PLT = Pivoting Linear Tracker

Let's move on to more fun stuff!

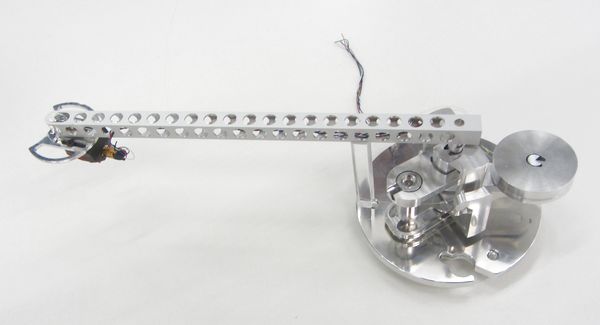

Our forum brainiac Mark Kelly has been quiet these days so I decided to take liberty (Don't kill me, Mark!) to link his ideas and pictures from another forum on here just to stir up some more discussion. I want to or at least I try to be as encompassing as possible to cover all topics on this genre of tonearms. Below is Mark's diy effort and experiment, along with his comments. Very cool!

I owe you another beer, Mark!

Let's move on to more fun stuff!

Our forum brainiac Mark Kelly has been quiet these days so I decided to take liberty (Don't kill me, Mark!) to link his ideas and pictures from another forum on here just to stir up some more discussion. I want to or at least I try to be as encompassing as possible to cover all topics on this genre of tonearms. Below is Mark's diy effort and experiment, along with his comments. Very cool!

Posted on October 25, 2012

PLT = Pivoting Linear Tracker.

I've been playing with this concept a while, here's one of my efforts. As you can see this is a proof of concept prototype made with bamboo sticks and scavenged bearings. I would have used better bits for the next version if I hadn't come up with a different design which I like much more.

I blue-tacked a pointer to the headshell at 90 degrees to the cantilever. It points directly over the spindle at 60mm radius:

And also at 150mm radius, and all points in between to within 0.1mm.

BTW the data on these pic files says they are over three years old, so obviously I'm not going anywhere with them. Anyone who wants to use the ideas can.

Your problem will be bearings. The main bearing in the phot is the head drum out of a VCR. The secondary bearing (hidden under the arm at the end) came out of a failed HDD. Neither are good enough for theis application but obtaining the correct bearings has eluded me for years.

Mark Kelly

I owe you another beer, Mark!

I posted my message after not getting a lot of sleep.

Hi, Sprags

That is what I meant by dumb-o rays, a name invented by my friend, for doing things on too little sleep. Your idea is a very good one, even if part of it was also thought of by someone else. (that someone is Straight Tracker, who was throwing you a compliment).

I got hit by the rays myself in my own post, started at 8AM on too little sleep (the "12-in SME3009" screw-up).

Thanks to our diplomatic host, Direct Driver, I at least got to correct things.

Last edited:

My ideas come at all times. While working for Boeing Helicopters I came up with a fixture design that was used for both turning and milling rotor links for CH-46 and 47's. Saved immensely on set up times and added to precision of the part. I thought of that one when I couldn't sleep and drove into work at 2AM and had the concept ready for presentation in a 10AM meeting. Just one of many....

Last edited:

Arms that move on rails do indeed follow the original cutter path perfectly, but that's not the whole story. The entire arm mass (counterweight, pivot housing, arm & pickup) must be moved as well. Since the arm stays perpendicular to a radius, how can its pickup move inward across the record? The answer is, "it can't." The spiral groove pulls the stylus (cantilever) out of position and the mass is dragged by it. This is very bad for the record and stylus, not to mention the sound. "Air-bearings" remove rail friction, but the mass must still be handled.

Based on my readings of Poul Ladegaard, the above is nothing more than a common misconception. But since this is a pivoting tonearm thread (and I love it so much), let's pretend that linear trackers have some kind of inherent issue.

Hi, tnargs,

Thanks for checking my post, but my reading of Poul's arm is different. He says (Poul Ladegaard's Air Bearing Tangential Tonearm Page),

"Here, the idea of a new principle of movement had to be tried. The mass of a lead weight was to be transformed into the needed horizontal pull force using a pulley.

