I do not see that as impossible. Power line decoupling is probably the most critical but should be doable.

A logical issue is of course that when you have put the TPA3116 or TPA3255 on the PCB as SMT component, why would you then swap to "through-hole" for the rest?

Welllll.... I'm not sure. One thought was easier servicing and then these old eyes aren't getting any better... Mostly it's a curiosity question.

Welllll.... I'm not sure. One thought was easier servicing and then these old eyes aren't getting any better... Mostly it's a curiosity question.

I can follow your logic but it is not the words of a man that wants our Ponzi-economy to continue. With other words, SMT is "invented" for cheap automated assembly but not to facilitate repair. Defect? - buy new, buy new! We the DIY'ers are just a small splinter in the finger of the general consumption. Also I prefer working with through-hole components. SMT-repair is possible with the appropriate gear and good magnifying goggles such as used by dentists.

We the DIY'ers are just a small splinter in the finger of the general consumption. Also I prefer working with through-hole components. SMT-repair is possible with the appropriate gear and good magnifying goggles such as used by dentists.

Hey, I'm no fan of "designed for the dump" and made a career out of fixing stuff. When I rejoined the DIY thing about 4 1/2 years ago I promised myself that anything I built would be a good example of a serviceable product.

But before I launch into something big, I want to be sure that through hole is still a viable build technique. I know there are some things in RF where the frequencies are high enough that trace density mandates SMT parts, but I don't think any of that is in the audio realm (far as I know).

So, I thought, Hey... I joined this forum, a while back... Why don't I ask them!

Last edited:

In RF, the leads can form own parasitic components.

Class D operating up to 1MHz should be possible with "through-hole".

I admire your "to be repaired" approach and I believe that the European administration is considering rules allowing much more electronic/mechanic repair than is done today. For environmental reasons. It is just a very radical change from the use-and-dump approach that we have learned during 50 years.

Class D operating up to 1MHz should be possible with "through-hole".

I admire your "to be repaired" approach and I believe that the European administration is considering rules allowing much more electronic/mechanic repair than is done today. For environmental reasons. It is just a very radical change from the use-and-dump approach that we have learned during 50 years.

Pet peeve ... people who toss out chargers and wall warts where the plug has come off or the cat bit the cord.

It's a 2 minute repair... Yet, some of them even get angry when I tell them: "Hey I can fix that"... I get these blank stares like I'm speaking Klingon or something. The idea that something can be fixed, A) never occurred to them and B) is so foreign to them they can't believe it.

It's a 2 minute repair... Yet, some of them even get angry when I tell them: "Hey I can fix that"... I get these blank stares like I'm speaking Klingon or something. The idea that something can be fixed, A) never occurred to them and B) is so foreign to them they can't believe it.

Last edited:

In RF, the leads can form own parasitic components.

That was one of my concerns, but I agree that under 1mhz that should not be much of a problem.

You might be surprised just how pleasant SMT is to build once you try. Picking parts for the first time has a learning curve, and placement is a bit fiddly at first, but the actual soldering is way easier. I used a little soldier paste syringe to put a dab on every pad, tweezers to place the parts (you can be a bit sloppy), then I heated the board on top of an aluminum block on my stove until the solder flowed and pulled all the parts into place. It was a breeze, aside from a little touch up of some bridges. I was quite surprised.

You might be surprised just how pleasant SMT is to build once you try.

I've done some very limited SMT work. While building the board is relatively easy as you point out, I certainly didn't enjoy being the poor schmuck who had to fix one.

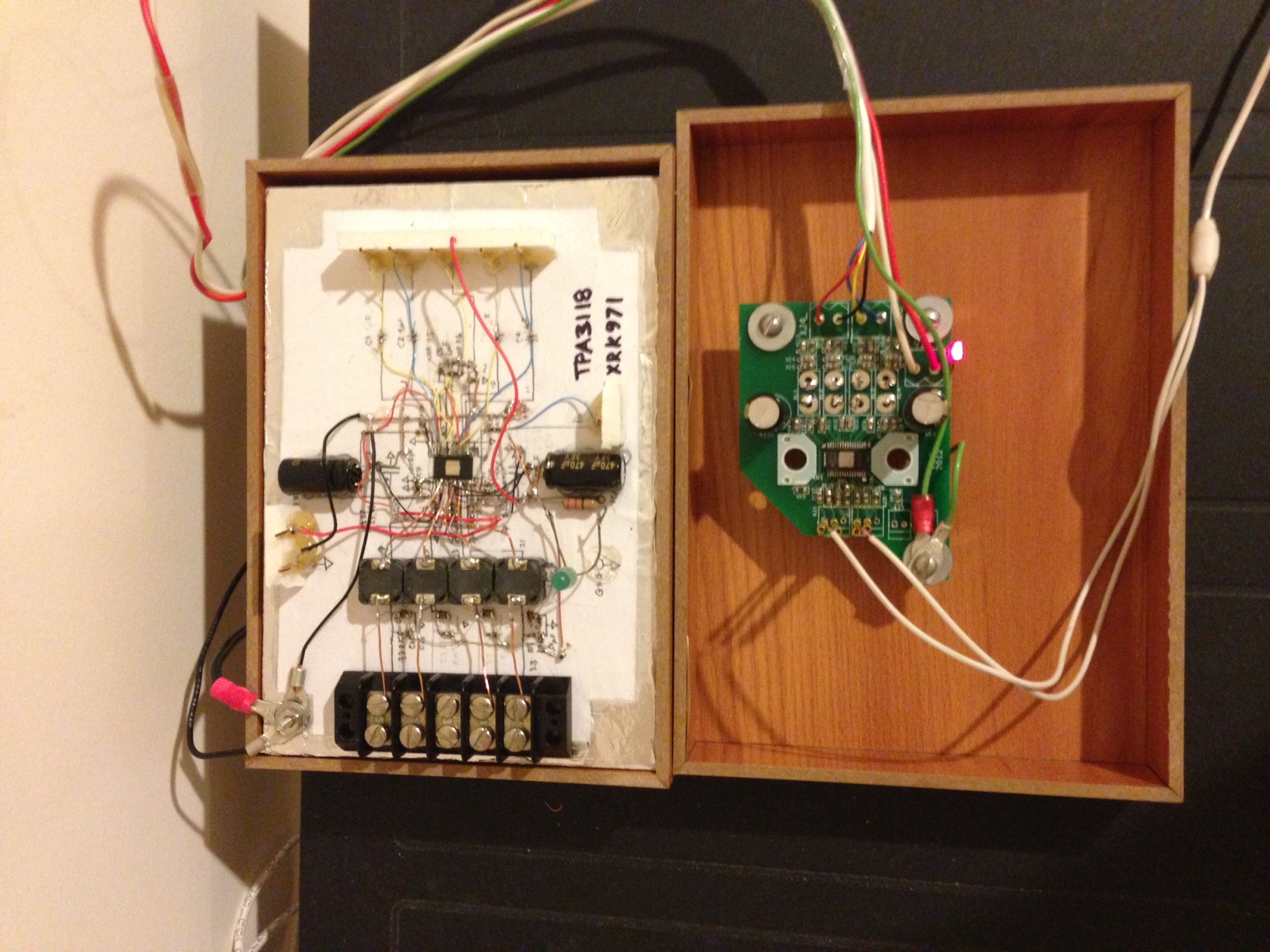

Does this count?

Sure does ... were there any unusual problems or issues?

That was the amp that kicked off the TPA3116D2 amp thread. What ever happened to the OP? As far as I know, he posted that amp build and dissappered.

I did a P2P version of the TPA3116 using SMT components glued onto a piece of paper lined with an aluminum foil ground plane. Here is my P2P next to DUG's fine mostly SMT TPA3116 (the inductors are through hole) amp. I still use DUG's amp to this day.

This was before you could find them for $6 to $10 on Aliexpress or eBay.

If you wish to do an all-through-hole class D amp, there is the TPA3122D2 - it is a DIP through hole package. Sounds very nice too.

http://www.ti.com/product/TPA3122D2

Although nowadays, I think the TPA31xx are not quite state of the art anymore and have turn on and off thump issues which are avoided in other newer designs.

I did a P2P version of the TPA3116 using SMT components glued onto a piece of paper lined with an aluminum foil ground plane. Here is my P2P next to DUG's fine mostly SMT TPA3116 (the inductors are through hole) amp. I still use DUG's amp to this day.

This was before you could find them for $6 to $10 on Aliexpress or eBay.

If you wish to do an all-through-hole class D amp, there is the TPA3122D2 - it is a DIP through hole package. Sounds very nice too.

http://www.ti.com/product/TPA3122D2

Although nowadays, I think the TPA31xx are not quite state of the art anymore and have turn on and off thump issues which are avoided in other newer designs.

Last edited:

This was before you could find them for $6 to $10 on Aliexpress or eBay.

Yeah, I've actually used quite a few of those "ready to use" boards and complete mini-amps already. The TPA3116 is a very attractive chip. It pushes enough juice for most bookshelf or stand mount speakers with minimal parts and pretty good sound in the bargain.

As I wrote before... If I build a major project, I will want it to be as easy to service and update as I can make it. I know that unless I'm playing with flea power I will have to surface mount some of the chips but I would like to do the rest of the job using through-hole parts if I can.

Reading some of the data sheets, I see that for some of the chips the way parts are laid out becomes a consideration and their example templates would place several components under a heatsink floating only millimetres above the board... So I'm trying to find out how critical these layouts really are.

For example in the two projects pictured, were there any issues with EMI, Parasitics etc. that I should be aware of when designing?

With SMT you need the right tools - for repair a hot-air rework station is a requirement, replacing components is then straightforward (you have to be more patient though). Once a components heated up you remove with tweezers and place in the new one - usually there's enough old solder, all you need is a bit more rosin to flow it. Ceramic tipped tweezers are great BTW, never seem to wear out, handle high temperatures, never get magnetized, tough as metal it seems.I've done some very limited SMT work. While building the board is relatively easy as you point out, I certainly didn't enjoy being the poor schmuck who had to fix one.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Class D

- Chip Amps with through hole parts