Hey guys. This is just a fun little project I just finished up for a good friend of mine BigDwiz. If you're into old school car audio, you must check out his site if only to reminisce of the good old days  Old School Stereo: Old School Car Audio Tribute Video - Submitted

Old School Stereo: Old School Car Audio Tribute Video - Submitted

Anyway, this is his Power 650 which he essentially wanted "freshened up" and I was happy to help.

Enjoy

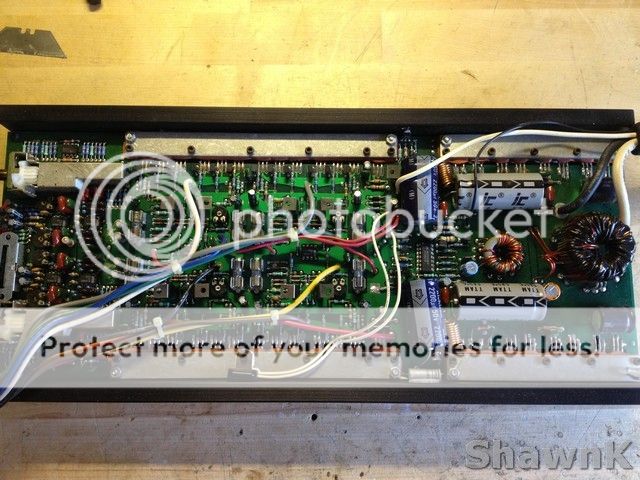

Before pic:

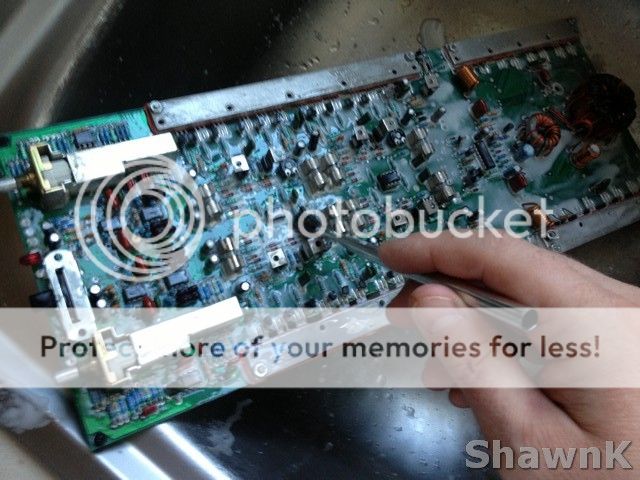

Stripped down and cleaned:

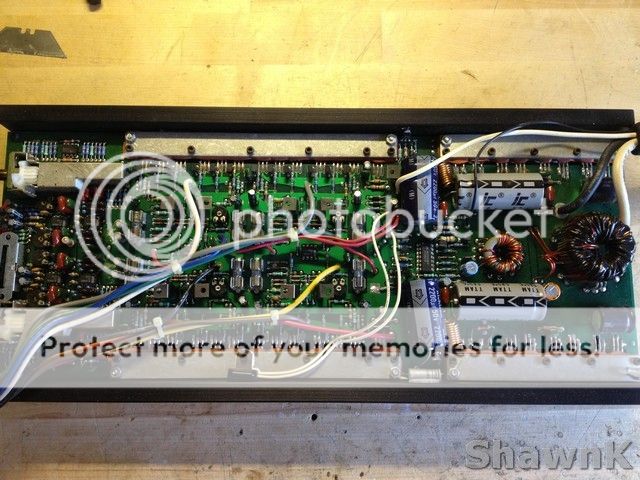

New 8ga power leads installed as well as new supply & rail caps:

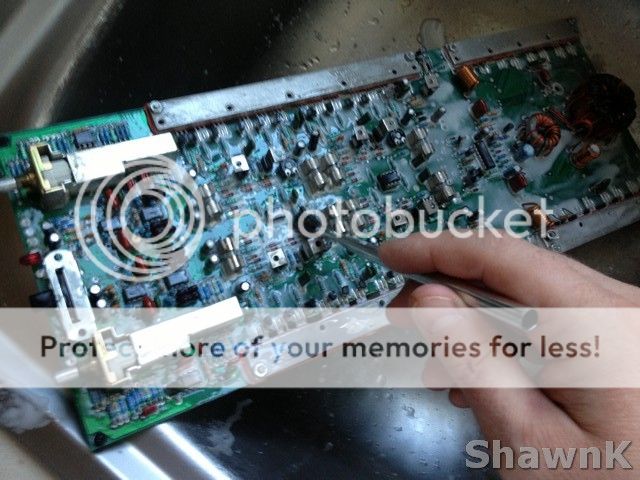

Speaker leads were removed and "tidied up". Rail supply jumpers were relocated to the bottom of the board. New gain pots installed:

Anyway, this is his Power 650 which he essentially wanted "freshened up" and I was happy to help.

Enjoy

Before pic:

Stripped down and cleaned:

New 8ga power leads installed as well as new supply & rail caps:

Speaker leads were removed and "tidied up". Rail supply jumpers were relocated to the bottom of the board. New gain pots installed:

Thanks guys! I'm glad you like, and I appreciate the comments!

I'll be the first to admit that I'm not an experienced tech, but I can honestly say that I "give a damn" more than a lot of true techs out there. From some of the work I have personally seen, it seems like some of these guys just don't care about quality work

I'll be the first to admit that I'm not an experienced tech, but I can honestly say that I "give a damn" more than a lot of true techs out there. From some of the work I have personally seen, it seems like some of these guys just don't care about quality work

It's nice work but I think you have to understand the difference between professional technicians and hobbyists. Professional techs must make x number of dollars/hour to pay the bills, employees, etc... I'm guessing that it took between 6 and 8 hours of time from start to finish (including buying the various parts, cables, etc...) to do this job (unless the amp was in absolutely pristine condition when you started). If a pro tech has to make $50/hour (on the low side for most techs in high-rent districts), that would mean that he would have had to charge $300-400 for that work. It's extremely unlikely that anyone would pay that.

Think of it like this... a person restoring an older vehicle on their own time may take the time to strip the entire inside of a gas tank and re-coat it. A good mechanic would not do anything like this if it wasn't necessary but that doesn't mean he doesn't care.

For most repairs, I do what's necessary to make the amp 100% reliable but I don't generally do anything to it cosmetically. The exception would be if a nice amp came in and had a heatsink or board that was extremely dusty/dirty. In that case, I may clean them up. Otherwise, it's simply not practical (profitable) to do this type of work.

A tech that doesn't care would be (in my opinion)

*someone too lazy to pull a board to replace parts and solders the new parts to the cut legs of the older parts

*someone who uses mismatched parts, even though they know they would get better reliability from matched parts

*someone who sees a problem (like a terminal block that's very near to coming desoldered completely) and doesn't repair it

*someone too lazy to remove all of the old heatsink compound and replace it with new compound

The reason that I'm posting this is because I don't want people to think that their technician is doing substandard work when they fail to do this type of work (unless the owner of the amp is paying them to do precisely this type of work).

Think of it like this... a person restoring an older vehicle on their own time may take the time to strip the entire inside of a gas tank and re-coat it. A good mechanic would not do anything like this if it wasn't necessary but that doesn't mean he doesn't care.

For most repairs, I do what's necessary to make the amp 100% reliable but I don't generally do anything to it cosmetically. The exception would be if a nice amp came in and had a heatsink or board that was extremely dusty/dirty. In that case, I may clean them up. Otherwise, it's simply not practical (profitable) to do this type of work.

A tech that doesn't care would be (in my opinion)

*someone too lazy to pull a board to replace parts and solders the new parts to the cut legs of the older parts

*someone who uses mismatched parts, even though they know they would get better reliability from matched parts

*someone who sees a problem (like a terminal block that's very near to coming desoldered completely) and doesn't repair it

*someone too lazy to remove all of the old heatsink compound and replace it with new compound

The reason that I'm posting this is because I don't want people to think that their technician is doing substandard work when they fail to do this type of work (unless the owner of the amp is paying them to do precisely this type of work).

perry,

just curious....how do you find time to help all of us techs/hobbyists with our problems and still do your day job..

Personally, its hard for me to stay on top with alot of the amps i work on in my spare time. I am a metrologist/electronics engineer for a pharmaceutical company and a father of 3. So, i agree with you about what is needed to make an amp reliable and function vs. making it look good.

just curious....how do you find time to help all of us techs/hobbyists with our problems and still do your day job..

Personally, its hard for me to stay on top with alot of the amps i work on in my spare time. I am a metrologist/electronics engineer for a pharmaceutical company and a father of 3. So, i agree with you about what is needed to make an amp reliable and function vs. making it look good.

Perry is correct, there is a big difference between "Restoration" work, and "Repair" work.

Let me also say I enjoyed seeing the thread post of the "Restoration" work.

I did something similar to support a clients desires on another Forum a while back. But if you factor in the time to the money aspect I made less then $10.00 a hour. I did it to promote proper ethic and technical approach to bringing back the dead to like new or better performance. 25 year old car amps need more work then a 1 or 2 year old car amp, and most clients don't want to pay for such things.

People confuse "factory flat repair rates" with the true cost to do a "restoration repair" on a 30 year old car amp that has no factory support any longer.

I like what you did to the amp. But might i dare to suggest when you replace the large rail caps don't over look the little caps as they take a beating also with age and heat, and have less size and capacity to absorb the heat and noise the switching supply tends to make. Keep up the good work though....

Let me also say I enjoyed seeing the thread post of the "Restoration" work.

I did something similar to support a clients desires on another Forum a while back. But if you factor in the time to the money aspect I made less then $10.00 a hour. I did it to promote proper ethic and technical approach to bringing back the dead to like new or better performance. 25 year old car amps need more work then a 1 or 2 year old car amp, and most clients don't want to pay for such things.

People confuse "factory flat repair rates" with the true cost to do a "restoration repair" on a 30 year old car amp that has no factory support any longer.

I like what you did to the amp. But might i dare to suggest when you replace the large rail caps don't over look the little caps as they take a beating also with age and heat, and have less size and capacity to absorb the heat and noise the switching supply tends to make. Keep up the good work though....

Hi Perry,

Please don't take my previous statement the wrong way. I was a professional installer for 12+ years and it is really the same situation. If I had to put a number on it, I'd say only 25% of the "professional" installers out there actually care about quality work and execution. It's unfortunate, but true. Even within the short time that I've been attempting to do these amp repairs, I've personally seen some pretty shotty work from "professional" techs. Even right now I have an amp on my bench that was elegedly repaired by a well-known, regional repair tech that is, imo, short of adequate. There is heatsink compound plastered all around the internals, the solder joints look like a 5yo did them, a couple of the circuit board's mounting screws are loose, and the soot from the previous malfunction looks like it was just quickly wiped away and never really cleaned up. Keep in mind that this customer already paid $200 This is just one example. Unfortunately, I have seen many more.

This is just one example. Unfortunately, I have seen many more.

I may have come across the wrong way. I wasn't trying to bash ALL techs, and I'm not trying to discourage people from having a tech repair their amps. As with all of the 12v installers out there, there are plenty of great techs I'm sure. It just strikes me that even as a novice, I've personally seen more bad than good.

