Last edited:

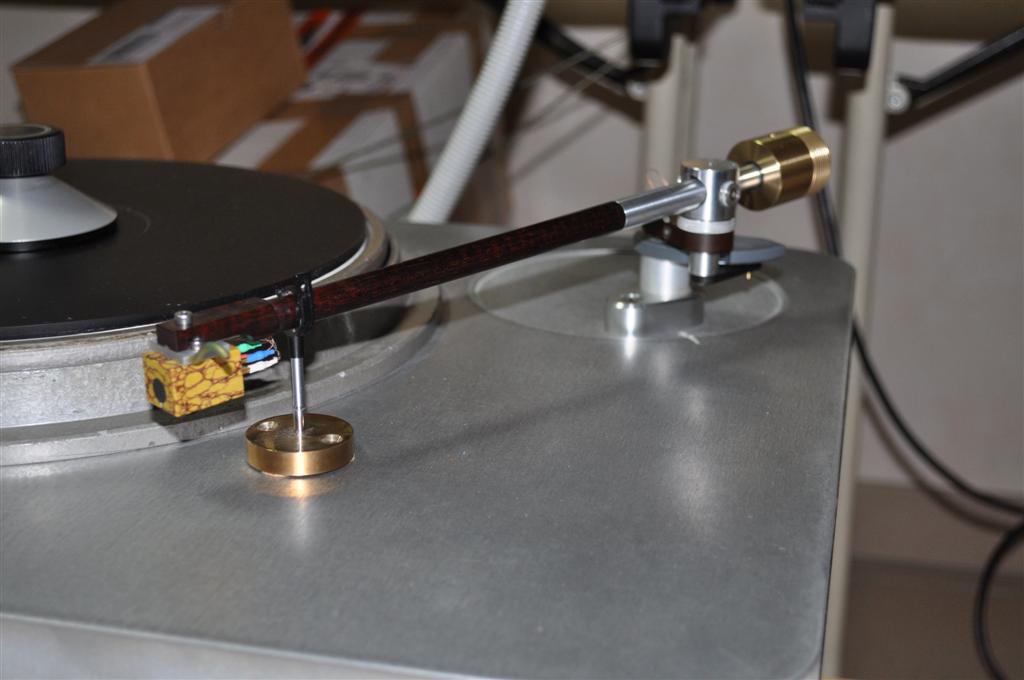

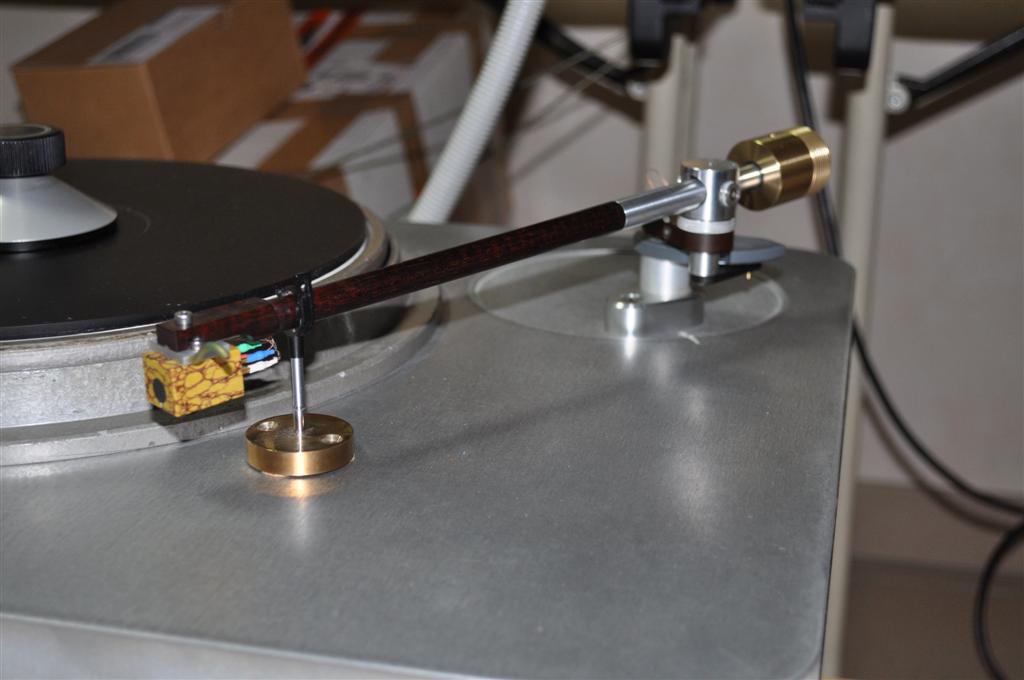

More images of the Schroder LT arm from European Triode Festival 2011 and I believe Frank's system with the LT arm won the turntable shootout.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

how it will behave on the records with substantial eccentricity.

I don't see eccentric records being an issue for this arm. It would behave just like any other pivot arm. As long as the guiding mechanism is low friction and geometrically precise, I believe it will work just fine. I'm just curious about how the "magnet guide rail system" works. All will be revealed when we get to see what's underneath the pivot... I'm surprised this arm is still under the radar and hasn't been discussed in more mainstream press. I want to see more of this type of products, since the advent of the Thales arm.

WARNING Going up to the homepage on the link in (post 225, iirc) http://www.diyaudio.com/forums/anal...-tangential-pivot-tonearms-5.html#post2783869 AVG identifies a virus associated with that page, not the linked page. That link is this one: Platine bras radial

_-_-bear

_-_-bear

False positive, source and image verified and i'm sure. It is absolutely clean.WARNING Going up to the homepage on the link in (post 225, iirc) http://www.diyaudio.com/forums/anal...-tangential-pivot-tonearms-5.html#post2783869 AVG identifies a virus associated with that page, not the linked page. That link is this one: Platine bras radial

_-_-bear

AVG makes often this kind of mistakes with images, which can are often contain funny patterns.

But, for now, one of the other links seems broken. And we cannot edit posts after a while, here ;-(

when do we get to see underneath? Is this beauty non-active, meaning non- powered (don't want to say passive)?

What is underneath is purely mechanical. Yes, this is a passive device. Non-active, no motor or sensor system. That brown cantilevered plate is holding the main arm for only horizontal movement. But to keep the arm tangent something has to guiding the behavior of its pivot and all that mechanism is hidden underneath that gray plate. Said to be magnetically coupled and tunable in the guiding mechanism. When do we get to see underneath? Good question. It's still not commercially ready yet so my guess is Frank will release it when the patent gets approved. Maybe sometime next year? I have no idea and cannot speak for Frank but I sure look forward to seeing more of it and having Frank discuss more about it. It's a very elegant design. I hope see more products like this--that is, addressing tangency without resorting to air-bearing or motor--in the future.

.

a little over the top...

guys, I haven't been on this thread for sometime, but isn't this all getting overly complicated? The only requirement is that the stylus stays perpendicular (as in tangent) to the record groove. That's it.

The only question that remains is what's the most effective way to accomplish this in a purely passive system? RS Labs uses a headshell that passively pivots. The old Garrard "Zero" arm uses a linkage and a rotating headshell. Schroeder rotates the complete mount. The Thales tonearms (either the original or the Simplicity) uses a passive linkage and a rotating headshell.

If the friction can be reduced to being insignificant when compared to the tonearm pivot, a passive pivoting headshell can work. I'm just not sure if that is reality. That leaves either Mr. Schroeder's solution or the Thales/Garrard solution (which pretty much amounts to the same thing).

Anytime an engineered solution gets complicated, the solution may bring other issues into play. Simplicity itself should be the goal. Mr. Schroeder's solution may be very effective, but can a mount that rotates really be any better than a headshell that does the same thing? If a tangential arm with effectively zero error is wanted, then a passive linear tracker may be the only "true" solution (like the Souther and the Rauna Cantus).

guys, I haven't been on this thread for sometime, but isn't this all getting overly complicated? The only requirement is that the stylus stays perpendicular (as in tangent) to the record groove. That's it.

The only question that remains is what's the most effective way to accomplish this in a purely passive system? RS Labs uses a headshell that passively pivots. The old Garrard "Zero" arm uses a linkage and a rotating headshell. Schroeder rotates the complete mount. The Thales tonearms (either the original or the Simplicity) uses a passive linkage and a rotating headshell.

If the friction can be reduced to being insignificant when compared to the tonearm pivot, a passive pivoting headshell can work. I'm just not sure if that is reality. That leaves either Mr. Schroeder's solution or the Thales/Garrard solution (which pretty much amounts to the same thing).

Anytime an engineered solution gets complicated, the solution may bring other issues into play. Simplicity itself should be the goal. Mr. Schroeder's solution may be very effective, but can a mount that rotates really be any better than a headshell that does the same thing? If a tangential arm with effectively zero error is wanted, then a passive linear tracker may be the only "true" solution (like the Souther and the Rauna Cantus).

Hi Nanook,

Sorry to interfere, but my new arm is different in several ways to either the RS Labs arm, which, by no means, is a tangentially tracking arm(a common misunderstanding, often repeated on the net for a lack of understanding the idea behind it), or the Garrard, BJ, Van Eps, Simplicity or Thales arms, which ALL feature an offset angle, thereby requiring a form of skating force compensation(most elegantly realized in the Simplicity arm).

Skating force/skating compensation = varying preload on the cantilever.

On my new arm, 1,5 milligrams(possibly near zero in the production version) will deflect the arm vertically, 5mg or less horizontally(preloaded bearings, no slack)

When properly mounted, there is no skating force to be measured.

All passive linear trackers require a certain amount of force to "move" the carriage. The resulting deflection of the cantilever is often larger than the tracing error in properly set up pivoted arms. It gets worse when excentric records force the cartridge to "yank" the entire horizontal eff. mass back and forth.

I do not mean to bash existing solutions(I really like the Simplicity and the Cantus arms), but some have obvious drawbacks and some have drawbacks easily overlooked. They can still sound better than existing pivoted arms, it's just that there is more to the sonic performance of a tone arm than the tracing error(or lack thereof).

Happy holidays to all!

Frank

Sorry to interfere, but my new arm is different in several ways to either the RS Labs arm, which, by no means, is a tangentially tracking arm(a common misunderstanding, often repeated on the net for a lack of understanding the idea behind it), or the Garrard, BJ, Van Eps, Simplicity or Thales arms, which ALL feature an offset angle, thereby requiring a form of skating force compensation(most elegantly realized in the Simplicity arm).

Skating force/skating compensation = varying preload on the cantilever.

On my new arm, 1,5 milligrams(possibly near zero in the production version) will deflect the arm vertically, 5mg or less horizontally(preloaded bearings, no slack)

When properly mounted, there is no skating force to be measured.

All passive linear trackers require a certain amount of force to "move" the carriage. The resulting deflection of the cantilever is often larger than the tracing error in properly set up pivoted arms. It gets worse when excentric records force the cartridge to "yank" the entire horizontal eff. mass back and forth.

I do not mean to bash existing solutions(I really like the Simplicity and the Cantus arms), but some have obvious drawbacks and some have drawbacks easily overlooked. They can still sound better than existing pivoted arms, it's just that there is more to the sonic performance of a tone arm than the tracing error(or lack thereof).

Happy holidays to all!

Frank

Yes, And very expensive mechanic parts to reduce the frictional forces. When a motor and little electronic can do the job 10 times better. and very cheap.All passive linear trackers require a certain amount of force to "move" the carriage

Why to bother with complicated and expensive esoteric arms when you can find fantastic industrial linear tracking turntables (like Technics) for few bucks on the second-hand market.

Anyway, even CDs are dead, what about vinyl ?

I can understand one sell a purely optical cartridge for those who need to make professional restoration of old records, but an innovating arms to read 78rpms for end users ?

This thread is interesting on a intellectual point of view, it is a museum, and i believe nothing ( new ) will appear by a dark night, who care about "performance" ?

Last edited:

Hello Christophe,

You'd be surprised to find a lot of people caring about performance. I do own both Technics SL10(incl. the very good 310MC cartridge) and SL7. Neither sounds nearly as good as the best turntables in my collection, regardless of the arm being a linear tracker or a conventional pivoted arm. If the sound of an SL10 makes you happy, that's great for you, other might have higher aspirations.

I've also tested the ELP laser turntable extensively, sonically it's mediocre at best.

CDs may be dead soon, but LPs are not. Sales for new vinyl in Germany alone have tripled compared to last year. The statistics do not even take smaller and independent labels into account. Sales of used vinyl are HUGE, at least in my neighborhood...

The Rauna Table incl. arm was no more expensive than an SL10 when new, but the "complicated" (it really isn't)mechanism sure beats the SL10 sonically. And what do you do when the electronics in your 25year old "industrial linear tracking turntable" fail? Mmmhh...

I for one study the past to learn for the future, in other words, without museums we'd have no measure how far we've come.

Joyeux Noël!

Frank

You'd be surprised to find a lot of people caring about performance. I do own both Technics SL10(incl. the very good 310MC cartridge) and SL7. Neither sounds nearly as good as the best turntables in my collection, regardless of the arm being a linear tracker or a conventional pivoted arm. If the sound of an SL10 makes you happy, that's great for you, other might have higher aspirations.

I've also tested the ELP laser turntable extensively, sonically it's mediocre at best.

CDs may be dead soon, but LPs are not. Sales for new vinyl in Germany alone have tripled compared to last year. The statistics do not even take smaller and independent labels into account. Sales of used vinyl are HUGE, at least in my neighborhood...

The Rauna Table incl. arm was no more expensive than an SL10 when new, but the "complicated" (it really isn't)mechanism sure beats the SL10 sonically. And what do you do when the electronics in your 25year old "industrial linear tracking turntable" fail? Mmmhh...

I for one study the past to learn for the future, in other words, without museums we'd have no measure how far we've come.

Joyeux Noël!

Frank

This is due to the resonance of the plate.Just try a heavy (silicon ?) dumping plate's cover ?Neither sounds nearly as good as the best turntables in my collection,

You can too add a magnet system to improve the pressure of the counter plate rotating piece too. And isolate better the arm from the plastic cover's resonances. Very easy, in fact.

I know there is nostalgia about Vinyls. It is "fashionable". As an old record sound engineer, i know how far is a analog record from the original magnetic track, and as near digital is.

Without direct comparison, one can prefer the sound of the distorted media.

On my side, i'm not very interested about "how good" sound a system, only as "transparent" it is.

Yes vinyl add some magic, digs holes for imagination.

Adds.and removals.

All those amazing arms are very good looking, it helps imagination too ;-)

Merry Christmas to you too.

Last edited:

Hello Christophe,

I'm well aware of ways to keep any type of resonance, structural or fundamental under control(but thanks for the tips).

I also happen to own master tapes, laquers and white pressings of the same titles, so while I may fool myself, at least I have the foundation for reasonably accurate assessments of transparency which, off course, is what I meant by writing about "how good" a system or a turntable sounds. Let not fight over semantics unless you really thought I was into some kind of euphonic, K2 heavy "sound".

Is it asking too much to reveal who you recorded and for which labels you worked?

Maybe you never had an opportunity to listen to a turntable that got very close to a master tape played back on the same maschine it was recorded on. Or do you just believe in the superiority of digital playback?

Cheers,

Frank

I'm well aware of ways to keep any type of resonance, structural or fundamental under control(but thanks for the tips).

I also happen to own master tapes, laquers and white pressings of the same titles, so while I may fool myself, at least I have the foundation for reasonably accurate assessments of transparency which, off course, is what I meant by writing about "how good" a system or a turntable sounds. Let not fight over semantics unless you really thought I was into some kind of euphonic, K2 heavy "sound".

Is it asking too much to reveal who you recorded and for which labels you worked?

Maybe you never had an opportunity to listen to a turntable that got very close to a master tape played back on the same maschine it was recorded on. Or do you just believe in the superiority of digital playback?

Cheers,

Frank

So, i believe we are on the same wave lengh.Hi berlinta,

Sorry, i do not want to talk too much about my career here, as i post under a pseudo and do not want it can be correlated with my real name.

As a free lance, i had worked, since 1970, for almost all major records companies, all over the world, RCA, EMI, Philips, in France, US, England (and 2 times in Germany ;-).

Of course, i had listened quite all my master tapes and compared with grooved samples during so many mastering/cutting sessions. On the grooving machine itself, most of the time (Pretty good turn tables ;-).

It is a part of the job. And, of course, carefully analyzed the vinyls themselves, at home, in the studios, in the producer's offices or record companies offices and listening rooms

Always disappointed, (specially about dynamic and transients) until CD appears, it is true.

Mr. Schroeder, this is not interference.

Firstly, how can I think that your comments would be interference at any level? Any insight that you pass along is highly valued.

And I am willing to accept that I am far from "expert", however I do have some experience and knowledge regarding LP systems and tonearm geometries and construction. My "219" tonearm is an example: essentially an Altmann "joke" arm that I improved using much better materials and bearing. It easily gives my SME 309 (magnesium version) a run for the money. The existence of an offset angle can help the tracking at the initial point of an LP. This can be as seemingly little as providing a spot that is convenient where tracking error can be as close to "zero" as an initial state while keeping the length of a tonearm some reasonable length, as long as one looks at the stylus tip as the endpoint of the tonearm/cartridge system. This assumes that there is no error in azimuth.

As far as I understand things, using your system, as the LP rotates, the base location also moves in an appropriate arc and the initial state should stay intact: if the cartridge/headshell was tangent to the record groove at any given point it should remain (essentially) the same. If one were to provide an arc for the pivot point of the tonearm to travel (that has exactly the same as the arc the tonearm would travel if not pivoting), then a "perfect" path could occur. The key is that whatever the orientation of the headshell/stylus tip at the initial state was, it should remain in that state. This could be accomplished by allowing only vertical travel of the arm, while the base provides the rotation. A very minute amount of lateral force would be applied to the stylus, but it could be countered by a constant force in the opposite direction. Not an anti-skating force so much as a force to pull the stylus tip into the center of the groove and leave it there. Once determined, a static weight would be appropriate, as the amount required would remain constant

Obviously if a very high precision optical sensor, and control electronics can be implemented, then the use of a totally passive system may be moot. Perhaps I shouldn't have cut up an old Sony SL7.

These are just a few thoughts, and perhaps I am completely out of touch with the realities of this type of system, in which case I'll nod off back to sleep

Hi Nanook,

Sorry to interfere, but my new arm is different in several ways to either the RS Labs arm, which, by no means, is a tangentially tracking arm(a common misunderstanding, often repeated on the net for a lack of understanding the idea behind it), or the Garrard, BJ, Van Eps, Simplicity or Thales arms, which ALL feature an offset angle, thereby requiring a form of skating force compensation(most elegantly realized in the Simplicity arm).

Skating force/skating compensation = varying preload on the cantilever.

On my new arm, 1,5 milligrams(possibly near zero in the production version) will deflect the arm vertically, 5mg or less horizontally(preloaded bearings, no slack)

When properly mounted, there is no skating force to be measured.

All passive linear trackers require a certain amount of force to "move" the carriage. The resulting deflection of the cantilever is often larger than the tracing error in properly set up pivoted arms. It gets worse when excentric records force the cartridge to "yank" the entire horizontal eff. mass back and forth.

I do not mean to bash existing solutions(I really like the Simplicity and the Cantus arms), but some have obvious drawbacks and some have drawbacks easily overlooked. They can still sound better than existing pivoted arms, it's just that there is more to the sonic performance of a tone arm than the tracing error(or lack thereof).

Happy holidays to all!

Frank

Firstly, how can I think that your comments would be interference at any level? Any insight that you pass along is highly valued.

And I am willing to accept that I am far from "expert", however I do have some experience and knowledge regarding LP systems and tonearm geometries and construction. My "219" tonearm is an example: essentially an Altmann "joke" arm that I improved using much better materials and bearing. It easily gives my SME 309 (magnesium version) a run for the money. The existence of an offset angle can help the tracking at the initial point of an LP. This can be as seemingly little as providing a spot that is convenient where tracking error can be as close to "zero" as an initial state while keeping the length of a tonearm some reasonable length, as long as one looks at the stylus tip as the endpoint of the tonearm/cartridge system. This assumes that there is no error in azimuth.

As far as I understand things, using your system, as the LP rotates, the base location also moves in an appropriate arc and the initial state should stay intact: if the cartridge/headshell was tangent to the record groove at any given point it should remain (essentially) the same. If one were to provide an arc for the pivot point of the tonearm to travel (that has exactly the same as the arc the tonearm would travel if not pivoting), then a "perfect" path could occur. The key is that whatever the orientation of the headshell/stylus tip at the initial state was, it should remain in that state. This could be accomplished by allowing only vertical travel of the arm, while the base provides the rotation. A very minute amount of lateral force would be applied to the stylus, but it could be countered by a constant force in the opposite direction. Not an anti-skating force so much as a force to pull the stylus tip into the center of the groove and leave it there. Once determined, a static weight would be appropriate, as the amount required would remain constant

Obviously if a very high precision optical sensor, and control electronics can be implemented, then the use of a totally passive system may be moot. Perhaps I shouldn't have cut up an old Sony SL7.

These are just a few thoughts, and perhaps I am completely out of touch with the realities of this type of system, in which case I'll nod off back to sleep

Thanks for your reply Christophe. I don't want to take this thread away from the topic, you answered my questions quite genereously.

We may not be on the same wavelength, but at least it's not a question of AM vs. FM

BUT, while I've heard plenty of fantastic digital masters, I've yet to hear a truly satisfactory CD.

All cutting lathes I've inspected had arms(if any) ranging from SME 3012 and Ortofon RMG309s to Neumann arms. Quite good, not exceptional. The cartridges were the weakest link: Stantons, Pickerings, Ortofon SPUs at best(nice "sound" ;-). Good for a quick check, but again, a Lyrec or Technics SL10MkIII motor doesn't turn a Stanton into a transparent cartridge.

Despite all of that, I understand your position much better now.

Good night,

Frank

We may not be on the same wavelength, but at least it's not a question of AM vs. FM

BUT, while I've heard plenty of fantastic digital masters, I've yet to hear a truly satisfactory CD.

All cutting lathes I've inspected had arms(if any) ranging from SME 3012 and Ortofon RMG309s to Neumann arms. Quite good, not exceptional. The cartridges were the weakest link: Stantons, Pickerings, Ortofon SPUs at best(nice "sound" ;-). Good for a quick check, but again, a Lyrec or Technics SL10MkIII motor doesn't turn a Stanton into a transparent cartridge.

Despite all of that, I understand your position much better now.

Good night,

Frank

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms