surely that still has tracking angle error at either end, much less, but some none the less.

No, it doesn't.

See fig 3 in the last image in post #519 to understand why.

Hi, Direct Driver

Those are excellent pix of the B-J arm. They sure got the attention of a few posters here.

The first few times I saw them I noticed (in post #518) the plan view dtut mentions (and possibly Mark as well) and the mosaic page from the patent. Now they're gone. What happened? And what was the source?

Andy

Those are excellent pix of the B-J arm. They sure got the attention of a few posters here.

The first few times I saw them I noticed (in post #518) the plan view dtut mentions (and possibly Mark as well) and the mosaic page from the patent. Now they're gone. What happened? And what was the source?

Andy

Questions answered! Vinylengine.com (the source, apparently) was "down for maintenance." They're back now.

I also noticed a spirited exchange among its members as to what to call it, how accurate it is, etc. "Our" dtut was in the middle of it. How about it, Doug? Any satisfaction?

Andy

I also noticed a spirited exchange among its members as to what to call it, how accurate it is, etc. "Our" dtut was in the middle of it. How about it, Doug? Any satisfaction?

Andy

Andy,

There was some discussion that involved a bit of confusion and consternation because the BJ sort of looks like a pivot if you're not a follower of the "Angling for 90 Degrees" thread. I'd forgotten about that. Eventually, it all got back on track.

As I said then, I'd love to get my hands on a BJ, but the last two I saw for sale were a little pricey for me and involved shipping from England or Australia.

Maybe, if that drawing is to scale, I can put together a clone of some sort. I've got plenty of ABS plumbing pipe, some cheap ceramic bearings, and lots of blue masking tape - that oughta do it.

There was some discussion that involved a bit of confusion and consternation because the BJ sort of looks like a pivot if you're not a follower of the "Angling for 90 Degrees" thread. I'd forgotten about that. Eventually, it all got back on track.

As I said then, I'd love to get my hands on a BJ, but the last two I saw for sale were a little pricey for me and involved shipping from England or Australia.

Maybe, if that drawing is to scale, I can put together a clone of some sort. I've got plenty of ABS plumbing pipe, some cheap ceramic bearings, and lots of blue masking tape - that oughta do it.

DIY

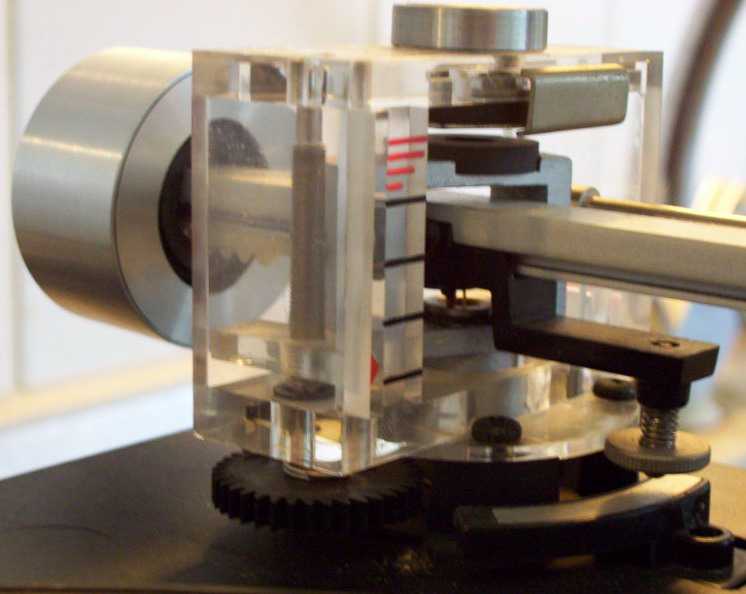

For DIY projects, I would prefer to copy a variation of the Garrard Zero 100 or that mysterious DIY arm with strings. Or you can use the specs of below DIY arm from post#343 by inventor Marek Bundzel because you can convert a conventional pivot arm into a tangential arm.

Good Luck!!

.

Maybe I can put together a clone of some sort. I've got plenty of ABS plumbing pipe, some cheap ceramic bearings, and lots of blue masking tape - that oughta do it.

For DIY projects, I would prefer to copy a variation of the Garrard Zero 100 or that mysterious DIY arm with strings. Or you can use the specs of below DIY arm from post#343 by inventor Marek Bundzel because you can convert a conventional pivot arm into a tangential arm.

Good Luck!!

.

Unknown Tangential Tonearm

I am new to this group and I have been following this thread with interest. There have been many great posts and the I have enjoyed reading them.

I have a turntable that I have owned for about 25 years. It is a JVC Nivico Perfect Tracking. In all that time I have never seen or heard of another one except for one sold in Malaysia. It is a large turntable probably made in the 1970s. The most interesting thing about it is the tonearm. It is a tangential tracking arm. It is nicely made with a jeweled movement. If anyone can tell me anything at all about it I would love to hear what they have to say. It plays well and sounds good. The cartridge is a Shure X8.

Can anyone tell me about this tonearm ?

I am new to this group and I have been following this thread with interest. There have been many great posts and the I have enjoyed reading them.

I have a turntable that I have owned for about 25 years. It is a JVC Nivico Perfect Tracking. In all that time I have never seen or heard of another one except for one sold in Malaysia. It is a large turntable probably made in the 1970s. The most interesting thing about it is the tonearm. It is a tangential tracking arm. It is nicely made with a jeweled movement. If anyone can tell me anything at all about it I would love to hear what they have to say. It plays well and sounds good. The cartridge is a Shure X8.