The problem now is to control the movement of the arm so as to ensure tangential tracking at all times. A heating wire slowly melting through stearin wax had the necessary properties and could by means of varying the electrical currrent be smoothly adjusted from a full stop to the necessary maximum speed. The wax was placed in a small tray in connection with the pulley wire. A wire in the wax along the edge of the tray was fastened to the arm base and thus it could steer/slow down the turning of the wax tray and thereby the movement of the arm.

The mistracking angle of the arm was measured with a photo cell, whose signal was converted into an evenly pulsating current in the heating wire."

He is using an "active" system, not a passive one. A falling lead weight pulls the arm, coupled by a pulley. The rate of fall is modulated by a heated wire in wax, said head controlled by optical feedback. When there is mistracking, the system tries to correct it.

This his "Arm 2", and there is likewise nothing in his other designs that suggests he violated either logic or the laws of physics.

Back then, he also did not treat articulated-head or moving-plinth designs.

Andy

Thanks for checking my post, but my reading of Poul's arm is different. He says (Poul Ladegaard's Air Bearing Tangential Tonearm Page),

"Here, the idea of a new principle of movement had to be tried. The mass of a lead weight was to be transformed into the needed horizontal pull force using a pulley.

The problem now is to control the movement of the arm so as to ensure tangential tracking at all times. A heating wire slowly melting through stearin wax had the necessary properties and could by means of varying the electrical currrent be smoothly adjusted from a full stop to the necessary maximum speed. The wax was placed in a small tray in connection with the pulley wire. A wire in the wax along the edge of the tray was fastened to the arm base and thus it could steer/slow down the turning of the wax tray and thereby the movement of the arm.

The mistracking angle of the arm was measured with a photo cell, whose signal was converted into an evenly pulsating current in the heating wire."

He is using an "active" system, not a passive one. A falling lead weight pulls the arm, coupled by a pulley. The rate of fall is modulated by a heated wire in wax, said head controlled by optical feedback. When there is mistracking, the system tries to correct it.

This his "Arm 2", and there is likewise nothing in his other designs that suggests he violated either logic or the laws of physics.

Back then, he also did not treat articulated-head or moving-plinth designs.

Andy

Last edited:

Angling for 90

I've wanted to bring this up in this thread for some time but haven't for fear of getting flamed. I have owned many Shure cartridges that incorporated that stabilizer brush assembly. I assume since it was used on the most expensive models that it was not detrimental at all to performance. I know of no reported tweaks to improve them which involved removing the brush. I'll mention as well that I used a cleaning device in the 80's called a dust bug which consisted of plastic arm with a brush and the brush tracked the LP grooves and traversed and cleaned as it went. The bristles followed the grooves and didn't require antiskate.

Could these principals not be used to propel the arm across the record and shoulder a large portion of the lateral force that normally would be transmitted to the cantilever? It would most like be best for it to float up and down like the Shure devices. By being several grooves wide it would sort of average the transverse forces so that the stylus will never be far from tangent and I think it would really help when the spindle hole was not drilled on center.

I've wanted to bring this up in this thread for some time but haven't for fear of getting flamed. I have owned many Shure cartridges that incorporated that stabilizer brush assembly. I assume since it was used on the most expensive models that it was not detrimental at all to performance. I know of no reported tweaks to improve them which involved removing the brush. I'll mention as well that I used a cleaning device in the 80's called a dust bug which consisted of plastic arm with a brush and the brush tracked the LP grooves and traversed and cleaned as it went. The bristles followed the grooves and didn't require antiskate.

Could these principals not be used to propel the arm across the record and shoulder a large portion of the lateral force that normally would be transmitted to the cantilever? It would most like be best for it to float up and down like the Shure devices. By being several grooves wide it would sort of average the transverse forces so that the stylus will never be far from tangent and I think it would really help when the spindle hole was not drilled on center.

Hello, LFM

Your idea is excellent. Just HOW excellent is shown by Shure's never-used follow-up to their brush patent (which was #4275888). That patent recalled other patents using pads, et al, to clean and stabilize the pickup.

