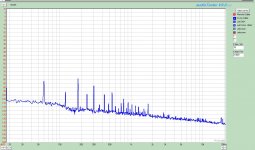

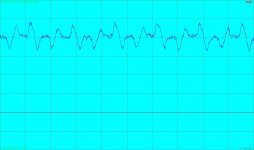

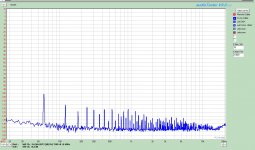

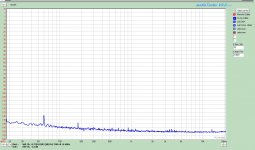

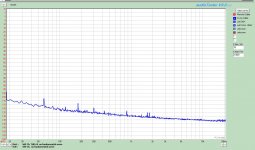

I am trying to troubleshoot my 12b4 Test bed and measurement system. I am finding a hum/noise problem that I can't track down. The test bed is currently a 12b4 with DC filament at 6.3V. Ripple is <1mV. I am running 300V from my Kepco 400B bench supply into a Simplistic HV shunt reg dropping to 280V B+. The shunt is passing 62mA. The Gain stage is a Waveborn Gyrator with the anode voltage set to 140V. Bias Current is 18.1mA. With no signal applied I get the FFT seen in the first attachment. Switching to scope mode the harmonic is clearly seen. The vertical scale is 200uV/div and the timescale is 10mS/div. I couldn't see this before with my Tek2430A scope as it is below the resolution of it.

What do you think would cause this kind of waveform?

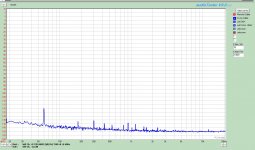

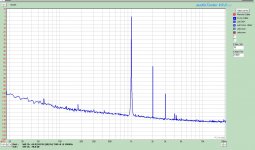

FYI The soundcard is a EMU 1616m and the software is audio tester. The baseline curve with the input cable disconnected from the testbed is seen in the third attachment.

I am thinking that it is an artifact from the incoming power I have here. On a scope my AC line looks like a square wave.

What do you think would cause this kind of waveform?

FYI The soundcard is a EMU 1616m and the software is audio tester. The baseline curve with the input cable disconnected from the testbed is seen in the third attachment.

I am thinking that it is an artifact from the incoming power I have here. On a scope my AC line looks like a square wave.

Attachments

Thanks Rotospec. P.M'd him and read the thread. Alot of work to do to clean this up. I have been lucky (more or less) a couple of times and made some very good clean measurements on my RIAA, but this one is kicking my butt. Making matters worse is that this is to be my test bench for my new preamp.

Nope, Just trying to make the pretty measurements that I see posted here without all the grass. Most importantly I am trying to understand what is causing it so I have confidence in the data I am getting on the DUT.

As it stands now the best I have been able to measure is a 73 S/N ratio as a result of the grass.

As it stands now the best I have been able to measure is a 73 S/N ratio as a result of the grass.

I'm assuming your Y axis is calibrated in dBV - i.e. 0 dB = 1 V rms. Since you mention lab supplies, I'm also assuming that you're dealing with a prototype setup.

-80 dBV hum/ripple on a prototype setup is actually quite good. Recall that some lab supplies switch the rectifiers on/off at 60 Hz when deriving low output voltages. My HP 6209B supply is an example of such a supply. No regulator is perfect and there will be some ripple components present on the output of the supply.

Without having a circuit layout or schematic to look at, it's hard to come up with a qualified guess. But a ground loop could cause hum. In case of a ground loop, the induced hum would drop if the loop is broken or if the loop area is reduced.

~Tom

-80 dBV hum/ripple on a prototype setup is actually quite good. Recall that some lab supplies switch the rectifiers on/off at 60 Hz when deriving low output voltages. My HP 6209B supply is an example of such a supply. No regulator is perfect and there will be some ripple components present on the output of the supply.

Without having a circuit layout or schematic to look at, it's hard to come up with a qualified guess. But a ground loop could cause hum. In case of a ground loop, the induced hum would drop if the loop is broken or if the loop area is reduced.

~Tom

More Info

After reading TheGimp's thread I have started to implement some of the suggestions with some decent results.

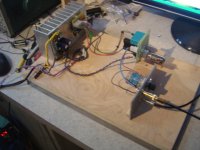

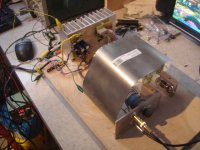

First 0dB=1V. Attached is a couple of photo's of my bench set-up. In the second photo you can see the steel sheet that I placed under the test set-up. I will post a schematic of the system in a minute since it is on another computer.

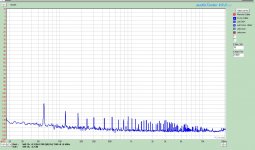

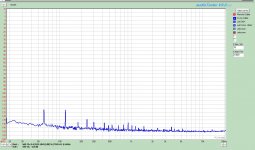

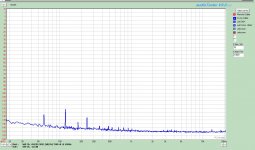

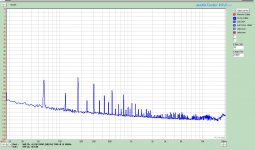

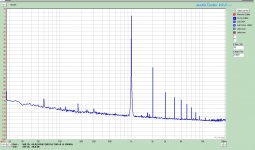

The harmonic grass is certainly coming from noise and/or some ground loops. I get the same grass as my first post even with the system turned off. The first FFT on this post shows the noise spectrum (power off) when the ground of the lab power supply is lifted by a ying/yang diode. The second is a marked improvement when the steel sheet is bonded to the power supply ground. Getting Closer but still not there yet.

In both of these fft's the test equipment is fully hooked up. I also turn the monitor that is close to the test off when making measurements even though it doesn't seem to impact it.

After reading TheGimp's thread I have started to implement some of the suggestions with some decent results.

First 0dB=1V. Attached is a couple of photo's of my bench set-up. In the second photo you can see the steel sheet that I placed under the test set-up. I will post a schematic of the system in a minute since it is on another computer.

The harmonic grass is certainly coming from noise and/or some ground loops. I get the same grass as my first post even with the system turned off. The first FFT on this post shows the noise spectrum (power off) when the ground of the lab power supply is lifted by a ying/yang diode. The second is a marked improvement when the steel sheet is bonded to the power supply ground. Getting Closer but still not there yet.

In both of these fft's the test equipment is fully hooked up. I also turn the monitor that is close to the test off when making measurements even though it doesn't seem to impact it.

Attachments

Further Progress

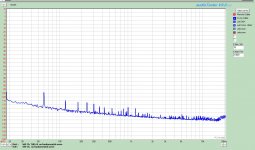

For grins and giggles, I took another piece of sheet steel and loosly bent it over part of the circuit, clipped an aligator clip to it and the plate ground and then measured. In the photo you can see the sheet and the FFT snap shot shows even further improvement. Almost there.

FYI, the filament power is on for these tests.

For grins and giggles, I took another piece of sheet steel and loosly bent it over part of the circuit, clipped an aligator clip to it and the plate ground and then measured. In the photo you can see the sheet and the FFT snap shot shows even further improvement. Almost there.

FYI, the filament power is on for these tests.

Attachments

Redid the cover and bonded it to the shield ground better. onlything left now is a little 60Hz.

1) Photo of Test Bed with improved Cover.

2) FFT of test bed with power and filament off

3) FFT of test bed with power off and filament on.

Not going to complaign about it any more. Time to start testing.

Can see a little 120Hz as a result of the rectification of the filament power. Using some temporary caps right now since I accidently blew up the good ones I had. FYI 10V rated caps won't work here when you have 12Vac. Duh!!!!

1) Photo of Test Bed with improved Cover.

2) FFT of test bed with power and filament off

3) FFT of test bed with power off and filament on.

Not going to complaign about it any more. Time to start testing.

Can see a little 120Hz as a result of the rectification of the filament power. Using some temporary caps right now since I accidently blew up the good ones I had. FYI 10V rated caps won't work here when you have 12Vac. Duh!!!!

Attachments

Summary of what worked

To sum it up.

FFT 1. Original test result. Had ground loops and picked up environmental noise.

Step 1. Broke ground loop between earth ground and circuit ground via ying/yang diodes. Seen in FFT 2.

Step 2. Loosley shielded and bonded shield to earth ground. FFT 3.

Attached FFT's are with the 12b4 fully on at 20mA and 140V anode.

Will make me think twice about building a simple wooden chassis! Certainly one needs to incorporate at least some shielding internal to the box as it will certainly drop the noise floor.

The final 2 FFT shows the test bed with a GE 12b4a jan tube running at 1kHz and a Sylvania 12b4a. Setpoints were not adjusted just rolled tubes. Good to have a clean measurement to see the differences.

Now on the the quest of building my next preamp.

To sum it up.

FFT 1. Original test result. Had ground loops and picked up environmental noise.

Step 1. Broke ground loop between earth ground and circuit ground via ying/yang diodes. Seen in FFT 2.

Step 2. Loosley shielded and bonded shield to earth ground. FFT 3.

Attached FFT's are with the 12b4 fully on at 20mA and 140V anode.

Will make me think twice about building a simple wooden chassis! Certainly one needs to incorporate at least some shielding internal to the box as it will certainly drop the noise floor.

The final 2 FFT shows the test bed with a GE 12b4a jan tube running at 1kHz and a Sylvania 12b4a. Setpoints were not adjusted just rolled tubes. Good to have a clean measurement to see the differences.

Now on the the quest of building my next preamp.

Attachments

Hello SGregory,

Thanks for posting your trials and tribulations. Looks like computer, lighting and any other power supplies in the area grow grass.

Try going to the GoodWill store to the cookie tin department. I have a preamplifier built in a 1991 OREO Christmas cookie tin. The tin fixed the audible hum. Punch a couple of holes, solder a ground lead to the bottom.

The best option is to buy a new cookie tin and eat the Christmas cookies.

DT

All just for fun!

Thanks for posting your trials and tribulations. Looks like computer, lighting and any other power supplies in the area grow grass.

Try going to the GoodWill store to the cookie tin department. I have a preamplifier built in a 1991 OREO Christmas cookie tin. The tin fixed the audible hum. Punch a couple of holes, solder a ground lead to the bottom.

The best option is to buy a new cookie tin and eat the Christmas cookies.

DT

All just for fun!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Wacky Hum and Harmonics