I aslo wasn't really trying to compare this specific project to the "everyday" repair. You're absolutely right in that a project like this is not cost prohibitive for shops. Especially those with high overhead, but even with the general repair work I attempt to do, I take the time and effort to do quality solder work, cleaning, and testing (I'm just hoping I can expand my technical knowledge) which I don't think is asking too much from a "professional"

Please don't take my previous statement the wrong way. I was a professional installer for 12+ years and it is really the same situation. If I had to put a number on it, I'd say only 25% of the "professional" installers out there actually care about quality work and execution. It's unfortunate, but true. Even within the short time that I've been attempting to do these amp repairs, I've personally seen some pretty shotty work from "professional" techs. Even right now I have an amp on my bench that was elegedly repaired by a well-known, regional repair tech that is, imo, short of adequate. There is heatsink compound plastered all around the internals, the solder joints look like a 5yo did them, a couple of the circuit board's mounting screws are loose, and the soot from the previous malfunction looks like it was just quickly wiped away and never really cleaned up. Keep in mind that this customer already paid $200

I may have come across the wrong way. I wasn't trying to bash ALL techs, and I'm not trying to discourage people from having a tech repair their amps. As with all of the 12v installers out there, there are plenty of great techs I'm sure. It just strikes me that even as a novice, I've personally seen more bad than good.

I aslo wasn't really trying to compare this specific project to the "everyday" repair. You're absolutely right in that a project like this is not cost prohibitive for shops. Especially those with high overhead, but even with the general repair work I attempt to do, I take the time and effort to do quality solder work, cleaning, and testing (I'm just hoping I can expand my technical knowledge) which I don't think is asking too much from a "professional"

just curious....how do you find time to help all of us techs/hobbyists with our problems and still do your day job...

Perry is a robot... only explanation.

Perry is correct, there is a big difference between "Restoration" work, and "Repair" work.

Let me also say I enjoyed seeing the thread post of the "Restoration" work.

I did something similar to support a clients desires on another Forum a while back. But if you factor in the time to the money aspect I made less then $10.00 a hour. I did it to promote proper ethic and technical approach to bringing back the dead to like new or better performance. 25 year old car amps need more work then a 1 or 2 year old car amp, and most clients don't want to pay for such things.

People confuse "factory flat repair rates" with the true cost to do a "restoration repair" on a 30 year old car amp that has no factory support any longer.

I like what you did to the amp. But might i dare to suggest when you replace the large rail caps don't over look the little caps as they take a beating also with age and heat, and have less size and capacity to absorb the heat and noise the switching supply tends to make. Keep up the good work though....

Thanks man!

Again, I apologize if I came off the wrong way. It really is the day to day work that I have seen and been disapointed with.

Yes, this project is certainly not "general repair", but I look at it like I do with installs for instance. Larger (custom) installs are not the norm, and do cost a premium, but there is a market non-the-less

And PLEASE suggest all day long!! haha! I'm completely open and wanting to learn more. Which capacitors specifically would would you recommend replacing on top of what I already have? I don't see it feasible to virtually replace them all, but if there are others I certainly would like to know! Thanks

Thanks man!

Again, I apologize if I came off the wrong way. It really is the day to day work that I have seen and been disapointed with.

Yes, this project is certainly not "general repair", but I look at it like I do with installs for instance. Larger (custom) installs are not the norm, and do cost a premium, but there is a market non-the-less

And PLEASE suggest all day long!! haha! I'm completely open and wanting to learn more. Which capacitors specifically would would you recommend replacing on top of what I already have? I don't see it feasible to virtually replace them all, but if there are others I certainly would like to know! Thanks

Were cool, no hurt feelings here, but thanks for being polite. You should fit in nicely here on this forum, Welcome !

I tend to go overboard and replace then all. It costs just a few dollars, and about a hour or so to do a complete re-cap of the amp. I consider wet capacitors as expendables when looking into a 20 something year old amp. plus bringing back the dead is always so time consuming I say while your there might as well do it completely. It's not like your going to make big money on it what with the time sink it becomes to redress a vintage amp, eh?

And like Perry I also replace all Silicon heatsink compounds, because the silicon grease component tends to creep away with age and heat leaving dry caked Alumina powder filling the voids between the surfaces. Plus it just works better when its still has it silicon grease content. Sil-Pads have replaced that technology nowadays, but here again we are restoring so replacement is always acceptable, and recommended by most transistor manufacturers.

As I said earlier I like what you did with your efforts. usually when I see one of these vintage amps though its been beat to death so there are chores like checking output bias voltage, Dc offsets, etc...oh and of course power testing the amp to see it will withstand a full power operation into multiple load values. On request I also do rebirth sheets showing its output power into test loads with a standard test bench setup. Bringing back the dead always feels better when you know the amp will produce rated power without folding over on itself and letting the smoke out like so many of then do anyway.

After all of that, its hard to make a living just because of the time required to complete all of that work. On newer amps 1 to 5 years old its always easier since less long term age and heat damage are present. usually its just repair all the damaged components and test the amp basically for DC offset, bias and VIOLA ! your back online and in full trim of service. Vintage amps require much more attention to other little details like what you repaired, and then a fair amount more of nit picking and looking for possible issues that age and use cause. Nothing last forever, and I don't care who built it or how much it cost. Everything fails with age, even me..lol lol lol.

Again please keep up your efforts of bringing back the dead. I love the "Doll-up" you did. I call it "Doll-up" because you restored many of the cosmetic issues along with replacing the main caps like you did. Truly a installers touch and I mean that in a complimentary way....

Were cool, no hurt feelings here, but thanks for being polite. You should fit in nicely here on this forum, Welcome !

I tend to go overboard and replace then all. It costs just a few dollars, and about a hour or so to do a complete re-cap of the amp. I consider wet capacitors as expendables when looking into a 20 something year old amp. plus bringing back the dead is always so time consuming I say while your there might as well do it completely. It's not like your going to make big money on it what with the time sink it becomes to redress a vintage amp, eh?

And like Perry I also replace all Silicon heatsink compounds, because the silicon grease component tends to creep away with age and heat leaving dry caked Alumina powder filling the voids between the surfaces. Plus it just works better when its still has it silicon grease content. Sil-Pads have replaced that technology nowadays, but here again we are restoring so replacement is always acceptable, and recommended by most transistor manufacturers.

As I said earlier I like what you did with your efforts. usually when I see one of these vintage amps though its been beat to death so there are chores like checking output bias voltage, Dc offsets, etc...oh and of course power testing the amp to see it will withstand a full power operation into multiple load values. On request I also do rebirth sheets showing its output power into test loads with a standard test bench setup. Bringing back the dead always feels better when you know the amp will produce rated power without folding over on itself and letting the smoke out like so many of then do anyway.

After all of that, its hard to make a living just because of the time required to complete all of that work. On newer amps 1 to 5 years old its always easier since less long term age and heat damage are present. usually its just repair all the damaged components and test the amp basically for DC offset, bias and VIOLA ! your back online and in full trim of service. Vintage amps require much more attention to other little details like what you repaired, and then a fair amount more of nit picking and looking for possible issues that age and use cause. Nothing last forever, and I don't care who built it or how much it cost. Everything fails with age, even me..lol lol lol.

Again please keep up your efforts of bringing back the dead. I love the "Doll-up" you did. I call it "Doll-up" because you restored many of the cosmetic issues along with replacing the main caps like you did. Truly a installers touch and I mean that in a complimentary way....

Thanks a million for your comments and input. I truly do value them!

I really enjoyed this project and to be honest, I really didn't make much on it. Probably in the $2/hr range with the time I had invested

Oh and I had to laugh at your comment: "Everything fails with age, even me..lol lol lol." Man do I hear you. I'm 35, I hit the gym regularly and I'm the strongest I've ever been, but just found out that I already have severe arthritis in both of my shoulders (it's hereditary

WOW that was alot of reading to catch up on this post!!!

lol.. just chatn' away

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Car Audio

- Restored Rockford Power 650 w/internal pics!