The newer patent (#4514836) was more like your idea and answers your question about the old brush's good or bad side. It states, in part:

"Frequent cleaning of the brush is required. In addition, excess lateral force, as from manual error, causes the bristles to bend and possibly disengage from the groove, or cause side thrust on the stylus affecting the tracking of the stylus in the groove and increasing stylus and record wear."

In other words, the bristles may introduce problems. And they may help or hurt side thrust.

There is a common principle in the world: you may not find out what's wrong with something until a) the competition points it out or b) the company itself makes (or intends to make) a better version.

[Note: Shure originally didn't understand how the bristles worked. By the time of the newer patent, they did.]

Hope this answers your question!

Andy

Your idea is excellent. Just HOW excellent is shown by Shure's never-used follow-up to their brush patent (which was #4275888). That patent recalled other patents using pads, et al, to clean and stabilize the pickup.

The newer patent (#4514836) was more like your idea and answers your question about the old brush's good or bad side. It states, in part:

"Frequent cleaning of the brush is required. In addition, excess lateral force, as from manual error, causes the bristles to bend and possibly disengage from the groove, or cause side thrust on the stylus affecting the tracking of the stylus in the groove and increasing stylus and record wear."

In other words, the bristles may introduce problems. And they may help or hurt side thrust.

There is a common principle in the world: you may not find out what's wrong with something until a) the competition points it out or b) the company itself makes (or intends to make) a better version.

[Note: Shure originally didn't understand how the bristles worked. By the time of the newer patent, they did.]

Hope this answers your question!

Andy

Last edited:

I've wanted to bring this up in this thread for some time but haven't for fear of getting flamed.

Not on this thread, at least not by me. You're more than welcome to chime in. We don't bite.

The idea that the stylus has problems 'dragging' a linear tracking arm across the record is, IMO, a furphy. As I mentioned above.

Care to elaborate your claim that horizontal mass has no effect on performance? Besides sonic performance, how do you deal with eccentric records? Enlighten us.

Hi, tnargs,

Thanks for checking my post, but my reading of Poul's arm is different. He says (Poul Ladegaard's Air Bearing Tangential Tonearm Page),....

Care to elaborate your claim that horizontal mass has no effect on performance? Besides sonic performance, how do you deal with eccentric records? Enlighten us.

Hi guys, if I were you I wouldn't want to rely on me for your enlightenment,

Firstly, the forces involved in moving an arm from the edge to the centre of an LP, are much less than the forces resulting from eccentricity of the hole. So let's confine discussion to the latter.

Andy quoted the right document but the wrong extract. Referring to Ladegaard's #3 (final) arm, he wrote:

The arm and carriage weigh 160 grams altogether, which was increased up to a total of 300 grams with two triangular lead weights.

Now one might fear that poorly centered records would provoke the stylus too much when it has to move so much 'baggage'. .... On the arms described here, the load was typically around +/- 50 milligrams. This is insignificant compared to a normal tracking force of 1.8 grams.

Now one might fear that poorly centered records would provoke the stylus too much when it has to move so much 'baggage'. .... On the arms described here, the load was typically around +/- 50 milligrams. This is insignificant compared to a normal tracking force of 1.8 grams.

This is on an arm weighing three hundred grams! A typical Airtangent-type has maybe one eighth of this sliding mass.

How significant is one eighth of 'insignificant'? And that is only with poorly centred records.

Another perspective: let's look at the uncorrected lateral forces on a stylus attached to a pivot arm. A typical figure for constant skating force is 200 milligrams, plus a modulation skating force peaking at 200 milligrams (Kogen, 1967). Even assuming a best-case scenario for anti-skating compensation perfectly applied (200 milligrams constant plus half of 200 milligrams modulational), the uncorrectable skating force will be 100 milligrams modulational. That doesn't look good compared to one eighth of 50 = 6 milligrams. And it is present on all records, not just poorly centred ones. Therefore, any performance effect of lateral stylus forces in a linear tracking arm will also be present in pivot arms, but more strongly.

