Just for fun. NOT TO BE TAKEN SERIOUSLY!

The groove of the record is not perfectly tangential due to it being a spiral. As it is a constant pitch spiral the angle of the groove relative to the tangent will increase towards the end of the record. The angle can be determined using ;

Φ =atan(p/2πr)

Where p is groove pitch and r is groove radius.

The groove will vary from tangential from the outer to inner groove from 0.0063° to 0.0147° assuming a pitch of 100um.

This is meaningless. Although the groove might not be perfectly tangential the motion of the cutting head is perfectly radial (at 90° to the tangent) so the information stored in the groove is still tangential even if the groove isn't.

Even if this wasn't the case 0.0147° is going to be smaller than the manufacturing tolerance of even the best cartridges and massively smaller than can be achieved in manual cartridge alignment.

Furthermore an eccentricity of only 0.02mm would result in the same average groove angle relative to the tangent.

The angle of the groove due to it being a spiral really doesn't have any effect.

Niffy

The groove of the record is not perfectly tangential due to it being a spiral. As it is a constant pitch spiral the angle of the groove relative to the tangent will increase towards the end of the record. The angle can be determined using ;

Φ =atan(p/2πr)

Where p is groove pitch and r is groove radius.

The groove will vary from tangential from the outer to inner groove from 0.0063° to 0.0147° assuming a pitch of 100um.

This is meaningless. Although the groove might not be perfectly tangential the motion of the cutting head is perfectly radial (at 90° to the tangent) so the information stored in the groove is still tangential even if the groove isn't.

Even if this wasn't the case 0.0147° is going to be smaller than the manufacturing tolerance of even the best cartridges and massively smaller than can be achieved in manual cartridge alignment.

Furthermore an eccentricity of only 0.02mm would result in the same average groove angle relative to the tangent.

The angle of the groove due to it being a spiral really doesn't have any effect.

Niffy

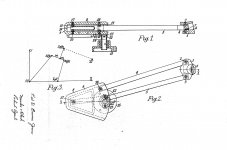

The klaudio design probably has the lowest offset of any pivoted arm. Ranging from about -7° via 0° to +7° across the playing area of the record. This will result in an average of only a couple of degrees, much lower than the 20+° of most arms. This will massively reduce skating force and the requirements of a bias mechanism. It could explain why I can't see an anti-skate mechanism on this arm. The resulting skating force is too small to be worried about compared to the complexity of the required bias mechanism.

Niffy

Not sure where you get the +/- 7 degrees from. If you put a ruler on your screen while viewing these video clips, it is hard to see any deviation from zero tracking error.

YouTube

YouTube

I see no reason why the mechanism should not be able to achieve true zero tracking error across the record. Offset angle in the context of overhang and [skating] force plays by different rules with a klaudio because the stylus friction force is acting upon multiple moving pivots. Are you are thinking of offset here as in terms of multi-link arms such as Burne-Jones or Van-Epps?

The B-J arm would be expected to [skate] towards a middle, neutral position.

This being so, it is nonetheless puzzling why klaudio offer the arm in 10 inch and 12 inch versions if both achieve the same result. Is the skating devil lurking here? Let's see, where's my string...

Ray K

Attachments

Hi Ray,

My calculations were based on memory and I had thought the klaudio was 14" and not 10" or 12". The +/-7° was based on this error. The 7° was the maximum offset angle not the lateral tracking error. Due to the arm being shorter than I thought the maximum offset will be slightly higher. The tracking error is as close to zero with this arm as makes no odds.

The longer version of the arm will have lower average offset and thus lower skating force. The reason for the longer arm might simply be that a lot of people who are after lower tracking errors already have 12" arms so the 12" version will mount on their deck with minimal modification.

Niffy

My calculations were based on memory and I had thought the klaudio was 14" and not 10" or 12". The +/-7° was based on this error. The 7° was the maximum offset angle not the lateral tracking error. Due to the arm being shorter than I thought the maximum offset will be slightly higher. The tracking error is as close to zero with this arm as makes no odds.

The longer version of the arm will have lower average offset and thus lower skating force. The reason for the longer arm might simply be that a lot of people who are after lower tracking errors already have 12" arms so the 12" version will mount on their deck with minimal modification.

Niffy

The groove of the record is not perfectly tangential due to it being a spiral. As it is a constant pitch spiral the angle of the groove relative to the tangent will increase towards the end of the record. The angle can be determined using ;

Φ =atan(p/2πr)

Where p is groove pitch and r is groove radius.

The groove will vary from tangential from the outer to inner groove from 0.0063° to 0.0147° assuming a pitch of 100um.

This is meaningless. Although the groove might not be perfectly tangential the motion of the cutting head is perfectly radial (at 90° to the tangent) so the information stored in the groove is still tangential even if the groove isn't.

Even if this wasn't the case 0.0147° is going to be smaller than the manufacturing tolerance of even the best cartridges and massively smaller than can be achieved in manual cartridge alignment.

Furthermore an eccentricity of only 0.02mm would result in the same average groove angle relative to the tangent.

The angle of the groove due to it being a spiral really doesn't have any effect.

Niffy

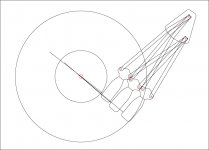

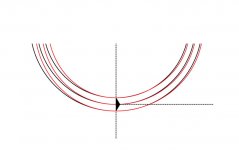

Agree. Here is a diagram to illustrate what I was thinking about. Black lines are parts of cycle and red lines are parts of spiral. Black triangle is a cutting head.

Attachments

two arm lengths

On page 4 of the manual, it states the mounting distances for the 10" and 12" arms are 250mm and 298mm.

I believe the motive behind the two lengths is a commercial one. Notice the mounting base is similar to SME style and the arm uses a detachable headshell. Klaudio is based in Korea and it is very common to target the Asian market of vintage audio - something I'm quite familiar with - that covets Ortofon SPU cartridges or other cartridges from the vintage land and many SPU users have classic arms like SME 3010 & 3012, various Ortofon and EMT 10" and 12" arms. A lot of the demo videos by Klaudio use the SPU. They just created a linear arm that's user friendly or drop-in replacement for the vintage market for turntable with existing mounting holes. Essentially I agree with Niffy about their two options.

it is nonetheless puzzling why klaudio offer the arm in 10 inch and 12 inch versions if both achieve the same result.

My calculations were based on memory and I had thought the klaudio was 14" and not 10" or 12".

The reason for the longer arm might simply be that a lot of people who are after lower tracking errors already have 12" arms so the 12" version will mount on their deck with minimal modification.

On page 4 of the manual, it states the mounting distances for the 10" and 12" arms are 250mm and 298mm.

I believe the motive behind the two lengths is a commercial one. Notice the mounting base is similar to SME style and the arm uses a detachable headshell. Klaudio is based in Korea and it is very common to target the Asian market of vintage audio - something I'm quite familiar with - that covets Ortofon SPU cartridges or other cartridges from the vintage land and many SPU users have classic arms like SME 3010 & 3012, various Ortofon and EMT 10" and 12" arms. A lot of the demo videos by Klaudio use the SPU. They just created a linear arm that's user friendly or drop-in replacement for the vintage market for turntable with existing mounting holes. Essentially I agree with Niffy about their two options.

Last edited:

oh no - not the offset

Now this is where you get to tear me into pieces.

The solution to moving a tonearm without a side force or deflecting the cantilever sideways is to use a well-designed conventional pivoted arm, build it with zero offset angle, and then use an active servo to move the pivot horizontally in order to maintain zero tracking error.

I have attentively followed this thread “Angling for 90”, the “DIY linear tonearm” thread, the “Air Bearing Linear Arm” thread here on diyaudio, and most every other linear tracking arm thread elsewhere on other forums than diyaudio. Invariably, these threads seem to have started because of a uniform dismissal of servo-arms as intrinsically “always in error”, crabbing, or even outright condemnation because of some negative experience or another. This could have been due to bad design, bad user experience, or even incompetent dealers who didn’t know how to properly set the arm up. Understandable.

I’ve been very careful here on diyaudio to keep my posts on topic while participating in these threads, so I’ve never made posts advocating servo-control as a solution to problems regarding bearing friction/sticktion, [skating] force, high lateral mass, etc. I know servo systems have their own inherent design issues, but as a diy’er I feel more comfortable dealing with servo electronics than with most of the mechanical challenges encountered by other posters in these passive linear threads. I’m working on starting my own thread for people who like servo arms, and we’ll see how that goes.

Ok, no more servo talk from me.

Ray K

Why yes, since you asked…long life to the offset

Now you will tear me in pieces but, after so many TAs (lately even a weird linear tracker) came up to me some naive doubts.

It's there a way to move a tonearm without a side force? or at least without generating bending?

carlo

Now this is where you get to tear me into pieces.

The solution to moving a tonearm without a side force or deflecting the cantilever sideways is to use a well-designed conventional pivoted arm, build it with zero offset angle, and then use an active servo to move the pivot horizontally in order to maintain zero tracking error.

I have attentively followed this thread “Angling for 90”, the “DIY linear tonearm” thread, the “Air Bearing Linear Arm” thread here on diyaudio, and most every other linear tracking arm thread elsewhere on other forums than diyaudio. Invariably, these threads seem to have started because of a uniform dismissal of servo-arms as intrinsically “always in error”, crabbing, or even outright condemnation because of some negative experience or another. This could have been due to bad design, bad user experience, or even incompetent dealers who didn’t know how to properly set the arm up. Understandable.

I’ve been very careful here on diyaudio to keep my posts on topic while participating in these threads, so I’ve never made posts advocating servo-control as a solution to problems regarding bearing friction/sticktion, [skating] force, high lateral mass, etc. I know servo systems have their own inherent design issues, but as a diy’er I feel more comfortable dealing with servo electronics than with most of the mechanical challenges encountered by other posters in these passive linear threads. I’m working on starting my own thread for people who like servo arms, and we’ll see how that goes.

Ok, no more servo talk from me.

Ray K

Member

Joined 2019

I’m working on starting my own thread for people who like servo arms, and we’ll see how that goes.

Ray, I am one of these people. I worked on a simple design, using my old Technics tonearm, but I abandoned it to try the Ivanov's floating tonearm idea.

Attachments

It's there a way to move a tonearm without a side force? or at least without generating bending? carlo

Why yes, since you asked…Ray

Hi Ray, I know well your idea, considering it absolutely rigorous and decisive - just as I consider Ralf's arm: really brilliant. But I was talking about passive TAs.

My opinion is no for every realization I know and perhaps, from the geometric point of view, for a true extensible Thales arm (but as you know my Syrinx was a complete failure, and had a guide that introduced skating too) or, from a pragmatic point of view, this hypothesis of obtaining it from offset, as a balance of forces. Unfortunately I have only a vague, foggy idea of how to do it, feeling from experience it will not work. Too many parts, mechanically awful.

Wishful thinking - it would be nice if producers and diyers who have created wonderful arms, immune from the defects of those of mere mortals, would publish a simple clip of the stylus at work on a average LP, with usual defects. We could save ourselves long years of discussion and speculation.

carlo

Dd, thanks for thanks: I do what I can, and knowing so little when stumbling on a strange idea, instead of setting it aside on a preliminary basis, I try it.

Long ago here in italy Someone said: "provando e riprovando"

Why yes, since you asked…Ray

Hi Ray, I know well your idea, considering it absolutely rigorous and decisive - just as I consider Ralf's arm: really brilliant. But I was talking about passive TAs.

My opinion is no for every realization I know and perhaps, from the geometric point of view, for a true extensible Thales arm (but as you know my Syrinx was a complete failure, and had a guide that introduced skating too) or, from a pragmatic point of view, this hypothesis of obtaining it from offset, as a balance of forces. Unfortunately I have only a vague, foggy idea of how to do it, feeling from experience it will not work. Too many parts, mechanically awful.

Wishful thinking - it would be nice if producers and diyers who have created wonderful arms, immune from the defects of those of mere mortals, would publish a simple clip of the stylus at work on a average LP, with usual defects. We could save ourselves long years of discussion and speculation.

carlo

Dd, thanks for thanks: I do what I can, and knowing so little when stumbling on a strange idea, instead of setting it aside on a preliminary basis, I try it.

Long ago here in italy Someone said: "provando e riprovando"

There is a way to eliminate all side forces that act on the stylus (except those due to groove modulation which are the ones we want) and at the same time keep the cartridge perfectly tangential. Unfortunately it breaks one of DD's thread rules. Sorry DD but it does involve an air pump. Yes, it's an air bearing linear arm. By itself this type of arm still has the potential for lateral track errors from a combination of inertia and varying groove angle when playing eccentric records. So the second part of the system is a record centering device so that the arm moves steadily in only one direction. This will have the additional benefit of improving speed stability by removing the wow caused by the eccentricity.

Hang on! I hear you shout surely you still have to have a side force to allow the arm to track across the record.

The air bearing is to all intent and purpose frictionless so no force is required to overcome this. As the arm will be moving at a steady pace and not accelerating no force is required. Remember F=Ma. If a is zero then F has to be zero also.

OK. You will have the resistance due to arm cables (and air line is using a moving bearing type arm) but these are not significant.

If you really want to get the lateral errors right down you have to centre the record. An average record will result in over a quarter of a degree error due to eccentricity on the inner grooves.

The effects of bending modes and other types of vibration, getting the effective mass right, getting azimuth right and getting VTA right all make more difference than LTA.

Niffy

Hang on! I hear you shout surely you still have to have a side force to allow the arm to track across the record.

The air bearing is to all intent and purpose frictionless so no force is required to overcome this. As the arm will be moving at a steady pace and not accelerating no force is required. Remember F=Ma. If a is zero then F has to be zero also.

OK. You will have the resistance due to arm cables (and air line is using a moving bearing type arm) but these are not significant.

If you really want to get the lateral errors right down you have to centre the record. An average record will result in over a quarter of a degree error due to eccentricity on the inner grooves.

The effects of bending modes and other types of vibration, getting the effective mass right, getting azimuth right and getting VTA right all make more difference than LTA.

Niffy

Member

Joined 2019

Yes, it's an air bearing linear arm. By itself this type of arm still has the potential for lateral track errors from a combination of inertia and varying groove angle when playing eccentric records. So the second part of the system is a record centering device so that the arm moves steadily in only one direction. This will have the additional benefit of improving speed stability by removing the wow caused by the eccentricity.

niffy, I know that the air bearing friction is very low, but do they exist some measured values of it? Just curious..

As for the acceptable maxima of the total lateral forces ( friction + inertial ). Shure declared a maximum increase of the stylus frictional force* of +20% in the modulated grooves as compared to the non-modulated. I have measured momentary increases up to +30%, but I will take the Shure value. Then the uncertainty of the skating force is ±10%. In a classical pivoted arm the antiskating mechanism can not compensate the skating force better than within ±10%.

If we take the Kogen's ratio for elliptical stylus Skating Force = 0.2 Tracking Force, then for Tracking Force of 2 g** we have Skating Force = 0.4 g with uncertainty of ± 40 mg. To name the skating force reduction in a tangential tonearm design "significant", we have to reduce this unsertainty at least to the ± 10 mg level - 4 times lower.

Considering the inertia component, a classical pivoted tonearm of m = 20 g effective mass will be exposed to inertial force maxima of 12 dyne when tracking a 0.5 mm disk eccentricity. It's 30 g TTT brother will behave the same way for eccentricity of 0.33 mm, while the TTT of 100 g will need a reduction of eccentricity to 0.1 mm.

The same could be said for the friction component in not air bearing designs. They must assure a friction force at least < 10 dyne.

* Kogen's terminology.

** g means gram-force

Last edited:

Hi Panayotis,

You've definitely highlighted a problem that plagues us designers. The acquisition of accurate and reliable data. No two investigations into the variation in stylus drag seem to agree. The source I have been using (I cannot remember who it's by) tested a wide range of cartridges with different stylus profiles and found that they differed greatly one from another. The overall rule of thumb was a coefficient of friction that varied from 0.3 to 0.6 from unmodulated to heavily modulated. This is a 100% variation, much greater than the 20% you say shure found.

Your analysis of the side forces due to eccentricity is spot on. The dyne is not a unit I use, I prefer the millinewton. Knowing what the forces are is not in itself useful. By combining these forces with the compliance of the cartridge and the length of the cantilever the lateral tracking error due to these forces for your cartridge can be determined. If you do this for all the aspects that can cause a force on the stylus (bearing friction, arm geometry, groove angle due to eccentricity etc) you can draw a more complete picture. The effects of each cannot be just added together to get a grand total. For instance the groove angle will be at a maximum at 90° of record rotation from where the effects of inertia will be at its maximum.

Some aspects will only effect the angle at which the stylus sits in the groove and some will also effect the alignment of the generator in the cartridge. As long as cartridge generator misalignment is small and within its linear range sound quality should not be affected.

By doubling the effective mass the force acting on the stylus due to eccentricity will also double. This will also double the tracking error (at these small angles the relationship can be considered linear). However doubling the mass will mean that the cartridge body will move half as much at audio frequencies (-6dB). If the record is concentric then the side force due to eccentricity will be zero, the same for both arm masses. The heavier arm will still have the 6dB advantage at audio frequencies. Generally reducing cartridge movement at audio frequencies (especially in the bass) has a much greater positive effect than reducing tracking error.

Niffy

You've definitely highlighted a problem that plagues us designers. The acquisition of accurate and reliable data. No two investigations into the variation in stylus drag seem to agree. The source I have been using (I cannot remember who it's by) tested a wide range of cartridges with different stylus profiles and found that they differed greatly one from another. The overall rule of thumb was a coefficient of friction that varied from 0.3 to 0.6 from unmodulated to heavily modulated. This is a 100% variation, much greater than the 20% you say shure found.

Your analysis of the side forces due to eccentricity is spot on. The dyne is not a unit I use, I prefer the millinewton. Knowing what the forces are is not in itself useful. By combining these forces with the compliance of the cartridge and the length of the cantilever the lateral tracking error due to these forces for your cartridge can be determined. If you do this for all the aspects that can cause a force on the stylus (bearing friction, arm geometry, groove angle due to eccentricity etc) you can draw a more complete picture. The effects of each cannot be just added together to get a grand total. For instance the groove angle will be at a maximum at 90° of record rotation from where the effects of inertia will be at its maximum.

Some aspects will only effect the angle at which the stylus sits in the groove and some will also effect the alignment of the generator in the cartridge. As long as cartridge generator misalignment is small and within its linear range sound quality should not be affected.

By doubling the effective mass the force acting on the stylus due to eccentricity will also double. This will also double the tracking error (at these small angles the relationship can be considered linear). However doubling the mass will mean that the cartridge body will move half as much at audio frequencies (-6dB). If the record is concentric then the side force due to eccentricity will be zero, the same for both arm masses. The heavier arm will still have the 6dB advantage at audio frequencies. Generally reducing cartridge movement at audio frequencies (especially in the bass) has a much greater positive effect than reducing tracking error.

Niffy

Member

Joined 2019

Hi, Niffy

One more point on this. In the real world even the perfectly centered disks are not 'acceleration free'. We have:

1. The various un-modulated parts, where acceleration and deceleration occurs. This does not affect the sound, but may cause some trackability problems, especially in the region of the final disk grooves, where the horizontal velocity rises from about 0.07 mm/s to more than 2 mm/s . But ..

2. We have some acceleration/deceleration in the modulated parts, due to the changes of the groove spiral pitch depending on the recorded signal level. I do not know the standards, related to the variable pitch recording. But I could do some rough calculation. If the recording system has to widen the grooves distance due to the coming of a strong x4 sound peak, this will mean roughly a pitch change from 0.1 to 0.2 mm * within 1.8 s or an acceleration of the order of 0.0055 cm/s and a lateral force rise of 0.17 dyne for a 30 g tonearm. Very small, indeed, but not 0.

I have read this statement also elsewhere and could never "accept it" quantitively. I know that the cartridge will react to the stylus movements as a large body, connected elastically to a small one. But what will be the level of this reaction? It will depend of the masses ratio. If we have a 30 g horizontal tonearm mass component and stylus effective tip mass of 0.3 mg ** , the ratio is 100000:1 or I expect a -100 dB tonearm response. Does it make any difference if we change -100 dB to -106 dB by doubling the tonearm mass? It sounds to me again like counting angels in the needle's edge..

* I take the modulation width = 0.5 of the groove spiral pitch.

** UNDERSTANDING PHONO CARTRIDGES BY KAB

So the second part of the system is a record centering device so that the arm moves steadily in only one direction. This will have the additional benefit of improving speed stability by removing the wow caused by the eccentricity.

….. As the arm will be moving at a steady pace and not accelerating no force is required. Remember F=Ma. If a is zero then F has to be zero also.

One more point on this. In the real world even the perfectly centered disks are not 'acceleration free'. We have:

1. The various un-modulated parts, where acceleration and deceleration occurs. This does not affect the sound, but may cause some trackability problems, especially in the region of the final disk grooves, where the horizontal velocity rises from about 0.07 mm/s to more than 2 mm/s . But ..

2. We have some acceleration/deceleration in the modulated parts, due to the changes of the groove spiral pitch depending on the recorded signal level. I do not know the standards, related to the variable pitch recording. But I could do some rough calculation. If the recording system has to widen the grooves distance due to the coming of a strong x4 sound peak, this will mean roughly a pitch change from 0.1 to 0.2 mm * within 1.8 s or an acceleration of the order of 0.0055 cm/s and a lateral force rise of 0.17 dyne for a 30 g tonearm. Very small, indeed, but not 0.

The heavier arm will still have the 6dB advantage at audio frequencies. Generally reducing cartridge movement at audio frequencies (especially in the bass) has a much greater positive effect than reducing tracking error.

I have read this statement also elsewhere and could never "accept it" quantitively. I know that the cartridge will react to the stylus movements as a large body, connected elastically to a small one. But what will be the level of this reaction? It will depend of the masses ratio. If we have a 30 g horizontal tonearm mass component and stylus effective tip mass of 0.3 mg ** , the ratio is 100000:1 or I expect a -100 dB tonearm response. Does it make any difference if we change -100 dB to -106 dB by doubling the tonearm mass? It sounds to me again like counting angels in the needle's edge..

* I take the modulation width = 0.5 of the groove spiral pitch.

** UNDERSTANDING PHONO CARTRIDGES BY KAB

Last edited:

Member

Joined 2019

As you point out the unmodulated portions cannot effect sound quality and whether concentric or not it's not going to have any effect.

The variation in pitch causing a change in acceleration of the arm? This really is counting angels. A 0.17 dyne force? With an average cartridge this would result in a deflection of a massive 0.0003°. About a thousand times to small to be heard by even the finest pair of ears.

The 6dB is very real for doubling the mass of the arm. An arm tuned to the recommended 10hz will have the cartridge body moving only - 10dB compared to the movement of the stylus at 20hz. That's about 30% in absolute terms. Double the mass will reduce this to around 15%. The relative movement decreases by 12dB per octave so by the time you get to 100hz the 10hz tuned arm is moving at -40dB and the heavier arm at -46dB. So yes by the time you get to high frequency the difference is small but the difference at low frequency is massive and definitely not counting angels. Even if your speakers can't reproduce 20hz the cartridge will still be moving at this frequency if the record is cut at that frequency. When reproducing the midrange would you prefer your cartridge to be moving a little or a lot at low frequency. Reducing low frequency movement of the cartridge has a positive impact across the entire audio range.

Niffy

The variation in pitch causing a change in acceleration of the arm? This really is counting angels. A 0.17 dyne force? With an average cartridge this would result in a deflection of a massive 0.0003°. About a thousand times to small to be heard by even the finest pair of ears.

The 6dB is very real for doubling the mass of the arm. An arm tuned to the recommended 10hz will have the cartridge body moving only - 10dB compared to the movement of the stylus at 20hz. That's about 30% in absolute terms. Double the mass will reduce this to around 15%. The relative movement decreases by 12dB per octave so by the time you get to 100hz the 10hz tuned arm is moving at -40dB and the heavier arm at -46dB. So yes by the time you get to high frequency the difference is small but the difference at low frequency is massive and definitely not counting angels. Even if your speakers can't reproduce 20hz the cartridge will still be moving at this frequency if the record is cut at that frequency. When reproducing the midrange would you prefer your cartridge to be moving a little or a lot at low frequency. Reducing low frequency movement of the cartridge has a positive impact across the entire audio range.

Niffy

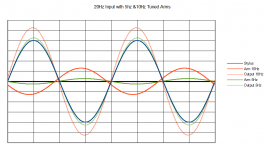

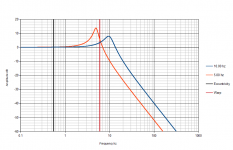

The things that determines the motion of the cartridge relative to the stylus/groove are the effective mass, compliance and damping. The stylus tip mass plays no part in this. The graph below shows the difference in response between an arm tuned at 10hz and one tuned at 5hz. In this case the 5hz arm would be 4 times heavier and have a relative motion 12dB lower.

And this one shows the actual difference in motion relative to the groove for the same two arms

Niffy

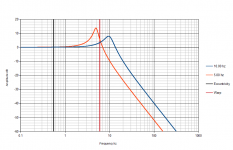

And this one shows the actual difference in motion relative to the groove for the same two arms

Niffy

Member

Joined 2019

Niffy, I agree with your last posts. Thank you! My comparison of masses is valid for free stylus movements, not for movements forced by the groove. In this case the stylus mass has nothing to do, at least at the very low frequencies.

So, a question arises. In the modern pivoted tonearms, those with effective mass > 25 g are considered 'heavy' and are quite rare. Why? A good bearing would keep the friction in the stylus radius quite low even in the case of a heavier arm, so friction is not the reason. Better trackability of warps is probably the main reason.

So, a question arises. In the modern pivoted tonearms, those with effective mass > 25 g are considered 'heavy' and are quite rare. Why? A good bearing would keep the friction in the stylus radius quite low even in the case of a heavier arm, so friction is not the reason. Better trackability of warps is probably the main reason.

Hi Panayotis,

For some unfathomable reason it has entered into the dogma of tonearm design that lateral and vertical effective masses have to be the same.

In the vertical plane you want to have the effective mass set so that the resonance due to the compliance of the cartridge suspension is around 10hz. This is so that the resonance is above the frequency of warps, which occur up to about 6hz, and below the audio band.

In the lateral plane there are no warps so the only low frequency motion is that due to eccentricity at 0.55hz. Bass frequencies are only cut laterally, there is no stereo information on a record below about 120hz. Increasing lateral mass reduces cartridge movement at low frequencies. I would recommend making lateral mass 4-5 times as great as the vertical, so it is tuned to 4.5-5hz. By the time you get up to the frequency where there is stereo information the vertical and lateral motion of the arm will be virtually the same.

One of the biggest advantages of the linear arm is that it tends to naturally have a higher lateral mass. It is strange that this is the thing most often said to be a negativeof this type of arm.

The only conventional pivoted arm that I know of that purposefully has a high lateral mass is the morch dp-8 which received universal glowing reviews.

Niffy

For some unfathomable reason it has entered into the dogma of tonearm design that lateral and vertical effective masses have to be the same.

In the vertical plane you want to have the effective mass set so that the resonance due to the compliance of the cartridge suspension is around 10hz. This is so that the resonance is above the frequency of warps, which occur up to about 6hz, and below the audio band.

In the lateral plane there are no warps so the only low frequency motion is that due to eccentricity at 0.55hz. Bass frequencies are only cut laterally, there is no stereo information on a record below about 120hz. Increasing lateral mass reduces cartridge movement at low frequencies. I would recommend making lateral mass 4-5 times as great as the vertical, so it is tuned to 4.5-5hz. By the time you get up to the frequency where there is stereo information the vertical and lateral motion of the arm will be virtually the same.

One of the biggest advantages of the linear arm is that it tends to naturally have a higher lateral mass. It is strange that this is the thing most often said to be a negativeof this type of arm.

The only conventional pivoted arm that I know of that purposefully has a high lateral mass is the morch dp-8 which received universal glowing reviews.

Niffy

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms