What is a normal operating temp for subwoofers?

How about a safe temp?

I know it gets difficult because the coil is most likely much hotter than the area which you can see/feel, but what is "safe"?

How about a safe temp?

I know it gets difficult because the coil is most likely much hotter than the area which you can see/feel, but what is "safe"?

That's going to vary by construction. Most pro speakers are wound with polyimide insulated wire which can take temperatures over 200C, but there is also the issue of the material used to bond the wire to the former, and the former to the cone. Low consumer grade speakers sometimes have wire that can't take much over 100C. Some companies use polyimide for the former as well, which doesn't conduct heat so well as aluminum formers, which helps keep the heat away from the triple point gluing. Some formers are made from glass epoxy, or other metals, and their max temp varies. You'd really need to consider the specific driver you're interested in. Running a dozen to failure under carefully selected condition would be the only way to know for sure. I don't think there's any simple answer to that question.

"Normal" would depend on the ambient temperature, one of the few subs I burned was during sine wave testing of a TH with the magnet directly in the hot desert sun.What is a normal operating temp for subwoofers?

How about a safe temp?

I know it gets difficult because the coil is most likely much hotter than the area which you can see/feel, but what is "safe"?

Under those conditions, the magnet structure can get close to boiling temperature without any coil heat. Since heat travels to cold, once the magnet structure is very hot, it no longer will "wick" the heat from the voice coil, and thermal conduction is primarily from the air in the gap.

When using the SpeakerPower SP1-4000 (2400 watts at 4 ohms, 4000 watts at 2 ohms)with pink noise just flickering the amp's limit light driving Lab 12s, it could put the speakers in to thermal compression in a matter of minutes.

The Lab 12 magnet structure was around 150 degrees after that test.

The B&C 18SW115-4 magnet structure hardly raised above ambient temperature with the same test.

As a rough estimate, I'd say if the magnet structure is over 200 F the speaker is no longer "safe".

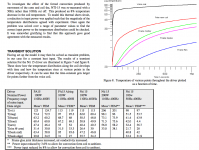

This has useful information:

http://www.cedrat.com/fileadmin/use...02/05/loudspeaker_motor_thermal_behaviour.pdf

Seems from their tests the magnet structure temperature ranges from about 86% to half the voice coil temperature, so a boiling temperature should be OK if the adhesives can withstand 450 F.

http://www.cedrat.com/fileadmin/use...02/05/loudspeaker_motor_thermal_behaviour.pdf

Seems from their tests the magnet structure temperature ranges from about 86% to half the voice coil temperature, so a boiling temperature should be OK if the adhesives can withstand 450 F.

Attachments

So art you were feeding a single 4.29 ohm lab 12 2400 watts? Or was it two (if two, what impedance, 8 or 2 ohms)?

Two in parallel for that test (2.145 ohms minimum), so around 2000 watts peak per driver cold.So art you were feeding a single 4.29 ohm lab 12 2400 watts? Or was it two (if two, what impedance, 8 or 2 ohms)?

Since pink noise has a crest factor of 12 dB (or 14?) the average power would be a bit less than 200 watts, about equal to the Lab 12's AES 400 watt rating (which uses six dB crest factor limited pink noise), but since that much power caused a couple dB power compression, the impedance would be higher than 4.29 ohm so power delivered would decrease accordingly.

The SP1-4000 could cook the Lab 12s with sine wave tones in a hurry, but with music, as long as the limit light only flashes they seem fine.

Art

Interesting to note that, in the Nti 15 test from the cedrat PDF the MAG temp is about half the VC temp 🙂 The PA 15 is not as good !

The 100 watt Nti 15 test shows the magnet at 53% of the voice coil temp, the PA 15 at 59.3%, the PA 15 voice coil temp 6.5% higher.Interesting to note that, in the Nti 15 test from the cedrat PDF the MAG temp is about half the VC temp 🙂 The PA 15 is not as good !

Also interesting that dropping the frequency range by about an octave resulted in 8% less heat due to more air movement.

A good way to cook a speaker is with high power sine wave signal in at Fb, cone movement and impedance both at minimum...

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Subwoofer operating temp