IMHO it looks like this claimed weakness of linear tracking arms has been misconceived, and it actually belongs with pivot arms. If at all. Maybe we should just 'forget' it.

What do you think? (I was pleased to read above that you don't bite

This is on an arm weighing three hundred grams! A typical Airtangent-type has maybe one eighth of this sliding mass. How significant is one eighth of 'insignificant'? And that is only with poorly centred records.

Here's the full quote:

TESTING AND MEASUREMENTS:

The objective was to get the horizontal plane arm resonance down to 2-3 Hz. The arm and carriage weigh 160 grams altogether, which was increased up to a total of 300 grams with two triangular lead weights. These were molded in the bottom of a leftover angle profile. This yielded the desired results. See measurements (Arm Graphs).

Now one might fear that poorly centered records would provoke the stylus too much when it has to move so much 'baggage'. In the old days - in the age of radial arms - there was something called a 'skateometer'. It came from Dual and could be fitted instead of the cartridge so that one could see if it had been properly adjusted. With this fitted on a tangential arm, the effect of excentric records could be evaluated. On the arms described here, the load was typically around +/- 50 milligrams. This is insignificant compared to a normal tracking force of 1.8 grams. More critical is the adjustment of the arm base to perfect level. But here is yet another advantage of this design. Simply lift the arm tube off the carriage and see if the carriage remains still.

I notice he's talking about skating force. A linear arm by nature has little or no skating force due to no offset angle and overhang, unlike a conventional pivot arm. But is this the same force as horizontal effective mass? If you use your finger to push the entire arm assembly on an airbearing or linear bearing tonearm to the record center, let say the vertical force is zero, will this lateral force be "50 milligrams"?

By the way, is horizontal resonance at 2-3Hz a little too low for warp records?

I've never owned an airbearing arm but I have friends who have and they noticed the cantilever is skewed to one side after long term use.

IMHO it looks like this claimed weakness of linear tracking arms has been misconceived, and it actually belongs with pivot arms. If at all. Maybe we should just 'forget' it.

Hmm.... I wonder why the Trans-Fi arm, a descendent of the Ladegaard design, or other airbearing arms, continues to decrease the mass of its armwand....

Where's Mark Kelly when we need him?!

I patented this concept (moving plate and still tangential arm) for the French company i was working for (Scientelec) in 1970.Produced in the 1960s (I think), the Transcriptor Transcriber moved the platter-bearing-motor on rails while the tonearm remained still (sort of).

According to Transcriptor's website, the Transcriber was produced between 1977-1981.

As the inertia of the plate is huge, and it can be suspended, you can get a nice filtering of the noise generated by the rotating screw used to move the plate.

http://www.esperado.fr/creations_audio/une_platine_a_bras_radial.html

Last edited:

The stylus still has to get from one place to another. So I wonder why the brush is not appreciated for pitching in on that task. It also introduces drag which should help with speed regularity on belt drive and direct drive units, no? Besides, the lead-in groove throws the stylus/cartridge/arm toward the center so doesn't inertia take care of skating??

Hi dd

I omitted the bit about the skateometer because it was irrelevant -- and confusing -- as it turned out to be.

No, he is talking about the lateral forces imposed on the stylus by an offset hole in the LP. He simply used an instrument that was intended to measure skating force to measure the 'offset hole force'. That doesn't make it skating force just because we use a skating force measurement instrument to measure a different force.

The lateral force under discussion is not skating force and will occur for any arm type. Its magnitude is directly proportional to the horizontal effective mass of tonearm plus cartridge. The Ladegaard arm is an extreme example of high horizontal effective mass, many times that of most modern LT arms, so most LT arms will exhibit this force at a small fraction of 50 milligrams, as per the direct proportionality. Yet the designer says the force is insignificant even in the Ladegaard arm.

If you use your finger the force will be whatever force you use in your finger!

Not according to Ladegaard. He's the expert. My own reading is that the offset centre oscillation is at 0.55 Hz (33 rpm) to 0.75 Hz (45 rpm), so the Ladegaard arm has a margin of 3 to 5 times.

I also notice that you mention warp records. That is a vertical error and not relevant to horizontal resonance. Ladegaard's arm has 10-16 Hz vertical resonance to deal with warps.

