No idea what this sentence means.

Current source - very high output impedance v a series resistor

Not so fast....there are several compounds used for the photo sensitive conductive layer each with quite different spectral response.LDRs are merely light dependent resistors. An LED-LDR optocoupler (which is what I assume you mean by "LDR") can be driven by whatever you wish; the LED is merely a forward-biased diode which happens to be an optical emitter too.

Dan.

All you have to do is listen to the difference, a battery v linear wall wart, if anyone can tell the difference in a blind A/B then you've bettered 100's that have tried this A/B on Audiogon and some reviewers have done.

Making elaborate supplies to power the leds is not discernible and a waist, especially if it's used to sell a product! As it adds to the customers buy price.

Cheers George

Making elaborate supplies to power the leds is not discernible and a waist, especially if it's used to sell a product! As it adds to the customers buy price.

Cheers George

All you have to do is listen to the difference, a battery v linear wall wart, if anyone can tell the difference in a blind A/B then you've bettered 100's that have tried this A/B on Audiogon and some reviewers have done.

Making elaborate supplies to power the leds is not discernible and a waist, especially if it's used to sell a product! As it adds to the customers buy price.

Cheers George

Which is simply because a 78xx is not going to get any better no matter how it is supplied,

its reached the end of its sonic capabilities - which are not very high to begin with.

Here is a comment from those taking the next step that you also need to do, comparing

a 78xx, ( in this case requiring 15 volts) , a 7815 to a LM317 also at 15 volts

"I was originally using an Lm317 based psu I borrowed from another project and I also had a rough board with a 7815 on. Switching between the two does prove a big difference, it’s just not enjoyable and sounds wrong with the 7815."

Making elaborate supplies to power the leds is not discernible and a waist...

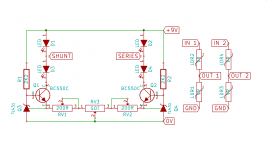

Please try mine, it's reasonably accurate, and inexpensive, run it at 12V not 9V as indicated, let me know what you think. Supply filtering isn't shown, add 100nF polyester // 1,000uF low ESR, then 33R in series to the PSU.

The control of the volume isn't log, but we know about that.

"I was originally using an Lm317 based psu I borrowed from another project and I also had a rough board with a 7815 on. Switching between the two does prove a big difference, it’s just not enjoyable and sounds wrong with the 7815."

If there's a bottle neck...

Attachments

Nice ! similarly I use TL431's ... how does it sound ?Please try mine, it's reasonably accurate, and inexpensive, run it at 12V not 9V as indicated, let me know what you think. Supply filtering isn't shown, add 100nF polyester // 1,000uF low ESR, then 33R in series to the PSU.

The control of the volume isn't log, but we know about that.

If there's a bottle neck...

Hi "itsme",

Your circuit reminds me of Peter's 'current drive' circuit back in 2008 shown in the #1000 post in Geoege's "Lightspeed Attenuator ...." thread

Nelson did a design too that included a simple buffer with jfets (a la B1 buffer)

Jeez, that's over 10 years ago

I recently used a SuperTeddy reg as the power source for Uriah Daley's "Clone Note" (see on "Build an Amp site) and it made a noticeable change in the performance, surprising enough - it uses a fixed value series resistance (ldr) and 23 position stepped shunt resistors that George originally found to be unsatisfactory - the series ldr resistor can be adjusted (via a pot) to alter the vol control's impedance - very simple, very clever, very transparent

Your circuit reminds me of Peter's 'current drive' circuit back in 2008 shown in the #1000 post in Geoege's "Lightspeed Attenuator ...." thread

Nelson did a design too that included a simple buffer with jfets (a la B1 buffer)

Jeez, that's over 10 years ago

I recently used a SuperTeddy reg as the power source for Uriah Daley's "Clone Note" (see on "Build an Amp site) and it made a noticeable change in the performance, surprising enough - it uses a fixed value series resistance (ldr) and 23 position stepped shunt resistors that George originally found to be unsatisfactory - the series ldr resistor can be adjusted (via a pot) to alter the vol control's impedance - very simple, very clever, very transparent

Hi "itsme",

Your circuit reminds me of Peter's 'current drive' circuit back in 2008 shown in the #1000 post in Geoege's "Lightspeed Attenuator ...." thread

Haven't seen that before, goes to show, there's nothing new under the sun.

Yeah, couldn't agree more - I think it was AndrewT's previous comments about leds preferring 'current drive' that started this variation - Paul Hynes did some good design in this area too.

Recently, I was told about some new devices called NTE 3085 that look quite interesting - we've settled on George's devices over the years and haven't looked any further and maybe there's now some new options?

I see also that the TLP 3543 would make good input selector switches - anybody know anything about these?

Recently, I was told about some new devices called NTE 3085 that look quite interesting - we've settled on George's devices over the years and haven't looked any further and maybe there's now some new options?

I see also that the TLP 3543 would make good input selector switches - anybody know anything about these?

Keeping 1/f noise caused modulations down, way down is always of benefit and in this case of LED constant current source is of little extra cost.....Making elaborate supplies to power the leds is not discernible and a waste.....

Dan.

Interestingly, I had one of Alan Flores "Warpspeed' kits and it did go totally silent - sounded pretty okay too - wasn't the most reliable unit as it became imbalanced in one channel (one of the ldrs) - on another kit, the 'warp engine' failed - pity, it was a neat little kit

Then the digital control units arrived and this neatly resolved a lot of the ldr limitations - my BTF prototype is still operating faultlessly alongside the "CloneNote"

Then the digital control units arrived and this neatly resolved a lot of the ldr limitations - my BTF prototype is still operating faultlessly alongside the "CloneNote"

Hi Alan, good to see you here again

Yes, that was what happened here too and I put my 'good engine' with his 'good ldrs' and we're back in business - I can see why kits are troublesome.

Are you still making the vol controls?

It's interesting that after all these years, there doesn't seem to be an alternative to the Silonex NSL-32SRS that I can remember, apart from the VTL units ...

Yes, that was what happened here too and I put my 'good engine' with his 'good ldrs' and we're back in business - I can see why kits are troublesome.

Are you still making the vol controls?

It's interesting that after all these years, there doesn't seem to be an alternative to the Silonex NSL-32SRS that I can remember, apart from the VTL units ...

I've been away for a number of years and it's interesting to find that we're still discussing the pros and cons of voltage versus current control of LDRs.

It seems to me that there is no issue here -- current control is mandatory for precision control. LDR resistance changes as LED brightness changes. LED brightness is driven by current, not voltage, and unless the current is monitored and constantly adjusted to remain steady, temperature variation at the LED will cause the LED to draw less or more current at a given voltage thus causing the variance in brightness which causes the LDR output resistance to vary.

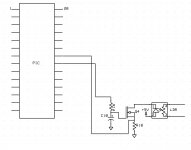

My solution is to put a microprocessor to work to hold LDR current rock-steady regardless of temperature or voltage variation, see the attached diagram. The processor running at 32MHz measures and corrects current to the LDR at a rate of thousands of times a second when the chip is not doing some other function like changing volume level, balance, etc, when the correction drops to hundreds of times a second which is still plenty.

BTW, I calibrated my LDR volume control years ago when I first put it in service and I haven't recalibrated since and it's still running perfectly because I do not allow more than 10ma through the LED at any time.

BTW, I use proprietary techniques to give my system 12-bit or a little better, resolution. Current control is that good.

James! Great to hear my prototype is still working well for you. It's been a while and obviously the software has changed quite a bit, especially the RE control board . . .

It seems to me that there is no issue here -- current control is mandatory for precision control. LDR resistance changes as LED brightness changes. LED brightness is driven by current, not voltage, and unless the current is monitored and constantly adjusted to remain steady, temperature variation at the LED will cause the LED to draw less or more current at a given voltage thus causing the variance in brightness which causes the LDR output resistance to vary.

