My Tektronix 575 was working last year when I put it aside to work on other projects. Today, I removed all the tubes and to test on my Hickok 580A, mainly to see how the tube tester was working and to clean up the dust inside the 575 curve tracer.

Lesson learned was not to forget to install the 12AU7 tube (V804) in the CRT circuit. Its got -150 volts on the cathode and only 500 volts on the anode. If you forget to reinstall, you might begin to smell all that voltage warming up other components as you stand around wondering why the CRT doesn't work.

In my defense, V804 is in there hiding, and is located away from all but one other tube. I realized I forgot to reinstall it when I started wondering where I got another RCA 12AU7 clear top tube.

All this was done while I was sober as a judge. (My grandfather used to have liquid lunch with a federal judge. They're both long gone).

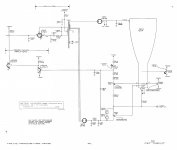

Two of these photos are from retro voltage.com and the schematic is from BAMA website, but mine looks exactly like the photos, even the tubes.

Lesson learned was not to forget to install the 12AU7 tube (V804) in the CRT circuit. Its got -150 volts on the cathode and only 500 volts on the anode. If you forget to reinstall, you might begin to smell all that voltage warming up other components as you stand around wondering why the CRT doesn't work.

In my defense, V804 is in there hiding, and is located away from all but one other tube. I realized I forgot to reinstall it when I started wondering where I got another RCA 12AU7 clear top tube.

All this was done while I was sober as a judge. (My grandfather used to have liquid lunch with a federal judge. They're both long gone).

Two of these photos are from retro voltage.com and the schematic is from BAMA website, but mine looks exactly like the photos, even the tubes.

Attachments

Oops!.

The old tube reliability guidelines suggested never removing a tube to test until it is confirmed it may be bad since the swapping process can stress and cause a tube to fail. They did not mention potential collateral damage if its not returned to the socket.

The old tube reliability guidelines suggested never removing a tube to test until it is confirmed it may be bad since the swapping process can stress and cause a tube to fail. They did not mention potential collateral damage if its not returned to the socket.

Also, one that's working fine in one location may not perform well enough in another.

The only tester I used in my 52 years of electronics was one in a shop I worked in as a teenager, and that was for customers who bought in valves in hope that they could cut costs of the repair. Often that was not the case. We'd find a slightly low emission valve and sell the customer a replacement but usually that wasn't the actual fault.

The only tester I used in my 52 years of electronics was one in a shop I worked in as a teenager, and that was for customers who bought in valves in hope that they could cut costs of the repair. Often that was not the case. We'd find a slightly low emission valve and sell the customer a replacement but usually that wasn't the actual fault.

No damage other than ingesting some heated up electronic component fumes...

I cleaned and tested every tube and calibrated per the manual. It's a real testament to how beefy and well built these machines are, that they can survive and still perform despite the abuse I put this thing through.

I cleaned and tested every tube and calibrated per the manual. It's a real testament to how beefy and well built these machines are, that they can survive and still perform despite the abuse I put this thing through.

The Tek equipment of that era - and the next 15 years or so, was really of the highest quality. I expect the military had better stuff!

It's alive... it's Alive... IT'S ALIVE!!!

After all these weeks, she's all dressed up, calibrated and ready to go. Here's a photo showing the same curves as the Tek 576 at work. Sorry, my iPhone photo skills (or lack of) don't allow me to show the traces properly because of the way the traces pulse on the screen...but they are alike on both machines using 2N4123 transistors.

After all these weeks, she's all dressed up, calibrated and ready to go. Here's a photo showing the same curves as the Tek 576 at work. Sorry, my iPhone photo skills (or lack of) don't allow me to show the traces properly because of the way the traces pulse on the screen...but they are alike on both machines using 2N4123 transistors.

Attachments

I've had a 575 for many years and it's needed a few filter caps and a tube now and then, but those Tek tube scopes were just superbly engineered. As the late Jim Williams said, "they radiated intellectual honesty". My daily scope is 545B that's been remarkably reliable for the last 25-30 years.

Now I see why these machines are so popular today. They are rock solid, dependable and so well engineered that they can be repaired and calibrated easily. I wish I could say that about all the old gear. Lesson to learn is that this Tektronix Curve Tracer suffered through my abuse and lives on. It wouldn't have survived if it was a lesser machine.

- Status

- Not open for further replies.

- Home

- Design & Build

- Equipment & Tools

- Tektronix 575 lesson learned