I'm tempted to build something up with just a crank, rather than a servo, to listen and see if the effort is worth it.

plenty of us reading this thread who could volunteer... I'm still agog - look at all them moving parts. I love to see the human mind at full stretch.

Conrad Hoffman: "I've been working on my own version of a conventional pivoted arm design, but with the pivot sliding in a track to the rear. .... Commercially it's probably out of the question."

Instead of a complete arm system, I think it's commercially feasible if someone can come up with a motorized gliding armboard or armbase with sensors. Think of it as an accessory product. Imagine the Rabco arm upside down minus the pivot arm section. Just the base so the user can mount their favorite pivot arm, eg., Rega, Jelco, Graham, Triplanar, FR, etc... I even thought of reusing some part from a couple beater Rabco arms--salvaging the motor, chain pulley, sensor, etc... and add modern linear bearings to the carriage such as THK linear bearings, etc. This way, the user can use their favorite pivot arm and mount that onto this armbase and achieve tangency. Obviously they have to readjust or straighten the offset angle at the headshell on their arms.

Anyway, just a thought.

.

Conrad, I would agree with near everything you said here. As for a matter of driving the pivot assembly of the arm along the track, I believe it is not necessary applying any kind of motor of another artificial drive, because the spinning record groove itself , been driven by the TT platter, is already a perfect kind of smooth driving system, both powerful and accurate. All we need to do is to figure out and apply some kind of mechanical device (let's say, a bar with a carbon brush), which will drag the arm pivot assembly.IMHO, all mechanical nightmares that probably introduce as many problems as they cure. Here's what I've been thinking about, but have yet to build. Pivoted tone arms are highly developed and work well, but I think that offset introduces forces that cause more trouble than can be fixed with anti-skate mechanisms, not to mention the obvious problem of getting the angle right at only two points. Rotating the head of an offset arm is not the answer! You must eliminate the offset. So, keep the standard tonearm, remove the offset and make it a bit longer. Now, just drive the pivot assembly along the back of the turntable in a track. Servo it, probably photoelectrically, but don't try for perfection. Let the tonearm do what it was designed to do. Try for silence and smoothness on the drive. I'm not sure what the best drive method would be, maybe a lead screw and DC motor, maybe a thin thread and drum drive or even a linear motor track. This is basically an electronic forum, so moving the pivot under motor control shouldn't be too difficult. The angular error will be very small even if the pivot location is off a couple mm- no human can align a cartridge that close regardless of what they claim. Maybe line the track with Teflon tape and/or make it a V-way for better stability. IMHO again, any system that tries for a rigid coupling between the tone arm and track (like air bearing arms) creates a horizontal mass problem that's completely unnecessary. The arm in this design can be a unipivot or whatever you like.

Conrad

tangential pivot tonearms

As I see, there were not so few record groove driven linear arm designs, before introduction of electronically guided motor driven ones. However, it seems that purely mechanical systems were still far from optimum.

Back to semi-tangential pivot arms, they seem to be resolving the horizontal angular mistake problem. However, still having skating-antiskating forces problems, not very dissimilar from those of conventional arms. If perfect antiskating device will be applied, would it solve them? What is a main problem with creating such a device?

As I see, there were not so few record groove driven linear arm designs, before introduction of electronically guided motor driven ones. However, it seems that purely mechanical systems were still far from optimum.

Back to semi-tangential pivot arms, they seem to be resolving the horizontal angular mistake problem. However, still having skating-antiskating forces problems, not very dissimilar from those of conventional arms. If perfect antiskating device will be applied, would it solve them? What is a main problem with creating such a device?

Last edited:

Hi,

The problem with creating the "perfect" skating force compensation device is that skating force depends on a multitude of parameters(i.e. vinyl formula, modulation level, stylus profile and quality of polishing,etc...), resulting in a compensation varying from 4-18% of the VTF. ALL antiskating mechanisms are a compromise with about 8% of VTF being a reasonable compromise.

@oshifis: It is NOT correct to assume that tangential tracking omits the skating force issue. I.e. , both the Thales and the Simplicity arm do compensate for the skating force that(in both cases) is decreasing with radius, despite the tangential tracking(tracing would be the more appropriate term). Both feature an offset angled headshell, so only if the design features NO offset angle, hidden or not, will there be no skating force. Essentially all servo driven linear trackers require a deviation from tangency to trigger the correction. This deviation results in a force comparable(qualitatively, not quantitatively) to the skating force present on pivoted arms with an offset angle. Only if another arm(preceding the actual tracking arm) reading(optically or mechanically) the (non constant) pitch would "govern" the tracking arm via a servo/feed forward circuit, the issue could be avoided. But a certain amount of tracking distorsion remains unavoidable irrespective of achieving perfect tangency.

Have a fun weekend,

Frank

The problem with creating the "perfect" skating force compensation device is that skating force depends on a multitude of parameters(i.e. vinyl formula, modulation level, stylus profile and quality of polishing,etc...), resulting in a compensation varying from 4-18% of the VTF. ALL antiskating mechanisms are a compromise with about 8% of VTF being a reasonable compromise.

@oshifis: It is NOT correct to assume that tangential tracking omits the skating force issue. I.e. , both the Thales and the Simplicity arm do compensate for the skating force that(in both cases) is decreasing with radius, despite the tangential tracking(tracing would be the more appropriate term). Both feature an offset angled headshell, so only if the design features NO offset angle, hidden or not, will there be no skating force. Essentially all servo driven linear trackers require a deviation from tangency to trigger the correction. This deviation results in a force comparable(qualitatively, not quantitatively) to the skating force present on pivoted arms with an offset angle. Only if another arm(preceding the actual tracking arm) reading(optically or mechanically) the (non constant) pitch would "govern" the tracking arm via a servo/feed forward circuit, the issue could be avoided. But a certain amount of tracking distorsion remains unavoidable irrespective of achieving perfect tangency.

Have a fun weekend,

Frank

Thank you, Frank. So, simplifying a bit, in both conventional and semi-tangential arms skating force varies:

a) depending of groove-from-record-center distance stylus placement on each record,

b) it varies differently on different records, depending on the different modulations (apart for now from stylus shape and vinyl components). How much it varies on later (percentage)? Assuming we achieved a "perfect" antiskating device for one record, how accurate it would be on others?

a) depending of groove-from-record-center distance stylus placement on each record,

b) it varies differently on different records, depending on the different modulations (apart for now from stylus shape and vinyl components). How much it varies on later (percentage)? Assuming we achieved a "perfect" antiskating device for one record, how accurate it would be on others?

motorized linear tracking

I was trying to see if there's any existing product out there that is thinking along the same line. All I can think of is the Pierre Lurne designed Audiomecca SL5 tonearm. If you gut the tonearm part out and keeping just the track and gliding mechanism and the armbase, what you have is close to what you have in mind. I would like to have something like the SL5 and try it with a high quality conventional pivot arm, say, a la Clearaudio Satisfy, straighten the offset angle at the headshell and mount that on the Audiomecca and simply using it as a linear tracking base with sensor. So the end product is more like an accessory that allows mounting different arms. If we use a 12" arm the whole thing can be assembled outside of the plinth of the turntable as a tonearm island.

