very understandable. i guess i suck somewhat less at coding than you. i am ahead of you by about 4K lines of code but those lines of code encompass the workings of a complete remote controlled radio/stereo/media player.I suck at coding so I go with what's easy.

the GUI/sw is what makes it tick, has appeal, adds functionality, makes everyone different.These 16x2 displays are only a couple bucks now. I personally don't like big displays and flashing lights on my audio equipment. The little screen should light up and show any adjustment I've made, then a couple seconds later the backlighting should shut off and stop annoying me.

and i am willing to give the code away for free if everybody is on side. if not everyone cobbles together there own contraption with what ever nuts and bolts you have on hand.

nothing wrong with that either, if that is what you chose to do and $ are tight.

sure that is why a next gen GUI is a ft800!! in the diy world.If I were to put a larger display on, I would want it to be a touch screen so there wouldn't be any switches on the front at all.

good luck programming a lcd touch screen.

a touch screen interface can be come very cumbersome and confusing if you have lots of features, with menus buried deep.

a touch screen for volume control = yuk

my portable is simple, channel selector, volume, freq/fav station, display what ever you want.

i am i the midst of designing a radio/alarm clock for my mother, the gui is as simple as it can gets, probably a 2 line display to keep the size down, but if someone is hard of seeing, you want a big display too, maybe a 4x20 will be the best for mother.

very understandable. i guess i suck somewhat less at coding than you. i am ahead of you by about 4K lines of code but those lines of code encompass the workings of a complete remote controlled radio/stereo/media player.

the GUI/sw is what makes it tick, has appeal, adds functionality, makes everyone different.

and i am willing to give the code away for free if everybody is on side. if not everyone cobbles together there own contraption with what ever nuts and bolts you have on hand.

nothing wrong with that either, if that is what you chose to do and $ are tight.

sure that is why a next gen GUI is a ft800!! in the diy world.

good luck programming a lcd touch screen.

a touch screen interface can be come very cumbersome and confusing if you have lots of features, with menus buried deep.

a touch screen for volume control = yuk

my portable is simple, channel selector, volume, freq/fav station, display what ever you want.

i am i the midst of designing a radio/alarm clock for my mother, the gui is as simple as it can gets, probably a 2 line display to keep the size down, but if someone is hard of seeing, you want a big display too, maybe a 4x20 will be the best for mother.

It's hard the beat big old LED 7 segment displays for anyone with vision problems. I use them for shop equipment I need to see quickly from a distance. All the DROs on my machines are LED. There's usually so much coolant stuck on them you would never see LCD.

i am carrying my pre-amp conversations in this thread

sure, i studied jal compiler, wrote some of it too when i was thinking of using a pic. i changed mcu to xmega, so jal, was of no use to me anymore. i took some of the useful coding bits and ported them over to bascom-avr.

see attached some of the a/d pre-amp front, rear panel concepts. have to say i would do it differently now!!

that is good to know that you built that hardware.thimios wrote:

NO i am not my friend!

I'm a builder only

Do you know JAL language?

sure, i studied jal compiler, wrote some of it too when i was thinking of using a pic. i changed mcu to xmega, so jal, was of no use to me anymore. i took some of the useful coding bits and ported them over to bascom-avr.

HDMI/DSP yet more complication to the equation. if you want less heat go with TPA3116/8 as your surround channel amps.I finally got a chance to look at your schematics. Nice work! I'd like to do something this elaborate eventually for my theater system but with room correction. HDMI switching and decoding would be good too. Right now I've got a Yamaha RX-V2700 cooking my equipment closet. It needs more power and less heat.

yes, that is an option as well. i run the 4 line lcd in big screen mode too, the characters are almost 2" high.It's hard the beat big old LED 7 segment displays for anyone with vision problems.

see attached some of the a/d pre-amp front, rear panel concepts. have to say i would do it differently now!!

Attachments

Last edited:

i am carrying my pre-amp conversations in this thread

that is good to know that you built that hardware.

sure, i studied jal compiler, wrote some of it too when i was thinking of using a pic. i changed mcu to xmega, so jal, was of no use to me anymore. i took some of the useful coding bits and ported them over to bascom-avr.

HDMI/DSP yet more complication to the equation. if you want less heat go with TPA3116/8 as your surround channel amps.

yes, that is an option as well. i run the 4 line lcd in big screen mode too, the characters are almost 2" high.

see attached some of the a/d pre-amp front, rear panel concepts. have to say i would do it differently now!!

The big LCD is a nicer looking option for sure.

Multi channels with lots of options get really busy quick! The last attachment isn't working. I draw everything in Corel Draw, then build it from there. There will likely be a Solidworks guru pop up now and tell me I'm doing it wrong but I can have it drawn up and on the mill before they have their page set up. I have a pretty well equipped machine shop. I get all the lettering done either in stickers or lazer etched. The guy who owns our graphics shop did Tony Stewarts pit crew helmets a few years ago. He's very talented with an air brush. I deal regularly with automotive painters and powder coaters too. Chassis are fun for me.

I've actually been planning on using Valery's CFA-CFPx2 for rear and center channels. They run stone cold and sound amazing.

Last edited:

attachments should work now i re-loaded them and checked again.

i used front panel designer/express, as i was planning on using them, but they are expensive. the s/w i do like, it is easier than say a real mech cad pkg.

nice to know you have excellent machining capabilities to your disposal, i have a drill press and some files

sure if valery's design fit the bill = great.

the tpa3116 design(s) can save a ton of space/heat/$ for a multi-channel amp. although many balk at class "D" ie. OS?

everything has a place and you do not know until you try.

i used front panel designer/express, as i was planning on using them, but they are expensive. the s/w i do like, it is easier than say a real mech cad pkg.

nice to know you have excellent machining capabilities to your disposal, i have a drill press and some files

sure if valery's design fit the bill = great.

the tpa3116 design(s) can save a ton of space/heat/$ for a multi-channel amp. although many balk at class "D" ie. OS?

everything has a place and you do not know until you try.

Really, anything works for designing. Basic PC board programs will give you XY positions good enough to mill off of and a good idea of what the finished product will look like.

I'm not a class D fan either. My midrange hearing is damaged but my high frequency hearing is still excellent. Class D seems harsh to me.

I'm not a class D fan either. My midrange hearing is damaged but my high frequency hearing is still excellent. Class D seems harsh to me.

" i studied jal compiler, wrote some of it too when i was thinking of using a pic. i changed mcu to xmega, so jal, was of no use to me anymore"

Is it possible you modify a little the source code for me?I want to change the welcome message to display my name if it isn't big effort for you.

Is it possible you modify a little the source code for me?I want to change the welcome message to display my name if it isn't big effort for you.

if I gave you a hex file are you able to program it into the pic?Is it possible you modify a little the source code for me?I want to change the welcome message to display my name if it isn't big effort for you.

let me investigate, it has been a while ago.

okay, the code you want to change is in "init_vv.jal file. as you can see or count the characters, it is a 16x2 display

i suggest to you

1) start a new thread and we can discuss it there

2) lets work on getting you the dev tools up and going, so that you can change as many things as you would like.

Code:

-- Written by Benjamin Hinrichs (ben@dh3ben.de) - DH3BEN - (c) 2003

--

-- Part of _VV.jal

-- Look there for copyright and further information

--

-- enable muting

muting = low

-- open all relays

clear_relays

-- turn the backlight of the display on

backlight = high

hd44780_clear -- LCD initialisation; won't work without it !

hd44780_line1

hd44780 = "P"

hd44780 = "r"

hd44780 = "e"

hd44780 = "a"

hd44780 = "m"

hd44780 = "p"

hd44780 = " "

hd44780 = "V"

hd44780 = "e"

hd44780 = "r"

hd44780 = "."

hd44780 = " "

hd44780 = "1"

hd44780 = "."

hd44780 = "0"

hd44780 = "0"

hd44780_line2

hd44780 = " "

hd44780 = " "

hd44780 = "E"

hd44780 = "l"

hd44780 = "e"

hd44780 = "k"

hd44780 = "t"

hd44780 = "o"

hd44780 = "r"

hd44780 = " "

hd44780 = "2"

hd44780 = "0"

hd44780 = "0"

hd44780 = "4"

hd44780 = " "

hd44780 = " "

-- Flash the LED for 2 seconds

flash_led(10)

hd44780_clear

-- there has to be a short delay before the eeprom access

-- first time start ?

eeprom_get (0, new_device)

if new_device != 42 then

restore_defaults

write_values_all

end if

-- read data from the eeprom

read_values_all

if channel1 == high then

setup -- enter the setup

read_values_all

set_volume

set_relays(act_channel)

end if

-- powerup_mute ?

if powerup_mute == 1 then -- mute

vol_left = 0

vol_right = 0

set_volume

end if

if powerup_mute == 2 then -- mute -> last

hd44780_clear

hd44780_line2

write_powerup

write_blank

write_mute

get_key

eval_rc5

-- wait for key pressed

while key_map_volume == 0 loop

get_key

eval_rc5

end loop

hd44780_clear

end if

if powerup_mute == 3 then -- preset

vol_left = powerup_left

vol_right = powerup_right

set_volume

end if

-- restore the last channel selection

set_relays(act_channel)

-- disable muting

muting = high

-- restore last volume setting

if use_ramp == 1 then

write_ramp

write_blank

write_up

ramp_oldval_r = vol_right

ramp_oldval_l = vol_left

vol_right = 0

vol_left = 0

ramp_up

else

set_volume

end if

count = 1

backlight_count = 1

update_values = high

Last edited:

sure that makes sense. i put my info out there as to what I have done and what i got working reliably. it really depends if you want to cobble something together with what you have on hand or something that everyone can do.

I am aware of this too, I wrote my own asm code to use the busy bit to speed up the display routines. I am using MCS bascom-avr compiler, it works like a charm. I bypassed ardunio hw/sw for many reasons. i would not recommend to design using mega or other lower grade parts, esp if you want to add internet connections, you want a path to the largest and fastest mcu, xmega is where it is at using 3.3V logic. everyone has choices to make in there design decisions, it is hard to get conscensis esp with many people stating what they want as far as feature sets go.

you have to wonder about a company like ESS for DIY stuff, when they make designing with there parts difficult. like where are the datasheets and app notes? I have to sign an NDA with them to get any info, what's with that?

So you use "raw code" instead of some proprietary one (arduino).

Whoa ... I think this is actually the same company that supplied the

DOS software at my old factory job.

This stuff runs more with less , polls the hardware.

PS - for those that don't know ... the basic is like a 100K program

in C that needs nothing (small and compact) vs. a Java-like one

that needs a big external library (dependent on everything).

Oh no , the xmega IC ... could I solder that ?? I'm not as young

anymore.

OS

So you use "raw code" instead of some proprietary one (arduino).

Whoa ... I think this is actually the same company that supplied the

DOS software at my old factory job.

This stuff runs more with less , polls the hardware.

PS - for those that don't know ... the basic is like a 100K program

in C that needs nothing (small and compact) vs. a Java-like one

that needs a big external library (dependent on everything).

Oh no , the xmega IC ... could I solder that ?? I'm not as young

anymore.

OS

A srynge of solder paste and a toaster over can solder almost anything. The trick is figuring out how much paste to put on but usually you need more than you think.

A srynge of solder paste and a toaster over can solder almost anything. The trick is figuring out how much paste to put on but usually you need more than you think.

I was thinking initial alignment. I remember those Infineon mosfet pins.

OS

raw code? hum no, i wrote the code in basic "bascom-avr". i use a small bit of asm code for the low level lcd control functions.So you use "raw code" instead of some proprietary one (arduino).

Home - MCS Electronics ?Whoa ... I think this is actually the same company that supplied the

DOS software at my old factory job.

sure you can, it is only 0.8mm pitch in 44 pin pkgOh no , the xmega IC ... could I solder that ?? I'm not as young

anymore.

when I remember designing with hc05/hc11/8051 what a PITA, esp if you are a code hacker like me.

that is exactly what i did with the portable, bottom row for display of menus over the 6 bourns encoders with builtin switches and bi-color leds, covers a lot of bases and makes for ease of use. without this ability the gui is nuts, i have a separate menu for the different functions, AM, FM, MP3 player, USB dac/codec. look a the tons of buttons on the a/d preamp = nuts, many done away with intelligent /dynamic menusOn screen menu selection with buttons around on side and on top or bottom work like the Tektronix TDS 754 type work great and language etc. never a problem.

Last edited:

Not quite like you Rsavas !

I had no problem reverse engineering my 1k arduino code.

Arduino is for dummies , everything in the environment is setup for

their dev boards.

Way bigger learning curve with the AVR (by raw , I meant basic like)

Whoa.

It looks like they did the clock with a WYSIWYG GUI. Too bad there is

not one of these for pre-amp controllers. But who has preamps ?

walmart don't

Wiznet - ahh, clock connects to the www.

OS

I had no problem reverse engineering my 1k arduino code.

Arduino is for dummies , everything in the environment is setup for

their dev boards.

Way bigger learning curve with the AVR (by raw , I meant basic like)

And many other functions, statements and directives

Whoa.

It looks like they did the clock with a WYSIWYG GUI. Too bad there is

not one of these for pre-amp controllers. But who has preamps ?

walmart don't

Wiznet - ahh, clock connects to the www.

OS

I can't find a finished one. Here's the pc board from it though. All that worrying about board layout is overblown. The top of Calvin's head and the rest of his body were RX an TX if I remember correctly.

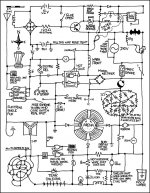

If you think that is funny

Here is our pre-amp schematic (below) -

Board layout at 1mhz is not like at 100mhz , check out the "snakes" on

a PC motherboard.

OS

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analog Line Level

- Pitchfork pre-amplifier