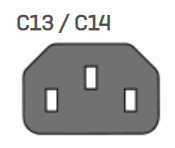

It is always convenient to design a new build around an IEC standard power adaptor, and generally people opt for the C13/C14 type, which is similar to (but not the same as) a 'kettle cord'.

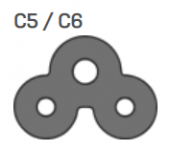

There is another polarised type with earth connector, the C5/C6, aka 'Cloverleaf' or 'Mickey Mouse' connector. It is rated to 2.5A, 7A in the US, so should be meaty enough for any amp with a 300VA power transformer, with plenty of margin for safety.

I'd like to retrofit some Quad II's with earthed power leads, and there is just insufficient room in the old voltage selector window for the C13/C14 type. Rather than hack the old chassis, I could fit a C5/C6 type with no surgery required.

To be on the safe side, I was wondering if there is there any safety reason not to do this?

There is another polarised type with earth connector, the C5/C6, aka 'Cloverleaf' or 'Mickey Mouse' connector. It is rated to 2.5A, 7A in the US, so should be meaty enough for any amp with a 300VA power transformer, with plenty of margin for safety.

I'd like to retrofit some Quad II's with earthed power leads, and there is just insufficient room in the old voltage selector window for the C13/C14 type. Rather than hack the old chassis, I could fit a C5/C6 type with no surgery required.

To be on the safe side, I was wondering if there is there any safety reason not to do this?

Attachments

There is another polarised type with earth connector, the C5/C6, aka 'Cloverleaf' or 'Mickey Mouse' connector. It is rated to 2.5A, 7A in the US, so should be meaty enough for any amp with a 300VA power transformer, with plenty of margin for safety.

I cant answer your question, but thanks for the info on this shape of IEC! I was not aware but now I do remember seeing them on stuff. Three clean hole punches to fit it rather than spending over an hour of cussing while trying to machine a decent IEC hole, nice.

An hour of cussing? I cut out a hole for the IEC connector with a cut off disc in my Dremel in under 5 minutes... Might not be perfect, but it fits and if it's not a perfect hole it doesn't matter since nobody looks at the back of the amp anyway

I'm a perfectionist I guess, when I look at the back side of the thing in a crooked hole I'm bothered!

My favorite is the Neutrik PowerCON connectors. They're pretty common on theatrical lighting and pro audio equipment these days. They're a nice, reliable locking connector and they use the same D-series mounting just like their XLR connectors.

The only downside is that they can't be disconnected under load, so probably not for a mass-market consumer product, but I really like them. No need to do awful chassis work, a standard 15/16 inch chassis punch and two screw holes and you're done.

The only downside is that they can't be disconnected under load, so probably not for a mass-market consumer product, but I really like them. No need to do awful chassis work, a standard 15/16 inch chassis punch and two screw holes and you're done.

My favorite is the Neutrik PowerCON connectors. ...

The only downside is that they can't be disconnected under load ...

Neutrik has a new line of connectors with breaking capacity. See for example: NAC3FPX-WOT-TOP | Neutrik

cheers, Derek

I have seen a type of IEC socket that has a built-in fuse holder and a power switch on one side. Like this:

Loops IEC C14 Switched & Fuse Power Socket -10A Snap: Amazon.co.uk: Electronics

Loops IEC C14 Switched & Fuse Power Socket -10A Snap: Amazon.co.uk: Electronics

Good Thursday everyone,

This is how I solved using a 3 wire power cable. This is a standard military/industrial connector. You can find them for $10 or less on "that" auction site. I found the mating connector with power cord already attached for $1/per. Bought 25 though I will never, ever use 25.

Ray

This is how I solved using a 3 wire power cable. This is a standard military/industrial connector. You can find them for $10 or less on "that" auction site. I found the mating connector with power cord already attached for $1/per. Bought 25 though I will never, ever use 25.

Ray

Attachments

My answer is that C13/14 cable is common and available almost everywhere. Whenever you need a power cable you can obtain it locally.It is always convenient to design a new build around an IEC standard power adaptor, and generally people opt for the C13/C14 type, which is similar to (but not the same as) a 'kettle cord'.

There is another polarised type with earth connector, the C5/C6, aka 'Cloverleaf' or 'Mickey Mouse' connector. It is rated to 2.5A, 7A in the US, so should be meaty enough for any amp with a 300VA power transformer, with plenty of margin for safety.

I'd like to retrofit some Quad II's with earthed power leads, and there is just insufficient room in the old voltage selector window for the C13/C14 type. Rather than hack the old chassis, I could fit a C5/C6 type with no surgery required.

To be on the safe side, I was wondering if there is there any safety reason not to do this?

Neutrik has a new line of connectors with breaking capacity. See for example: NAC3FPX-WOT-TOP | Neutrik

cheers, Derek

This is very cool- Not that the breaking issue has ever been a problem for me, but it's still neat to see that they have them.

Good Thursday everyone,

This is how I solved using a 3 wire power cable. This is a standard military/industrial connector. You can find them for $10 or less on "that" auction site. I found the mating connector with power cord already attached for $1/per. Bought 25 though I will never, ever use 25.

Ray

That's quite a nice solution, and those military connectors are bulletproof.

Also, because idiots keep doing it, please, please, please do not use XLR or SpeakON connectors for power applications. I see people in upper-level EE classes doing it, and it drives me insane. Aside from the obvious safety concerns, someone will inevitably plug that XLR into the input of a power amp or (worse) a console and blow it up.

The OP said he'd prefer to avoid metal work, which I can understand well, especially 'cause this inevitably would reduce the value of his classic gear. Even if the PowerCon's round body would fit into the given hole, which I'm not too sure of, he'd have to drill two additional 3 mm holes for the mounting screws.My favorite is the Neutrik PowerCON connectors. They're pretty common on theatrical lighting and pro audio equipment these days. They're a nice, reliable locking connector and they use the same D-series mounting just like their XLR connectors.

Best regards!

Also, because idiots keep doing it, please, please, please do not use XLR or SpeakON connectors for power applications. I see people in upper-level EE classes doing it, and it drives me insane. Aside from the obvious safety concerns, someone will inevitably plug that XLR into the input of a power amp or (worse) a console and blow it up.

My father brought back from WWII a couple of German field telephones. He used standard US two conductor power plugs and jacks to connect the telephone wires together. Years later as children we found them in a closet and first thing we did was plug them into a wall outlet. When the smoke cleared we ran to dad to find out what was wrong with them...

... reason not to do this?

It's a sewing machine connector.

Yes, widely adapted by laptops and even audio.

Within the 2.5A rating it seems to check all the boxes of the so-called "IEC" connector.

It serves the same function, so go for it. Avoiding sheet metal work is always good.

Also buying in sheet metal stamps can be very expensive.

The round ones aren't bad but IEC ones are very expensive.

Especially is just to be used once or twice.

Unless you buy one for the job then bang it on ebay when your finished.

That's quite a nice solution, and those military connectors are bulletproof.

Also, because idiots keep doing it, please, please, please do not use XLR or SpeakON connectors for power applications. I see people in upper-level EE classes doing it, and it drives me insane. Aside from the obvious safety concerns, someone will inevitably plug that XLR into the input of a power amp or (worse) a console and blow it up.

Wow, that's a staggeringly bad idea "let's use a low level signal connector for a high voltage source capable of delivering high current"

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- IEC Power Connector