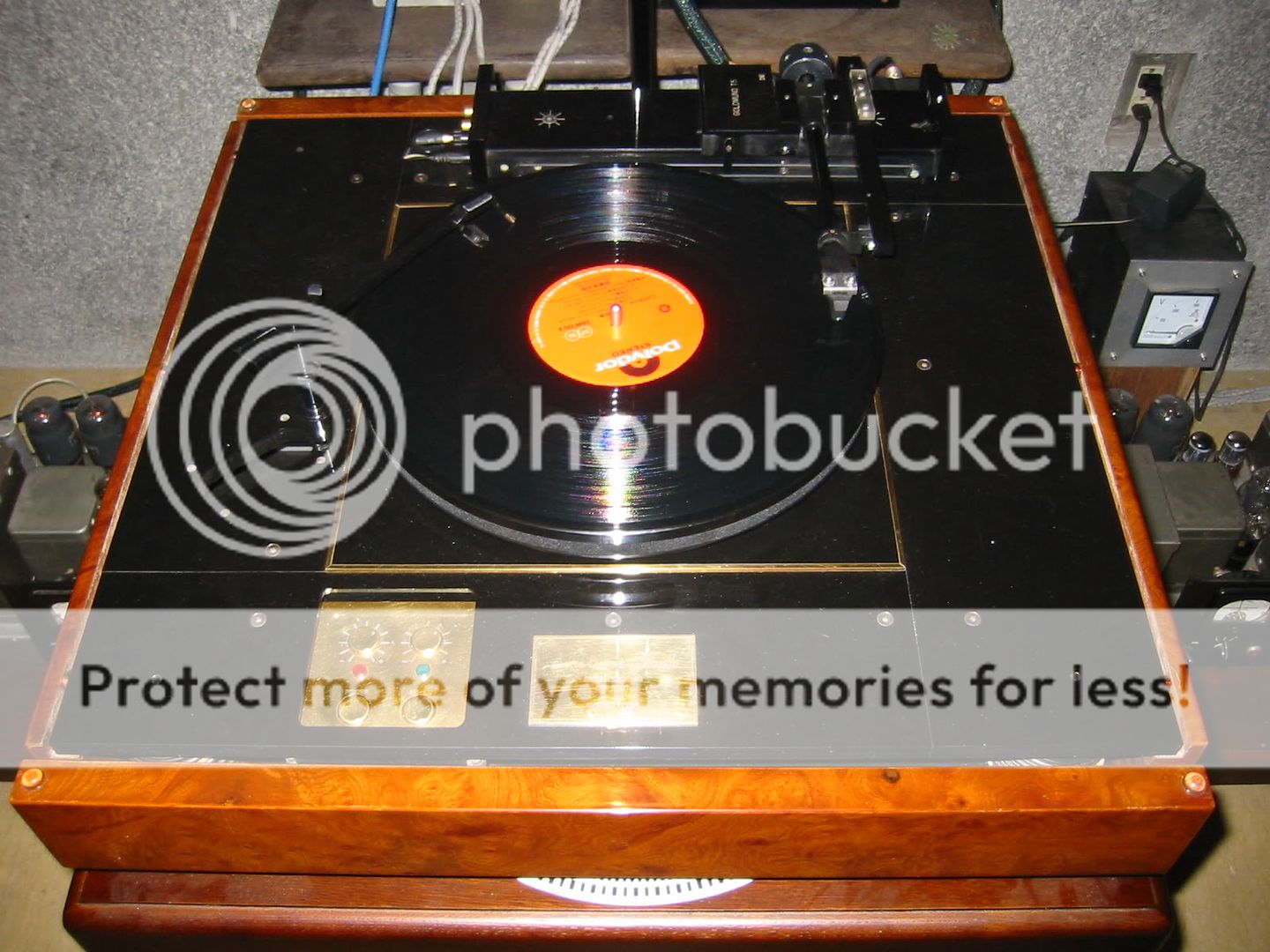

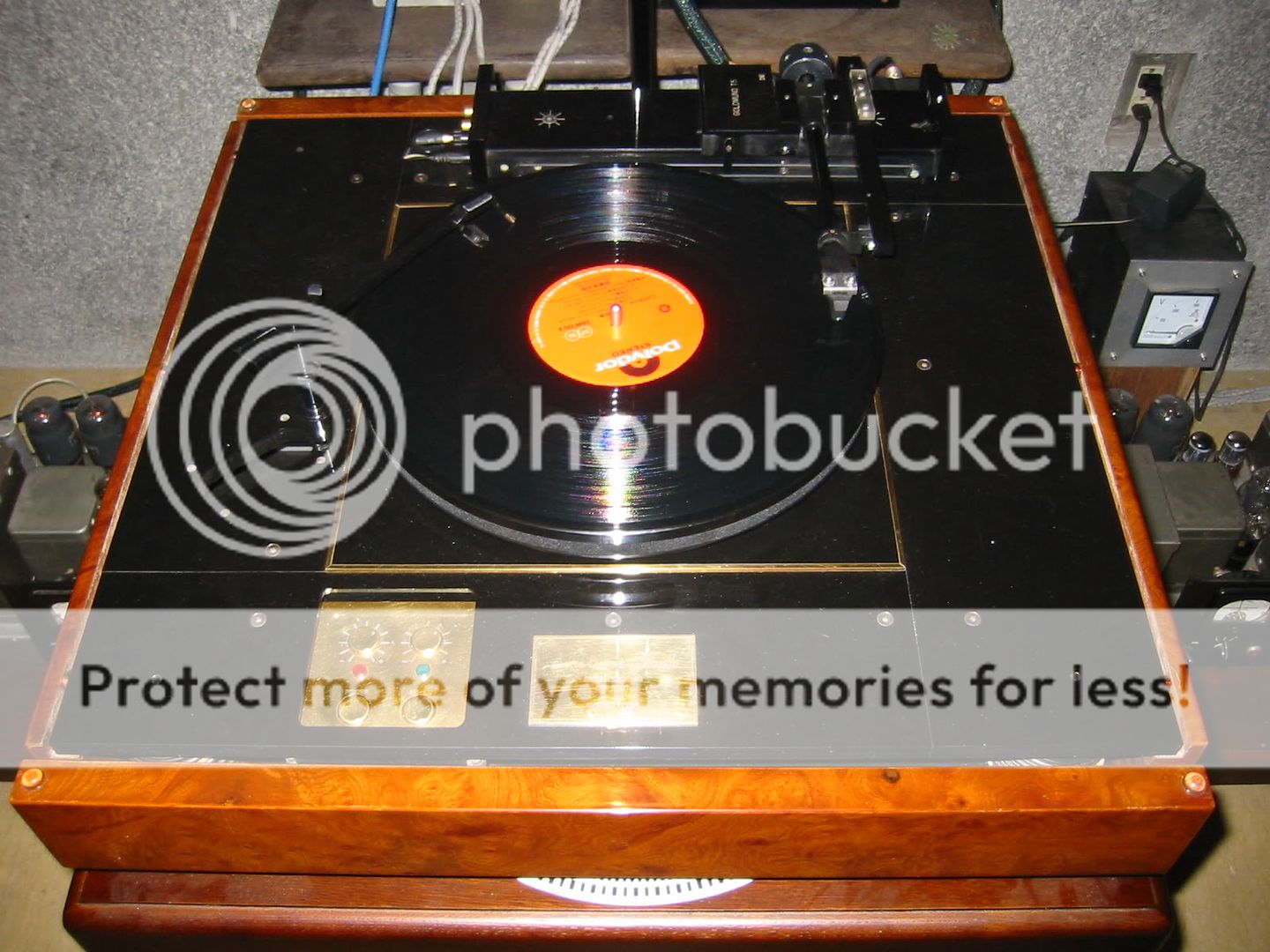

Here are some interesting pictures.

.

Conrad Hoffman: "Rotating the head of an offset arm is not the answer! You must eliminate the offset. So, keep the standard tonearm, remove the offset and make it a bit longer. Now, just drive the pivot assembly along the back of the turntable in a track. Servo it, probably photoelectrically, but don't try for perfection. Let the tonearm do what it was designed to do. Try for silence and smoothness on the drive. I'm not sure what the best drive method would be, maybe a lead screw and DC motor, maybe a thin thread and drum drive or even a linear motor track."

I was trying to see if there's any existing product out there that is thinking along the same line. All I can think of is the Pierre Lurne designed Audiomecca SL5 tonearm. If you gut the tonearm part out and keeping just the track and gliding mechanism and the armbase, what you have is close to what you have in mind. I would like to have something like the SL5 and try it with a high quality conventional pivot arm, say, a la Clearaudio Satisfy, straighten the offset angle at the headshell and mount that on the Audiomecca and simply using it as a linear tracking base with sensor. So the end product is more like an accessory that allows mounting different arms. If we use a 12" arm the whole thing can be assembled outside of the plinth of the turntable as a tonearm island.

Here are some interesting pictures.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

SL5 & T5

More pictures of the SL5 arm.

Goldmund also introduced the same arm called T5 under their name, usually mated with the Goldmund Studietto turntable.

.

More pictures of the SL5 arm.

Goldmund also introduced the same arm called T5 under their name, usually mated with the Goldmund Studietto turntable.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

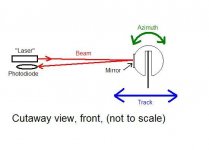

I have a similar plan as to that goldmund. It is going to be a short unipivot arm, with a mirror mounted perpendicularly over the pivot point. I will mount a laser/reciever on one end of the track, and bounce the laser off of the mirror and against a photodiode to control the speed. The speed feedback will not be on/off, but proportional to offset. This system should assure smooth travel, and perfect azimuth to boot.

Excited to see that!

Excited to see that!

Last edited:

@walterwalter: A groove modulation figure from zero to, say, 50 µ will require a change in antiskating force of about 2-4%, itself inseparable from the friction coefficient of the vinyl used for a particular record. The difference between vinyl formulas is (generally) greater than that caused by modulation variation. Since music usually changes in level all the time , the only way to create a - close to - "perfect" antiskating mechnism would be using a strain gauge cartridge and taking the net deflection of the gauges as the value on which to base the application* of a compensating force. *like the servo controlled pivoted arms of the 80s (Sony Biotracer, JVC, etc...). Except those took a preset value and tried to maintain it. Real time values can only be obtained from a strain gauge cartridge. Skating compensation is flawed in principle because all known mechanisms apply the force at the pivot point, not the stylus. Less than perfect bearings and a certain eff. mass will cause the cantilever to be deflected(unevenly loaded), throwing the mechanical symmetry of the generator(in the horizontal plane) out of balance.

@directdriver: You'd be well advised to leave the original armwand/bearing assemblies on the Lurne/Goldmund arms. They are vastly better(less resonant) than the Clearaudio Satisfy.

I've played for years with the idea of providing a base to convert pivoted arms to linear trackers. The fact alone that most pivoted arms are not surface mount designs and the difficulty altering the headshells or being able to lower the arms sufficiently kept me from doing it. Nor did I like most of the conventional arms sonically... would you put a bigger engine in a car that had a weak frame from the start? And the added complexity has its price(literally).

Anyway, Ralfs arm is, for the most part, the only design that tries to address nearly every geometrical issue related to tracing a record(conceptually superior to all commercial arms that travel on a line parallel to a radial line). Now Ralf, if you would only loose those carbon fiber tubes ;-)

Good night,

Frank

@directdriver: You'd be well advised to leave the original armwand/bearing assemblies on the Lurne/Goldmund arms. They are vastly better(less resonant) than the Clearaudio Satisfy.

I've played for years with the idea of providing a base to convert pivoted arms to linear trackers. The fact alone that most pivoted arms are not surface mount designs and the difficulty altering the headshells or being able to lower the arms sufficiently kept me from doing it. Nor did I like most of the conventional arms sonically... would you put a bigger engine in a car that had a weak frame from the start? And the added complexity has its price(literally).

Anyway, Ralfs arm is, for the most part, the only design that tries to address nearly every geometrical issue related to tracing a record(conceptually superior to all commercial arms that travel on a line parallel to a radial line). Now Ralf, if you would only loose those carbon fiber tubes ;-)

Good night,

Frank

Berlinta,

So long as you set up the laser/reciever such that the headshell is level, any later change in azimuth should cause the laser to no longer fall on the reciever properly. It would be obvious then that something was amiss.

I would mount the laser/reciever as far away from the tonearm as possible. If you mount it a foot away, that is two feet of beam path. This could be much more sensitive to a change in angle than any of the other designs I have seen.

Thoughts?

So long as you set up the laser/reciever such that the headshell is level, any later change in azimuth should cause the laser to no longer fall on the reciever properly. It would be obvious then that something was amiss.

I would mount the laser/reciever as far away from the tonearm as possible. If you mount it a foot away, that is two feet of beam path. This could be much more sensitive to a change in angle than any of the other designs I have seen.

Thoughts?

Attachments

Yes! That SL-5 is exactly on the lines of what I've been thinking about- thanks, never seen it before. No doubt, it too is far beyond my means.

As for laser and other position feedback, if you do the design right the sensitivity will be so high that there's no need for any extra beam path. The problem I worry about is manual cueing. I want to be able to grab the headshell and cue with the action no different from any manual arm.

Oshifis, I don't believe this is correct unless you mean the entire arm is tangential, and that traditionally wouldn't be pivoted. Unless you remove the offset, placing the pivot directly in line with the stylus, all the anti-skate issues remain. Think of any standard pivoted arm where you adjust the cartridge for perfect alignment at some arbitrary point on the record. That's no different than what most of these parallelogram arms do. They still have offset.

Berlinta, maybe without the offset you'd find the character of the arms changed significantly. IMO, that's the big question that only building the thing can answer!

As for laser and other position feedback, if you do the design right the sensitivity will be so high that there's no need for any extra beam path. The problem I worry about is manual cueing. I want to be able to grab the headshell and cue with the action no different from any manual arm.

? Tangential (be it pivoted or not) arms have no skating problem by definition.

Oshifis, I don't believe this is correct unless you mean the entire arm is tangential, and that traditionally wouldn't be pivoted. Unless you remove the offset, placing the pivot directly in line with the stylus, all the anti-skate issues remain. Think of any standard pivoted arm where you adjust the cartridge for perfect alignment at some arbitrary point on the record. That's no different than what most of these parallelogram arms do. They still have offset.

Nor did I like most of the conventional arms sonically...

Berlinta, maybe without the offset you'd find the character of the arms changed significantly. IMO, that's the big question that only building the thing can answer!

berlinta: "You'd be well advised to leave the original armwand/bearing assemblies on the Lurne/Goldmund arms. They are vastly better(less resonant) than the Clearaudio Satisfy."

Frank, I do not own the Lurne tonearm and I was NOT encouraging people to butcher an existing product. I was only suggesting if one builds a similar gliding arm-base along the line of the Lurne and Conrad Hoffman's idea, one can mount a conventional arm on it and the reason I suggested the Clearaudio Satisfy because it uses a rotatable headshell (Schroeder clone??) that can straighten the offset angle and its vertical bearings are not angled +-23° like many pivot arms and it's also not terribly expensive so DIYers can afford. I supposed one can also use a Rega or straight tube Jelco or any other budget arm for experiment. Mr. Lurne is a talented designer and I would not want to alter or butcher his product. Again, the suggestion was for a diy project only not existing product.

berlinta: "I've played for years with the idea of providing a base to convert pivoted arms to linear trackers. The fact alone that most pivoted arms are not surface mount designs and the difficulty altering the headshells or being able to lower the arms sufficiently kept me from doing it."

I understand the difficulties. With the proliferation of thick tall platters, it is possible to have enough height to mount a conventional pivot arm on the base without lowering the platform. If a plinth is not too big or wide, it is possible to mount the base on an arm-pod with an elongated hole for the mounting hardware to drop through so arms do not have to be surface mount design -- imagine a carriage or wagon on two rods with a wide hole in the middle. More and more arms are using headshell of your design, the Schroeder style headshell, so altering the headshell is not that hard, if we choose the arm wisely. Bottom line: it is totally doable. And I would love to hear the difference between a pivot arm in a conventional set up and in a "linear mode" set up.

Thanks for all the ideas and suggestions, Frank!

.

Conrad Hoffman: "The problem I worry about is manual cueing. I want to be able to grab the headshell and cue with the action no different from any manual arm."

I think if we implement the sensor mechanism closer to the pivot area (like the Rabco) or at the back close to the counterweight, it would not affect cueing like the sensor at the headshell area or at least not as awkward.

Anyway, your idea is totally doable!

.

Berlinta: " Skating compensation is flawed in principle because all known mechanisms apply the force at the pivot point, not the stylus. Less than perfect bearings and a certain eff. mass will cause the cantilever to be deflected(unevenly loaded), throwing the mechanical symmetry of the generator(in the horizontal plane) out of balance".

To Berlinta, one more question, trusting your experience. I already figured out technical solution for close to "ideal " antiskating compensator for one record(or, let's assume, it's statistical approximation). Keeping in mind all inherited problems you mention, would those irregularities on different records be still audible (if I'll succeed with this design and apply it)?

Or it is better get rid of skating problem at all and move to purely tangential design (I've already figured out that one too)? Been mechanically inclined, rather than electronically, I've chosen mechanical tracking and dragging principle.

However, for DIY-ers here, those who thinks of electronically guided one, I would suggest to consider CD-LD-DVD tracking solutions, those there seems to be using constant and smooth transition of laser pick up head, instead of sporadic movement with most of tangential tone arms...

To Berlinta, one more question, trusting your experience. I already figured out technical solution for close to "ideal " antiskating compensator for one record(or, let's assume, it's statistical approximation). Keeping in mind all inherited problems you mention, would those irregularities on different records be still audible (if I'll succeed with this design and apply it)?

Or it is better get rid of skating problem at all and move to purely tangential design (I've already figured out that one too)? Been mechanically inclined, rather than electronically, I've chosen mechanical tracking and dragging principle.

However, for DIY-ers here, those who thinks of electronically guided one, I would suggest to consider CD-LD-DVD tracking solutions, those there seems to be using constant and smooth transition of laser pick up head, instead of sporadic movement with most of tangential tone arms...

Last edited:

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms