I see some of the amplifiers have no mica or silicon sheets between the transistor and the output heatsink. What topology is it?

It's common solution in PA amplifiers. Just check out any new Dynacord amplifiers, such as CL1600. The heatsinks are isolated from the box, and are acting as power rails as well.

I'm working on a same solution.

Sajti

Attachments

Regarding output devices capacity is it better or worse to isolate the HS from the output devices?

Like here: http://www.diyaudio.com/forums/vend...e-mosfet-amplifier-module-47.html#post4582999

Like here: http://www.diyaudio.com/forums/vend...e-mosfet-amplifier-module-47.html#post4582999

Regarding output devices capacity is it better or worse to isolate the HS from the output devices?

Like here: http://www.diyaudio.com/forums/vend...e-mosfet-amplifier-module-47.html#post4582999

If You use common emitter output stage, where the collector and the case are on the rail voltage, there is no any problem with the capacitance.

Sajti

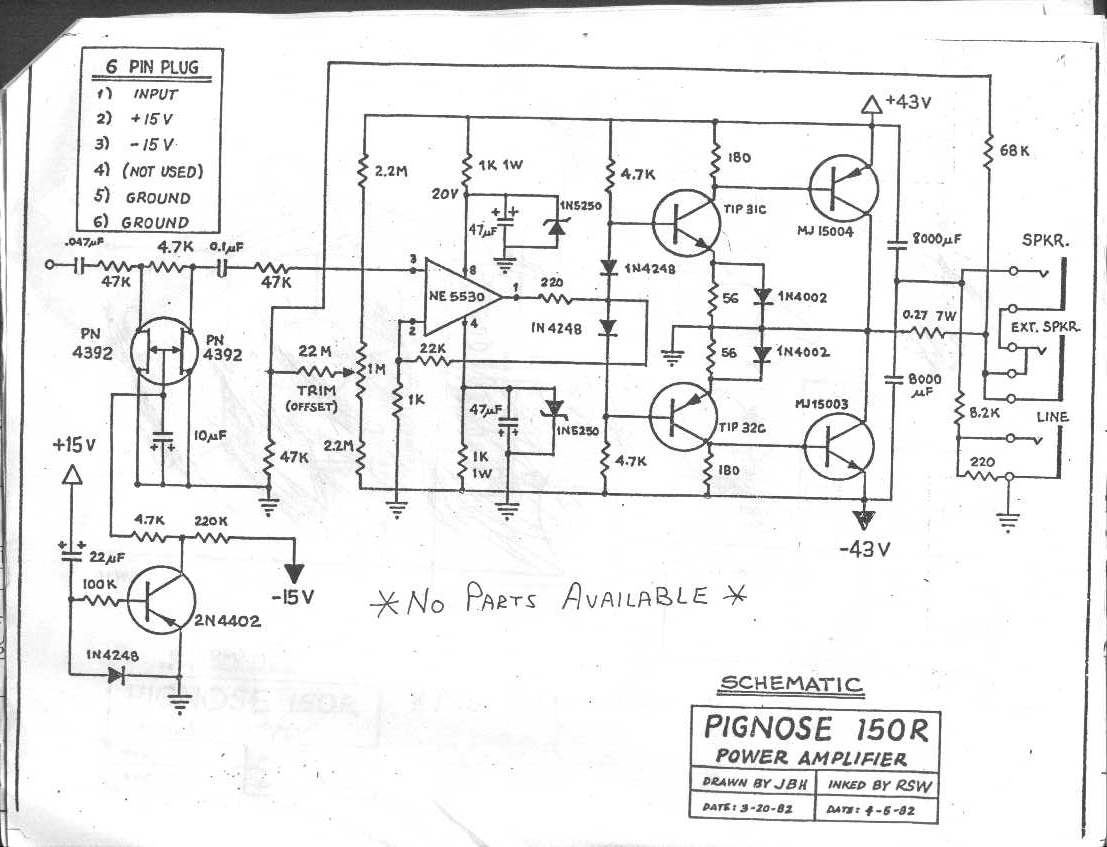

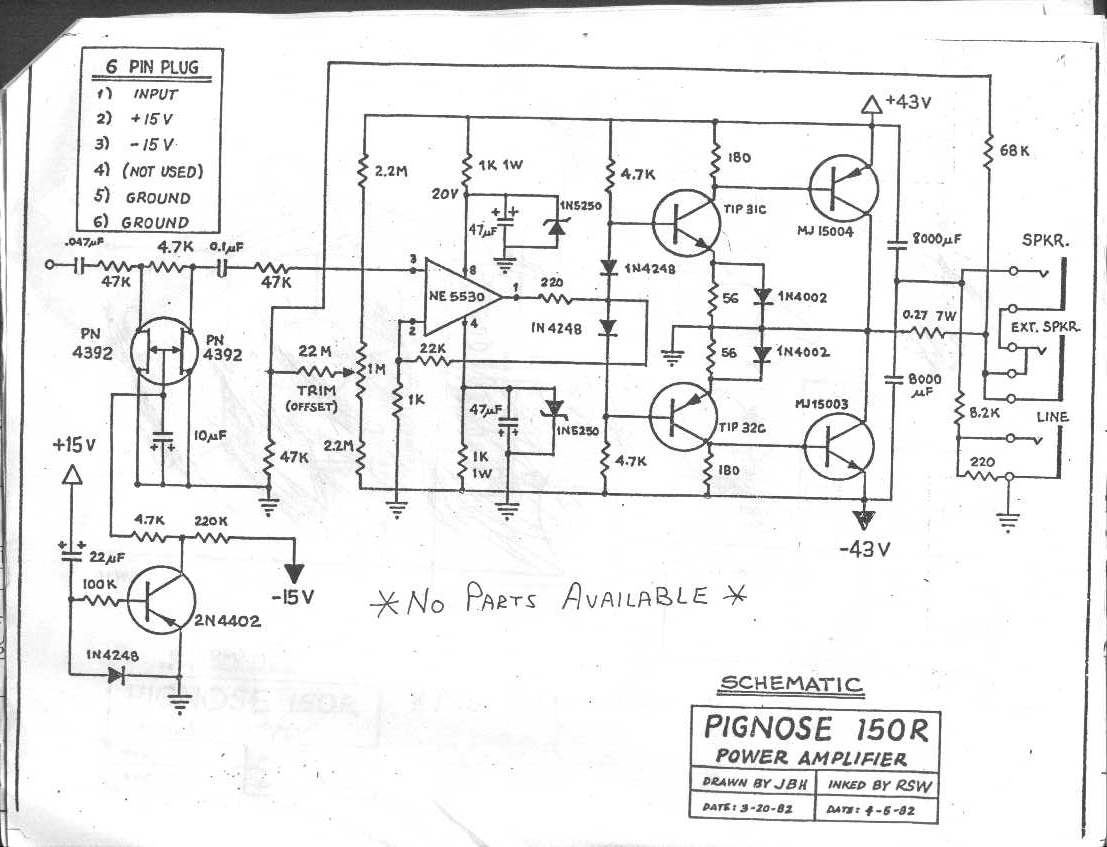

Oh, nothing new under the Sun: there's an old established design type which straight grounds power transistor collectors, so no need for mica/silpads nor to float heatsinks, which in low power versions may even be the chassis itself:

Pignose 150R Crossmix (1982):

pioneered by very high powered QSC PA rack amplifiers.

Grease must still be used, of course.

Pignose 150R Crossmix (1982):

pioneered by very high powered QSC PA rack amplifiers.

Grease must still be used, of course.

http://www.qsc.com/resource-files/p...x_legacy/cx4/q_amp_cxlegacy_cx4_schematic.pdf

QSC amplifiers use the type of circuit referred to by OP. The output transisters can be mounted directly on the heatsink and also connected to box. The power supply is isolated.

QSC amplifiers use the type of circuit referred to by OP. The output transisters can be mounted directly on the heatsink and also connected to box. The power supply is isolated.

what are the pros of using such direct mounting? one advantage is heat can be transferred faster. But how about if heatsinks are used on the sides of the amplifiers and the amp is running at above +80V so even the DC at that voltage will give some sort of shock.

Hi,

the pros:

- no insulator means better cooling. You can allow higher heatsink temperature, which means smaller heatsink. Mica washer can have 0.5K/W, which means 25degree higher juction temperature with 50W dissipation. You can save this 25degree

- using the heatsink as power supply rail means lower impedance on the rail, comparing to the PCB. And better safety in case of failure, because the copper from the pcb will no vaporize

Cons:

- complicated mechanical works, because of the isolation of the heatsink

- dangerous voltage inside the amp, which easily kill you, if You not careful enough

The amplifier on the attaached picture running +/-55/110V class H with live heatsink.

Sajti

Attachments

What +80V?

In the configuration shown above heatsinks are grounded, literally, so sit at 0V .

Conventional (common collector) amplifier means, that the rails are running on the heatsink.

QSC solution with the grounded heatsink looks very elegant, but sometime I feel, that they sacrifice too much from the sound quality to be able to do it.

Crest use live heatsink in the ProX200 series, but it's connected to the output, which is another possibility using common emitter output stage.

Sajti

Conventional (common collector) amplifier means, that the rails are running on the heatsink.

QSC solution with the grounded heatsink looks very elegant, but sometime I feel, that they sacrifice too much from the sound quality to be able to do it.

Crest use live heatsink in the ProX200 series, but it's connected to the output, which is another possibility using common emitter output stage.

Sajti

Dear Sajti,

Can you kindly elaborate about the sacrifices in sound quality ?

--gannaji

Dear Sajti,

Can you kindly elaborate about the sacrifices in sound quality ?

--gannaji

Hi,

using the output stage as common emitter section increase the nonlinearity of it. The loop feedback can reduce it somewhat, but not totally. QSC use no any local feedback, or local compensation. They keep the driver as simple as possible, which also not able to help enough.

Check the Crest solution with local feedback loop around the output stage. It sounds better comparing to QSC.

But of course this is just my personal taste.

Sajti

Well, the last thing I would call a typical QSC power amp is "simple". What with multiple power rails commutating, and separate little cards to control that, simple is the last thing I'd call them.

In a typical QSC, the TO3 outputs were bolted right to a grounded heat sink, with the emitters towards the power rails. They sound good enough for touring professionals.

You can make the case for direct contact to a heat sink as "better" heat transfer than through a mica or silicone insulator, but really, either method can easily be designed for proper heat removal, so it really is more a matter of how you want to do it, rather than heat. Either way works just fine.

Same argument for different topologies. We can point to one amp of one topology that sounds better than a different amp of another topology, but to blame the topology is to assume nothing else about the amps was different. Exellent sounding and performing amps can be made in any number of topologies, and the quality of the design is the determining factor, not the topology chosen.

So if you are looking for this answer is right and all others wrong, well, you won't find it.

In a typical QSC, the TO3 outputs were bolted right to a grounded heat sink, with the emitters towards the power rails. They sound good enough for touring professionals.

You can make the case for direct contact to a heat sink as "better" heat transfer than through a mica or silicone insulator, but really, either method can easily be designed for proper heat removal, so it really is more a matter of how you want to do it, rather than heat. Either way works just fine.

Same argument for different topologies. We can point to one amp of one topology that sounds better than a different amp of another topology, but to blame the topology is to assume nothing else about the amps was different. Exellent sounding and performing amps can be made in any number of topologies, and the quality of the design is the determining factor, not the topology chosen.

So if you are looking for this answer is right and all others wrong, well, you won't find it.

Well, the last thing I would call a typical QSC power amp is "simple". What with multiple power rails commutating, and separate little cards to control that, simple is the last thing I'd call them.

Yes, they are complicated. But the amplifier stage itself is very simple.

You can make the case for direct contact to a heat sink as "better" heat transfer than through a mica or silicone insulator, but really, either method can easily be designed for proper heat removal, so it really is more a matter of how you want to do it, rather than heat. Either way works just fine.

Yes this is absolutely true. The only question is the price of it. Using insulator means worse heat transfer. You need to use more output devices and/or bigger heatsink to be able to get out high power.

but to blame the topology is to assume nothing else about the amps was different.

I don't blame the topology itself, but the implementation method of the topology.

Sajti

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- output stage for direct contact with the heatsink without mica/silicon washer