Can anyone tell me about this tonearm ?

Attachments

Hi, robertmc48

Your tonearm does indeed seem to be the same design as the Garrard Zero-100 (Klein, U.S. pat. #2983517, or British equivalent from A.B. Say). Do you still have the manual it had originally? Can you post any of it if you do? Thanks for sharing this player with us!

Andy

Your tonearm does indeed seem to be the same design as the Garrard Zero-100 (Klein, U.S. pat. #2983517, or British equivalent from A.B. Say). Do you still have the manual it had originally? Can you post any of it if you do? Thanks for sharing this player with us!

Andy

It is a JVC Nivico Perfect Tracking. In all that time I have never seen or heard of another one except for one sold in Malaysia. It is a large turntable probably made in the 1970s. The most interesting thing about it is the tonearm. It is a tangential tracking arm. It is nicely made with a jeweled movement.

Wow. Thanks for posting and sharing with us such an interesting tonearm. As others have mentioned, it looks to be a Japanese copy of the Garrard Zero 100, except the guiding rod is on the left side of the main armwand, whereas Garrard is on the right. Looks like better pivot quality and well constructed. And the anti-skating uses a more conventional string and weight design than magnets. To me it's more attractive than the flimsy Garrard.

Thanks again!

JVC Victor Nivico Perfect Tracking

In all that time I have never seen or heard of another one except for one sold in Malaysia.

I am glad that some of you have enjoyed seeing this turntable. I have owned it for about 25 years and it always gets a lot of comments when it is seen by someone who appreciates turntables. I have owned many turntables over the years but this one remains a favorite. I think it looks better in person and it really does work and sound good.

vertical bearing

I posted this before about this hypothetical design that the vertical bearing does NOT pivot. It's "pistonic" and it moves up and down without changing tracking or raking angle. It's like a linear bearing for vertical movement. I wonder if we use miniature linear bearing for the vertical plane, the horizontal mass can be significantly reduced and we can then use another set of linear bearings for horizontal movement or a use pivot bearing. The advantage of vertical linear bearing is that gravity doing the tracking force and use a string or spring to push or pull up the headshell assembly as a counter-weight. On a tangential pivot arm, the armwand only has to move horizontally sort of like the Dynavector arm.

I know the "teeter-totter" effect was something objected by the late Bo Hansson, designer of the Opus 3 Cantus linear tracking tonearm, hence the lack of pivot point for the vertical movement in the design.

The manufacture has since deleted the page so I guess they aborted the project due to either technical difficulties or too expensive as an investment. It sure gave me food for thoughts though.

Whaddaya think?

.

I posted this before about this hypothetical design that the vertical bearing does NOT pivot. It's "pistonic" and it moves up and down without changing tracking or raking angle. It's like a linear bearing for vertical movement. I wonder if we use miniature linear bearing for the vertical plane, the horizontal mass can be significantly reduced and we can then use another set of linear bearings for horizontal movement or a use pivot bearing. The advantage of vertical linear bearing is that gravity doing the tracking force and use a string or spring to push or pull up the headshell assembly as a counter-weight. On a tangential pivot arm, the armwand only has to move horizontally sort of like the Dynavector arm.

Work is underway on the nextgen of innovation, a maglev linear tracking & "armless" design (pictured below). It's sans an “arm” tube or wand, utilizing a vertical hydraulic piston with internal magnetic dampening. The stylus cannot leave perfect tangent & the piston is sans relative mass, only tracking force. It cannot “teeter-totter" as in pivoting or linear tracking "armed" designs. No other design maintains perfect vertical tangent and azimuth alignment, and it's linear maglev!

An externally hosted image should be here but it was not working when we last tested it.

I know the "teeter-totter" effect was something objected by the late Bo Hansson, designer of the Opus 3 Cantus linear tracking tonearm, hence the lack of pivot point for the vertical movement in the design.

The manufacture has since deleted the page so I guess they aborted the project due to either technical difficulties or too expensive as an investment. It sure gave me food for thoughts though.

Whaddaya think?

.

To further simplify it (pun intended), wouldn't it be easier to use TWO unipivot bearings? To me, it begs for such bearings.

Whaddaya think?

You will still have the two bearings at the headshell end. Possibly varying amounts of play/friction will caused the unipivots to rattle?

Cheers Steve

You will still have the two bearings at the headshell end. Possibly varying amounts of play/friction will caused the unipivots to rattle?

The advantage of a unipivot is that the contact point is preloaded and has the least amount of contact area, a single point, hence low friction. Even Michel Huber of Thales admitted his double cardanic bearing has the lowest possible friction but NOT lower than a unipivot.

Michel Huber in an interview: "Our tangential pivoted construction can compare with any ball bearing design regarding friction, but not with unipivot tonearms as they have only one contact point."

They will not rattle due to the preloading and it will simplify the geometry. And having two unipivot points they stabilize each other in the azimuth plane. Then at least we can concentrate on the quality of the headshell bearings. Once the base pivots are taken care of we don't have to worry as much and focus on whatever headshell design we can come up with.

For a dual-wand design, using two unipivots at the base is the simplest and most effective solution, to me at least. The creativity and design ingenuity is in the headshell pivots, which is another topic on its own. While I love the look and design of the Thales Simplicity design, I would still prefer one main rod that has majority of the mass and one smaller rod for guiding. The equal mass armwands design of the Simplicity or Van Eps arm is too technically difficult to materialize in a DIY project.

To simplify simplicity is not so simple after all.

.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms