I've been building DIY speakers for quite a few years and I think DIY speakers can be fairly competitive against commercial speakers, within some limits. As the price gets higher to about 40K a pair, I think DIY may not have the resource to compete because commercial can have better access to cabinet materials that DIYers can't. For high-end, cabinets are just as important as xover or drivers.

For preamp, can a DIY compete with say a Conrad Johnson ART preamp? I have to admit commercial preamps can be pretty expensive. When you look inside them, there are not that much that can cost too much money.

For preamp, can a DIY compete with say a Conrad Johnson ART preamp? I have to admit commercial preamps can be pretty expensive. When you look inside them, there are not that much that can cost too much money.

Easily, its got mediocre performance, far worse than most opamps for instance.For preamp, can a DIY compete with say a Conrad Johnson ART preamp?

That is a product to part stupid rich people's money from them, pure and simple.

All info for making a super duper preamp can be found on this website. From all kind of super regulators for psu, muses high end remote volume controle, a lot of info about relais, buffers, UGS modules...

I ‘m surprised that for example in many expensive high end preamps an Alps volume pot is used

I have build the Calvin buffers supplied by the jung didden superregs which sound better than my PS audio preamp.

Currently I’m finishing the pcb layout for the Blowtorch line amp and psu.

I ‘m surprised that for example in many expensive high end preamps an Alps volume pot is used

I have build the Calvin buffers supplied by the jung didden superregs which sound better than my PS audio preamp.

Currently I’m finishing the pcb layout for the Blowtorch line amp and psu.

Easily, its got mediocre performance, far worse than most opamps for instance.

Hilarious. Yet, in a strictly technical way, true.

For preamp, can a DIY compete with say a Conrad Johnson ART preamp?

Absolutely. It is fairly easy to clone something as simple as a CJ ART and build it using better sounding parts and especially with a better sounding PS than CJ.

It is amusing how long companies like ARC and CJ took to realise that minimalistic, NFB free preamp circuits hold a much bigger sonic potential than the complex high NFB drek they were producing for years. And patenting

In this particular case i believe diy-ers, mostly from Japan, took the lead and the big companies reluctantly followed.

Its not that easy to compete with pro designs.

First of all there has to be the engineering knowledge to be learned to compete with pro equipment. Because pro equipment was designed, calculated and build by professionals, not amateurs.

At this stage, most DIY struggle with own designs that meet or exceed the excellent pro designs. They stuck in the Kindergarten of electronic designs, forever. Because they don't have the energy, the time and the resources to go on furter to exceed good designs.

Proof is in the thousands of DIY gears and schemos, that have spread all over the internet today. Most of them show big designs flaws by the task of designing a tube amp right from the scratch. They copy parts from other amps, understand just half the theory behind it, or modify parts of the amps plans and combine whatever they want or think that sounds good. The results are design errors, the gear may be funtioning, but suboptimal. Most DIY is in heaven, when its gear just produces some right tones. Then an audio forum has to be there, in which the hymns of their own designs must be written for the next generations of DIY. Of course its the best of the world design, an award winning tube amp, if there were ever such things as DIY- design awards.

Most of them struggle even with the practical approach, that is given when it comes to the building stage. Seen all those wood- frames with an aluminum top plate, looking like audio gear of the late 1950's in today times? That is, because its the most simple method to build a frame and chassis for a tube amp. You will rarely see someone, who is able to handle the metalwork and capable of designing something more professional. Thats because it has to be made most often by own machinery in the basements or on the kitchen table at night, when family is sleeping.

Forgot about small batch series of own plans for building the framework by a professional company. Every company will laugh at you, because they hate prototyping, or they want some grand cash notes before even doing one step towards the final housing.

So there are many dificulties to become a good designer, a good practical worker for building its own tube gear.

Its like everything in life: invest the energy, invest the money and invest the necessary labor and time and you will receive the equivalent value in own tube gear.

For most of the working people, they have not enough time and effort for self educating, learning often took years or decades to master one subject of knowledge, not enough knowledge to be a superior electronic gear designer, not enough talent, not enough money it all takes to be able to produce own gear in a professional mannor.

And that is visible in the end result, the ready made object. Circuits with big design flaws and errors, housings that look not fancy but ugly and building style and practice of work that shows big difficulties to solder two wires together in the way it should have been done.

I just have read a sentence about the usual consumer of gear, living in a first world country.

For him (or her), the most advanced technical machine they ever work with in their lifes is their motor car.

And even with the maintenance, service, correct treatment of this machine most of the people are too inexperienced, not enough interested in the subject and show too low effort to handle it the right way it should be done.

And those people should DIY better gear than pro- companies?

There will always only a few which are being able to achieve such a goal.

Most of the DIY never will, but enjoy doing it anyway. Achieving some goals, is the best part of it. It could make for a happy man, and that goal should be always in the foreground, not to beat a pro company. Because, it won't happen easily.

First of all there has to be the engineering knowledge to be learned to compete with pro equipment. Because pro equipment was designed, calculated and build by professionals, not amateurs.

At this stage, most DIY struggle with own designs that meet or exceed the excellent pro designs. They stuck in the Kindergarten of electronic designs, forever. Because they don't have the energy, the time and the resources to go on furter to exceed good designs.

Proof is in the thousands of DIY gears and schemos, that have spread all over the internet today. Most of them show big designs flaws by the task of designing a tube amp right from the scratch. They copy parts from other amps, understand just half the theory behind it, or modify parts of the amps plans and combine whatever they want or think that sounds good. The results are design errors, the gear may be funtioning, but suboptimal. Most DIY is in heaven, when its gear just produces some right tones. Then an audio forum has to be there, in which the hymns of their own designs must be written for the next generations of DIY. Of course its the best of the world design, an award winning tube amp, if there were ever such things as DIY- design awards.

Most of them struggle even with the practical approach, that is given when it comes to the building stage. Seen all those wood- frames with an aluminum top plate, looking like audio gear of the late 1950's in today times? That is, because its the most simple method to build a frame and chassis for a tube amp. You will rarely see someone, who is able to handle the metalwork and capable of designing something more professional. Thats because it has to be made most often by own machinery in the basements or on the kitchen table at night, when family is sleeping.

Forgot about small batch series of own plans for building the framework by a professional company. Every company will laugh at you, because they hate prototyping, or they want some grand cash notes before even doing one step towards the final housing.

So there are many dificulties to become a good designer, a good practical worker for building its own tube gear.

Its like everything in life: invest the energy, invest the money and invest the necessary labor and time and you will receive the equivalent value in own tube gear.

For most of the working people, they have not enough time and effort for self educating, learning often took years or decades to master one subject of knowledge, not enough knowledge to be a superior electronic gear designer, not enough talent, not enough money it all takes to be able to produce own gear in a professional mannor.

And that is visible in the end result, the ready made object. Circuits with big design flaws and errors, housings that look not fancy but ugly and building style and practice of work that shows big difficulties to solder two wires together in the way it should have been done.

I just have read a sentence about the usual consumer of gear, living in a first world country.

For him (or her), the most advanced technical machine they ever work with in their lifes is their motor car.

And even with the maintenance, service, correct treatment of this machine most of the people are too inexperienced, not enough interested in the subject and show too low effort to handle it the right way it should be done.

And those people should DIY better gear than pro- companies?

There will always only a few which are being able to achieve such a goal.

Most of the DIY never will, but enjoy doing it anyway. Achieving some goals, is the best part of it. It could make for a happy man, and that goal should be always in the foreground, not to beat a pro company. Because, it won't happen easily.

Last edited:

I'd actually say its much, much harder to beat commercial speakers than any other audio component. Speaker designers have at their disposal anechoic chambers and test equipment and go through many design iterations. Speaker designers also can negotiate with driver manufacturers for custom drivers and more-over, driver pre-testing and screening. So, they end up with both a repeatable product and an iteratively designed product.

To beat a Commercial Preamp is very easy:

1. Know what you are driving downstream. Do you need to drive fully balanced lines to distant equipment, or just Single Ended RCA. If fully balanced, do you want transformer coupling or cap coupling. Your preamp needs to drive whatever impedance is downstream.

2. How do you want to Attenuate and Switch Inputs? Are hand controls sufficient, or do you want IR Remote with relay switching. Do you want fancier switching (i.e. over TCP/IP)?

3. Choose your Class A line stage topology. Discrete semi or tube

4. Do you need Gain? In today's era, probably not much. Let your Phono Preamp give you gain. Plan on 2Vp-p input from a DAC or other Line device.

One you answer those questions, you can find solutions to all 4 questions with existing PCBs and developed/proven modules. The rest is planning the fancy case!

To beat a Commercial Preamp is very easy:

1. Know what you are driving downstream. Do you need to drive fully balanced lines to distant equipment, or just Single Ended RCA. If fully balanced, do you want transformer coupling or cap coupling. Your preamp needs to drive whatever impedance is downstream.

2. How do you want to Attenuate and Switch Inputs? Are hand controls sufficient, or do you want IR Remote with relay switching. Do you want fancier switching (i.e. over TCP/IP)?

3. Choose your Class A line stage topology. Discrete semi or tube

4. Do you need Gain? In today's era, probably not much. Let your Phono Preamp give you gain. Plan on 2Vp-p input from a DAC or other Line device.

One you answer those questions, you can find solutions to all 4 questions with existing PCBs and developed/proven modules. The rest is planning the fancy case!

What makes this pre-amp so special apart from its expensive price tag and the sentimental value of vacuum tubes. State of the art engineering technology from the 1950's is hardly impressive.It would be difficult to compete with something like these. I don't recall a DIY that has this kind of engineering.

It would be difficult to compete with something like these. I don't recall a DIY that has this kind of engineering.

I don't see that BAT amp as particularly hard to replicate. Much of the fancy back and front panel can be fabricated in single quantity using small volume CNC services like Front Panel Express. I've spent weekends in the CAD tool getting drillpoints laid out - etc - and you can achieve a very elegant look as far as metal work goes if you are willing to put in several weekends doing the layout and verification. If you want something special, you can have it for a couple hundred bucks and your time.

The rest of that? As far as PCBs, if you really want PCBs you can also lay those out and have them done in small quantities. PCBs aren't economical in small quantities- but sometimes they are convenient... Other people's PCBs - as modules and building blocks - now that makes ALOT of sense as far as economies of scale and time savings.

Example. K&K Audio's Mir. He has some awesome components and modules he will sell you. He even designed a nice case for it. I would actually refabricate his front panel with something much, much nicer - anodized, with paint filled inlays and recesses for buttons and switches... And better knobs. And you or I or anyone could achieve that for a small investment of time.

Mir Line Stage Preamplifier – K & K Audio

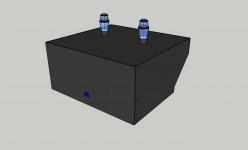

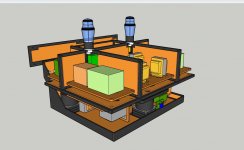

Some of us can make the effort for a great diy result. Here is my DHT preamp on the breadboard as well as sketches of the final chassis which I am most of the way through building...based on the work of others smarter than me that have made the effort required for great diy and/or commercial...it measures and sounds great even with this poor breadboard layout.

The preamp circuit suits exactly the complex amplifer load, six source inputs and single output both BNC and RCA, remote volume control and input selection, dead silent on 110dB/w/m horns. The chassis is designed to be large enough for good sparse layout to suit the particular components and to minimise sensitive things from picking up interference and has a lot of vibration minimisation/dissipation employed so that if necessary it can be put on the floor or on a cabinet and the wonderful near 100yo tubes will not make me suffer with microphonics.

Can't wait to get it all boxed up and squared away...the hardest part will be not having it in my system for a day or two while it is being broken down and then reassembled properly in the new chassis.

Can diy compete with commercial preamps? Yes. With some caveats. I previously have built a number of diy SS preamps and they were more or less failures in terms of sound and the specific requirements in my system. Likewise I purchased some commercial preamps including a US$12k SS linestage and a couple of different pre-built SS modules with state-of-the-art measurements...but they too were not good enough. This preamp is the first and only one so far to meet all my criteria and it is based on the work of one man that I personally know, who is brilliant (wound the power transformers, common mode and power chokes and designed and built the DHT filament CCS), and another that is not known to me but seems very smart and has been working on this particular type of preamplifier circuit for many years.

Then there is the volume control. I've tried them all: simple pots in between buffers, things like the Muse chip in two implementations, simple resistor ladders on Elna switches, relay based, nestled in the preamp feedback loop to vary gain, but could not get them as good as well implemented digital volume control in the playback software...until I bought pre-built autoformer modules from someone that had perfected them. They are ideal for the exact application of my preamp and not necessarily ideal for anybody elses.

So, for most of us, unless we are extremely gifted and/or experienced with this stuff, we will be unable to 100% diy from scratch something that can run with the big boys. We need to first clearly identify our targets and then identify who can help us get there, and then persist and experiment if we want a 'top shelf' result.

And preamps...I think they are very difficult to diy just right...I think more difficult than power amplifiers.

The preamp circuit suits exactly the complex amplifer load, six source inputs and single output both BNC and RCA, remote volume control and input selection, dead silent on 110dB/w/m horns. The chassis is designed to be large enough for good sparse layout to suit the particular components and to minimise sensitive things from picking up interference and has a lot of vibration minimisation/dissipation employed so that if necessary it can be put on the floor or on a cabinet and the wonderful near 100yo tubes will not make me suffer with microphonics.

Can't wait to get it all boxed up and squared away...the hardest part will be not having it in my system for a day or two while it is being broken down and then reassembled properly in the new chassis.

Can diy compete with commercial preamps? Yes. With some caveats. I previously have built a number of diy SS preamps and they were more or less failures in terms of sound and the specific requirements in my system. Likewise I purchased some commercial preamps including a US$12k SS linestage and a couple of different pre-built SS modules with state-of-the-art measurements...but they too were not good enough. This preamp is the first and only one so far to meet all my criteria and it is based on the work of one man that I personally know, who is brilliant (wound the power transformers, common mode and power chokes and designed and built the DHT filament CCS), and another that is not known to me but seems very smart and has been working on this particular type of preamplifier circuit for many years.

Then there is the volume control. I've tried them all: simple pots in between buffers, things like the Muse chip in two implementations, simple resistor ladders on Elna switches, relay based, nestled in the preamp feedback loop to vary gain, but could not get them as good as well implemented digital volume control in the playback software...until I bought pre-built autoformer modules from someone that had perfected them. They are ideal for the exact application of my preamp and not necessarily ideal for anybody elses.

So, for most of us, unless we are extremely gifted and/or experienced with this stuff, we will be unable to 100% diy from scratch something that can run with the big boys. We need to first clearly identify our targets and then identify who can help us get there, and then persist and experiment if we want a 'top shelf' result.

And preamps...I think they are very difficult to diy just right...I think more difficult than power amplifiers.

Attachments

I've been building DIY speakers for quite a few years and I think DIY speakers can be fairly competitive against commercial speakers, within some limits. As the price gets higher to about 40K a pair, I think DIY may not have the resource to compete because commercial can have better access to cabinet materials that DIYers can't. For high-end, cabinets are just as important as xover or drivers.

For preamp, can a DIY compete with say a Conrad Johnson ART preamp? I have to admit commercial preamps can be pretty expensive. When you look inside them, there are not that much that can cost too much money.

Can DIY preamps be competitive vs commercial preamps ?

Yes; if there the right approach was realized, your diy pre-amp outperform each commercial preamp device.

Very important is enough idle current and no voltage gain (i. e. unity-gain character).

The one-transistor diy preamp in post #1 under

Delivery Source wanted for this Cinch female Connectors in special Outline

runs with 1A quiescent current but operates with only 12V-DC.

The circuit is basically the same than from Andrea Ciuffoli's power follower (MOSFET is a IRF710) - go to

the Power Folllower

Also important for best possible results by listening tests is a dual mono outdoor power supply.

Until now I haven't found a commercial pre-amp which provide similar sonic character.

But I am still looking around for such a commercial line-level pre-amp device.

Last edited:

These days low volume pcbs are very economical

Indeed. I don't bother making my own pcb's anymore. Double sided through-metalisation and single side screenprint is affordable, even cheap.

And if you phone a bit around and can do your own cad drawing, you can even get housings made to measure. I found a company that has no problem cutting a few pieces for me if I deliver the files. Ok, more expensive than pcb's but still possible. I regulary have metal cut for my live steam hobby.

No problem exceeding commercial preamps except for a very few. But it is still possible to do so, just not as easily.

Many commercial products actually have engineering mistakes in them. This is even more true for high end, uber expensive products. So while some of us couldn't beat a commercial product, some of us easily do so. Everyone else falls somewhere in between. With a good kit or project your odds are significantly improved.

-Chris

Many commercial products actually have engineering mistakes in them. This is even more true for high end, uber expensive products. So while some of us couldn't beat a commercial product, some of us easily do so. Everyone else falls somewhere in between. With a good kit or project your odds are significantly improved.

-Chris

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analog Line Level

- Can DIY preamps be competitive vs commercial preamps