Looks like a lot of amps are roughly 430mm (17ish inch) wide, so lets settle for that. Since I will use wooden sides - yes, real old school - I can deduct roughly 20mm/side plus the aluminum sides and 2mm sheets should be okay for that. So 2x2mm = 4mm and 390 - 4 = 386mm of real interior space. On top of that we want some margin, lets say 30mm per side, 386 - 20 = 366mm as the maximum motherboard width.

Oneminde

Oneminde

RCA & XLR

You are right Ine, they are not cheap

RCA

Searching the internet for a while to find the RCA connector used in the XP-12 ended up at Cardas GRFA DBL PRT G. They cost $25/pcs. Cardas is market as esoteric audio, so the price is a reflection of the branding.

Another solution comes from a French company called ELECAUDIO and offer a similar product (stacked connector for PCB mount).

This ELECAUDIO ER-110 RCA stereo socket is particularly suitable for PCB mounting. It has a special design with two long, angled contact pins and 3 fixing tabs, making it easy to mount on a printed circuit board. In addition, this base has a good manufacturing quality, with gold-plated copper alloy contacts ensuring good conductivity and excellent oxidation resistance as well as PTFE insulation.

Spécifications :

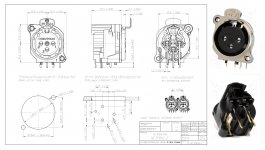

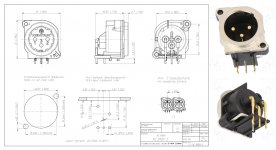

XLR

UGS MUSES uses Neutrik NC3FAV1 (female-IN) with 1+G, common ground, and Neutrik NC3MAV (male-OUT) which use separate ground. PASS XP-12 use Neutrik NC3FDM3-H (female-IN) which use separate ground, and Neutrik NC3MD-H (male-OUT) which use separate ground. Original UGS MUSES uses the rear mounting style which I prefer while PASS uses external mounting which I do not like. Its just a matter of visual preference, that is all.

When it comes to the models I have selected, I am taking it a step further:

If we do like the XP-12, then we have 5 inputs ( 3 pcs RCA and 2 pcs XLR) and 2 outputs (1 pcs RCA and 1 pcs XLR). I like that and it should be enough for most people.

Oneminde

You are right Ine, they are not cheap

RCA

Searching the internet for a while to find the RCA connector used in the XP-12 ended up at Cardas GRFA DBL PRT G. They cost $25/pcs. Cardas is market as esoteric audio, so the price is a reflection of the branding.

Another solution comes from a French company called ELECAUDIO and offer a similar product (stacked connector for PCB mount).

This ELECAUDIO ER-110 RCA stereo socket is particularly suitable for PCB mounting. It has a special design with two long, angled contact pins and 3 fixing tabs, making it easy to mount on a printed circuit board. In addition, this base has a good manufacturing quality, with gold-plated copper alloy contacts ensuring good conductivity and excellent oxidation resistance as well as PTFE insulation.

Spécifications :

- Type : Stereo RCA plug

- Contacts material : Copper Alloy

- Plating: Gold

- Insulation : PTFE

XLR

UGS MUSES uses Neutrik NC3FAV1 (female-IN) with 1+G, common ground, and Neutrik NC3MAV (male-OUT) which use separate ground. PASS XP-12 use Neutrik NC3FDM3-H (female-IN) which use separate ground, and Neutrik NC3MD-H (male-OUT) which use separate ground. Original UGS MUSES uses the rear mounting style which I prefer while PASS uses external mounting which I do not like. Its just a matter of visual preference, that is all.

When it comes to the models I have selected, I am taking it a step further:

- Metal mounting flange featuring continuous circumferential ground contact to chassis for best EMC and RF protection.

If we do like the XP-12, then we have 5 inputs ( 3 pcs RCA and 2 pcs XLR) and 2 outputs (1 pcs RCA and 1 pcs XLR). I like that and it should be enough for most people.

Oneminde

Attachments

-

XP-12_rear.jpg309.8 KB · Views: 524

XP-12_rear.jpg309.8 KB · Views: 524 -

rcabuchsen-grfadblprtg-p36-3.jpg42.5 KB · Views: 506

rcabuchsen-grfadblprtg-p36-3.jpg42.5 KB · Views: 506 -

elecaudio-er-110-rca-plugs-stereo-gold-plated-for-pcb.jpg64.5 KB · Views: 494

elecaudio-er-110-rca-plugs-stereo-gold-plated-for-pcb.jpg64.5 KB · Views: 494 -

elecaudio-er-110-rca-plugs-stereo-gold-plated-for-pcb2.jpg56 KB · Views: 497

elecaudio-er-110-rca-plugs-stereo-gold-plated-for-pcb2.jpg56 KB · Views: 497 -

Neutrik NC3FBH2-E.jpg399 KB · Views: 196

Neutrik NC3FBH2-E.jpg399 KB · Views: 196 -

Neutrik NC3MBH-E.jpg364.5 KB · Views: 204

Neutrik NC3MBH-E.jpg364.5 KB · Views: 204

Last edited:

Hi,By hardware, you mean chassis etc ? Probably not cheap no

yes I mean chassies.

Guaranteed not cheap, if don't have a very good friend in the right business ?

I might have mentioned it before, if not, then now. Since I have an education in both carpentry and metal work (CNC operator), the design and in part manufacturing will be carried out by me. While I don't have a CNC machine yet, there are ways to work around that, its called manual labor  - I need to fully design the chassis and the very complex volume wheel, before I know what it takes. The most labor intensive part will be the front and volume wheel.

- I need to fully design the chassis and the very complex volume wheel, before I know what it takes. The most labor intensive part will be the front and volume wheel.

Right now, I am trying to figure out the inner workings of the wheel since it demands both a static structure containing the display and a rotating section containing the index wheel for the rotary encoder. Never done this either, but I'm not too worried

Right now, I am trying to figure out the inner workings of the wheel since it demands both a static structure containing the display and a rotating section containing the index wheel for the rotary encoder. Never done this either, but I'm not too worried

Good news. Found a very useful tool, a Code wheel generator. With this software, I will be able to design the custom encoder wheel which probably will be photo etched brass. Together with the Vishay Transmissive Optical Sensor, this will be the best and simplest solution.

Oneminde

Oneminde

Sure, I can consider BNC instead of RCA. After all, professional audio use BNC instead of RCA. Why RCA has maintained its wide dominance for home AV equipment is beyond me. The one thing that "worries" me is difference in resistance between an RCA and BNC. I see BNC has primarily two resistance values, 50 and 75 ohm. Producers of RCA connectors typically do not mention impedance for RCA connectors.

On another note. I hade a conversation with a good friend of me who have been building amps etc. for many years. He helped a friend with his equipment and mentioned that between some WBT and Cardas RCA connetors, the Cardas sounded better. So we had a conversation about the sound. When it comes to conductors - be that cable or connector - I deal with 3 factors: Capacitance, Inductance and Resistance, that's it. All 3 can be seen as resistance which impede the flow of current. Meaning, a connector or cable will always lower the signal integrity compared to what the source puts out, it can never add some magical substance to the signal (audiophoolery). In the end, we are looking at choosing a connector and cable that has the least amount of the 3 factors.

Back to my friend. If both WBT and Cardas use pure copper, the difference in sound has to be sourced back to one of the connectors having one of the 3 factors a bit lower than the other. If the material is equal, then the reduction factor must be found somewhere els. But strangely enough, WBT use copper and Cardas use eutectic Brass. Copper is a better conductor and should maintain better signal integrity. So the difference in sound and the difference can be debated, but is best measured.

I contacted Elecaudio because I wanted to know what they meant by "Copper alloy". Since Brass and Bronze are considered a copper alloy, my suspicions were that the general material used in the ER-110 RCA connector is brass - they replied.

So to sum things up, the most common contact material is brass, and ofc one can debate wether or not the small amount of material used really matter. If one didn't know which material is used and one do a blind test between different materials, would one be able to tell which is better (?)

On another note. I hade a conversation with a good friend of me who have been building amps etc. for many years. He helped a friend with his equipment and mentioned that between some WBT and Cardas RCA connetors, the Cardas sounded better. So we had a conversation about the sound. When it comes to conductors - be that cable or connector - I deal with 3 factors: Capacitance, Inductance and Resistance, that's it. All 3 can be seen as resistance which impede the flow of current. Meaning, a connector or cable will always lower the signal integrity compared to what the source puts out, it can never add some magical substance to the signal (audiophoolery). In the end, we are looking at choosing a connector and cable that has the least amount of the 3 factors.

Back to my friend. If both WBT and Cardas use pure copper, the difference in sound has to be sourced back to one of the connectors having one of the 3 factors a bit lower than the other. If the material is equal, then the reduction factor must be found somewhere els. But strangely enough, WBT use copper and Cardas use eutectic Brass. Copper is a better conductor and should maintain better signal integrity. So the difference in sound and the difference can be debated, but is best measured.

I contacted Elecaudio because I wanted to know what they meant by "Copper alloy". Since Brass and Bronze are considered a copper alloy, my suspicions were that the general material used in the ER-110 RCA connector is brass - they replied.

I then spent some time going over Cardas and Neutrik and indeed, contact material is brass or phosphor bronze. A quick search XLR which use copper as the contact material and EIZZ and Viborg pop up as alternatives.Hello,

Thank you for your interest of our products.

Our ER-110 are made of brass / phosphorus bronze. And not only pure copper.

It is indeed copper alloy, because in brass or bronze phosphorus, there is a part of copper.

So to sum things up, the most common contact material is brass, and ofc one can debate wether or not the small amount of material used really matter. If one didn't know which material is used and one do a blind test between different materials, would one be able to tell which is better (?)

RCA becomes BNC.

OBS.

I've had some time to consider the signal infrastructure since Mark Tillotson commented using BNC instead of RCA is better. Since I will build most if not all of the audio equipment, I can just go ahead and select XLR & BNC as the only connectivity I will use, but keep in mind that this does not affect you who which to build a UGS MUSES Scion preamplifier. We will move forward with panel mount connectors only, meaning you are free to choose BNC or RCA and model / manufacturers at your hearts content. The motherboard does not care.

I will collect some info on my personal choices for the XLR and BNC and publish it in a post soon.

Oneminde

OBS.

I've had some time to consider the signal infrastructure since Mark Tillotson commented using BNC instead of RCA is better. Since I will build most if not all of the audio equipment, I can just go ahead and select XLR & BNC as the only connectivity I will use, but keep in mind that this does not affect you who which to build a UGS MUSES Scion preamplifier. We will move forward with panel mount connectors only, meaning you are free to choose BNC or RCA and model / manufacturers at your hearts content. The motherboard does not care.

I will collect some info on my personal choices for the XLR and BNC and publish it in a post soon.

Oneminde

I can mention that I found a fairly simple solution for the glass section for the display area, but due to limited access to dimensions, I can't incorporate it into the volume wheel design just yet. So I'll wait with that until I have the product in my hands. In the meantime I will continue with the motherboard. As soon as I have something to show, I will post it as I am certain that it will be open for debates

Thank you. It will happen, no question about it. With me being sick atm and also doing research for loudspeaker development (company) projects like this is developed in chunks since I cannot devote 100% of my time. Its a side project that I am passionate about. So me being quiet does not mean I quit, just busy with other things ... besides being sick atm

- Home

- Source & Line

- Analog Line Level

- UGS MUSES Scion Preamplifier