My solution is to put a microprocessor to work to hold LDR current rock-steady regardless of temperature or voltage variation, see the attached diagram. The processor running at 32MHz measures and corrects current to the LDR at a rate of thousands of times a second when the chip is not doing some other function like changing volume level, balance, etc, when the correction drops to hundreds of times a second which is still plenty.

BTW, I calibrated my LDR volume control years ago when I first put it in service and I haven't recalibrated since and it's still running perfectly because I do not allow more than 10ma through the LED at any time.

BTW, I use proprietary techniques to give my system 12-bit or a little better, resolution. Current control is that good.

James! Great to hear my prototype is still working well for you. It's been a while and obviously the software has changed quite a bit, especially the RE control board . . .

Attachments

Last edited:

Further comparison of contact distortion vs LDR distortion may be needed

What I think I have understood so far, I will explain briefly.

LDR attenuators are effective in rejecting distortion caused by nonlinear contact resistances, which are present in switches of stepped attenuators and in potentiometers of cheaper attenuators.

On the other hand LDR attenuator introduces small amount of harmonic distortion, which seems to be mostly 3rd and 5th.

The harmonic distortion caused by an LDR attenuator is a function of attenuation and signal level. The distortion is least in small attenuation and in low signal level. The distortion is worst in moderate attenuation and high signal level. It seems that LDR attenuator follows the first watt principle: Low level signals survive with lowest distortion.

On the other hand, attenuators that depend on electromechanical contacts (rotary switch, relay or potentiometer for example) introduce such distortion that is worst when signal level is small.

I don't support the idea of "euphonic distortion", but the harmonic distortion caused by an LDR attenuator seems to be small, and the absence of highest overtones is also good.

It would be interesting to compare different distortions. I have not found research papers about the kind of crossover distortion that contacts generate at low signal levels. However I found a paper that describes how such distortions could be measured.

K. Hajek & J. Sikula: Contact voltage of third harmonic distortion for contact reliability investigation. January 2006. IEEE Transactions on Components and Packaging Technologies. 28(4):717 - 720. DOI: 10.1109/TCAPT.2005.859756

What I think I have understood so far, I will explain briefly.

LDR attenuators are effective in rejecting distortion caused by nonlinear contact resistances, which are present in switches of stepped attenuators and in potentiometers of cheaper attenuators.

On the other hand LDR attenuator introduces small amount of harmonic distortion, which seems to be mostly 3rd and 5th.

The harmonic distortion caused by an LDR attenuator is a function of attenuation and signal level. The distortion is least in small attenuation and in low signal level. The distortion is worst in moderate attenuation and high signal level. It seems that LDR attenuator follows the first watt principle: Low level signals survive with lowest distortion.

On the other hand, attenuators that depend on electromechanical contacts (rotary switch, relay or potentiometer for example) introduce such distortion that is worst when signal level is small.

I don't support the idea of "euphonic distortion", but the harmonic distortion caused by an LDR attenuator seems to be small, and the absence of highest overtones is also good.

It would be interesting to compare different distortions. I have not found research papers about the kind of crossover distortion that contacts generate at low signal levels. However I found a paper that describes how such distortions could be measured.

K. Hajek & J. Sikula: Contact voltage of third harmonic distortion for contact reliability investigation. January 2006. IEEE Transactions on Components and Packaging Technologies. 28(4):717 - 720. DOI: 10.1109/TCAPT.2005.859756

Last edited:

"The harmonic distortion caused by an LDR attenuator is a function of attenuation and signal level "

In my experience it is the copious exnovation applied, that causes distortion, not the LDr itself. Exnovation - Wikipedia

In my experience it is the copious exnovation applied, that causes distortion, not the LDr itself. Exnovation - Wikipedia

"The harmonic distortion caused by an LDR attenuator is a function of attenuation and signal level "

In my experience it is the copious exnovation applied, that causes distortion, not the LDr itself. Exnovation - Wikipedia

Exnovation

Often heard around... "If it ain't broke don't fix it."

- Home

- Source & Line

- Analog Line Level

- LDR Attenuator Impressions