The ability to independently tune H and V resonances is a huge advantage of the LT arm over pivot arms, which Ladegaard has gleefully taken advantage of.

Well, something is wrong with their implementation or application or execution of their individual tonearms. Maybe their air pressure is so low the slide drags on the rail, or so high the air exhausts asymmetrically. Or some impurity has lodged between the slide and its rail and needs to be cleaned out. Or the rail is not quite level. Or it's a diy arm and the slide is dragging on the rail due to tolerances.

But one thing it is NOT due to, is the offset centre force I discussed in my previous post, as this is sinusoidal with an average of zero, so it will never twist a stylus to one side.

And it is NOT due to the force needed to 'drag' the arm towards the spindle. In fact if we want to get technical, for an air bearing LT arm with none of the issues covered above, this force is exactly zero. Well, it would be if the groove width was constant. Variations in groove width are so small that, if you want me to work out numbers for the force generated, I will estimate right now they will be ' orders of magnitude smaller than insignificant'.

Well, that will increase the vertical resonant frequency. Horizontal is another matter: if they want to, they can decrease arm wand weight and increase sliding carriage weight so the vertical resonant frequency is increased but not the horizontal.

Well you've got me, so all is well. <strictly joking!!>

Is anyone starting to appreciate my suggestion that the arguments against LT arms related to high horizontal mass are a 'common misconception'?

Here's the full quote:

I omitted the bit about the skateometer because it was irrelevant -- and confusing -- as it turned out to be.

I notice he's talking about skating force.

No, he is talking about the lateral forces imposed on the stylus by an offset hole in the LP. He simply used an instrument that was intended to measure skating force to measure the 'offset hole force'. That doesn't make it skating force just because we use a skating force measurement instrument to measure a different force.

A linear arm by nature has little or no skating force due to no offset angle and overhang, unlike a conventional pivot arm. But is this the same force as horizontal effective mass? If you use your finger to push the entire arm assembly on an airbearing or linear bearing tonearm to the record center, let say the vertical force is zero, will this lateral force be "50 milligrams"?

The lateral force under discussion is not skating force and will occur for any arm type. Its magnitude is directly proportional to the horizontal effective mass of tonearm plus cartridge. The Ladegaard arm is an extreme example of high horizontal effective mass, many times that of most modern LT arms, so most LT arms will exhibit this force at a small fraction of 50 milligrams, as per the direct proportionality. Yet the designer says the force is insignificant even in the Ladegaard arm.

If you use your finger the force will be whatever force you use in your finger!

By the way, is horizontal resonance at 2-3Hz a little too low for warp records?

Not according to Ladegaard. He's the expert. My own reading is that the offset centre oscillation is at 0.55 Hz (33 rpm) to 0.75 Hz (45 rpm), so the Ladegaard arm has a margin of 3 to 5 times.

I also notice that you mention warp records. That is a vertical error and not relevant to horizontal resonance. Ladegaard's arm has 10-16 Hz vertical resonance to deal with warps.

The ability to independently tune H and V resonances is a huge advantage of the LT arm over pivot arms, which Ladegaard has gleefully taken advantage of.

I've never owned an airbearing arm but I have friends who have and they noticed the cantilever is skewed to one side after long term use.

Well, something is wrong with their implementation or application or execution of their individual tonearms. Maybe their air pressure is so low the slide drags on the rail, or so high the air exhausts asymmetrically. Or some impurity has lodged between the slide and its rail and needs to be cleaned out. Or the rail is not quite level. Or it's a diy arm and the slide is dragging on the rail due to tolerances.

But one thing it is NOT due to, is the offset centre force I discussed in my previous post, as this is sinusoidal with an average of zero, so it will never twist a stylus to one side.

And it is NOT due to the force needed to 'drag' the arm towards the spindle. In fact if we want to get technical, for an air bearing LT arm with none of the issues covered above, this force is exactly zero. Well, it would be if the groove width was constant. Variations in groove width are so small that, if you want me to work out numbers for the force generated, I will estimate right now they will be ' orders of magnitude smaller than insignificant'.

