Dear friends, I bring here a challenge from a dream of many years that is getting closer every day.

I am assembling the magnetic assembly to receive the recone kit from a commercial speaker.

It will not be commercialized but made available here in my DIY community, we have good diy amplifiers, but lack of speakers, we have absolutely nothing for a quality residential system.

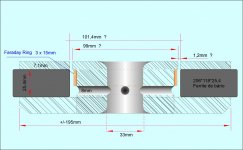

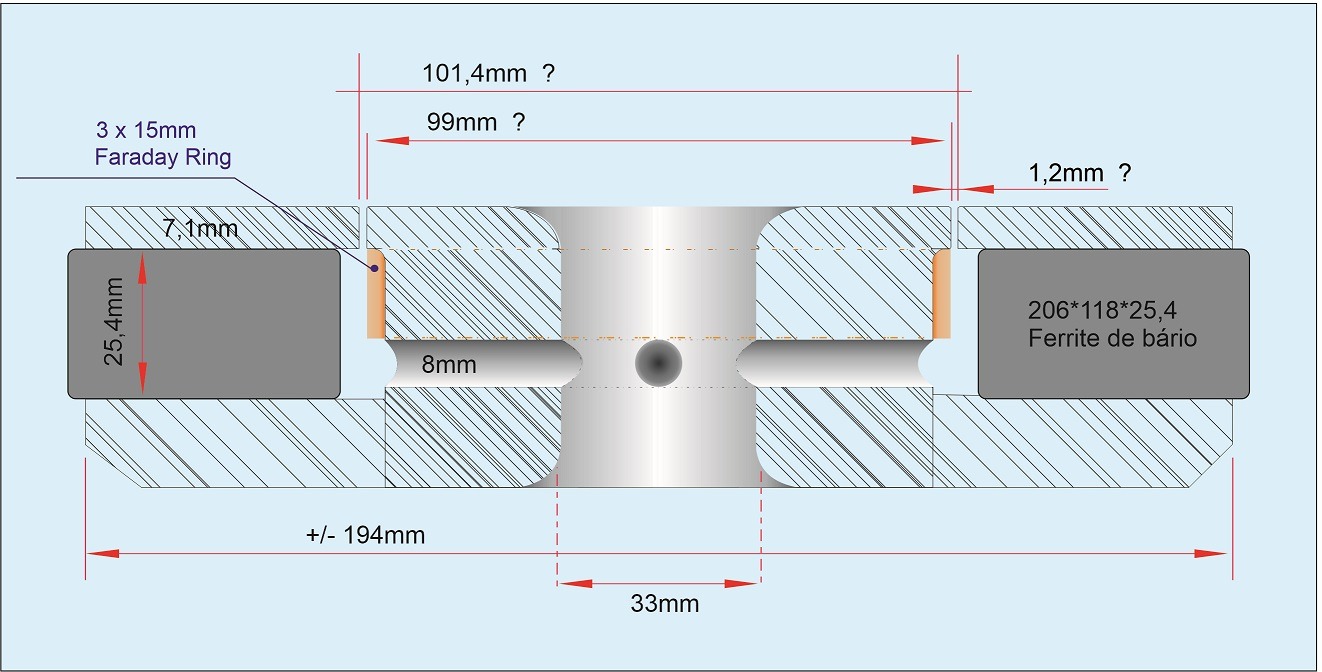

This drawing is amateur, I'm not a professional designer, but I ordered a drawing in SW that will be ready soon.

*I got inspired by the JBL2235H and made some changes

I am assembling the magnetic assembly to receive the recone kit from a commercial speaker.

It will not be commercialized but made available here in my DIY community, we have good diy amplifiers, but lack of speakers, we have absolutely nothing for a quality residential system.

This drawing is amateur, I'm not a professional designer, but I ordered a drawing in SW that will be ready soon.

*I got inspired by the JBL2235H and made some changes

Attachments

Last edited:

Updating information:

That would be the cone for this project.

SS Audio Recone Kit for JBL 2230, 2231, 2234, 2235, RK-JBL2235H

https://reconingspeakers.com/produc...2234h-2235h-136a-15-pre-assembled-recone-kit/

https://qsr.net.au/shop/speaker-parts/speaker-cones/jbl-2235h-cone/

That would be the cone for this project.

SS Audio Recone Kit for JBL 2230, 2231, 2234, 2235, RK-JBL2235H

https://reconingspeakers.com/produc...2234h-2235h-136a-15-pre-assembled-recone-kit/

https://qsr.net.au/shop/speaker-parts/speaker-cones/jbl-2235h-cone/

Oi Sílvio, parabéns.

Where/how will you magnetize that beast?

What about speaker frame?

Cast, I suppose?

Post pictures when you have the physical parts available.

PS: how will you cover the mids-highs cabinet section?

Hello JMFhey! Thank you for participating.

I had the personalized magnets made, they will be delivered magnetized. Some questions I need support. I don't know if I should buy the medium magnetism factor or the strongest, they are arranged like this: Y30, Y35, Y40.

The basket I intend to buy in China.

https://www.alibaba.com/product-det...00138621911.html?spm=a2700.9114905.0.0.drs7NUAs for the medium-high cabinets that I have not defined, I need my product parameters to be able to decide.

I am clueless in this but adding this to my watch thread out of interests.

However, I am wondering, if you are getting the basket in China, and the magnet magnetized from another source, how are you intending to assemble them? IIRC, the magnets in for example a JBL compression driver is so strong it is totally immovable from the casing when magnetized. They need to demagnetize it in order to realign the gap.

I wonder if you will have the same issue.

However, I am wondering, if you are getting the basket in China, and the magnet magnetized from another source, how are you intending to assemble them? IIRC, the magnets in for example a JBL compression driver is so strong it is totally immovable from the casing when magnetized. They need to demagnetize it in order to realign the gap.

I wonder if you will have the same issue.

I guess you are using Koim~as magnetic circuits, custom made to your orders.

Which they supply magnetized, of course.

I asked because magnetizers are the single most expensive and complicated machine needed to make speakers from scratch, almost nobody has their own.

I have 2 1/2 of them he he, the 1/2 meaning I haven´t yet completed the huge (fridge size) capacitor bank needed do 190 to 250mm magnets, like the one you show.

Don´t you have Customs problems bringing the cast frames in?

Brazil DOES protect its own Industry, combining Tariff and bureaucratic red tape.

Which they supply magnetized, of course.

I asked because magnetizers are the single most expensive and complicated machine needed to make speakers from scratch, almost nobody has their own.

I have 2 1/2 of them he he, the 1/2 meaning I haven´t yet completed the huge (fridge size) capacitor bank needed do 190 to 250mm magnets, like the one you show.

Don´t you have Customs problems bringing the cast frames in?

Brazil DOES protect its own Industry, combining Tariff and bureaucratic red tape.

He´s getting the fully assembled and magnetized magnetic circuit, which is then bolted to a cast aluminum frame, which is non magnetic, so no big deal.I am clueless in this but adding this to my watch thread out of interests.

However, I am wondering, if you are getting the basket in China, and the magnet magnetized from another source, how are you intending to assemble them? IIRC, the magnets in for example a JBL compression driver is so strong it is totally immovable from the casing when magnetized. They need to demagnetize it in order to realign the gap.

I wonder if you will have the same issue.

Look at the CAD drawing above, you´ll see a ferrite ring sandwiched between 2 iron disks, with a polepiece at the center.

I will bring the basket from China yes.He´s getting the fully assembled and magnetized magnetic circuit, which is then bolted to a cast aluminum frame, which is non magnetic, so no big deal.

Look at the CAD drawing above, you´ll see a ferrite ring sandwiched between 2 iron disks, with a polepiece at the center.

I'm only making the 15" speaker, the midrange and tweeter will be commercials for other brands.

I'm not making a JBL cabinet, just a speaker with its repair kit, it has good properties.

They own the magnetizing machine and provide Y30, Y35, Y40.

Last edited:

I guess you are using Koim~as magnetic circuits, custom made to your orders.

Which they supply magnetized, of course.

I asked because magnetizers are the single most expensive and complicated machine needed to make speakers from scratch, almost nobody has their own.

I have 2 1/2 of them he he, the 1/2 meaning I haven´t yet completed the huge (fridge size) capacitor bank needed do 190 to 250mm magnets, like the one you show.

Don´t you have Customs problems bringing the cast frames in?

Brazil DOES protect its own Industry, combining Tariff and bureaucratic red tape.

I'm not buying from Koimas, another local company will produce 300$ of a minimum "lot" to customize.

I will have customs problems yes, I didn't find another way, I don't find them in Brazil.

Last edited:

The drawing is amateur, I'm waiting for the CAD SW. Note that I have inserted a horizontal hole so that the air circulation is sucked and pumped from the gap spaceHe´s getting the fully assembled and magnetized magnetic circuit, which is then bolted to a cast aluminum frame, which is non magnetic, so no big deal.

Look at the CAD drawing above, you´ll see a ferrite ring sandwiched between 2 iron disks, with a polepiece at the center.

He´s getting the fully assembled and magnetized magnetic circuit, which is then bolted to a cast aluminum frame, which is non magnetic, so no big deal.

Look at the CAD drawing above, you´ll see a ferrite ring sandwiched between 2 iron disks, with a polepiece at the center.

I understand now! I didn't realize 1) the magnetic assembly is full assembled, so it will be magnetized when assembled as a unit, and 2) the basket/frame is non-magnetic.

Yes, they are independent, and at a later stage bolted together:

As of magnetic grade, get the highest number available.

Here´s a comparison between Y30, which I find similar to "classic" ferrite, and Y40 which I see as improved.

Classic remanent magnetism Br was 3800-4000 mT (milli Tesla, I still call them Gauss, go figure , whitebeard Engineer here ), modern ones not only improves that to 4400 and above, but also very important, are much "harder" so you can use thicker gaps without much magnetic loss or use thinner rings , saving money and weight.

), modern ones not only improves that to 4400 and above, but also very important, are much "harder" so you can use thicker gaps without much magnetic loss or use thinner rings , saving money and weight.

It also makes it harder to magnetize

As of magnetic grade, get the highest number available.

Here´s a comparison between Y30, which I find similar to "classic" ferrite, and Y40 which I see as improved.

Classic remanent magnetism Br was 3800-4000 mT (milli Tesla, I still call them Gauss, go figure , whitebeard Engineer here

It also makes it harder to magnetize

This gentleman looks like he's from Spain, he teaches how to make a magnetizer with a coil of continuous aluminum tape.I guess you are using Koim~as magnetic circuits, custom made to your orders.

Which they supply magnetized, of course.

I asked because magnetizers are the single most expensive and complicated machine needed to make speakers from scratch, almost nobody has their own.

I have 2 1/2 of them he he, the 1/2 meaning I haven´t yet completed the huge (fridge size) capacitor bank needed do 190 to 250mm magnets, like the one you show.

Don´t you have Customs problems bringing the cast frames in?

Brazil DOES protect its own Industry, combining Tariff and bureaucratic red tape.

I don't understand the language perfectly, but you can subtitle.

Este mundo globalizado! 👀rsrsThanks, I´m Argentine, so Spanish is my native tongue.

And also fluent in Brazilian Portuguese.

By the way, sold many Guitar speakers in Brazil.

This globalized world lol!

I had a problem:I guess you are using Koim~as magnetic circuits, custom made to your orders.

Which they supply magnetized, of course.

I asked because magnetizers are the single most expensive and complicated machine needed to make speakers from scratch, almost nobody has their own.

I have 2 1/2 of them he he, the 1/2 meaning I haven´t yet completed the huge (fridge size) capacitor bank needed do 190 to 250mm magnets, like the one you show.

Don´t you have Customs problems bringing the cast frames in?

Brazil DOES protect its own Industry, combining Tariff and bureaucratic red tape.

The company that makes the magnet is not the same company that makes the Iron Set, Top Pole and "T". It is not recommended to magnetize separately, and I don't have the machine.

Are there any aluminum basket suppliers in the US?Thanks, I´m Argentine, so Spanish is my native tongue.

And also fluent in Brazilian Portuguese.

By the way, sold many Guitar speakers in Brazil.

You can´t spread it all over the place.I had a problem:

The company that makes the magnet is not the same company that makes the Iron Set, Top Pole and "T". It is not recommended to magnetize separately, and I don't have the machine.

I guess you got somebody with a CNC lathe to make the iron parts, then are buying the Ferrite magnet somewhere else (they are definitely not "making" it for you since smallest batch is 5 to 10 Tons), then assembling it at home then getting it magnetized (you won´t buy a BIG magnetizer, capable of 250-270mm magnets just to make a few).

Unless you are making, say, 5000 speakers within a year, your best bet is to work with somebody offering that service "all under one roof".

Be glad you have one such Company in Brazil:

https://www.koimas.com.br/

they custom make whatever you need, under your own specs; they will give you the ready built and assembled magnetic system, ready to bolt to frame and finish your custom JBL clone.

They make that for Selenium, Novik and many car speaker manufacturers.

Just curious, how many speakers do you want to make?

Not sure, but I bet most if not all are resellers, so avoid the middle man and buy straight from China.Are there any aluminum basket suppliers in the US?

"Buying" (individuals) and "Importing" (established Companies) is not the same.

If you buy just "samples", say 2 or 4 to test the idea, buy from China, have them sent by Courier, either ane of the big ones or EMS, you will pay fixed Tariff: 60% over actual cost + shipping

Expensive but the short easy path.

If you need, say, 100 or more (>500 would be best), then Import.

You will pay way less: space in a container (very cheap) and just Tariff and taxes which apply.

You will not have the required Importer registration number (I could never get mine ) but there are many people offering that service for a fee, what I did way back then.

Ok, good luck with your project.

CARCAÇA 15.8 Alumínio Injetado 15" Diâmetro do furo 127mm Furação centro a centro: 148mm Bobina 99Be glad you have one such Company in Brazil:

https://www.koimas.com.br/

they custom make whatever you need, under your own specs; they will give you the ready built and assembled magnetic system, ready to bolt to frame and finish your custom JBL clone.

They make that for Selenium, Novik and many car speaker manufacturers.

Just curious, how many speakers do you want to make?

CARCASS 15.8 Injected Aluminum 15" Hole Diameter 127mm Center-to-center drilling: 148mm Coil 99

---------------------

I will study the possibility of buying this aluminum basket from them, which will save me from having to import from China.

I sent a message to the company and I'm waiting for an answer about the possibility of them producing everything in one place.

My capital is small, companies like this demand large volumes, I believe I won't be able to.

The other company sells me 100$ worth of what is in stock, and they produce 300$ customized (it's a small volume so I need it)

Last edited:

[Vale ressaltar que não estou clonando, as medidas são diferentes, não existe design semelhante, vou usar apenas o kit recone]they custom make whatever you need, under your own specs; they will give you the ready built and assembled magnetic system, ready to bolt to frame and finish your custom JBL clone.

They make that for Selenium, Novik and many car speaker manufacturers.

Just curious, how many speakers do you want to make?

It is worth mentioning that I am not cloning, the measurements are different, there is no similar design, I will only use the recone kit

-----------

[Em AsTarifa de 60% são sobre o custo totla, não somente sobre o produto. 60% sobre produto real + frete.]

A tarifa de 60% incide sobre o custo total, não apenas sobre o produto. 60% no produto real + frete tributado também.

--------

I have to take into account that the final product may not sound good, it may not have good parameters, so I can't order a lot, besides not having money. I need a prototype by the hour.

Last edited:

- Home

- Design & Build

- Construction Tips

- 🟢 DIY speaker engineering