Hmm.... I wonder why the Trans-Fi arm, a descendent of the Ladegaard design, or other airbearing arms, continues to decrease the mass of its armwand....

Well, that will increase the vertical resonant frequency. Horizontal is another matter: if they want to, they can decrease arm wand weight and increase sliding carriage weight so the vertical resonant frequency is increased but not the horizontal.

Where's Mark Kelly when we need him?!

Well you've got me, so all is well. <strictly joking!!>

Is anyone starting to appreciate my suggestion that the arguments against LT arms related to high horizontal mass are a 'common misconception'?

Sorry dd, I misunderstood your 'finger' question. But I did answer it in my 'if we want to get technical' paragraph.

The air bearing arm is 'floating in space' so, like a space craft, once it is given a nudge to get started, no further force is needed if we consider the bearing to be frictionless.

The 50 milligrams force is not this force, it is the force to move the linear tracking Ladegaard arm back and forth as an offset record hole causes the vinyl groove to oscillate. Ladegaard would have measured this using a badly offset example LP, so for a good LP it might be one fifth of this, let's say 10 milligrams. And since most LT arms are about one eighth of the horizontal mass of Ladegaard's, divide 10 by 8 and whoops, we are down to 1 milligram on most records. Truly insignificant compared to the 1800 milligrams of vertical force on the stylus, and also insignificant compared to the 100-200 milligrams of uncorrectable radial skating force on all records with a pivot arm.

The air bearing arm is 'floating in space' so, like a space craft, once it is given a nudge to get started, no further force is needed if we consider the bearing to be frictionless.

The 50 milligrams force is not this force, it is the force to move the linear tracking Ladegaard arm back and forth as an offset record hole causes the vinyl groove to oscillate. Ladegaard would have measured this using a badly offset example LP, so for a good LP it might be one fifth of this, let's say 10 milligrams. And since most LT arms are about one eighth of the horizontal mass of Ladegaard's, divide 10 by 8 and whoops, we are down to 1 milligram on most records. Truly insignificant compared to the 1800 milligrams of vertical force on the stylus, and also insignificant compared to the 100-200 milligrams of uncorrectable radial skating force on all records with a pivot arm.

Hi, I think I covered this in post #509? Shure say the sound quality is less with the brush. And the lateral stylus forces in a good LT arm are insignificant.The stylus still has to get from one place to another. So I wonder why the brush is not appreciated for pitching in on that task.

I agree, but it's a different topic I suppose.It also introduces drag which should help with speed regularity on belt drive and direct drive units, no?

Besides, the lead-in groove throws the stylus/cartridge/arm toward the center so doesn't inertia take care of skating??

What skating? Are you talking about pivot arms?

I can't think of any form of inertia that would cancel out skating ---- could you explain this a different way for my slow brain please?

Burne-Jones

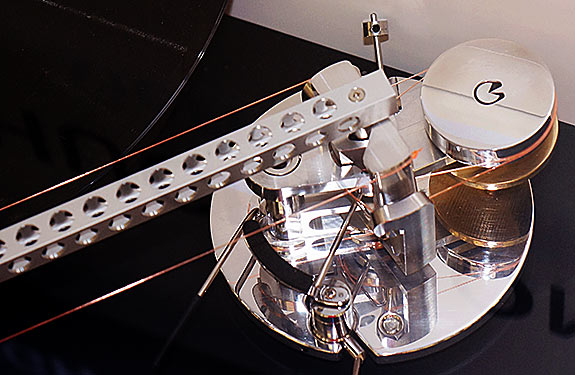

More pictures of one of the grand daddies of tangential pivot arms from this site.

I would prefer to make the vertical pivot close to the headshell area like the Dynavector split-plane design.

More pictures of one of the grand daddies of tangential pivot arms from this site.

I would prefer to make the vertical pivot close to the headshell area like the Dynavector split-plane design.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Burne-Jones

More pix.

----------------------------------------------------------------------

-------------------------------------------------------------

.

More pix.

----------------------------------------------------------------------

-------------------------------------------------------------

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

Last edited:

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms